Nonlinear elastic shock absorption bed board

A nonlinear and elastic technology, applied in the field of vibration reduction equipment, can solve the problems of unfavorable structural noise transmission, less consideration of acoustic requirements, short vibration transmission path, etc., to facilitate future maintenance, improve vibration transmission, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

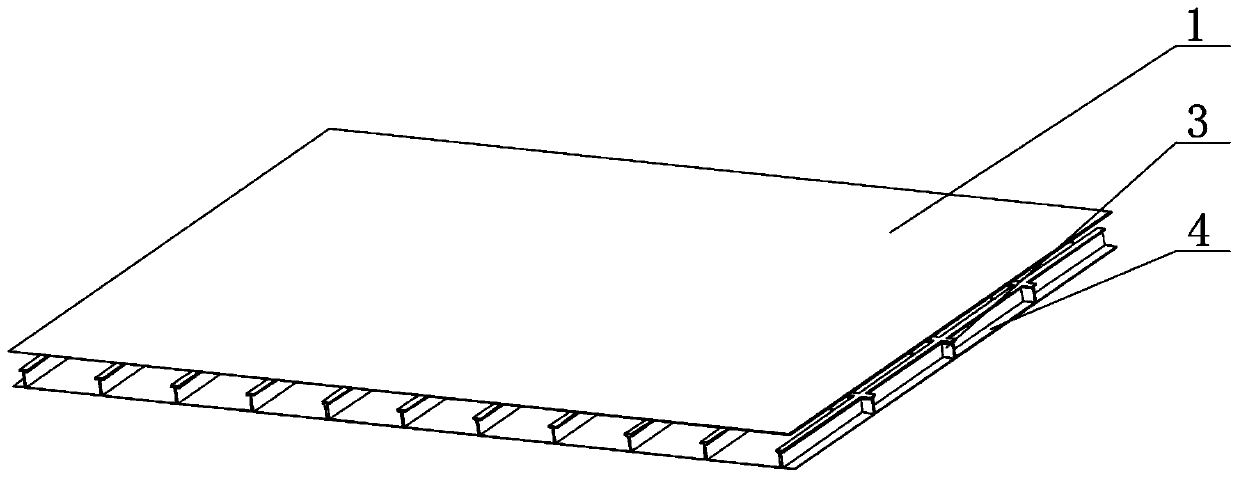

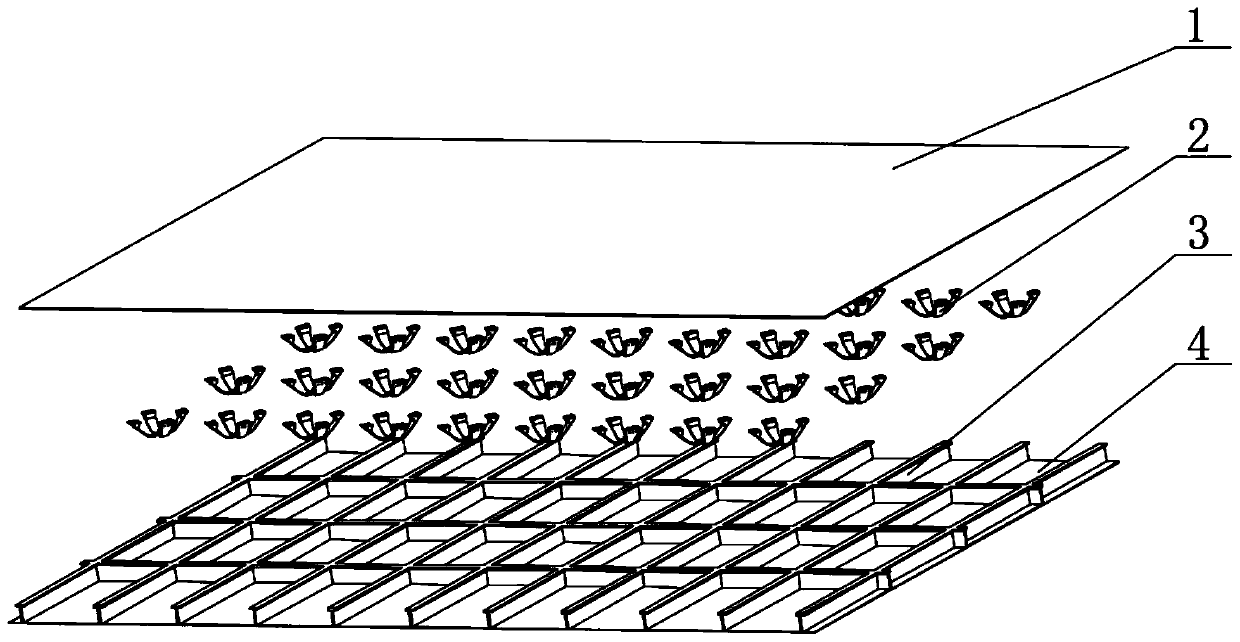

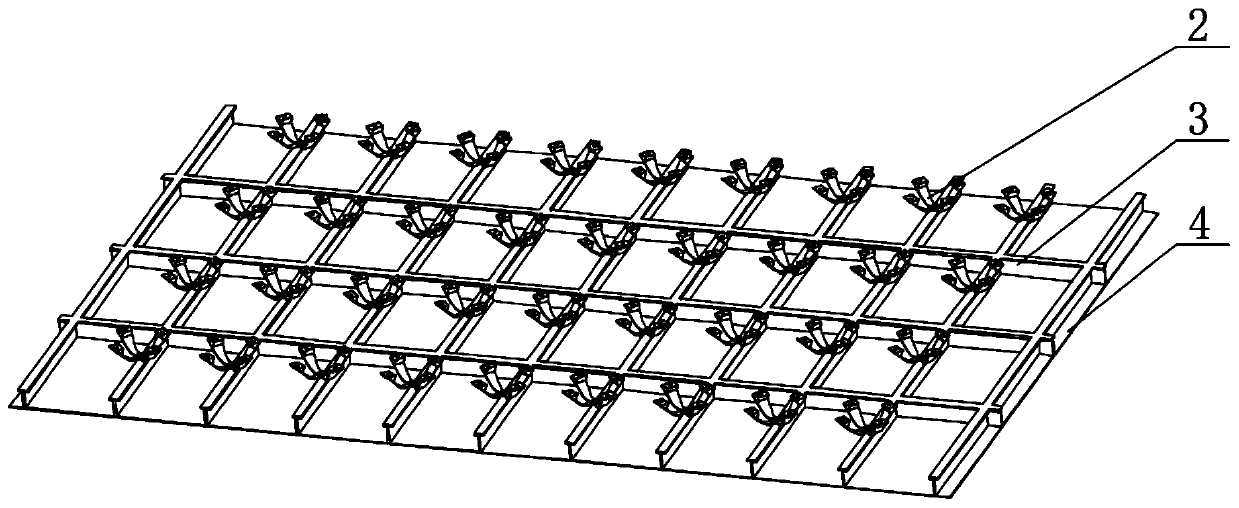

[0028] Such as figure 1 , figure 2 with image 3 As shown, the non-linear elastic damping plank of the present embodiment includes a bottom plate 4, the upper surface of the bottom plate 4 is welded with T-shaped steel 3 arranged vertically and horizontally at intervals, the upper surfaces of all T-shaped steel 3 are located at the same plane position, and the upper surface of the T-shaped steel 3 A plurality of supporting spring leaf assemblies 2 are uniformly distributed on the surface, and the upper part of the supporting spring leaf assemblies 2 is mounted on the panel 1 through fasteners.

[0029] Such as Figure 4 with Figure 5 As shown, the structure of a single support spring assembly 2 is as follows: a disc 204 is included, the lower bottom surface of the disc 204 is a plane, the upper surface is a conical surface, and a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com