Silicone rubber heat-insulating material for integral solid rocket ramjets and preparation method thereof

A solid impulse engine and thermal insulation material technology, which is applied in the field of silicone rubber thermal insulation materials for integrated solid impulse engines and its preparation, can solve problems such as poor elasticity, poor oxidation resistance, and burn-through, and achieve good elasticity and resistance to small molecules. The effect of strong migration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

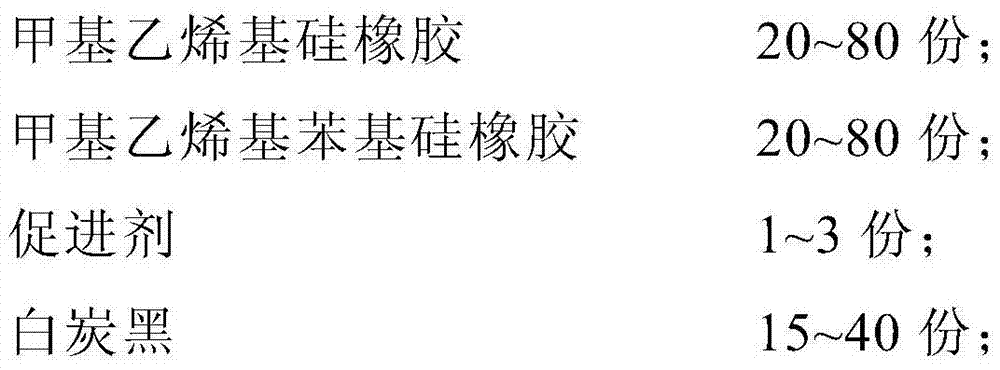

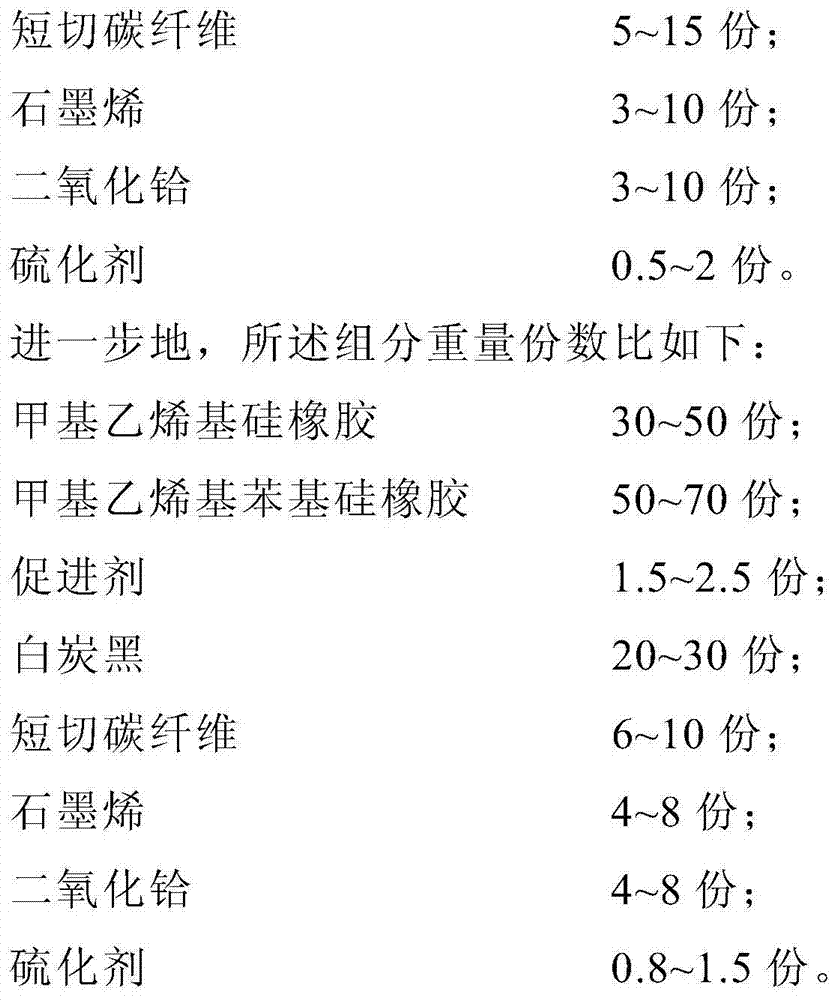

[0026] A silicone rubber heat insulating material for an integral solid-impact engine, the parts by weight of which are as follows:

[0027]

[0028] The above-mentioned preparation method of silicone rubber heat insulating material, it comprises the following steps:

[0029] 1) The surfaces of fumed silica, chopped carbon fibers with an average length of 6mm, nanoscale hafnium dioxide and graphene are all treated with γ-glycidoxypropyltrimethoxysiloxane and set aside;

[0030] 2) Add 20 parts of methyl vinyl silicone rubber, 80 parts of methyl vinyl phenyl silicone rubber, and 2 parts of butyltin dilaurate accelerator into a mixer according to the ratio of parts by weight to a transparent state, and prepare Silicone rubber matrix; wherein: the mass percentage content of vinyl in methyl vinyl silicone rubber is 0.2%, and the mass percentage content of phenyl in methyl vinyl phenyl silicone rubber is 10%;

[0031] 3) Add 40 parts of treated fumed silica, 5 parts of treated ...

Embodiment 2

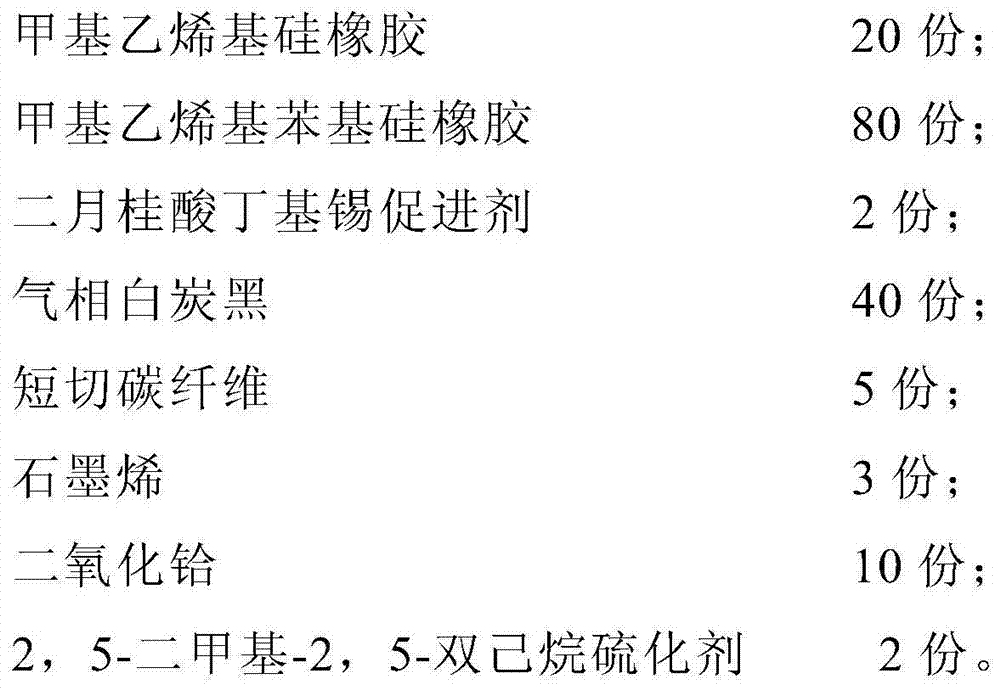

[0037] A silicone rubber heat insulating material for an integral solid-impact engine, the parts by weight of which are as follows:

[0038]

[0039] The above-mentioned preparation method of silicone rubber heat insulating material, it comprises the following steps:

[0040] 1) The surfaces of fumed silica, chopped carbon fibers with an average length of 7mm, nanoscale hafnium dioxide and graphene are all treated with γ-glycidoxypropyltrimethoxysiloxane and set aside;

[0041] 2) Add 35 parts of methyl vinyl silicone rubber, 65 parts of methyl vinyl phenyl silicone rubber, and 1.6 parts of butyltin dilaurate accelerator into a mixer according to the ratio of parts by weight to a transparent state, and prepare Silicone rubber matrix; wherein: the mass percentage content of vinyl in methyl vinyl silicone rubber is 0.1%, and the mass percentage content of phenyl in methyl vinyl phenyl silicone rubber is 10%;

[0042] 3) 25 parts of treated fumed silica, 10 parts of treated c...

Embodiment 3

[0048] A silicone rubber heat insulating material for an integral solid-impact engine, the parts by weight of which are as follows:

[0049]

[0050] The above-mentioned preparation method of silicone rubber heat insulating material, it comprises the following steps:

[0051] 1) Treat fumed white carbon black, chopped carbon fibers with an average length of 6.5 mm, nanoscale hafnium dioxide and graphene through γ-glycidoxypropyl trimethoxysiloxane and set aside;

[0052]2) Add 50 parts of methyl vinyl silicone rubber, 70 parts of methyl vinyl phenyl silicone rubber, and 2 parts of butyltin dilaurate accelerator into a mixer according to the ratio of parts by weight to a transparent state, and prepare Silicone rubber matrix; wherein: the mass percentage content of vinyl in methyl vinyl silicone rubber is 0.2%, and the mass percentage content of phenyl in methyl vinyl phenyl silicone rubber is 11%;

[0053] 3) Add 30 parts of treated fumed silica, 8 parts of treated chopped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com