Method for optimizing particle erosion resistance of turbomachinery blade runner structure

A technology for turbomachinery and blade runners, applied in the field of computer-aided design, can solve the problem of inability to effectively guide the cascade profile of turbomachinery, cascade profile and flow channel structure anti-erosion optimization method has not been established, optimization and improvement and other issues to achieve good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

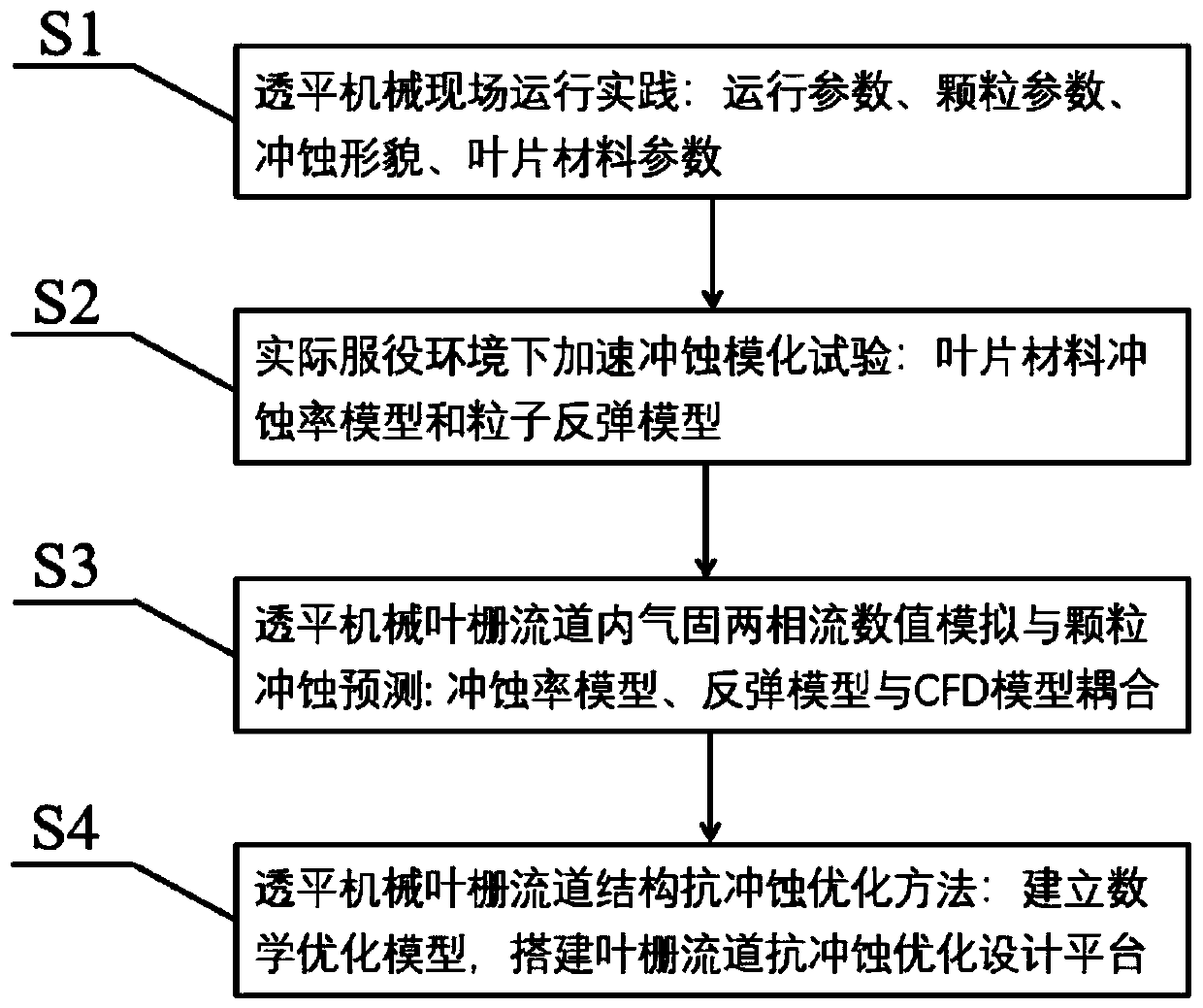

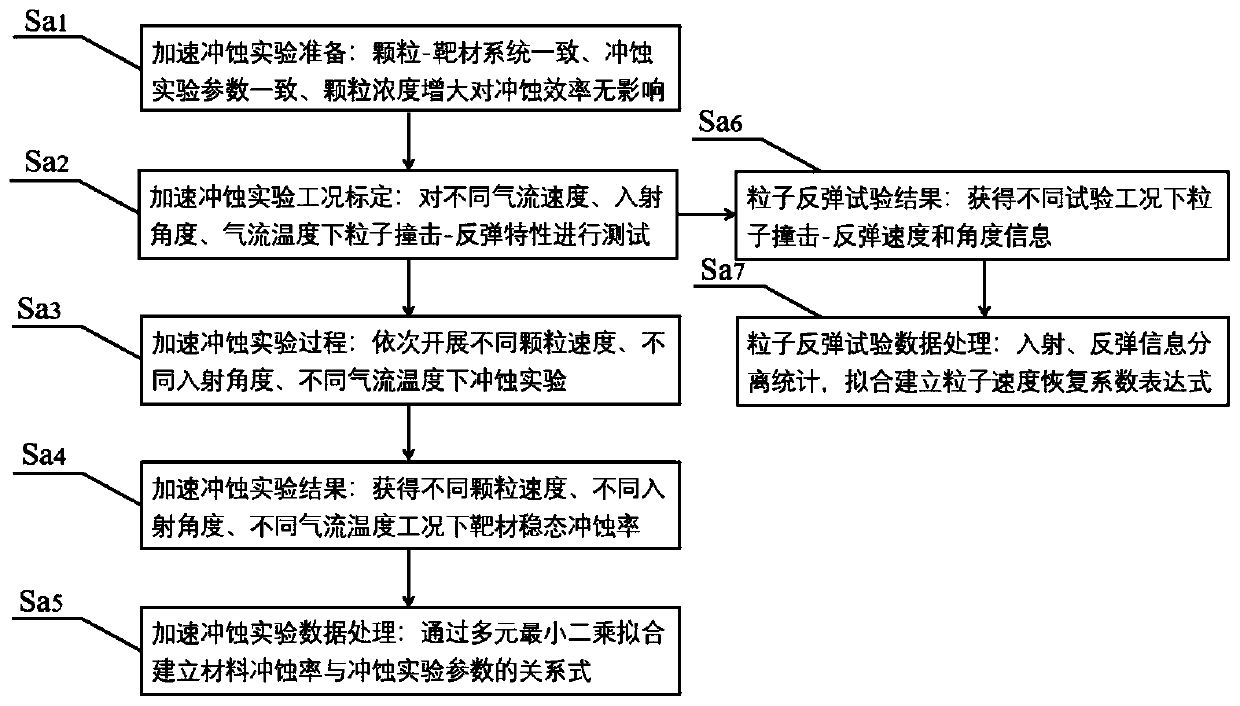

[0030] refer to figure 1 According to the present invention, the anti-particle erosion optimization method of the turbine blade runner structure comprises the following steps:

[0031] S1, to obtain the on-site data of the turbomachinery during operation;

[0032] The on-site data during the operation of the turbomachinery in step 1) includes the parameters of the typical operating conditions of the turbomachinery, the parameters of the particulate matter entering the flow channel of the turbomachinery, the erosion morphology of the flow channel of the turbomachinery blade after the preset period of operation, and the permeability Material parameters of flat machinery blades: Among them, the typical operating condition parameters of turbomachinery include turbine inlet air flow, pressure and temperature and turbine outlet air flow, pressure and temperature; The erosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com