Dyeing and finishing technology for high-elastic habijabi fabric

A kind of processing technology and technology, which is applied in the field of dyeing and finishing processing technology of high-elastic hemp fabric, can solve the problems of water resources and ecological environment threats, cannot guarantee the softness of fabrics, affect the dyeing quality, etc., and achieve obvious effects of energy saving and emission reduction. Good color reproducibility, improve the effect of dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

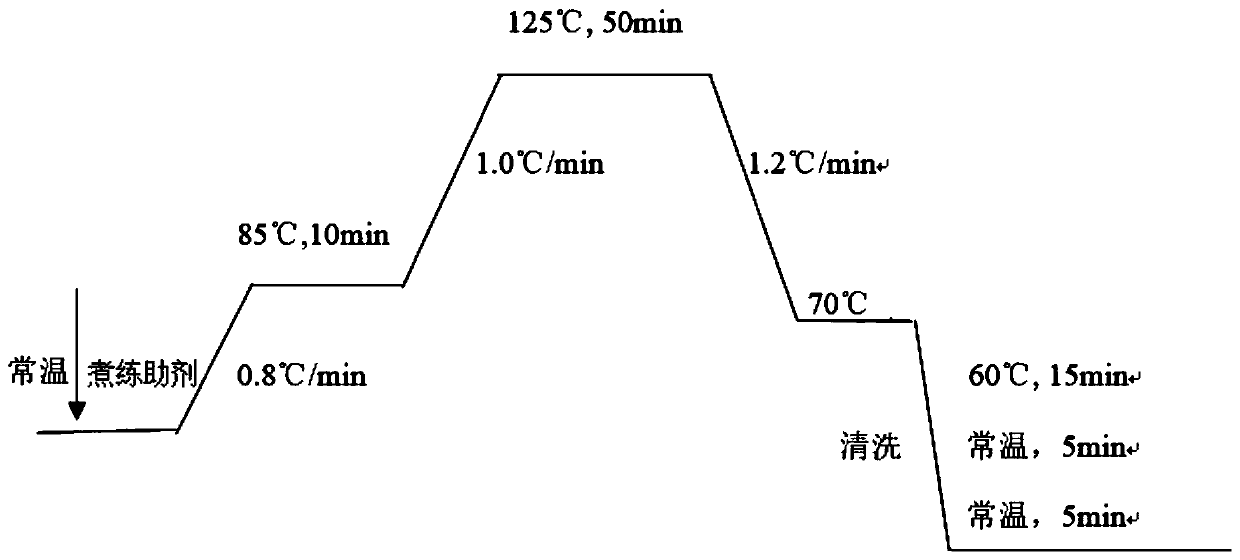

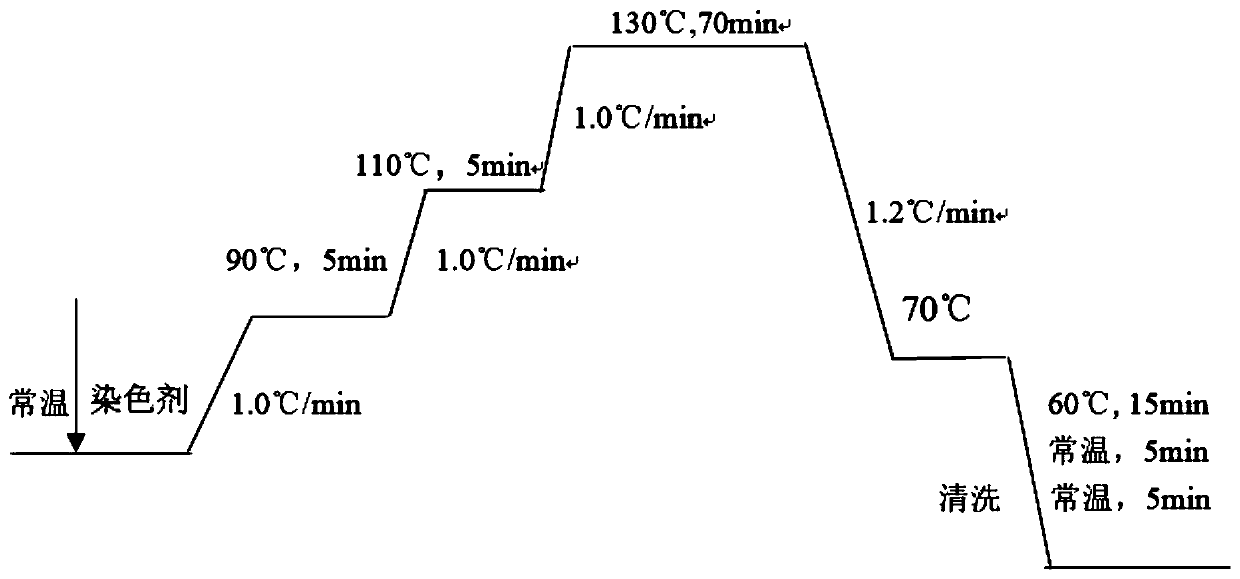

Method used

Image

Examples

Embodiment

[0047] Fabric fabric: width 206cm, 216g / cm 3 .

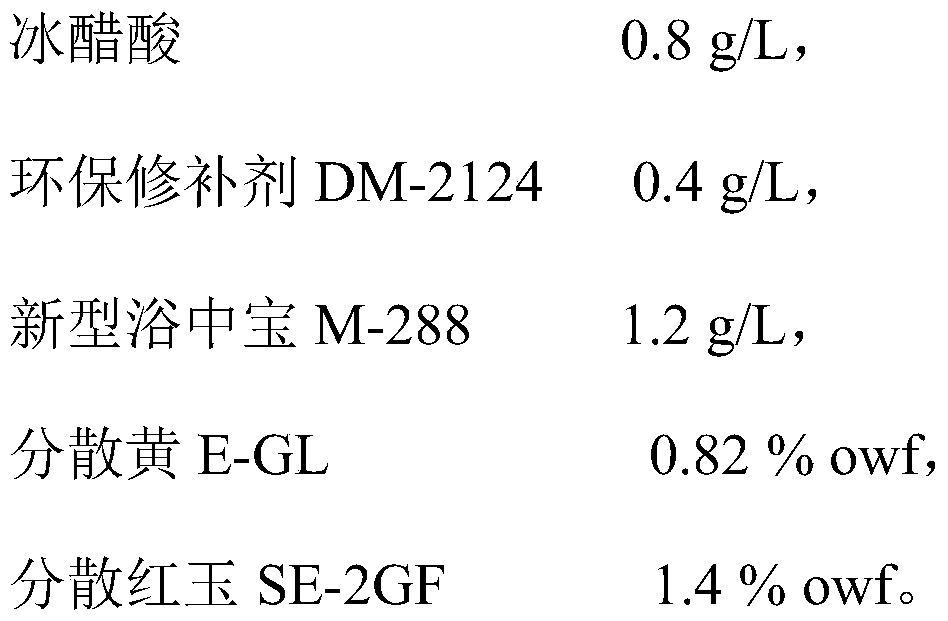

[0048] The dyestuff that this embodiment adopts, various auxiliary agents and the manufacturer and the model of the equipment used are as follows:

[0049] The dyes Disperse Yellow E-GL and Disperse Red Jade SE-2GF are all produced in Zhejiang Longsheng Group Co., Ltd.;

[0050] Auxiliaries Changche fast desizing agent TF-127HA, degreasing agent TF101, environmental protection repair agent DM-2124, new Yuzhongbao M-288, antistatic agent GH-580, all produced in Zhejiang Transfar Co., Ltd.;

[0051] Equipment OS-9V12000 open-width desizing machine (Taiwan Hongrong Dyeing and Finishing Machinery Equipment Co., Ltd.); XH-800 loose alkali weight reduction machine (Wuxi Xianghong Dyeing and Finishing Equipment Co., Ltd.); STF3-2HT high temperature and high pressure airflow dyeing machine ( Deyijia Machinery (Jiangsu) Equipment Co., Ltd.); MEGATE III setting machine (Korea Micron Machinery Co., Ltd.); RVMC-12 Mano photoelectric weft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com