Grip drive type screwdriver

A driving, screwdriver technology, applied in screwdrivers, manufacturing tools, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

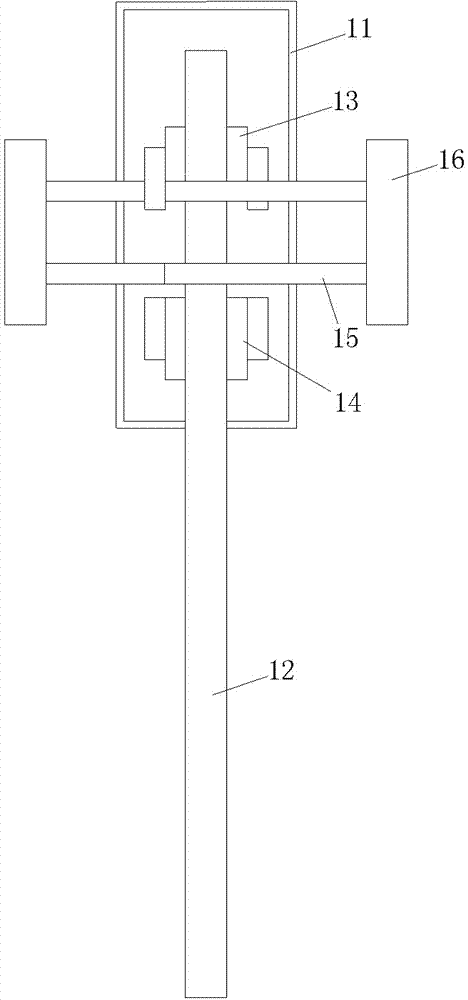

[0018] Examples of handheld drive screwdrivers, such as Figure 1-3 As shown, the hand driven screwdriver includes a handle 11 and a handle 12 .

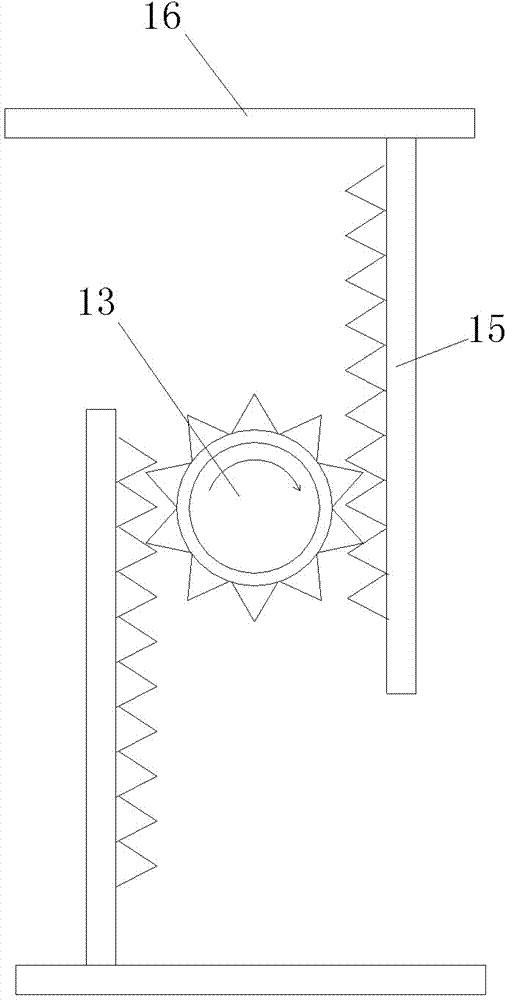

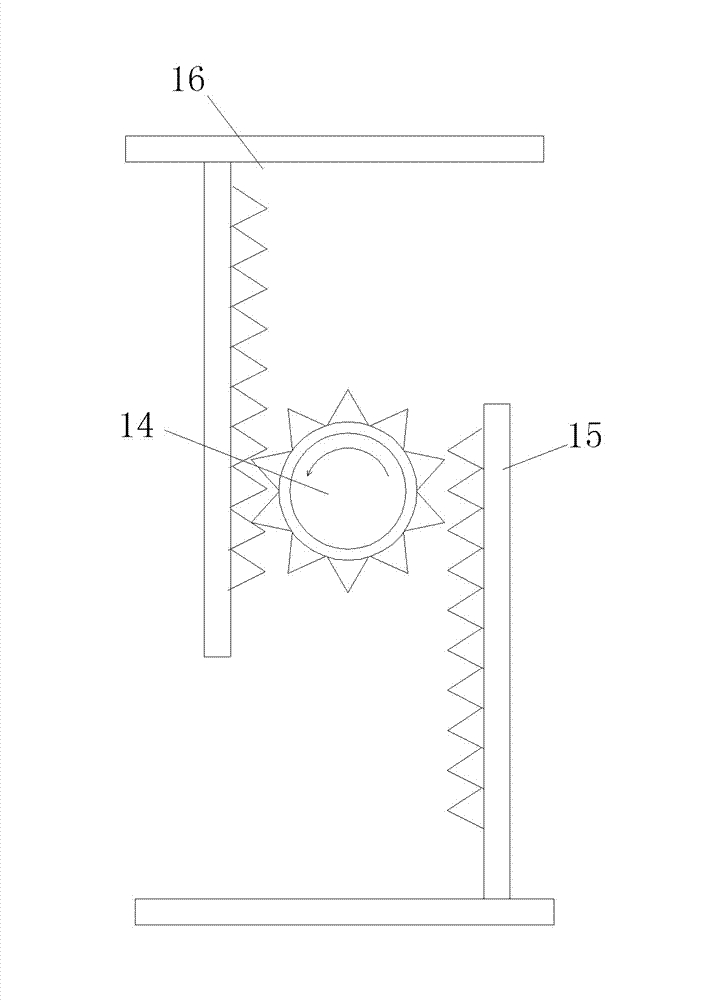

[0019] The inner hollow structure of the knife handle 11, the knife bar 12 is rotatably assembled on the knife handle 11 and can expand and contract in the knife handle 11 in the axial direction, and one end of the knife handle 11 is equipped with a one-way transmission wheel. In the embodiment What one-way transmission wheel adopts is flywheel and has two, and two one-way transmission wheels are arranged at intervals along the axial direction of cutter bar 12 and are divided into forward transmission wheel 13 and reverse transmission wheel 14 that transmission direction is opposite.

[0020] On the handle of a knife 11, tooth bar 15 is radially assembled, and rack 15 corresponds to the one-way drive wheel and cooperates with the handle of a knife 11 in the axial direction of the knife bar 12 to prevent movement, wherein each one-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com