Compact steel wire braided rubber hose and preparation method thereof

A steel wire braided rubber hose, compact technology, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of unreasonable rubber formula and skeleton layer design, and achieve the effect of light weight, increased service life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

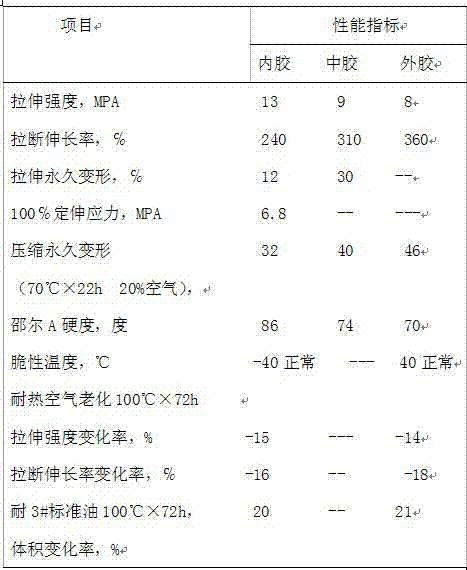

Embodiment 1

[0020] A preparation method of a compact steel wire braided rubber hose, the preparation method of the materials of the inner rubber hose, the middle rubber layer and the outer rubber layer is the same, comprising the following steps:

[0021] a. Weigh each raw material by weight, pass the raw rubber on the open mill, the roll distance is 0.5~0.8mm, and the time is 3~4min; Eat up all of them, add the reinforcing agent and softener in batches. When adding the compounding agent, don’t move the knife to turn over and add the vulcanization system. 3 times; then adjust the roller distance to 2~3mm, make 5 triangle bags and 3 rolls, and cool down the next piece;

[0022] b. The test piece is vulcanized on a flat vulcanizer, and the vulcanization condition is 151°C×60min;

[0023] Wherein: the materials for preparing the inner rubber tube, the middle rubber layer and the outer rubber layer are as follows:

[0024] The inner rubber of the inner rubber layer is prepared from the foll...

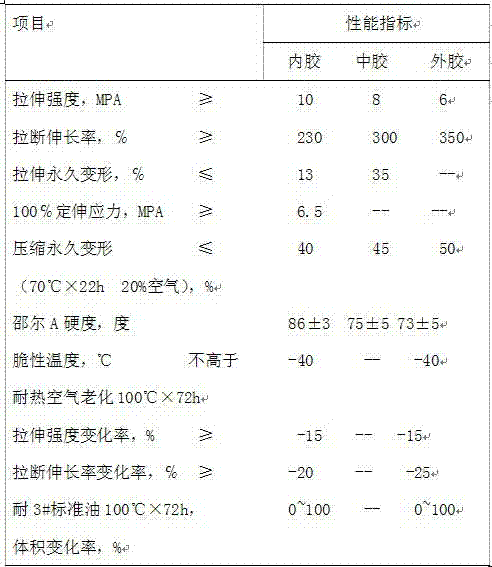

Embodiment 2

[0038] A preparation method of a compact steel wire braided rubber hose, the preparation method of the materials of the inner rubber hose, the middle rubber layer and the outer rubber layer is the same, comprising the following steps:

[0039] Step a, c are identical with embodiment 1, and step b is different,

[0040] Step b: The test piece is vulcanized on a flat vulcanizer, and the vulcanization condition is 151°C×60min;

[0041] Wherein: the materials for preparing the inner rubber tube, the middle rubber layer and the outer rubber layer are as follows:

[0042] The inner rubber of the inner rubber layer is prepared from the following raw materials by weight: raw rubber: nitrile rubber N1042 100kg, reinforcing agent: carbon black N660 90 kg and white carbon black 10kg; softener: dioctyl phthalate 10kg; small sample: 3kg of zinc oxide, 1kg of stearic acid, 2kg of antioxidant 2,2,4-trimethyl-1,2-dihydroquinoline, 1kg of sulfur, 5kg of binder RC and accelerator N-cyclohexyl ...

Embodiment 3

[0047] A preparation method of a compact steel wire braided rubber hose, the preparation method of the materials of the inner rubber hose, the middle rubber layer and the outer rubber layer is the same, comprising the following steps:

[0048] Step a, c are identical with embodiment 1, and step b is different,

[0049] Step b: The test piece is vulcanized on a flat vulcanizer, and the vulcanization condition is 151°C×60min;

[0050] Wherein: the materials for preparing the inner rubber tube, the middle rubber layer and the outer rubber layer are as follows:

[0051] The inner rubber of the inner rubber layer is prepared from the following raw materials by weight: raw rubber: nitrile rubber N1052 100kg, reinforcing agent: carbon black N550 115kg and white carbon black 13kg; softener: dioctyl phthalate 14kg ;Small sample: 6kg of zinc oxide, 3kg of stearic acid, 4kg of anti-aging agent N-isopropyl-N-phenyl-p-phenylenediamine; vulcanization system: 3kg of sulfur, 7kg of binder RC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com