Tape winding type optical unit optical cable and manufacturing process thereof

A manufacturing process and optical unit technology, applied in the direction of optical components, light guides, optics, etc., can solve the problems of difficulty in laying, time-consuming and labor-intensive installation and laying, and cost of construction time, etc., to achieve convenient and fast construction connection, easy construction and laying, and low bending radius small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

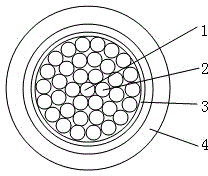

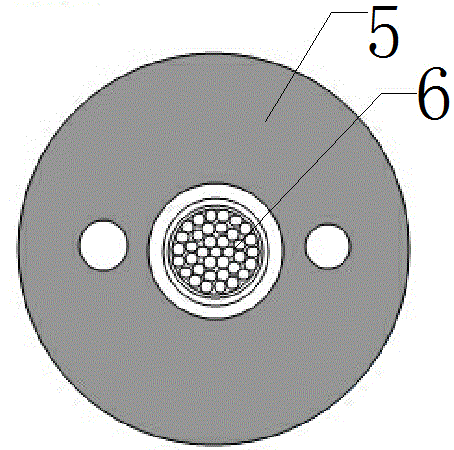

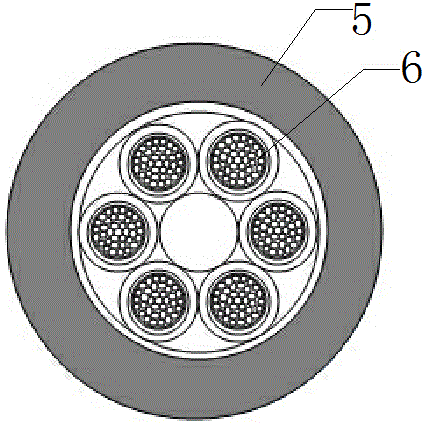

[0021] Such as Figure 1-8 As shown, a reel-type optical unit optical cable, the optical unit optical cable includes an optical unit 6 and a jacket layer 5, the optical unit includes a reel-type optical fiber ribbon 2, and the center of the reel-type optical fiber ribbon is a Aramid fiber 1, the roll-type optical fiber ribbon is wrapped with water-blocking material, cable tie 3, and sleeve 4 in sequence.

[0022] A manufacturing process of a tape-and-reel optical unit optical cable, comprising the following steps: 1. Making a number of 200 μm optical fibers into a mesh-shaped and bonded optical fiber ribbon 7 through a specific ribbon mould; 2. Making one or more fibers with different core numbers The optical fiber ribbon is slowly rolled into a closed circle through a U-shaped horn mold 12 with a smooth surface made of ceramics, and the optical fiber column 8 is formed through a shaping mold 13 made of ceramics. Put the material into the casing to form an optical unit after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com