Electric cable for hybrid power electric automobile

A hybrid electric and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of inconvenient laying, poor temperature resistance, interference, etc., and achieve good shielding effect, ideal safety, and improved flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will further describe the present invention in conjunction with the accompanying drawings of the embodiments, which will help the understanding of the technical contents and effects of the present invention, but the embodiments do not constitute a limitation to the technical solutions of the present invention.

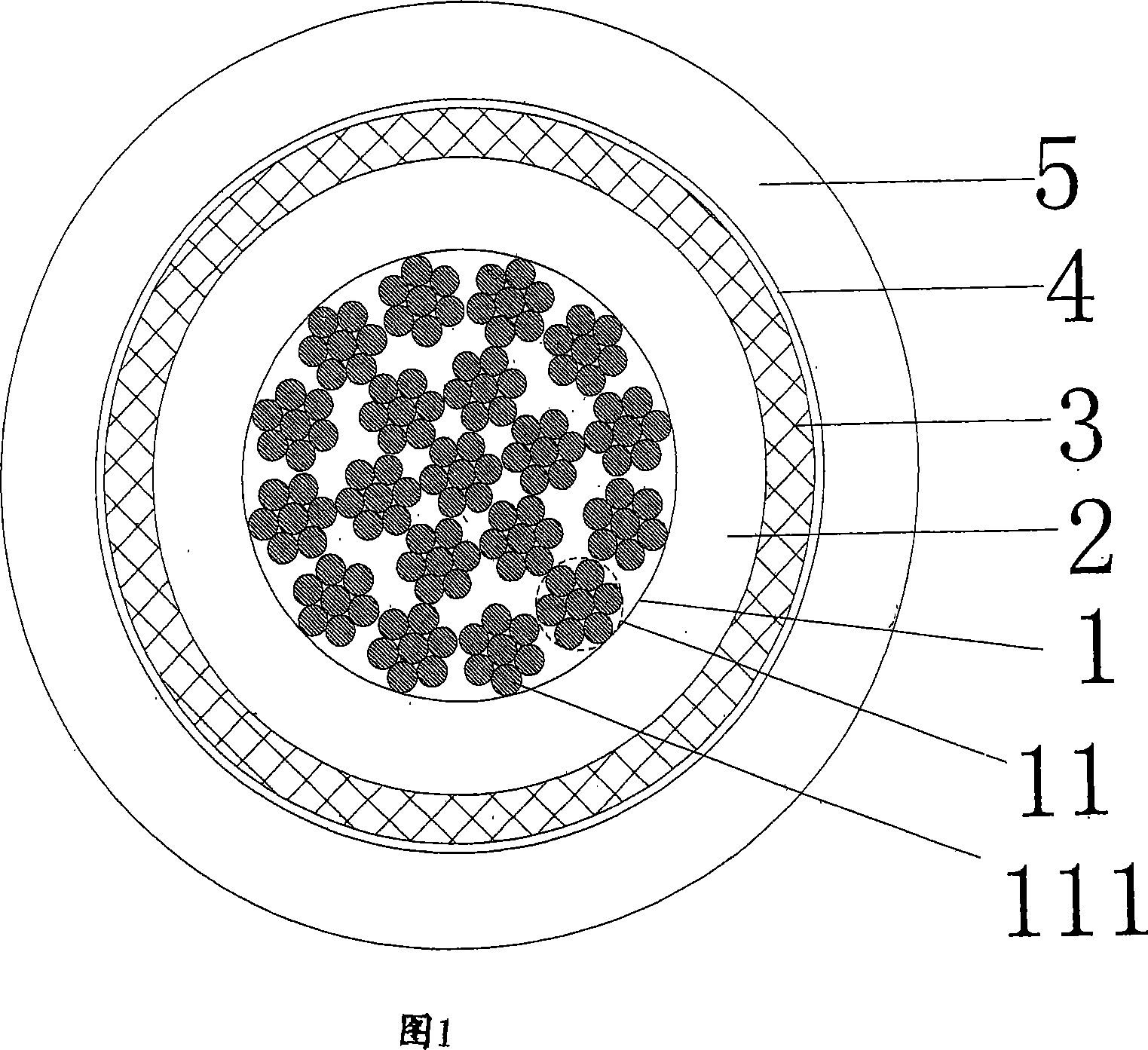

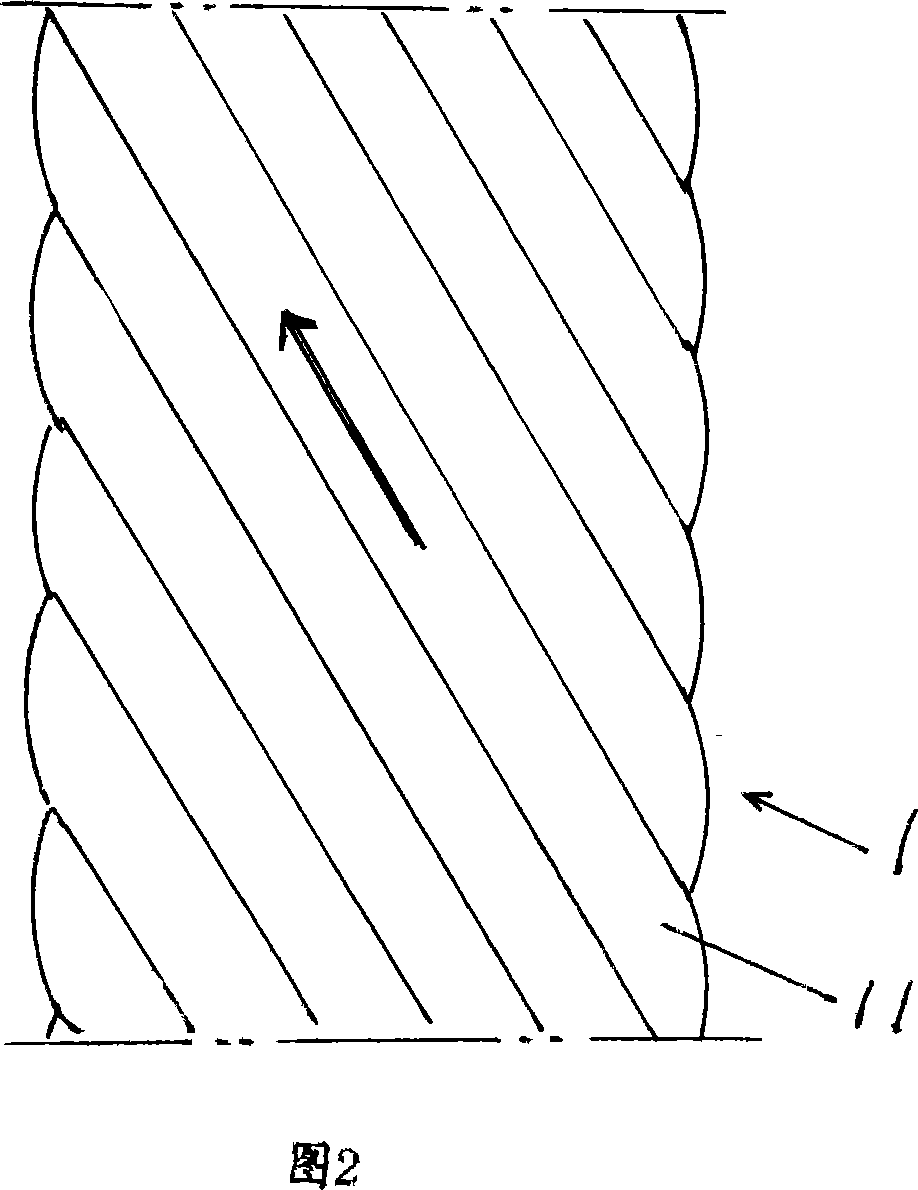

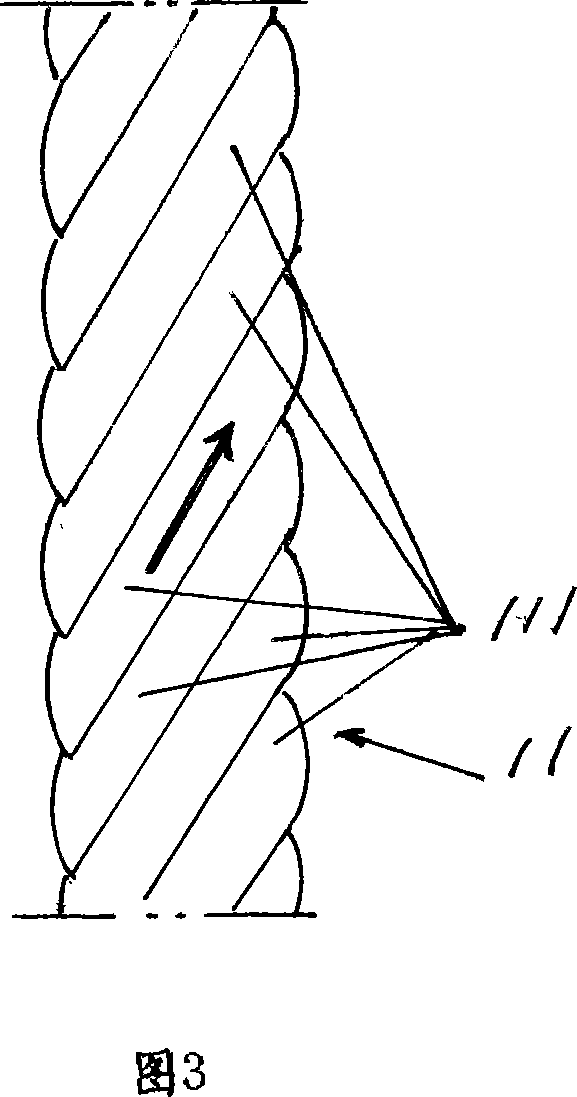

[0020] Referring to FIGS. 1 to 3 , there are 19 conductive units 11 . The 19 conductive units 11 are 12 times the pitch ratio and twisted in S direction to obtain the cable core 1 . As shown in Figure 2, it exhibits complex twisting in the S direction. The pitch ratio referred to here is the stranded wire pitch and pitch diameter ratio well known in the wire and cable industry, that is, the axial length of the single wire in the stranded wire turning around the stranded wire is called the stranded wire pitch; the pitch diameter ratio is The ratio of strand pitch length to strand diameter. For each conductive unit 11, the applicant exemplifies that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com