Mode converter having multi-layer structure and optical branching device

A mode conversion, multi-layer structure technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of low coupling efficiency of optical fibers and waveguides, unstable optical field transmission direction, etc., to reduce size, improve stability, and improve The effect of coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below through specific embodiments in conjunction with the drawings:

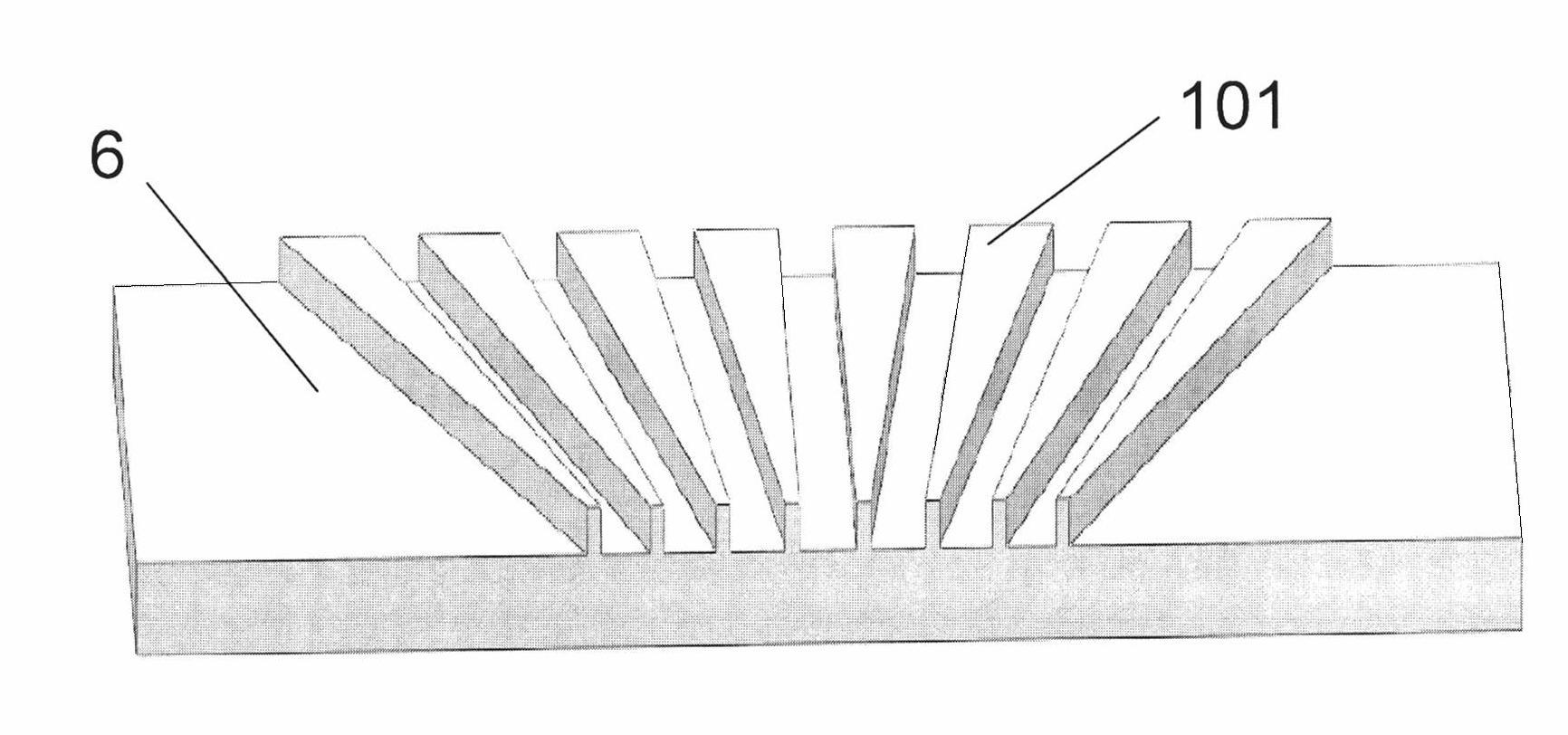

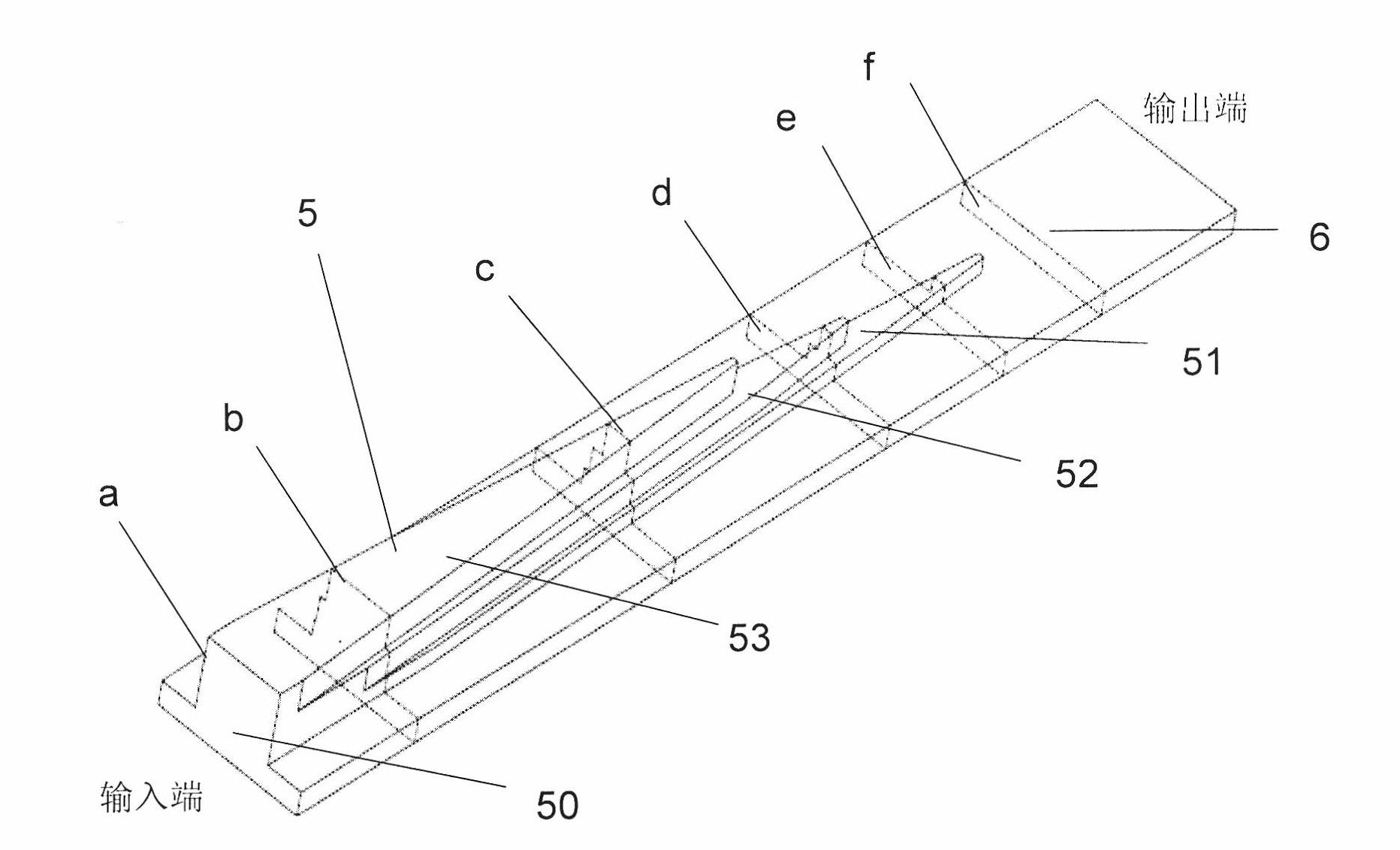

[0022] figure 2 The mode converter in the embodiment of the present invention is given, taking a three-layer ridge waveguide as an example. The ridge waveguide 5 and the slab waveguide 6 are deeply etched on the silicon wafer. The input end 50 of the ridge waveguide 5 is a single ridge waveguide on the slab waveguide 6 formed by deep etching. Three shallow ridge waveguide layers 51, 52, 53. The specific process can be as follows: deep etching is performed on the ridge waveguide 5 to form the ridge waveguide layer 51, then the ridge waveguide layer 51 is etched at a medium depth to form the ridge waveguide layer 52, and finally the ridge waveguide layer 52 is shallowly etched to form the ridge waveguide Layer 53. In this mode converter, the widths of the ridge waveguide layers 51, 52, and 53 gradually narrow from the input end to the output end, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com