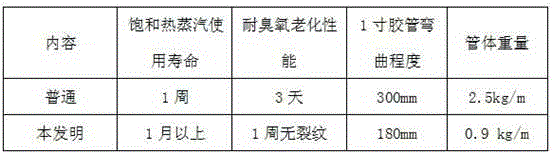

Hot steam rubber tube resisting temperature of 208 DEG C and preparation method thereof

A technology of hot steam and rubber hose, applied in the direction of hoses, pipes, mechanical equipment, etc., to reduce the number of replacement and maintenance, improve the construction safety factor, and reduce the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: A preparation method for a 208°C hot steam hose;

[0045] 1. First prepare the inner rubber and outer rubber layer material of the 208°C hot steam resistant rubber hose, and the preparation method of the inner rubber hose material includes the following steps:

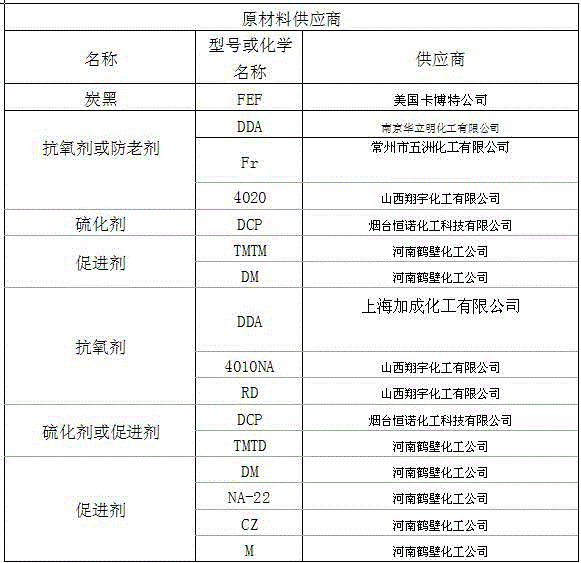

[0046] a Weigh the raw materials of the inner rubber of the inner rubber tube according to parts by weight. The raw materials of the inner rubber tube are as follows: chlorinated butyl rubber: 90-110 kg, carbon black: 70-80 kg, paraffin oil: 5-8 kg, white carbon black: 16 -25 kg, light calcium: 50-60 kg, nano zinc oxide: 1-4 kg, stearic acid: 1-3 kg, highly active magnesium oxide: 3-7 kg, antioxidant: 0.5-2 kg, anti-aging 2.5-5.5kg of curing agent, 1-4 kg of vulcanizing agent, 0.2-1 kg of accelerator; adjust the temperature of internal mixer: 100-120 ℃, the speed of 35-45r / min, first put the chlorinated butyl rubber in the internal mixing Plasticizing in the machine for 25-35s;

[0047] b. Add highl...

Embodiment 2

[0061] Example 2: A preparation method of a 208°C hot steam hose;

[0062] 1. First prepare the inner rubber and outer rubber layer material of the 208°C hot steam resistant rubber hose, and the preparation method of the inner rubber hose material includes the following steps:

[0063] a Weigh the raw materials of the inner rubber of the inner rubber tube by weight. The raw materials of the inner rubber tube are as follows: chlorinated butyl rubber: 90kg, carbon black: 70kg, paraffin oil: 5kg, white carbon black: 16kg, light calcium: 50kg, nano-oxidized Zinc: 1kg, stearic acid: 1kg, highly active magnesium oxide: 3kg, antioxidant DDA: 0.5kg, antioxidant FR2.kg, vulcanizing agent DCP: 1kg, accelerator TMTM: 0.2kg; adjust the temperature of the internal mixer: 100°C, speed 35r / min, masticate chlorinated butyl rubber in an internal mixer for 25s;

[0064] b. Add highly active magnesium oxide, nano-zinc oxide, anti-aging agent, paraffin oil to the internal mixer, and mix for 0.5 ...

Embodiment 3

[0078] Example 3: A preparation method of a 208°C hot steam hose;

[0079] 1. First prepare the inner rubber and outer rubber layer material of the 208°C hot steam resistant rubber hose, and the preparation method of the inner rubber hose material includes the following steps:

[0080] a Weigh the raw materials of inner rubber tube and inner rubber by parts by weight. The raw materials of inner rubber tube are as follows: chlorinated butyl rubber: 71kg, carbon black: 71kg, paraffin oil: 5.5kg, white carbon black: 17kg, light calcium: 52 kg, Nano Zinc Oxide: 2kg, Stearic Acid: 1.5kg, Highly Active Magnesium Oxide: 4kg, Antioxidant Fr: 0.6kg, Antiaging Agent 4020: 2.6kg, Vulcanizing Agent S: 1.5kg, Accelerator TMTD: 0.3kg; adjust Mixer temperature: 102°C, speed 36r / min, masticating chlorobutyl rubber in the mixer for 26s;

[0081] b. Add highly active magnesium oxide, nano-zinc oxide, anti-aging agent, paraffin oil into the internal mixer, and mix for 0.6 minutes;

[0082] c P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com