Preprocessing technology for high-elastic habijabi fabric

A process and fabric technology, which is applied in the field of pre-treatment process of high-elastic hemp fabric, can solve the problems of inability to guarantee the softness of the fabric and affect the dyeing quality, and achieve the effect of being conducive to dyeing processing, good dyeing uniformity, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Fabric fabric: width 206cm, 216g / cm 3 .

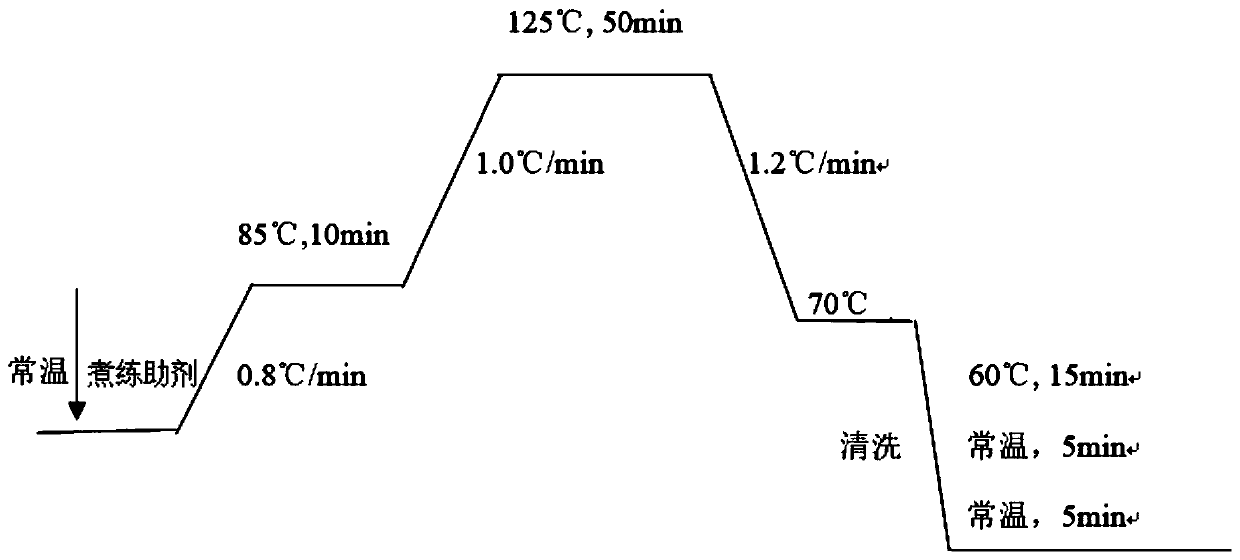

[0028] The dyeing and finishing process of the high-elastic hemp fabric provided in this embodiment includes a pre-treatment process, a dyeing process and a setting process, and the pre-treatment process includes an open-width desizing process and a cylinder training process in sequence. , pre-setting process and loose alkali reduction process, the specific steps of the dyeing and finishing process are as follows:

[0029] (1) Pretreatment process:

[0030] In the open-width desizing process, an open-width desizing machine is used to desizing the gray fabric. The formula of the desizing aid used in the open-width desizing process is as follows:

[0031] Liquid caustic soda 45g / L,

[0032] Long car fast desizing agent TF-127HA 2g / L,

[0033] Sodium tripolyphosphate 2g / L;

[0034] The temperature conditions of the open-width desizing process are 85°C and the vehicle speed is 40m / min.

[0035] Under hot alkali conditions, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com