Thermal barrier coating and preparation method thereof

A technology of thermal barrier coating and spraying equipment, which is applied in the field of cermet coating, can solve problems such as thermal expansion coefficient mismatch, and achieve the effect of reasonable composition preparation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

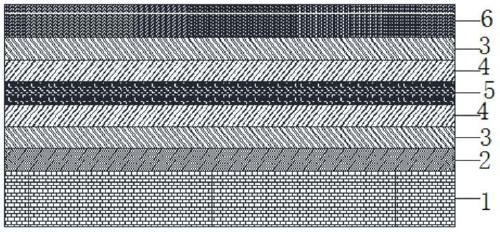

[0032] see figure 1 , the base layer 2 is pure metal Mo; the first transition layer 3 between the thermal insulation layer 5 and the base layer 2 is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 25%, the thickness is 0.1mm; the second transition layer 4 between the thermal insulation layer 5 and the base layer 2 is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 40%, the thickness is 0.1mm; the heat insulation layer is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 85%, the thickness is 0.4mm; the second transition layer 4 between the heat insulation layer 5 and the protective layer 6 is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 40%, the thickness is 0.12mm; the first transition layer 3 between the heat insulation layer 5 and the protective layer 6 is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 25%, and the thickness is 0.1mm. The protective layer is a pure metal Mo coating.

Embodiment 2

[0034] and figure 1 The structure shown is different, the base layer 2 is pure metal Mo; a single-layer transition structure (that is, only one filter layer) is adopted between the heat insulation layer 5 and the base layer 2, which is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 45%, the thickness is 0.15mm; the heat insulation layer is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 95%, and the thickness is 0.6mm; the single-layer transition layer structure (that is, only one filter layer) is also adopted between the heat insulation layer 5 and the protective layer 6, which is Mo and ZrO 2 mixed layer of ZrO 2 The content is 55%, and the thickness is 0.14mm; the protective layer 6 is a pure metal Mo coating.

Embodiment 3

[0036] Different from Example 1 and Example 2, the base layer 2 is pure metal Mo; the first transition layer 3 between the heat insulating layer 5 and the base layer 2 is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 30%, the thickness is 0.1mm; the heat insulation layer is Mo and ZrO 2 hybrid coating of ZrO 2 The content is 60%, and the thickness is 0.3 mm; there is no transition layer between the heat insulation layer 5 and the protective layer 6; the protective layer 6 is a pure metal Mo coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com