Composite sheet for absorbing type sanitary product

A hygienic product and composite sheet technology, which is applied in the direction of absorbent pads, medical science, bandages, etc., can solve the problems of reducing the potential risk of convex and concave effects, discounting the convex state, etc., and achieve the effect of small compression deformation and good convex state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

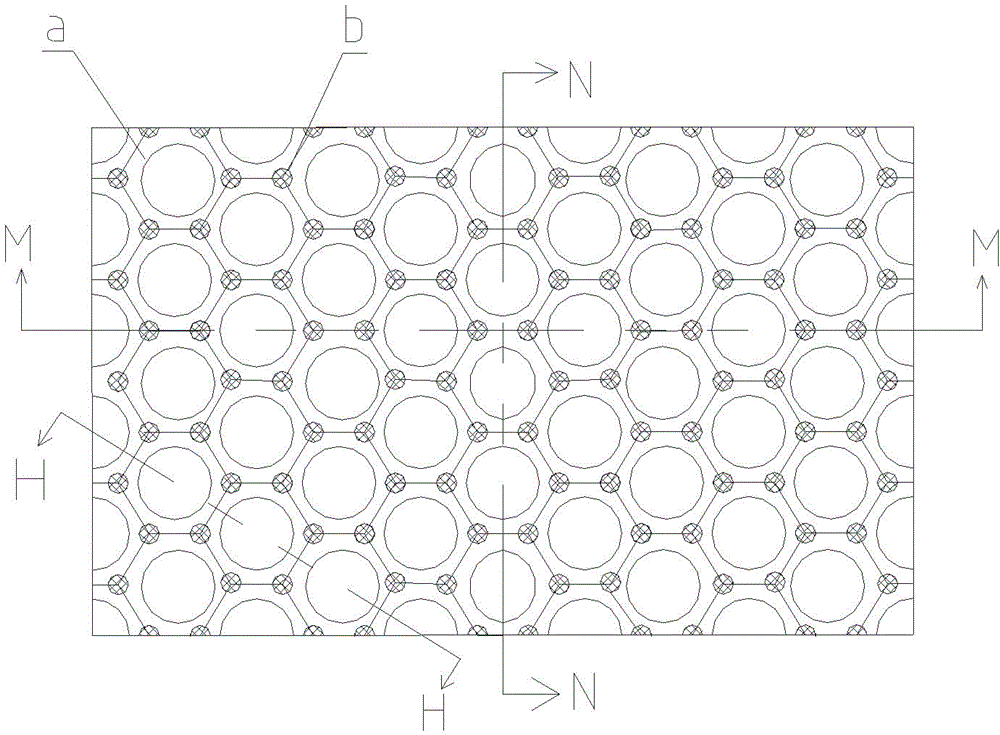

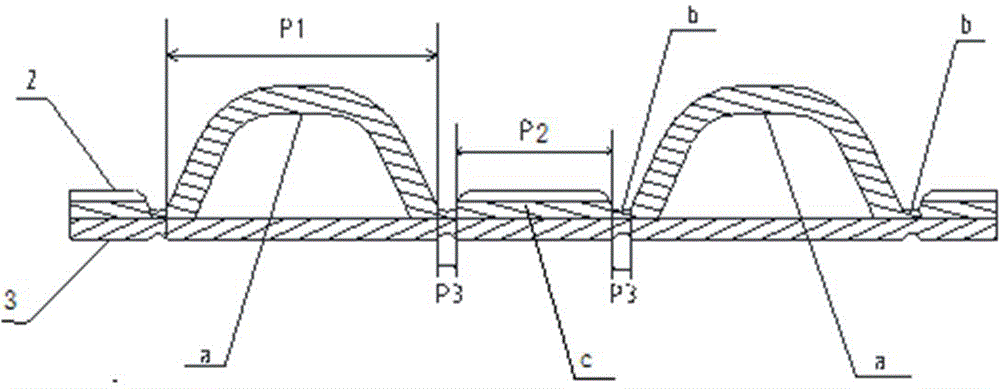

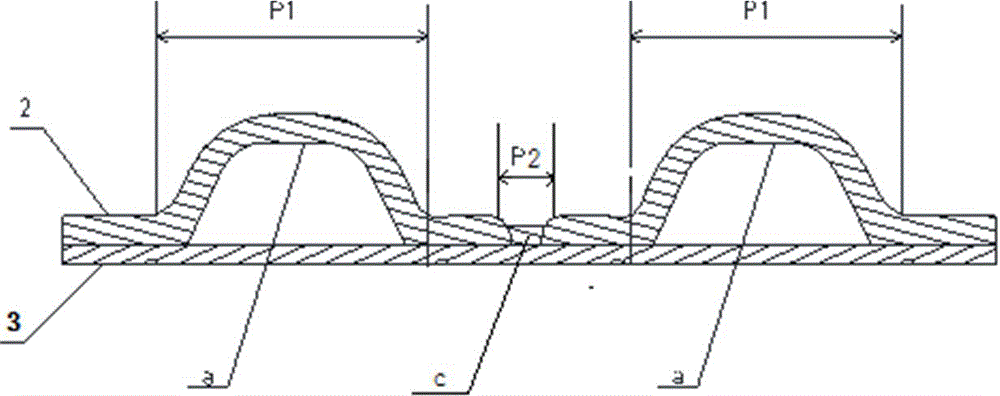

[0032] The specific implementation of the composite sheet for absorbent sanitary products of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] See attached Figures 1 to 4 , the composite sheet 1 for absorbent hygiene products has two layers of sheets, including the first sheet 2 on the top and the second sheet 3 on the bottom. Viewed from top to bottom, the first sheet 2 partially or completely overlaps On the second sheet 3, the first sheet 2 has a plurality of protrusions a arranged in a certain direction, and the circular root of each protrusion a is provided with several adhesives connected with the second sheet 3. Concave b, and the circumference of each protruding portion a is provided with several closed or open-closed bonding concavities b to surround, and then, viewed from one side, the interior of the protruding portion a is a hollow structure, The top is in the shape of an arc (arch), and the convex par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com