Low-frequency leakage flux based internal flaw detection circuit for ferro magnetic material

A technology of ferromagnetic materials and magnetic flux leakage, applied in the direction of material magnetic variables, etc., can solve the problems of limited penetration depth, high excitation frequency, low penetration depth, etc., and achieve the effects of enhanced detection sensitivity, high integration, and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

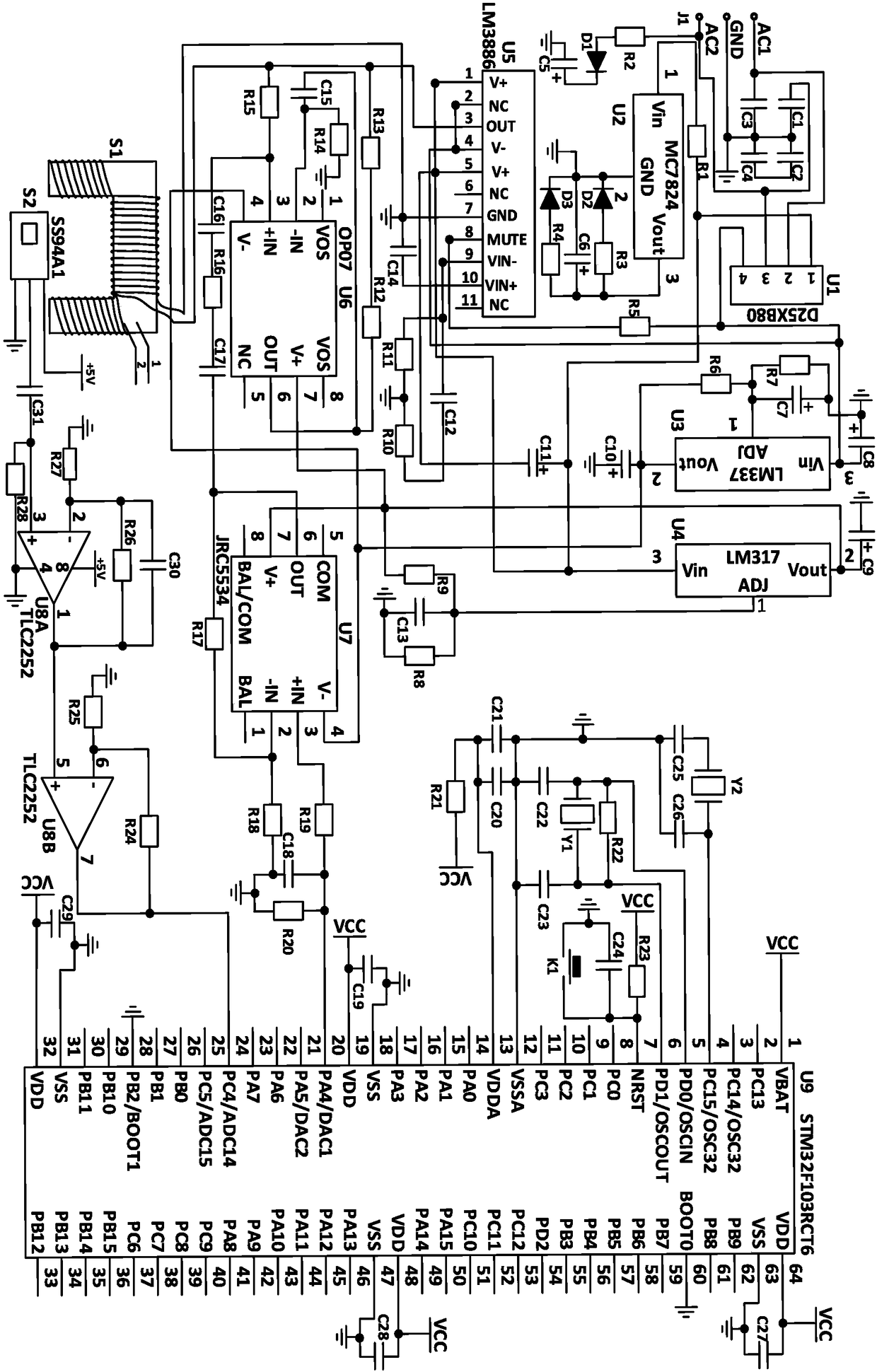

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] like figure 1 As shown, the VCC voltage provided to the circuit is +3.3V. An internal flaw detection circuit for ferromagnetic materials based on low-frequency magnetic flux leakage consists of a rectifier chip (U1), a voltage regulator chip (U2), a negative power chip (U3), a positive power chip (U4), a power amplifier chip (U5), and a servo chip. (U6), preamplifier chip (U7), signal acquisition first amplifier (U8A), signal acquisition second amplifier (U8B), signal control chip (U9), sensor head (S1), Hall effect sensor (S2 ), connector (J1), first capacitor (R1), second capacitor (C2), third capacitor (C3), fourth capacitor (C4), fifth capacitor (C5), sixth capacitor (C6), The seventh capacitor (C7), the eighth capacitor (C8), the ninth capacitor (C9), the tenth capacitor (C10), the eleventh capacitor (C11), the twelfth c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com