Continuous flexible reinforced adhesion-type composite tube

A bonded, composite pipe technology, applied in the field of composite pipes, can solve the problems of low service pressure, poor resistance to external pressure and negative pressure, and less installation auxiliary equipment for steel wire reinforced composite pipes, so as to reduce formation pollution and enhance adaptability performance, reducing the effect of cycle work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

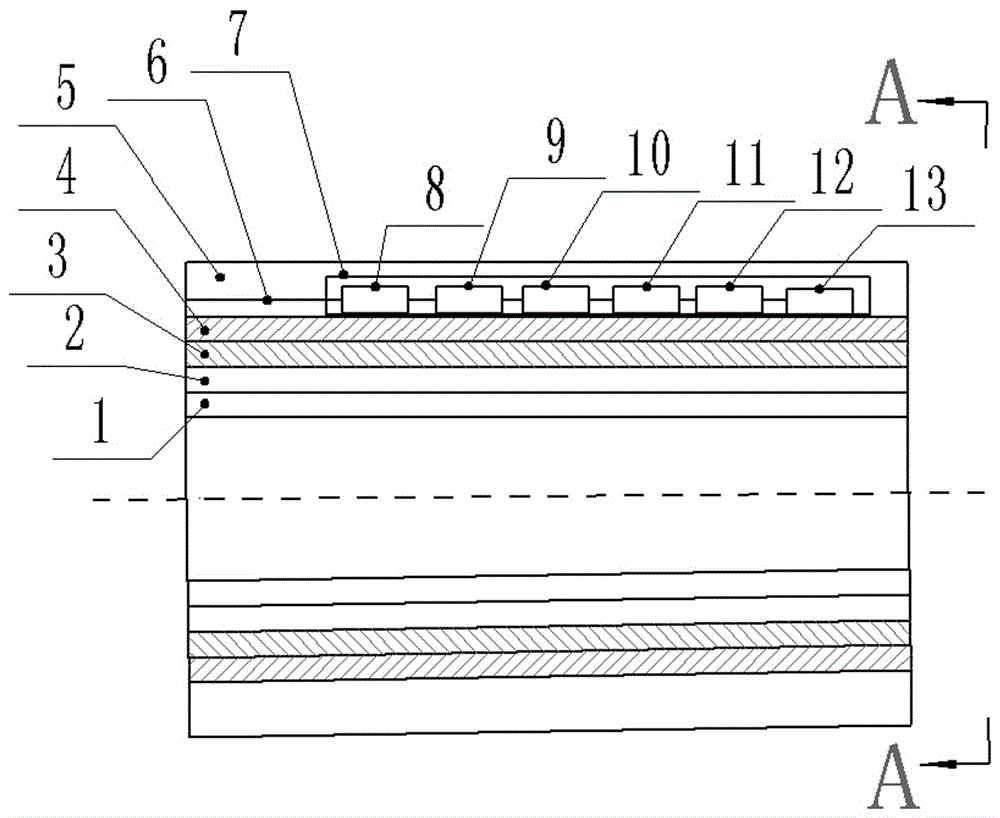

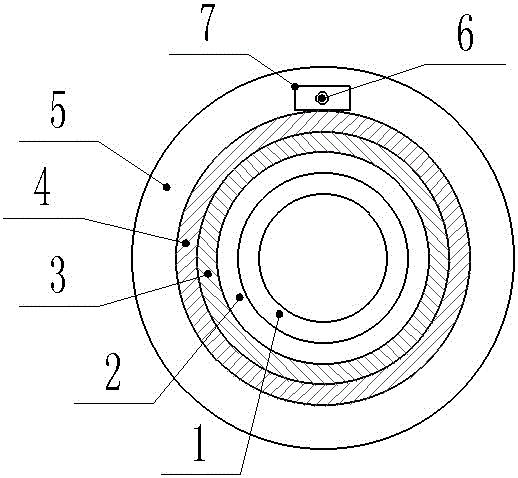

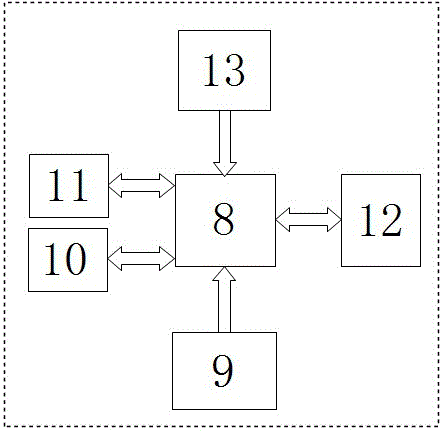

[0016] Example: According to Figure 1-Figure 3 As shown, a continuous flexible reinforced adhesive composite pipe of the present invention includes an inner liner 1, an anti-penetration layer 2, a compression-resistant reinforcement layer 3, a tensile reinforcement layer 4, and an outer sheath layer 5, and is characterized in that: The outer surface of the inner lining layer 1 is provided with an anti-penetration layer 2, a compressive reinforcement layer 3, a tensile reinforcement layer 4, and an outer sheath layer 5 in sequence; the inner lining layer 1 and the outer sheath layer 5 are made of polymer material A Extrusion molding, the anti-permeation layer 2 is extruded from polymer material B, and the compression reinforcement layer 3 and the tensile reinforcement layer 4 are formed by winding the reinforcement tape in the forward and reverse directions according to the design angle of 30°~70°, and the winding The number of layers is even, and the two winding directions ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com