Heating connection method for thermoplastic plastic adopting rivet

A thermoplastic and connection method technology, applied in the field of thermoplastic connection, can solve the problems of plastic melting and poor joint forming, and achieve the effect of saving time, simple preparation and low requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Punching: The connecting plate is made of thermoplastic: polypropylene (PP), with a thickness of 2mm and a semi-hollow aluminum rivet with a rivet size of Φ3mm×8mm. Drill a hole at the geometric center of the lap joint area of the sheet, the diameter of the hole being equal to the diameter of the rivet. Use sandpaper to smooth and remove burrs around the hole;

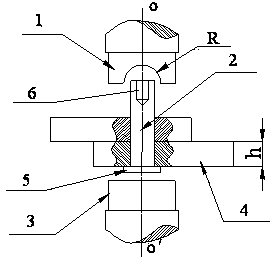

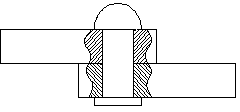

[0025] (2) Assembly: implant the semi-tubular rivets into the pre-punched holes of the plates to be connected, and press the plates tightly. The rivet head 5 is in close contact with the plates to be connected, and the excess part of the rivet is left on the semi-hollow side, exposing 4mm. Place the assembled joint between the two electrodes to avoid uneven deformation of the rivets during the welding process. The rivet head 5 is placed on the first electrode 3, the semi-hollow end 6 is opposite to the second electrode 1, and it is ensured that the semi-hollow rivet 2 is on the same axis OO' as the secon...

Embodiment 2

[0028] (1) Drilling: The connecting plate is thermosetting plastic: epoxy resin plate, thickness 2mm, rivet size is semi-hollow iron rivet of Φ3mm×8mm. Drill a hole at the geometric center of the lap joint area of the sheet, the diameter of the hole being equal to the diameter of the rivet. Sand around the hole smooth and deburr:

[0029] (2) Assembly: implant the semi-tubular rivets into the pre-punched holes of the plates to be connected, and press the plates tightly. The rivet head 5 is in close contact with the plates to be connected, and the excess part of the rivet is left on the semi-hollow side, exposing 4mm. Place the assembled joint between the two electrodes to avoid uneven deformation of the rivets during the welding process. The rivet head 5 is placed on the first electrode 3, the semi-hollow end 6 is opposite to the second electrode 1, and it is ensured that the semi-hollow rivet 2 is on the same axis OO' as the second electrode 1 and the first electrode 3; ...

Embodiment 3

[0032] (1) Drilling: the connection plate is epoxy resin plate and polypropylene (PP), the thickness is 2mm, and the rivet size is a semi-hollow aluminum rivet of Φ3mm×8mm. Drill a hole at the geometric center of the lap joint area of the sheet, the diameter of the hole being equal to the diameter of the rivet. Use sandpaper to smooth and remove burrs around the hole;

[0033] (2) Assembly: implant the semi-tubular rivets into the pre-punched holes of the plates to be connected, and press the plates tightly. The rivet head (5) is in close contact with the plates to be connected, and the excess part of the rivet is left on the semi-hollow side, exposing 4mm. Place the assembled joint between the two electrodes to avoid uneven deformation of the rivets during the welding process. The rivet head 5 is placed on the first electrode 3, the semi-hollow end 6 is opposite to the second electrode 1, and it is ensured that the semi-hollow rivet 2 is on the same axis OO' as the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com