Patents

Literature

45results about How to "Increase the spring rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

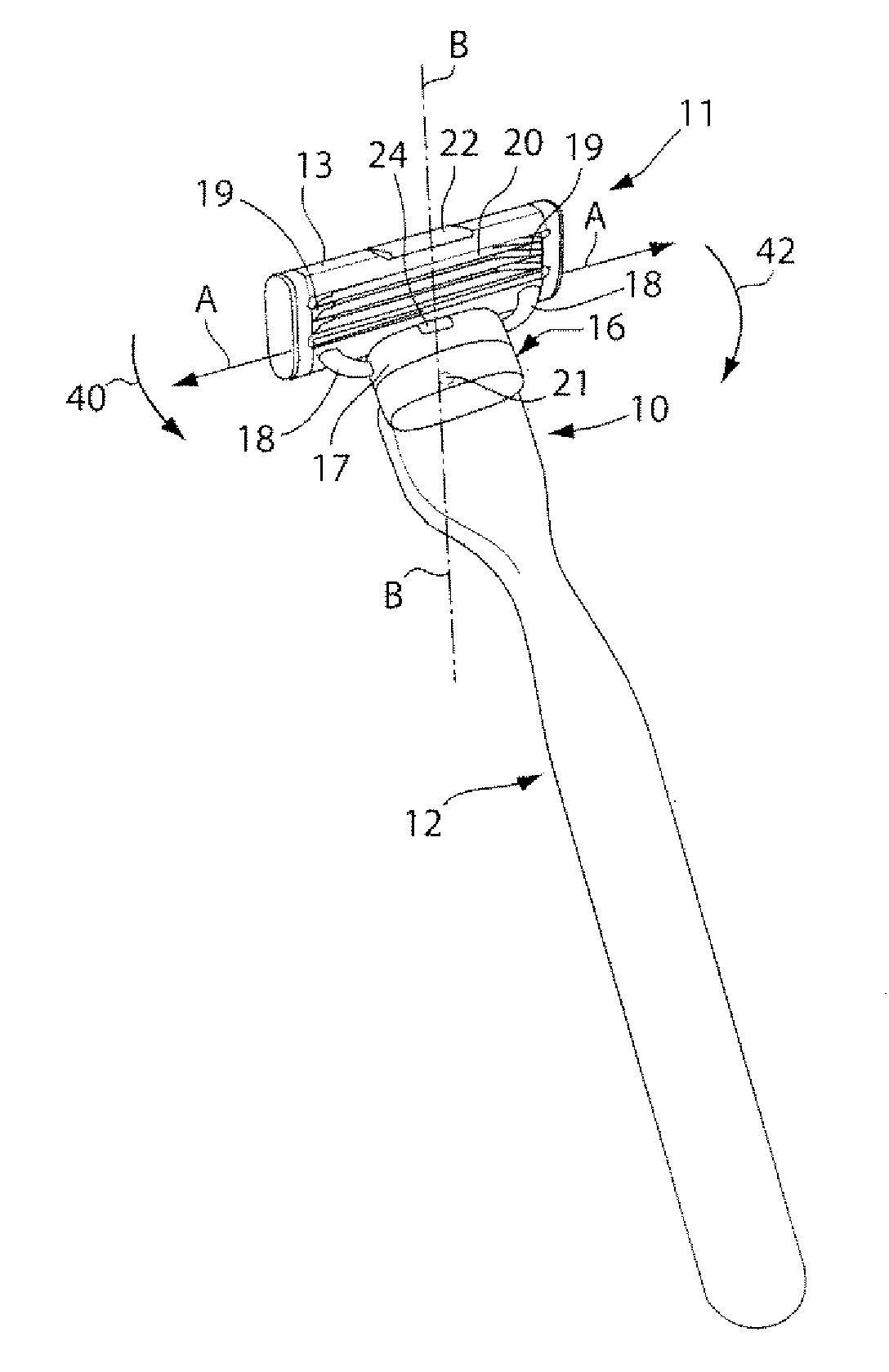

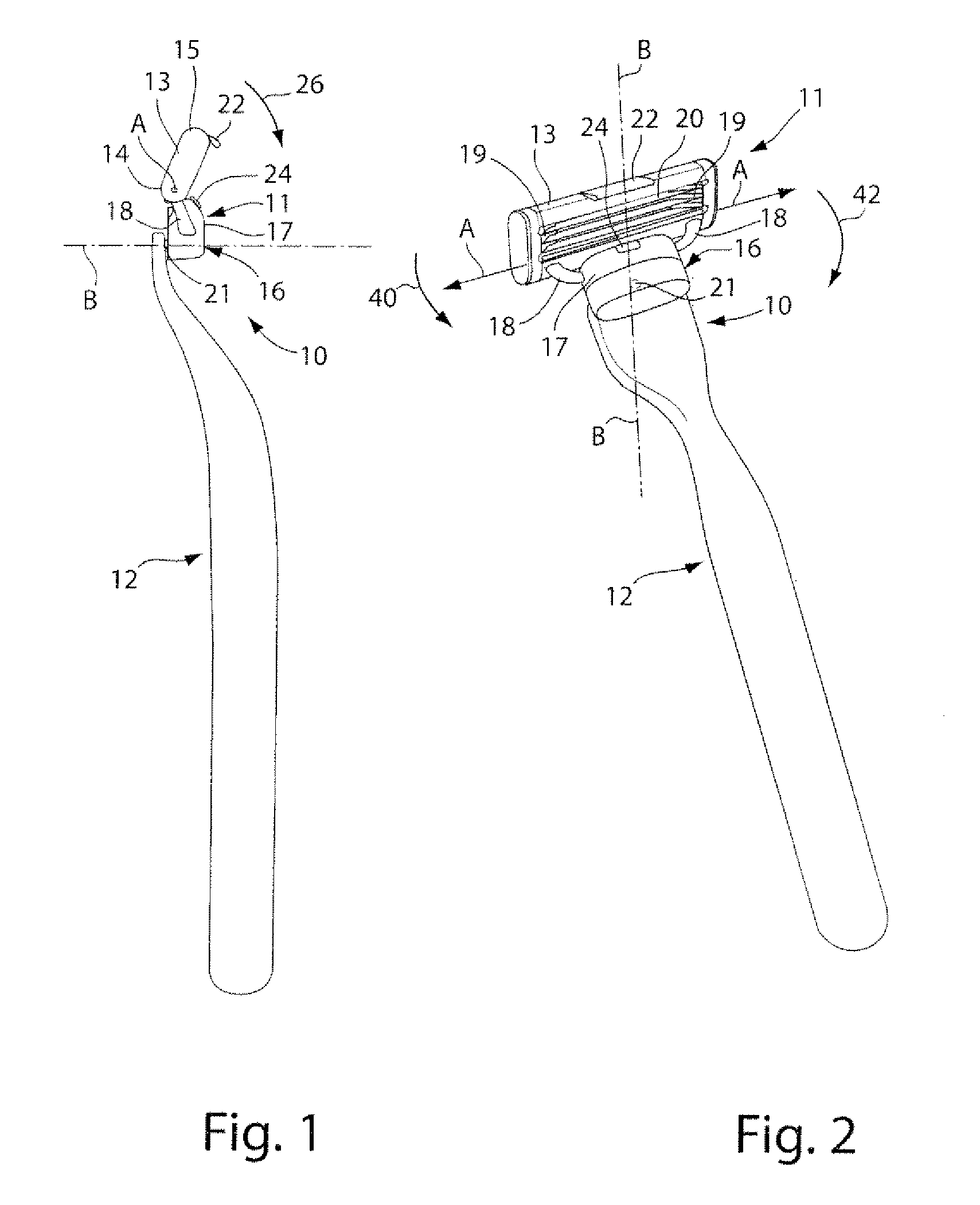

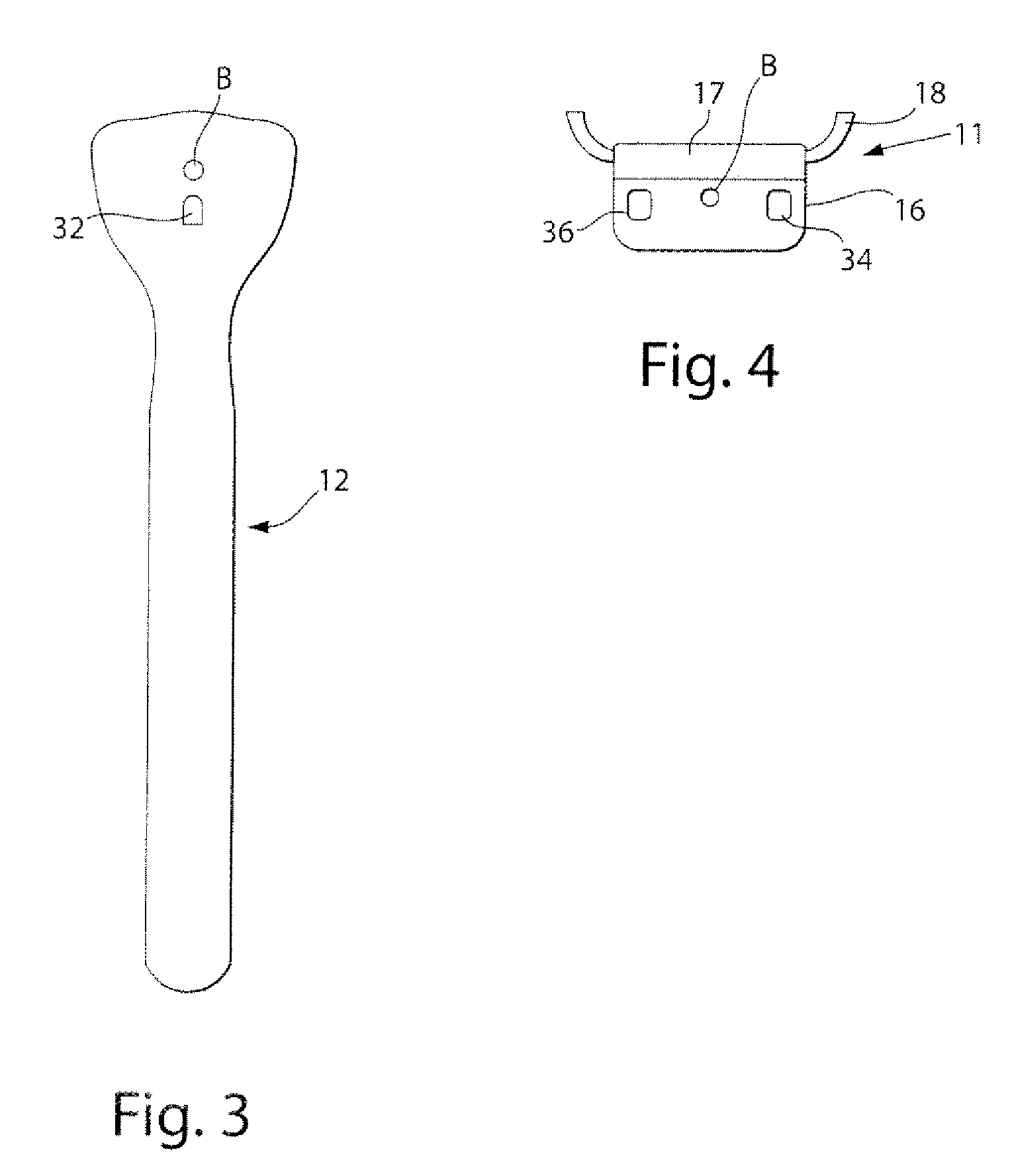

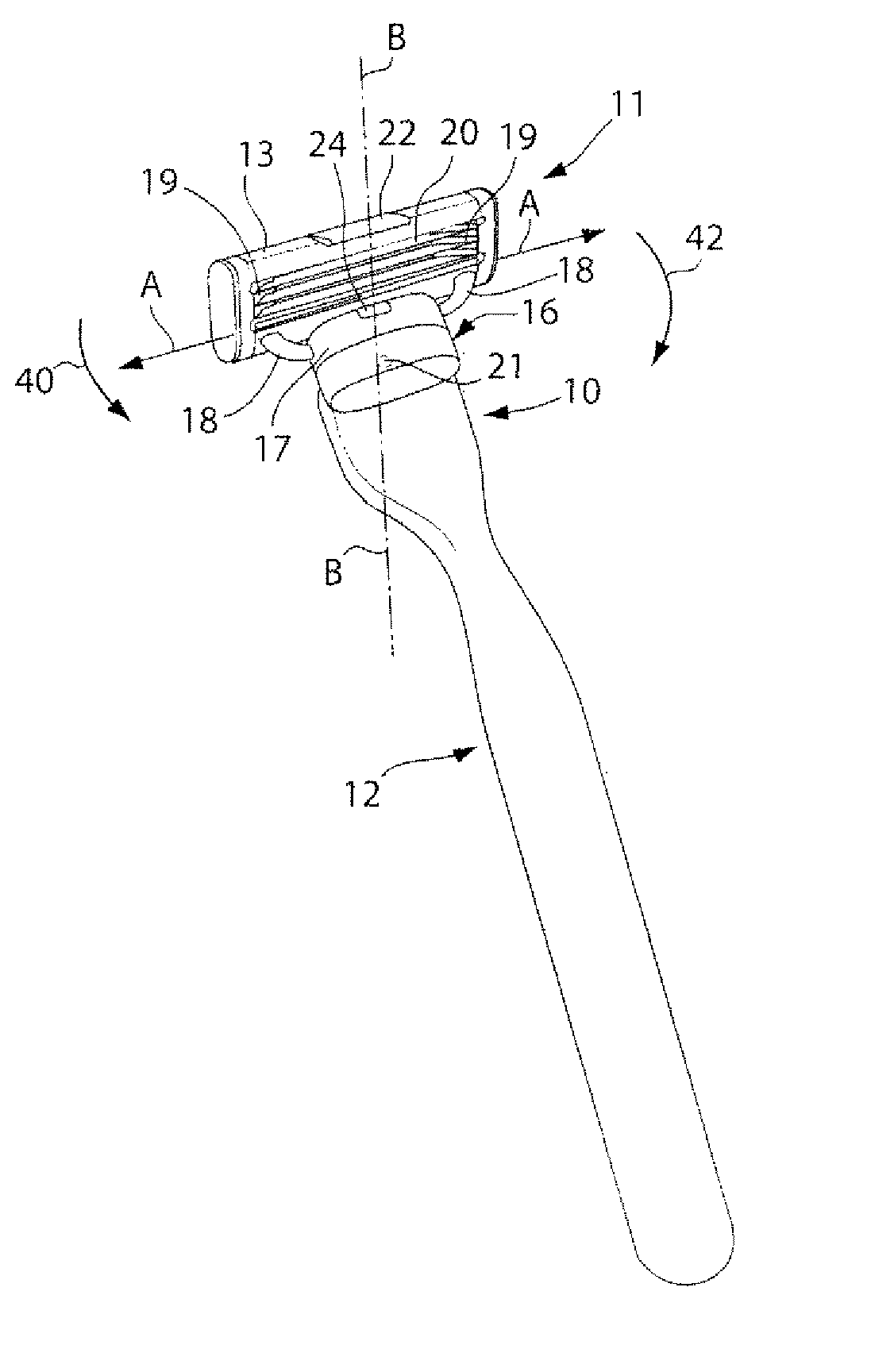

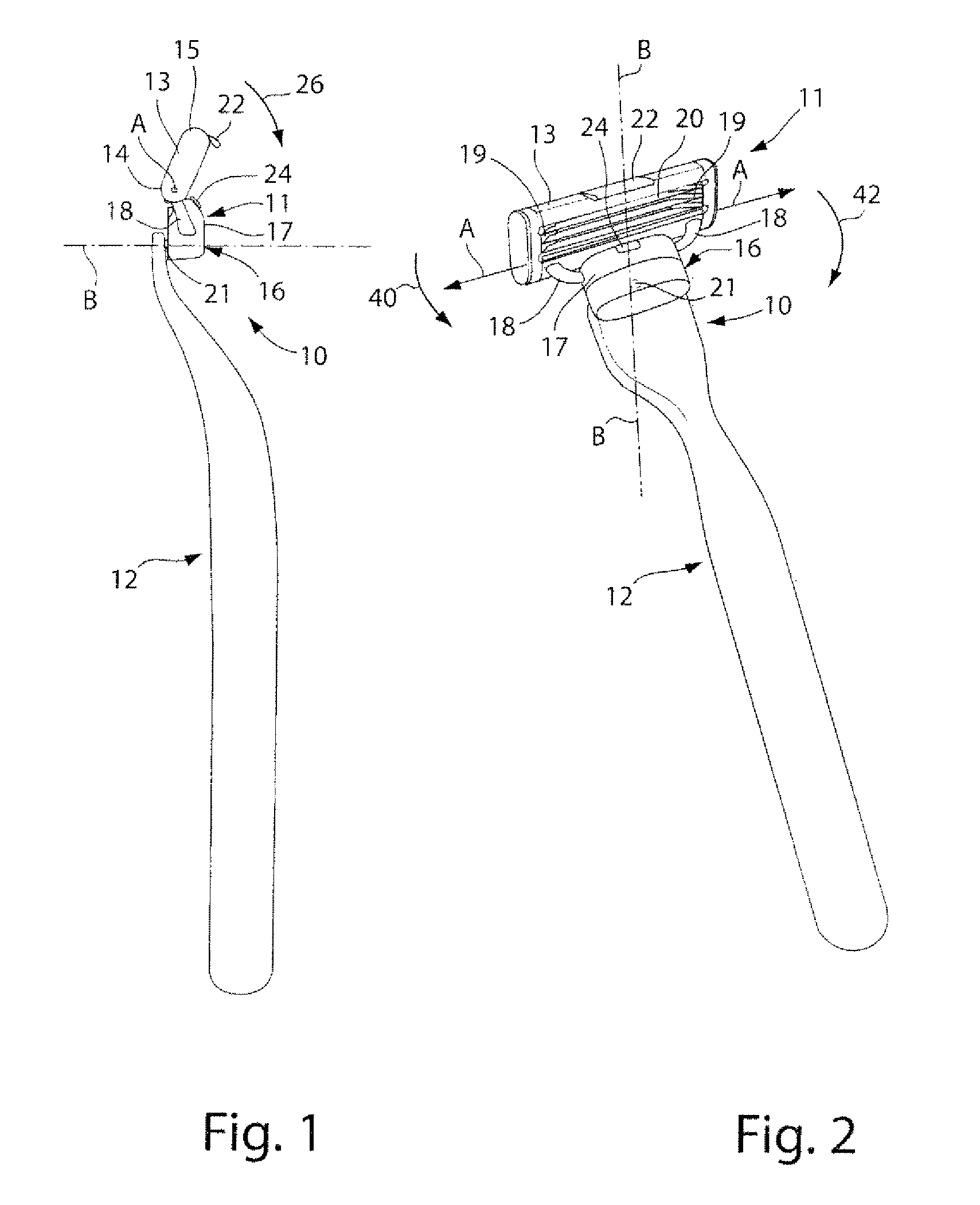

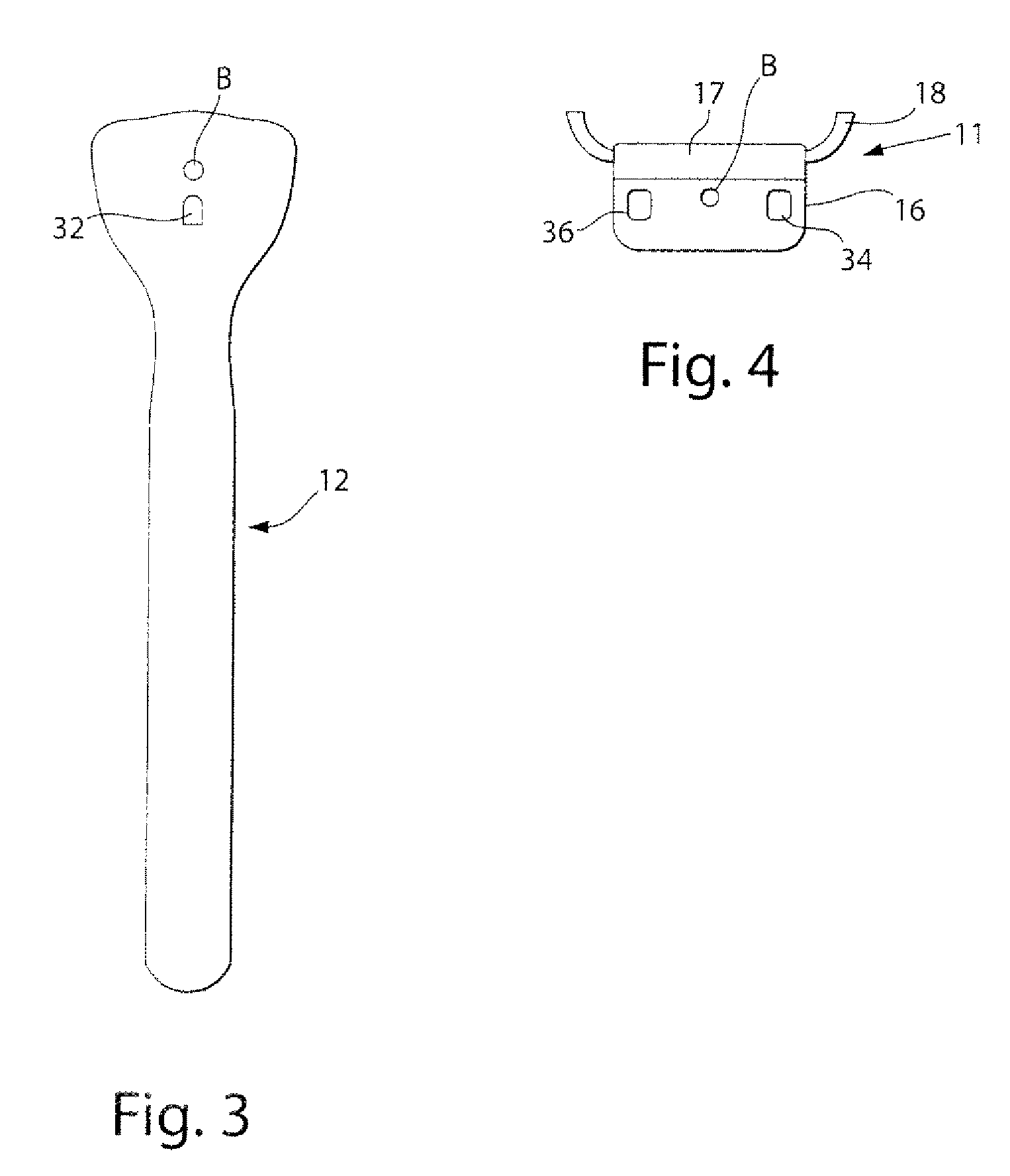

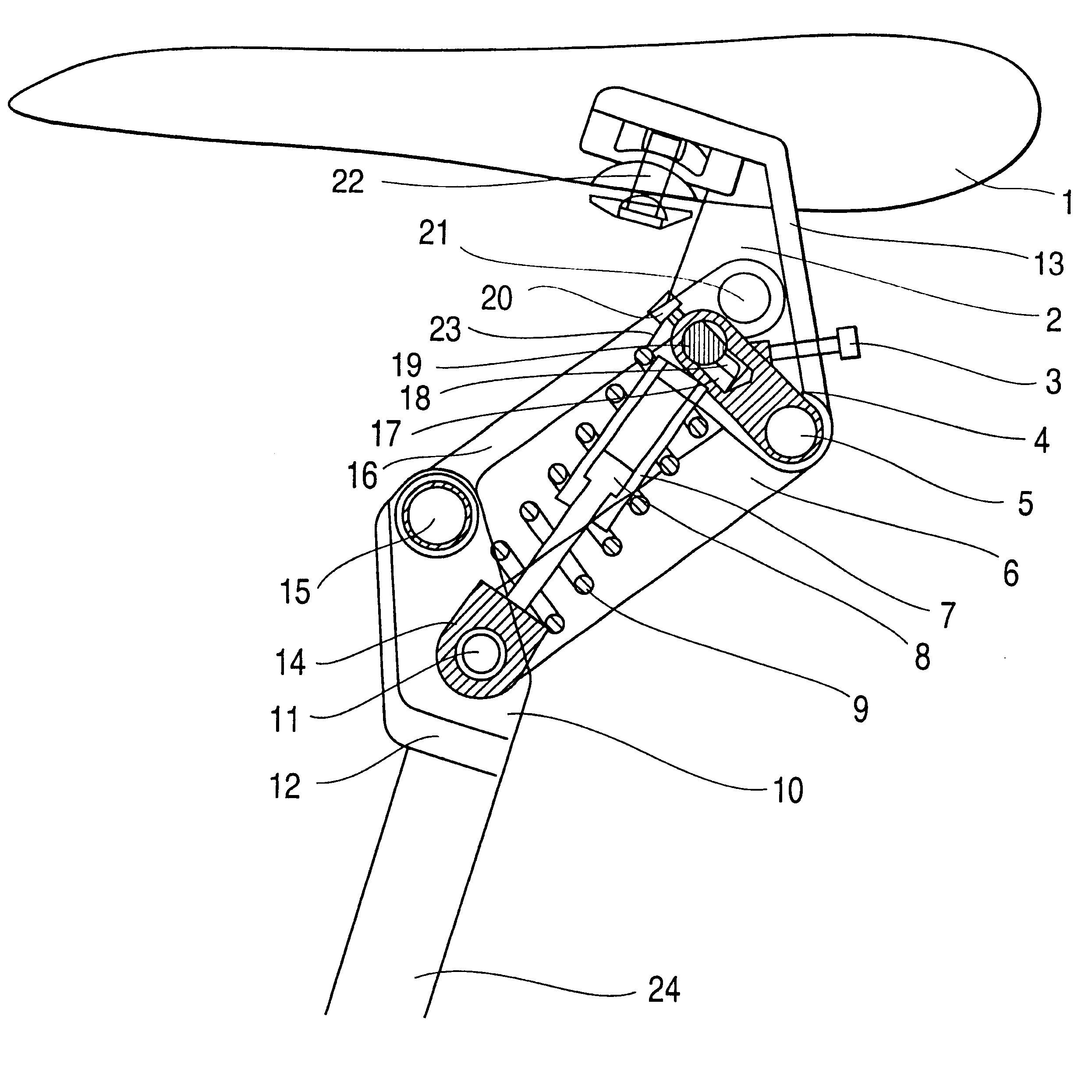

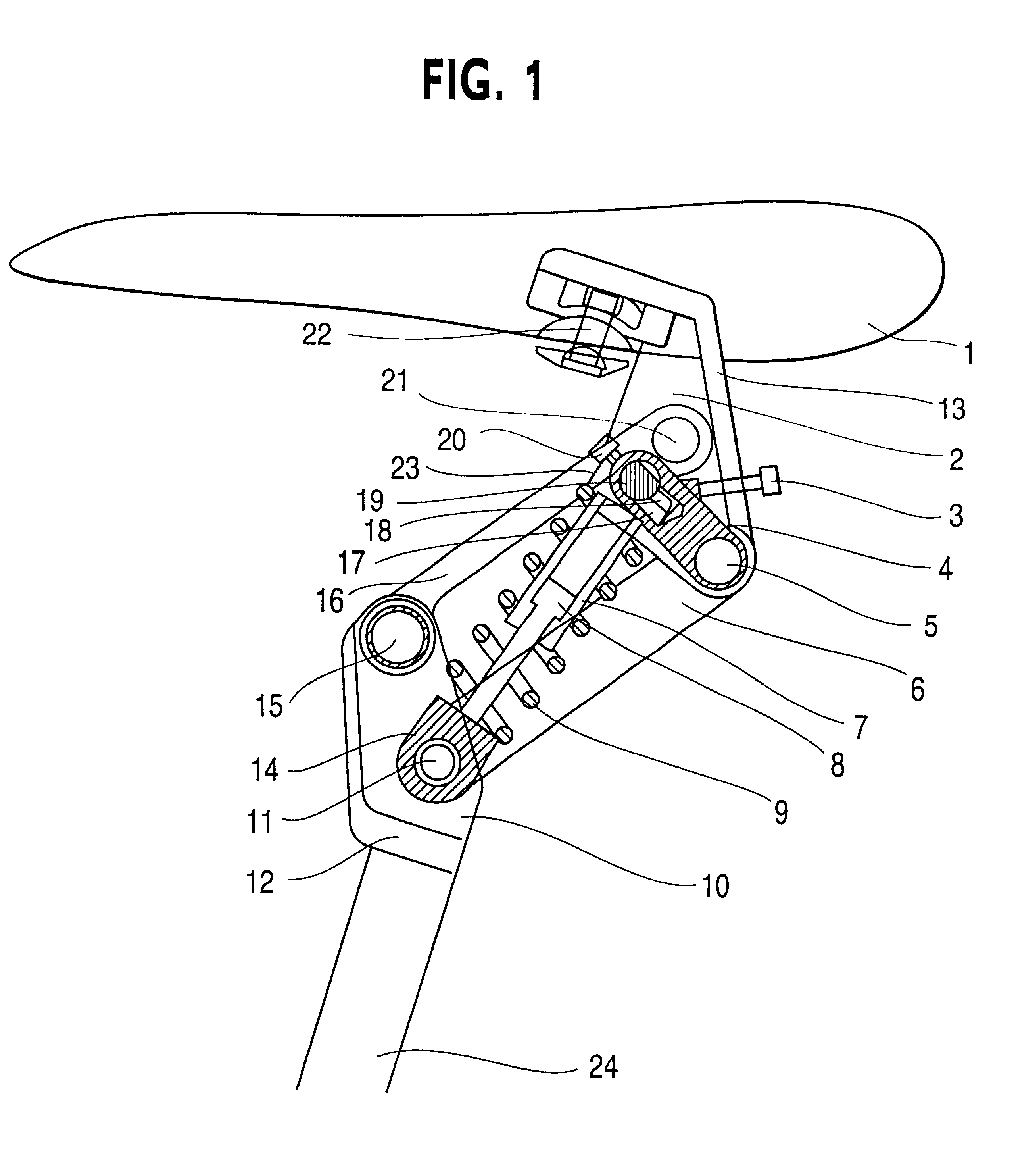

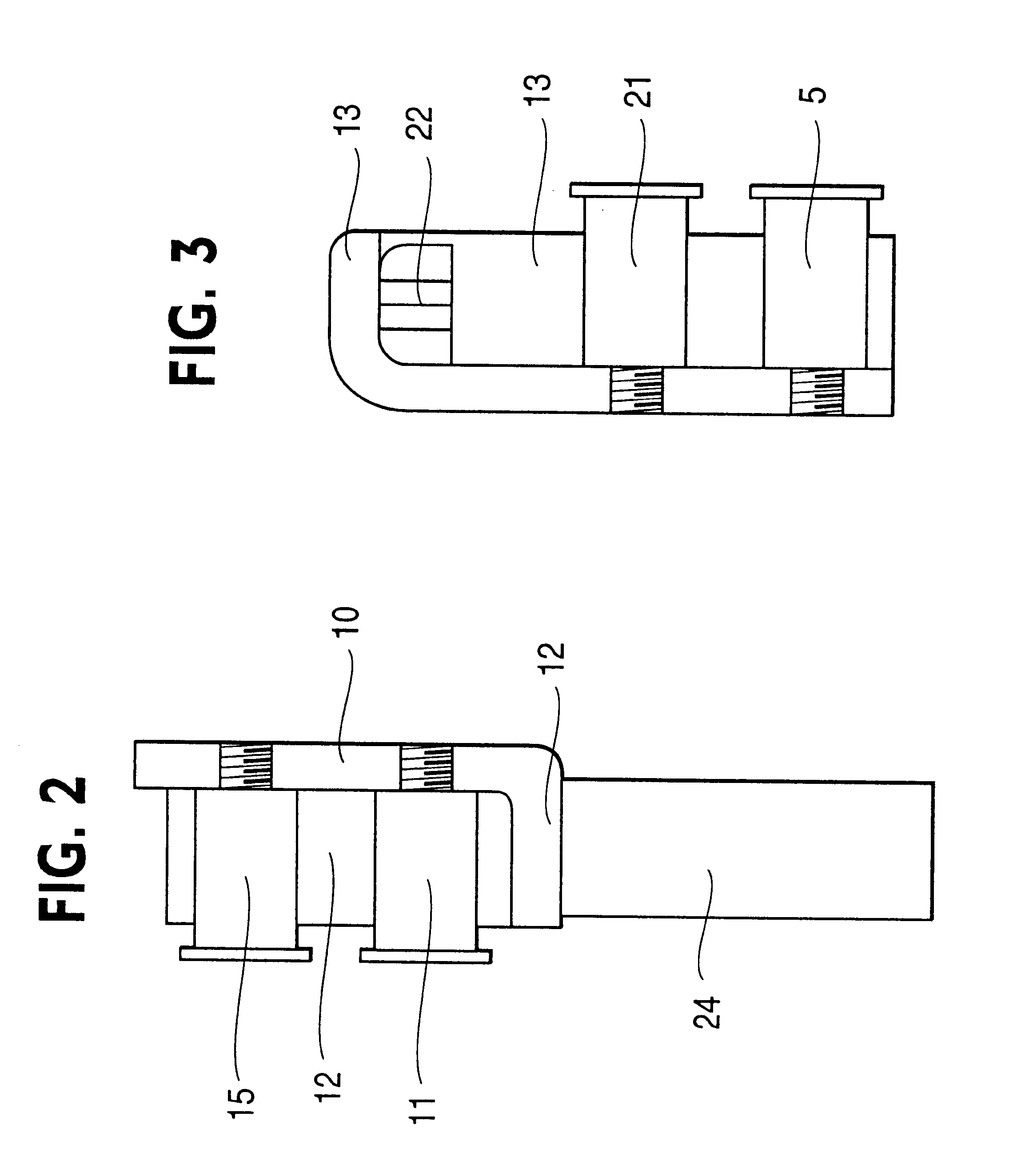

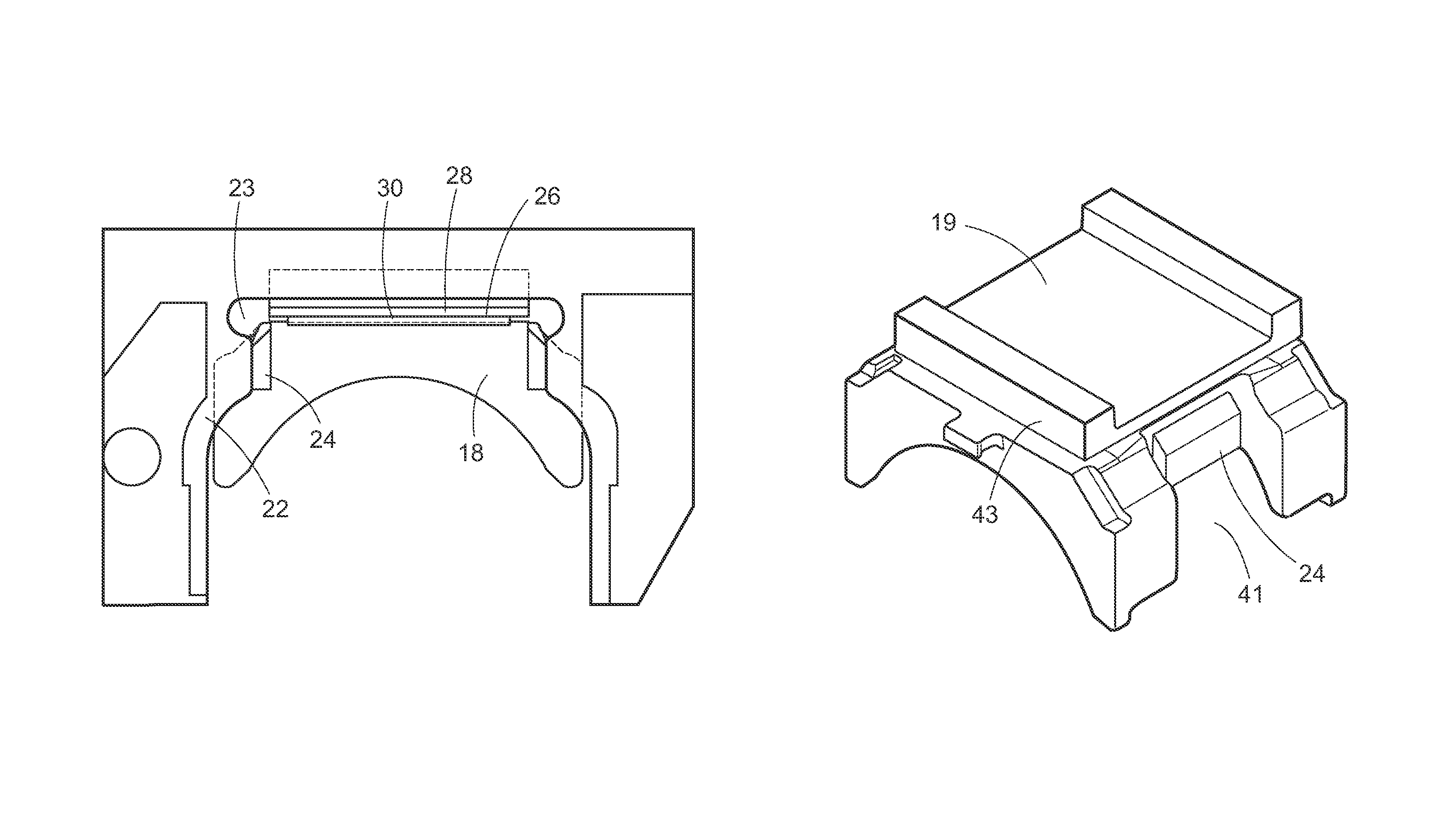

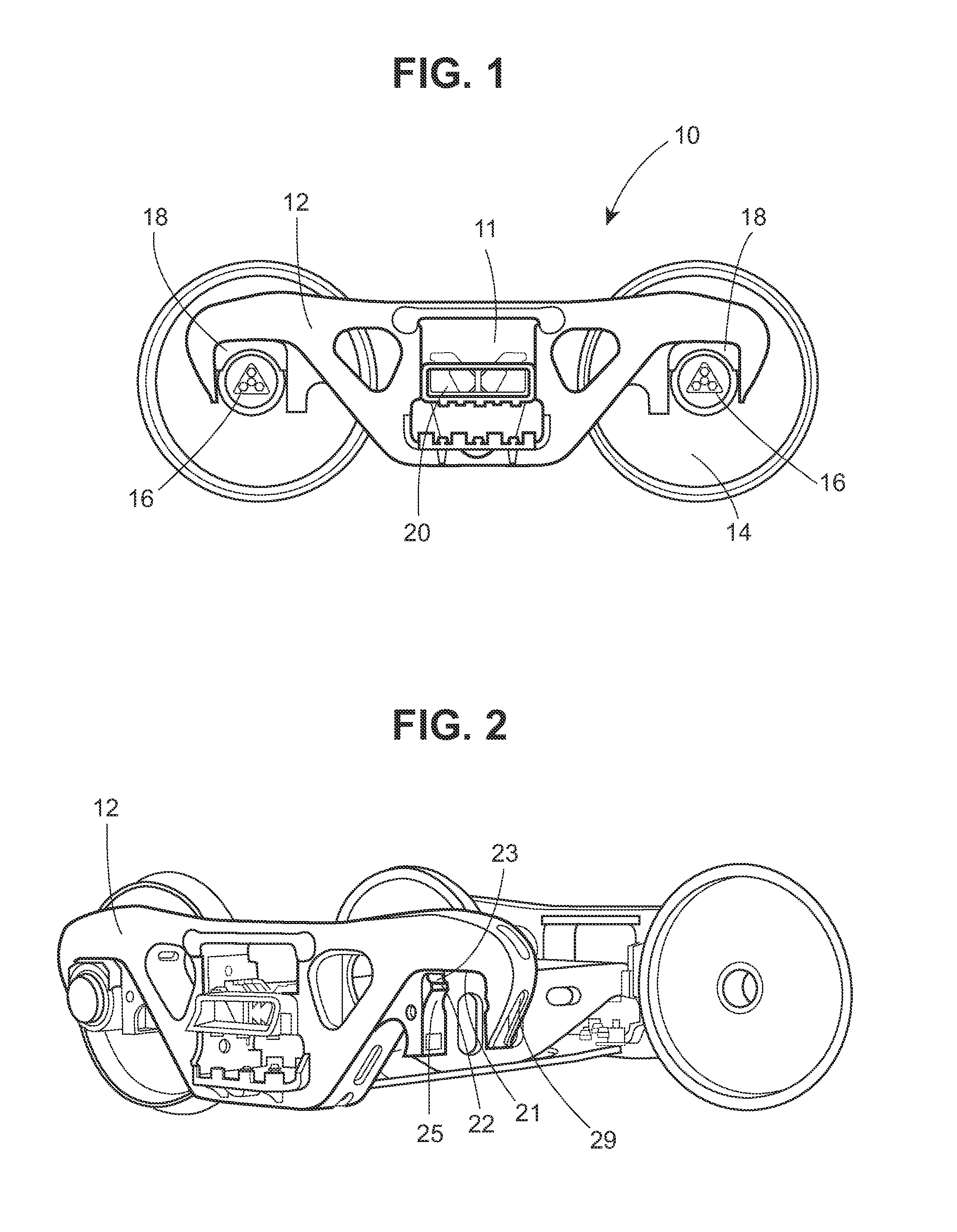

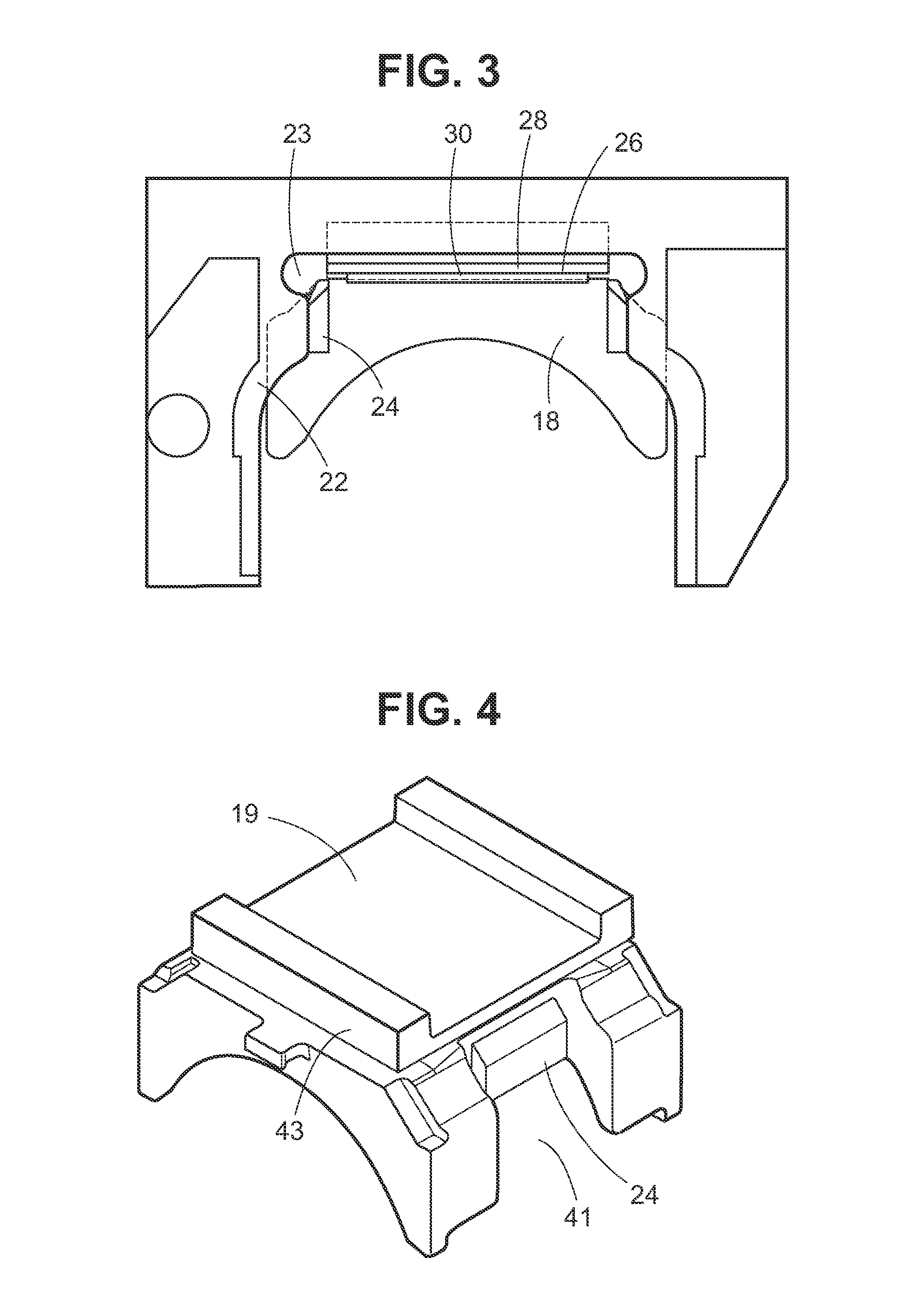

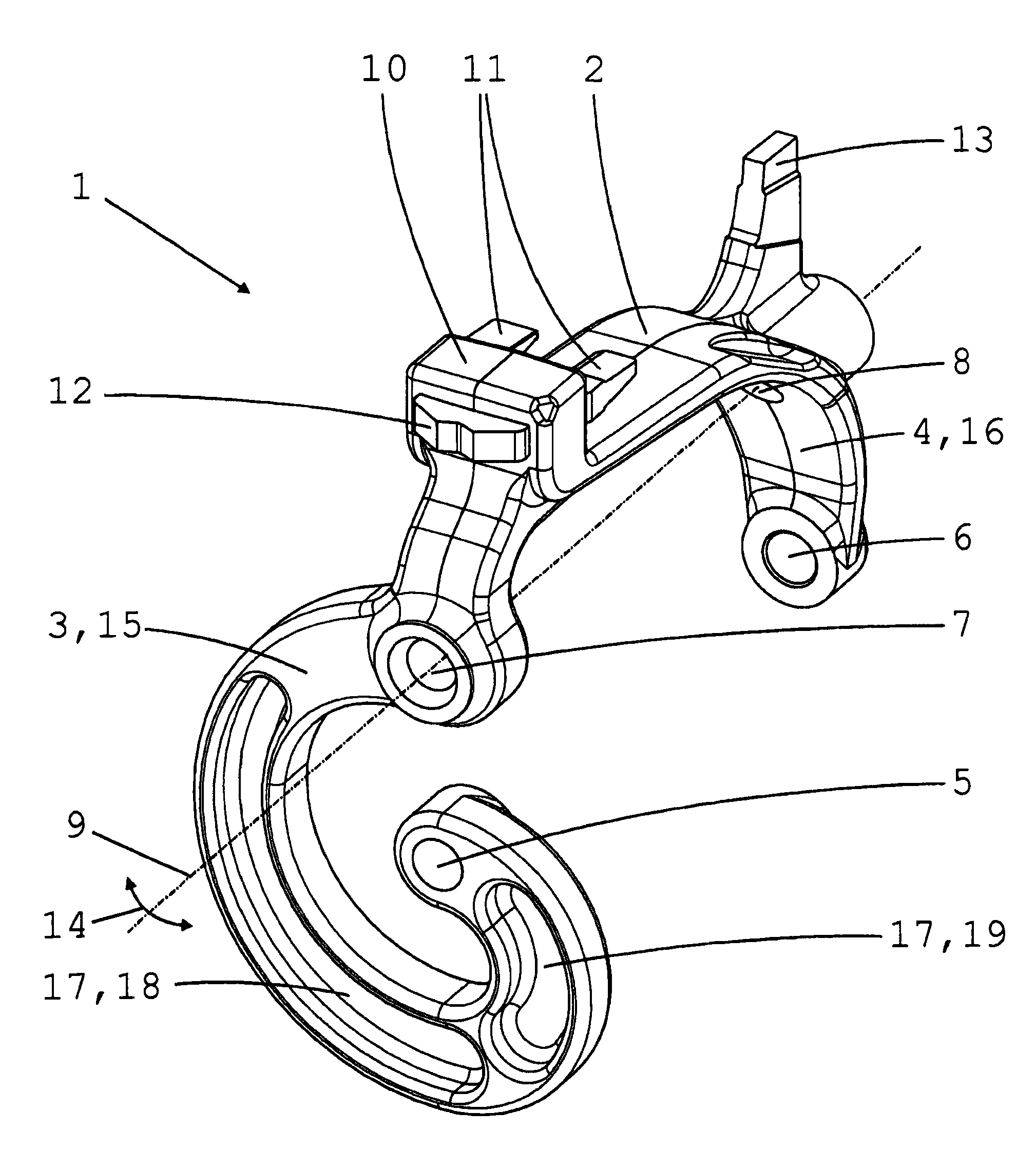

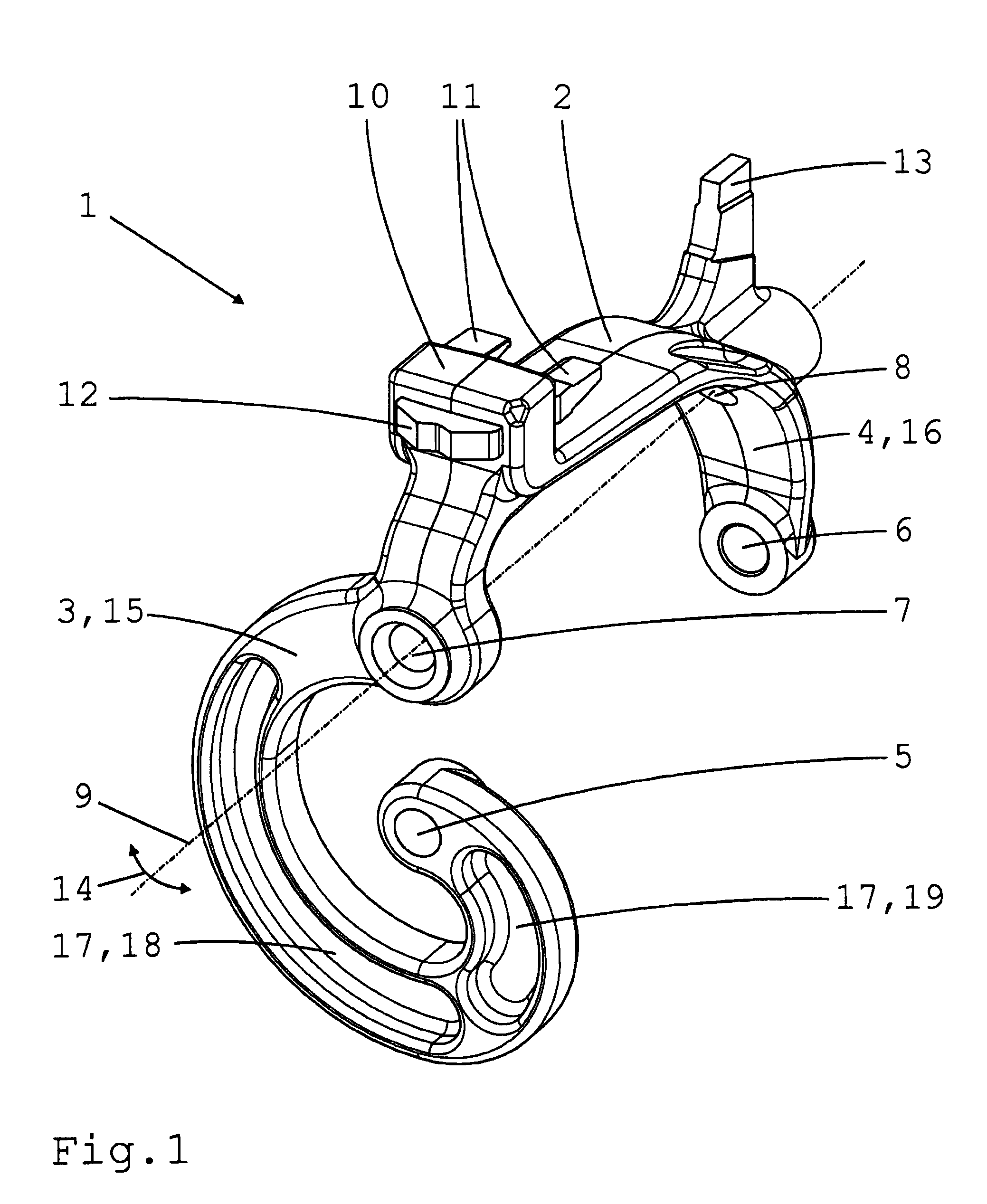

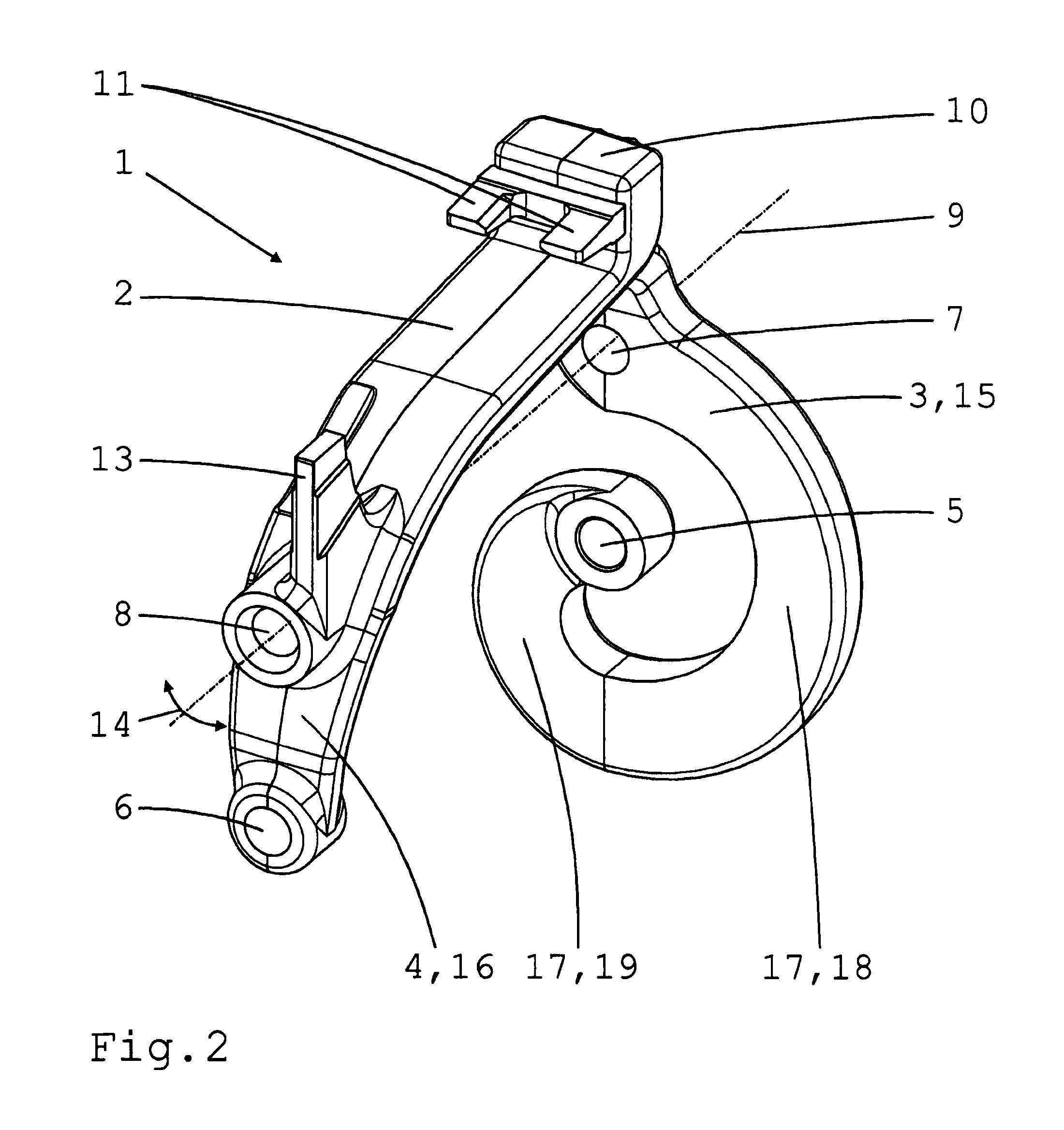

Safety razor with multi-pivot blade unit

ActiveUS20100083505A1Easy to modifyIncrease the spring rateMetal working apparatusKnife bladesEngineering

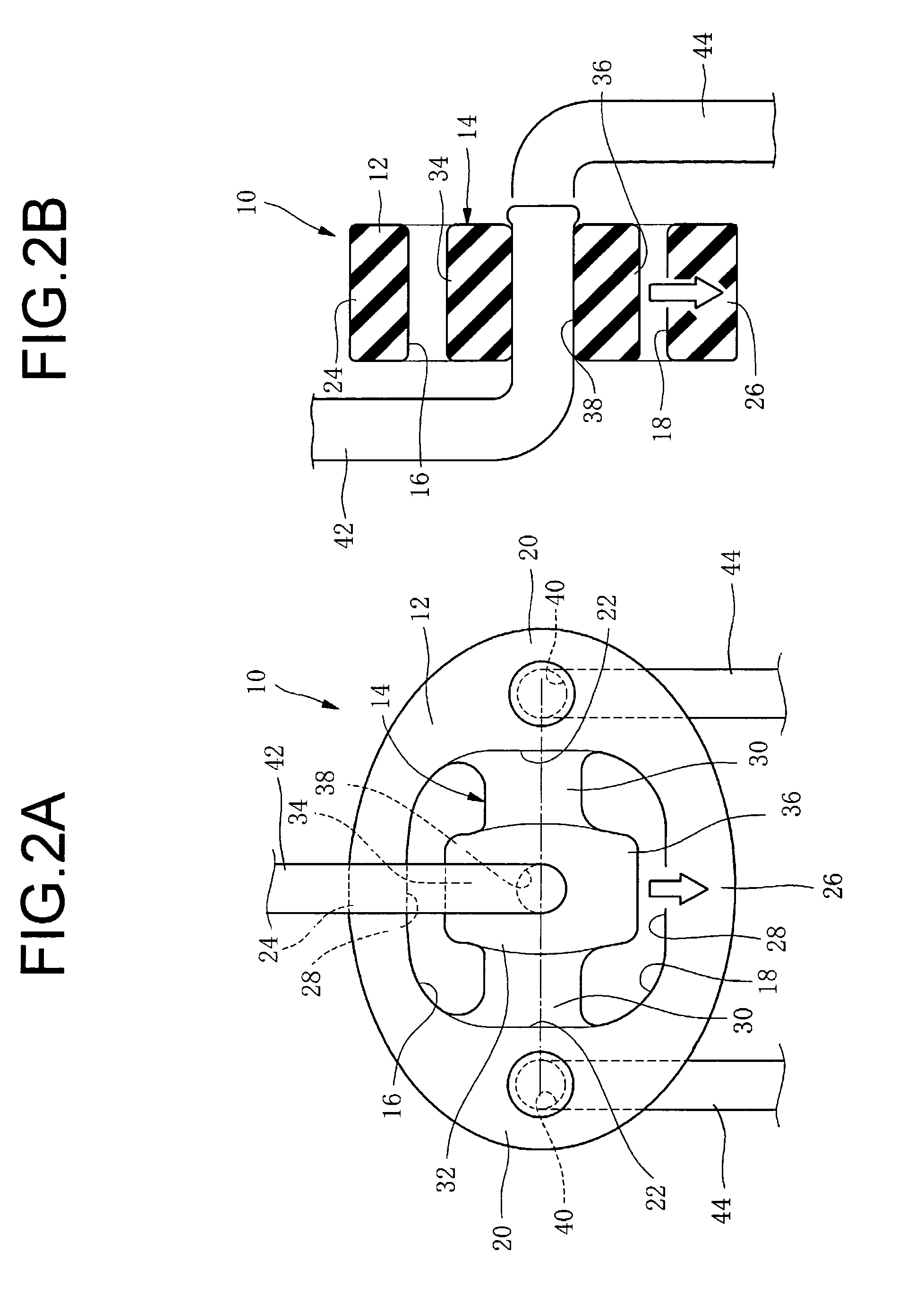

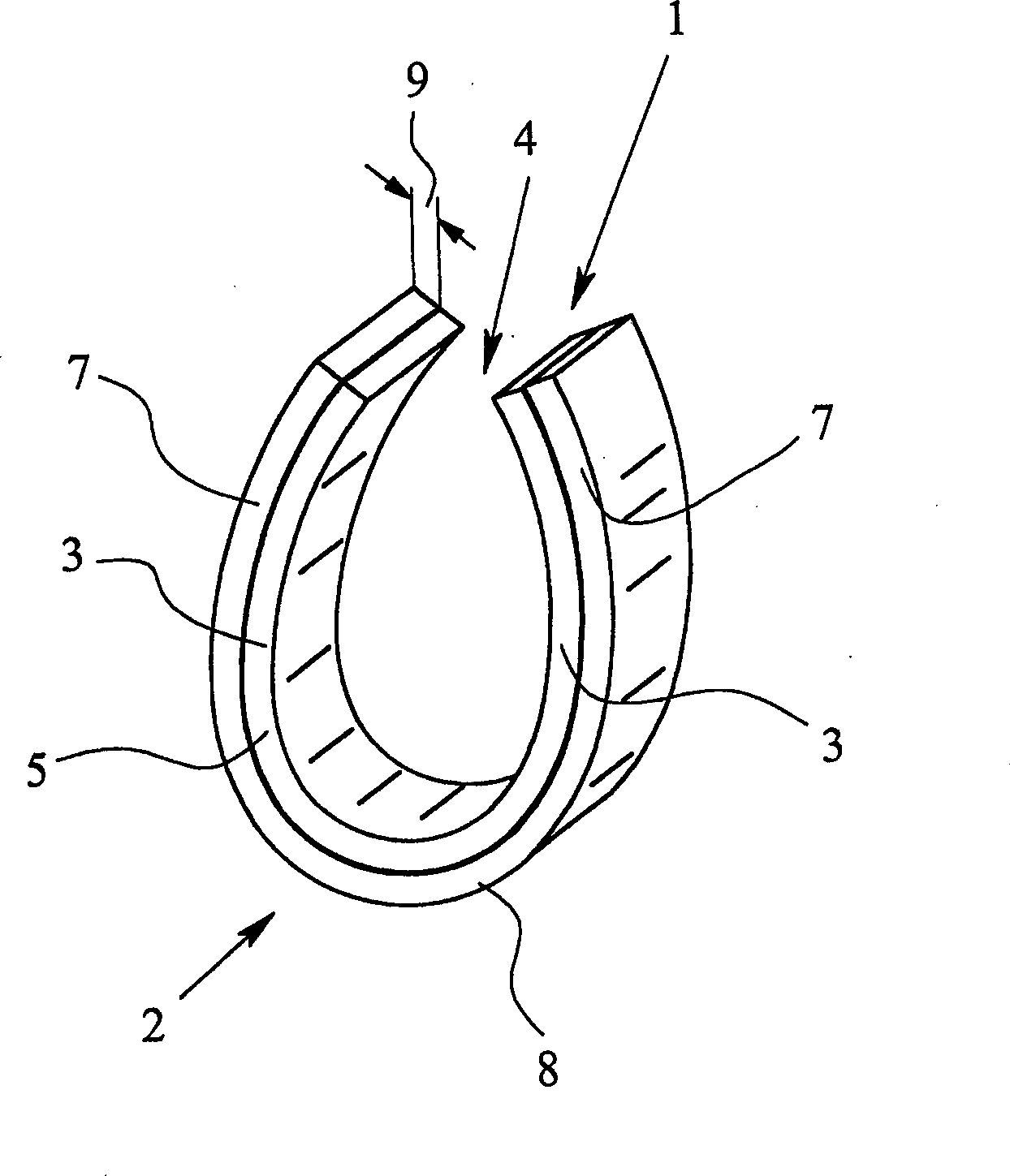

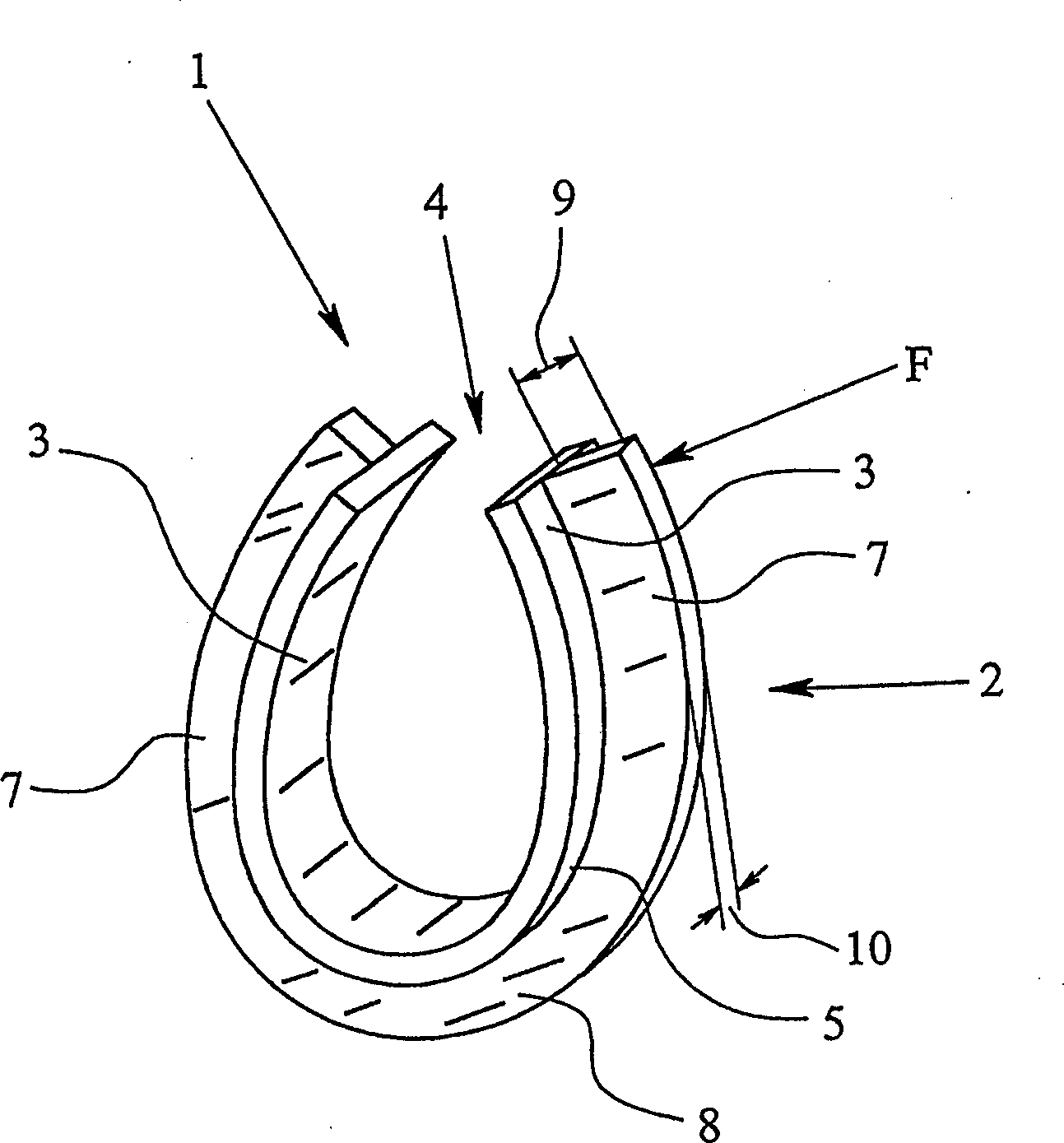

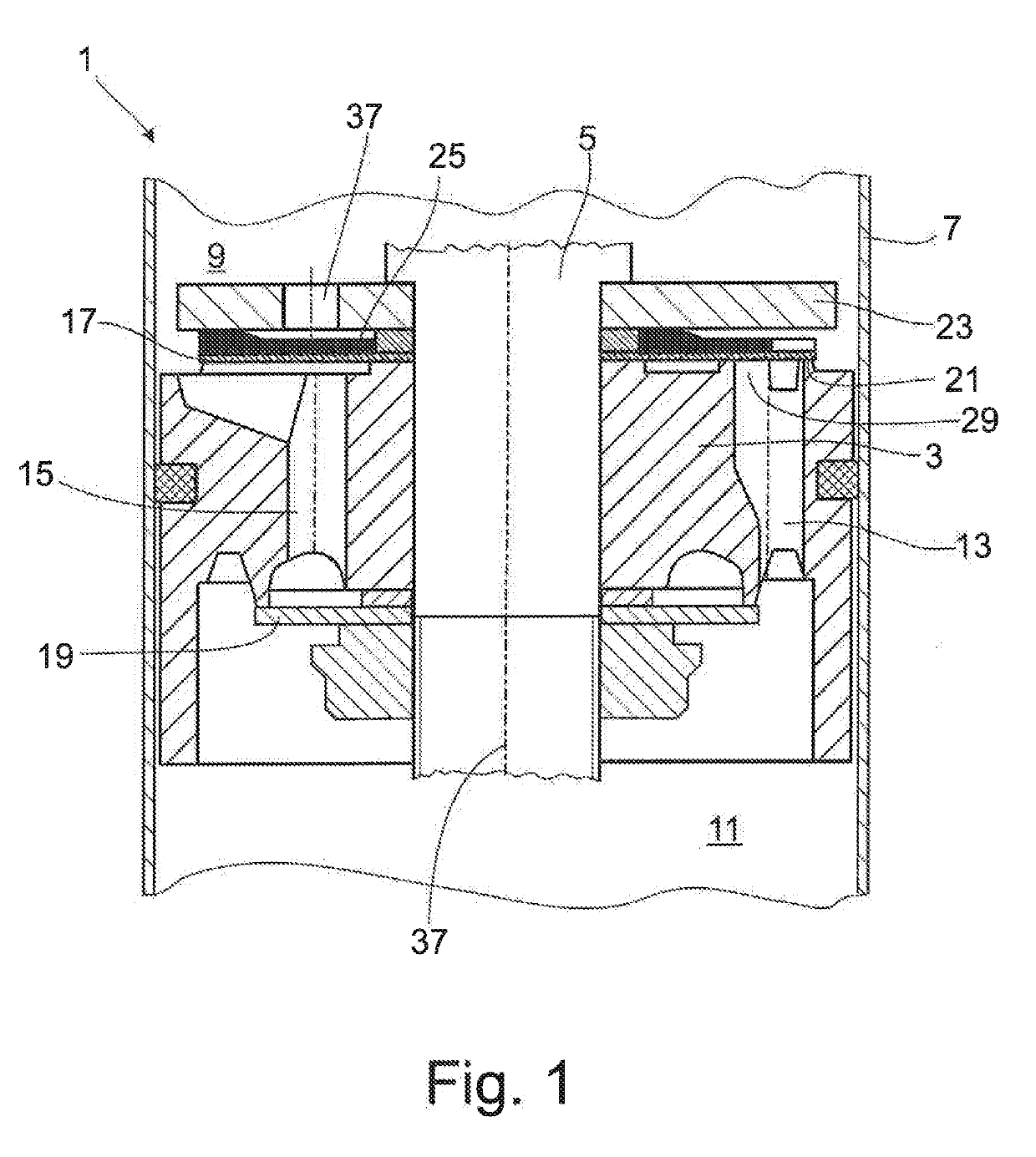

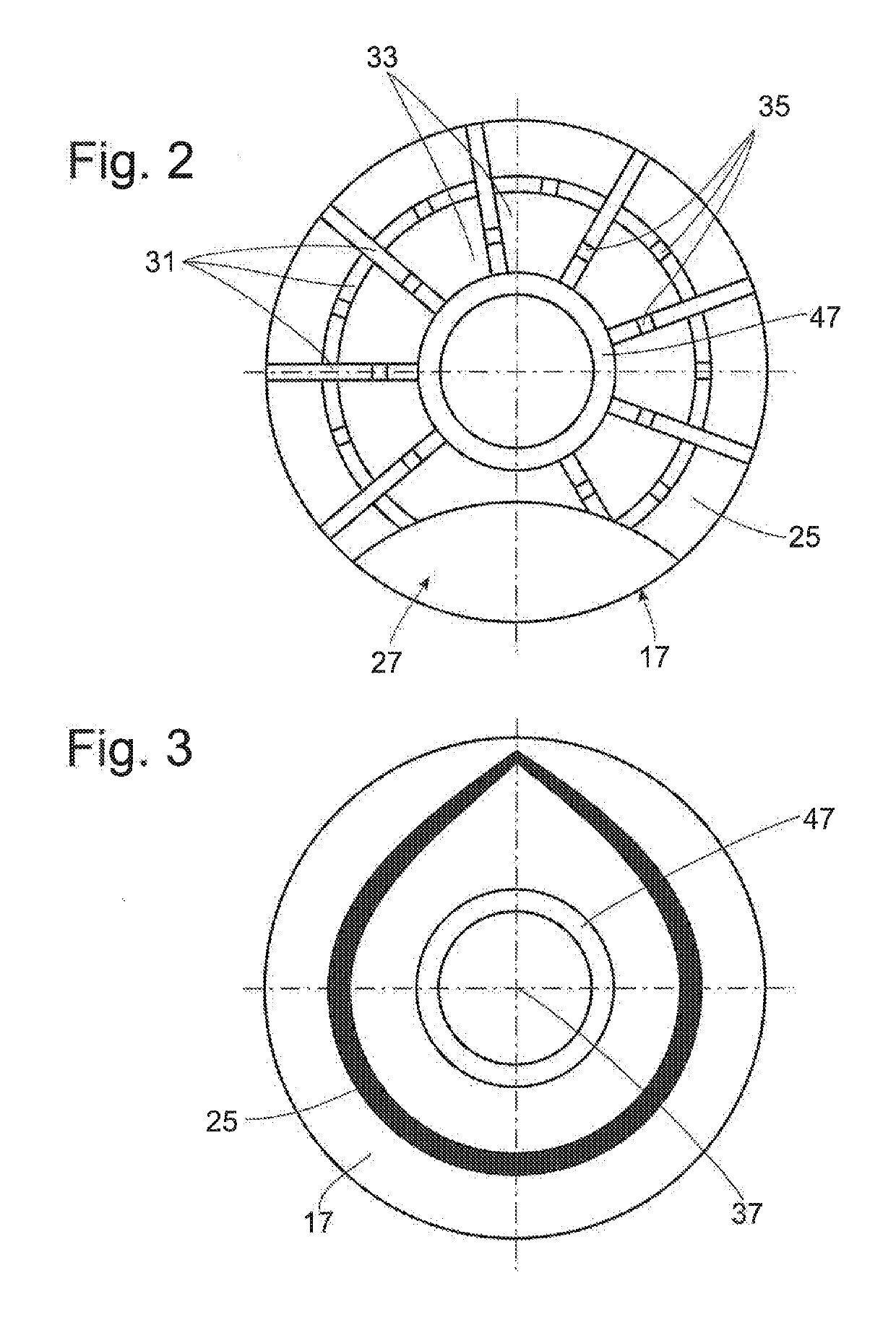

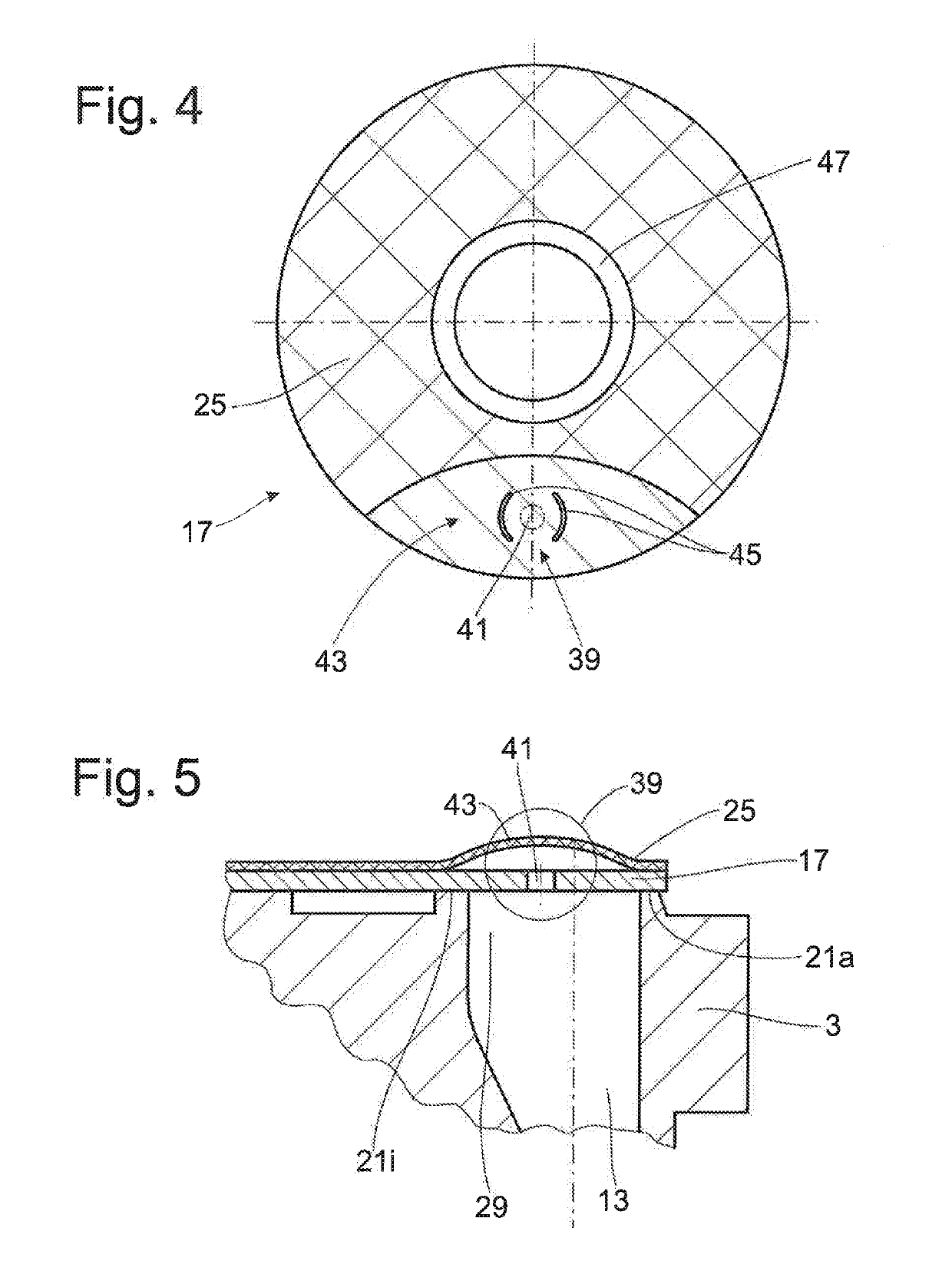

A safety razor blade unit mounted for pivotal movement relative to a razor handle about a pivot axis substantially perpendicular to a blade mounted in the blade unit. The blade unit is biased to a rest position by a magnetic return force generated by a set of magnetic elements. The set of magnetic elements are so disposed that the return force increases as the pivotal displacement of the blade unit from the rest position increases.

Owner:THE GILLETTE CO

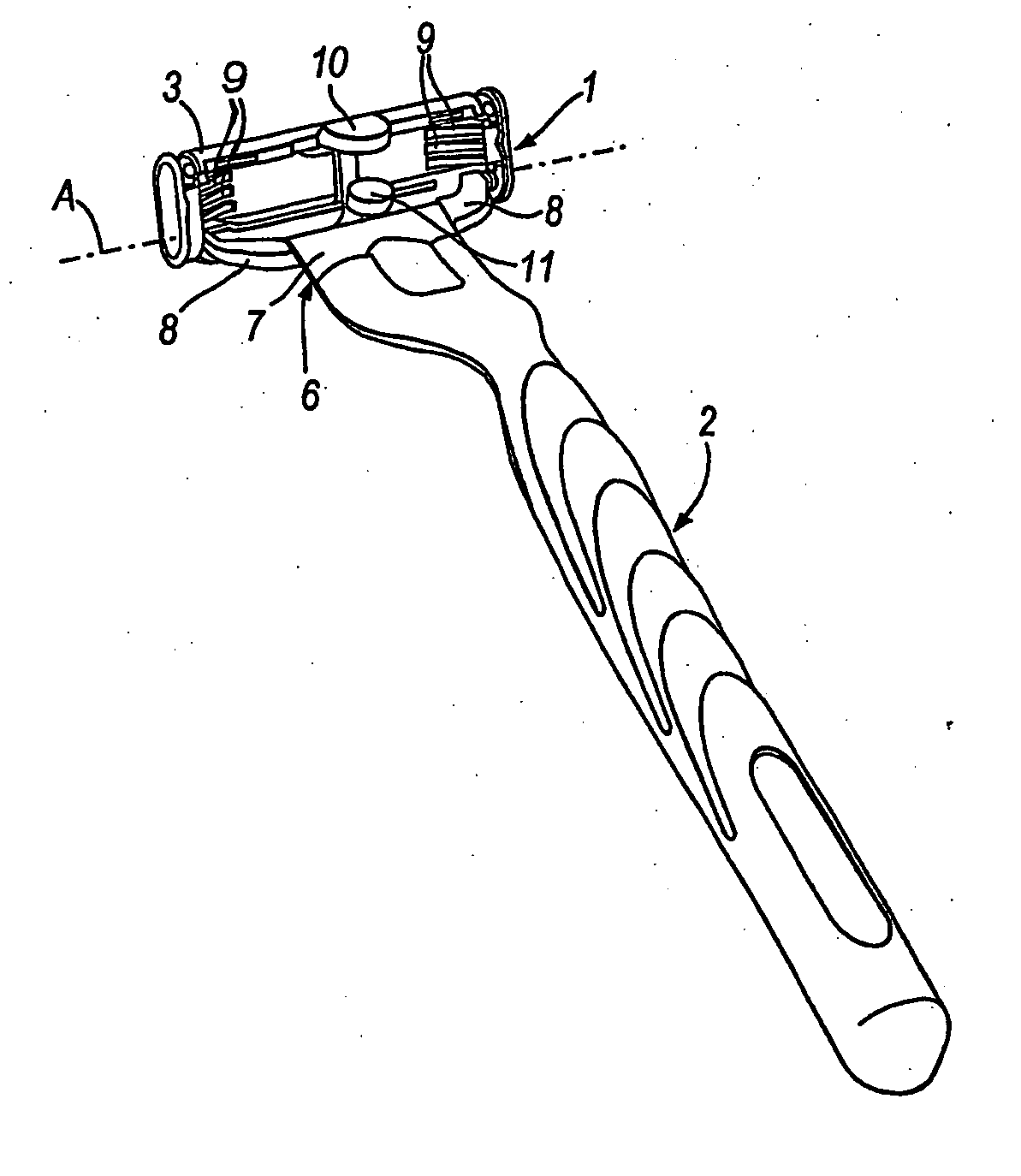

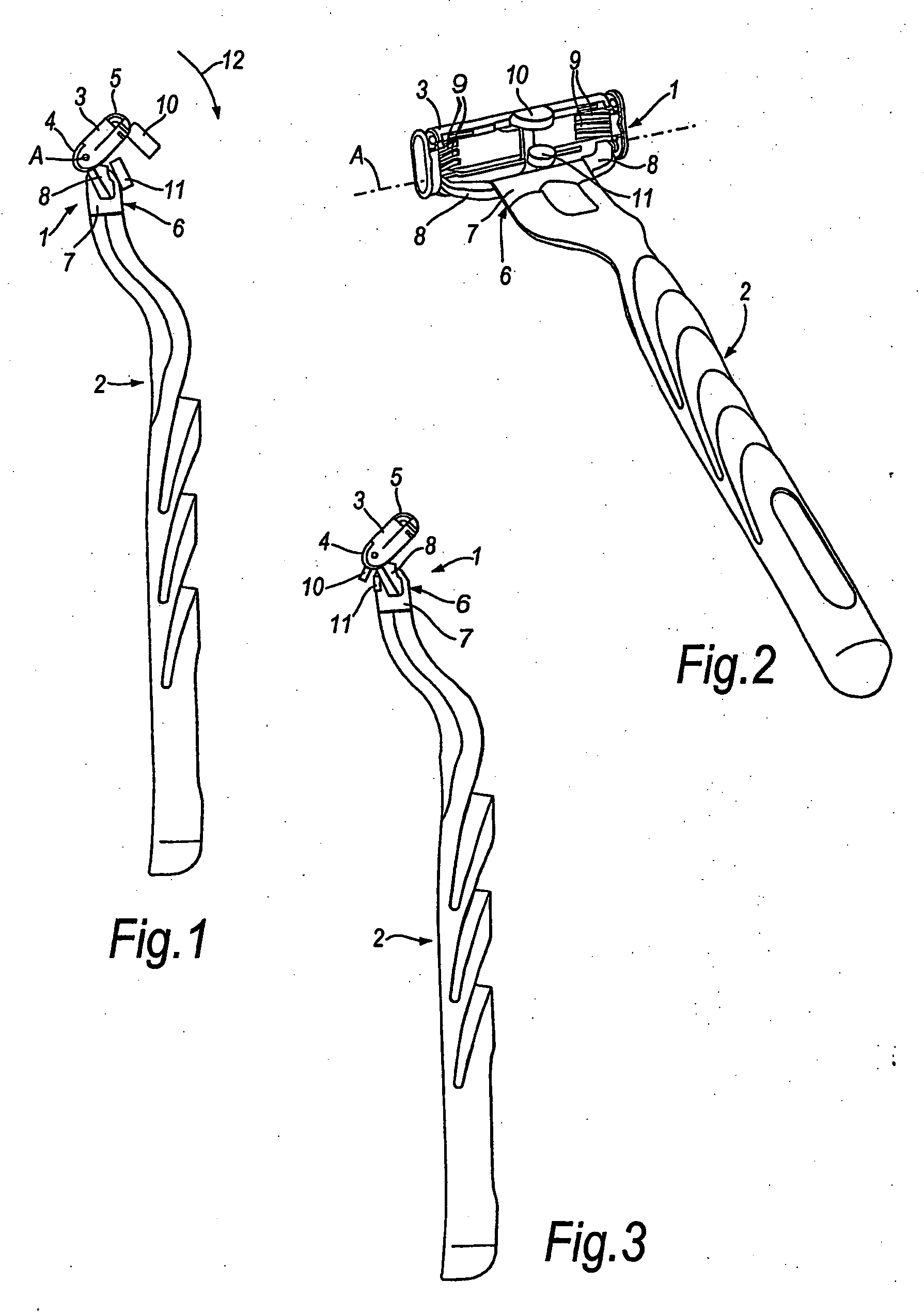

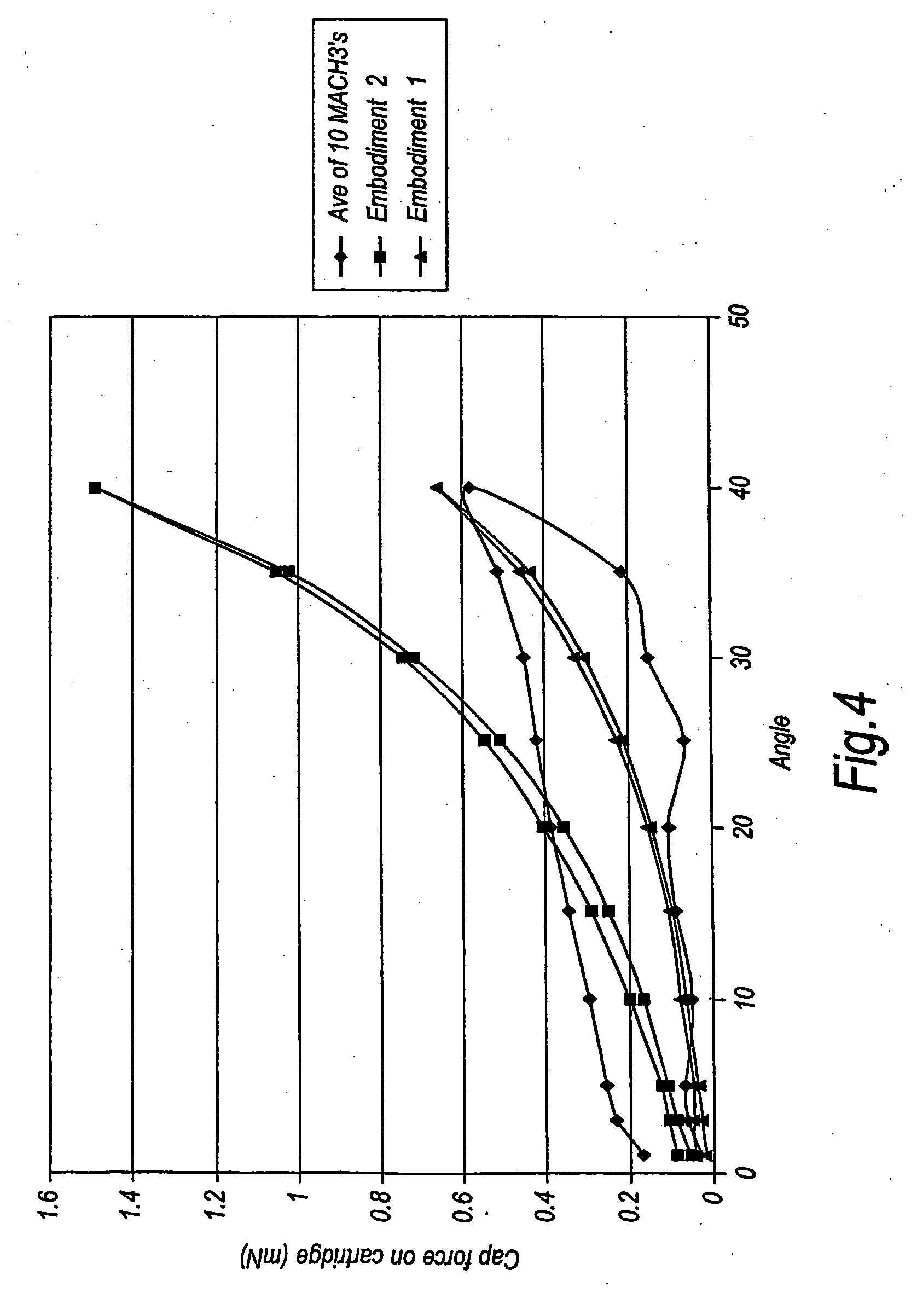

Safety razor with multi-pivot blade unit

ActiveUS7913393B2Easy to modifyIncrease the spring rateMetal working apparatusRest positionEngineering

A safety razor blade unit mounted for pivotal movement relative to a razor handle about a pivot axis substantially perpendicular to a blade mounted in the blade unit. The blade unit is biased to a rest position by a magnetic return force generated by a set of magnetic elements. The set of magnetic elements are so disposed that the return force increases as the pivotal displacement of the blade unit from the rest position increases.

Owner:THE GILLETTE CO

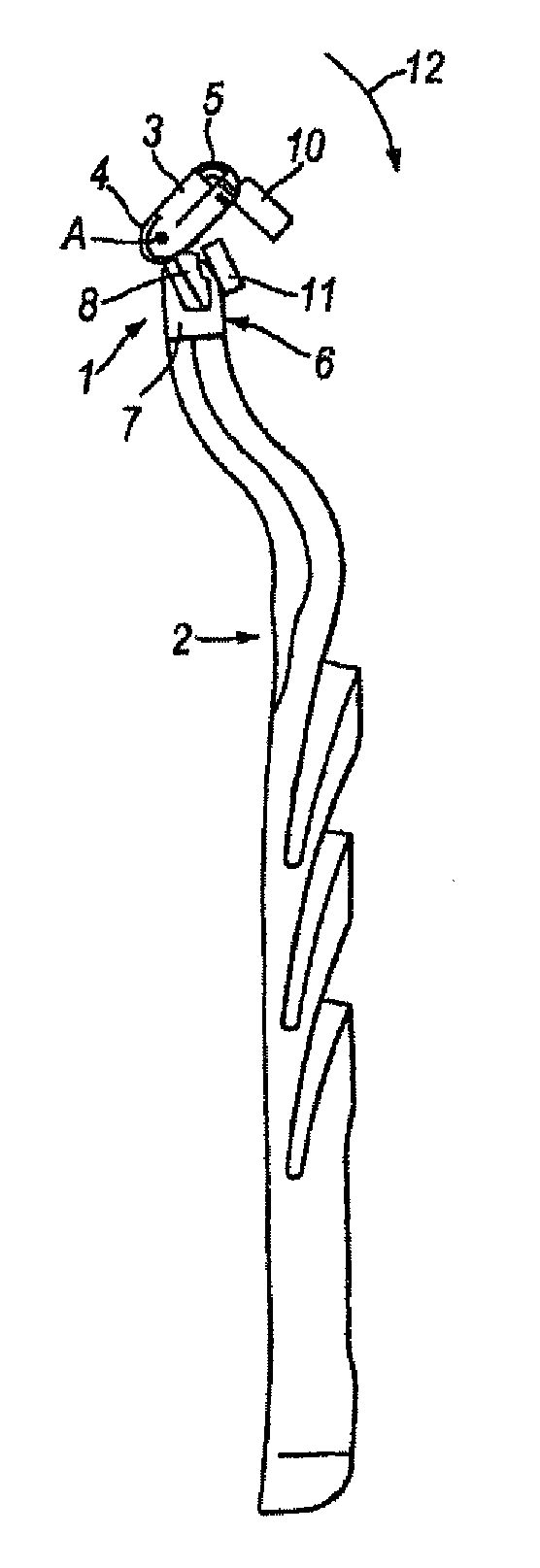

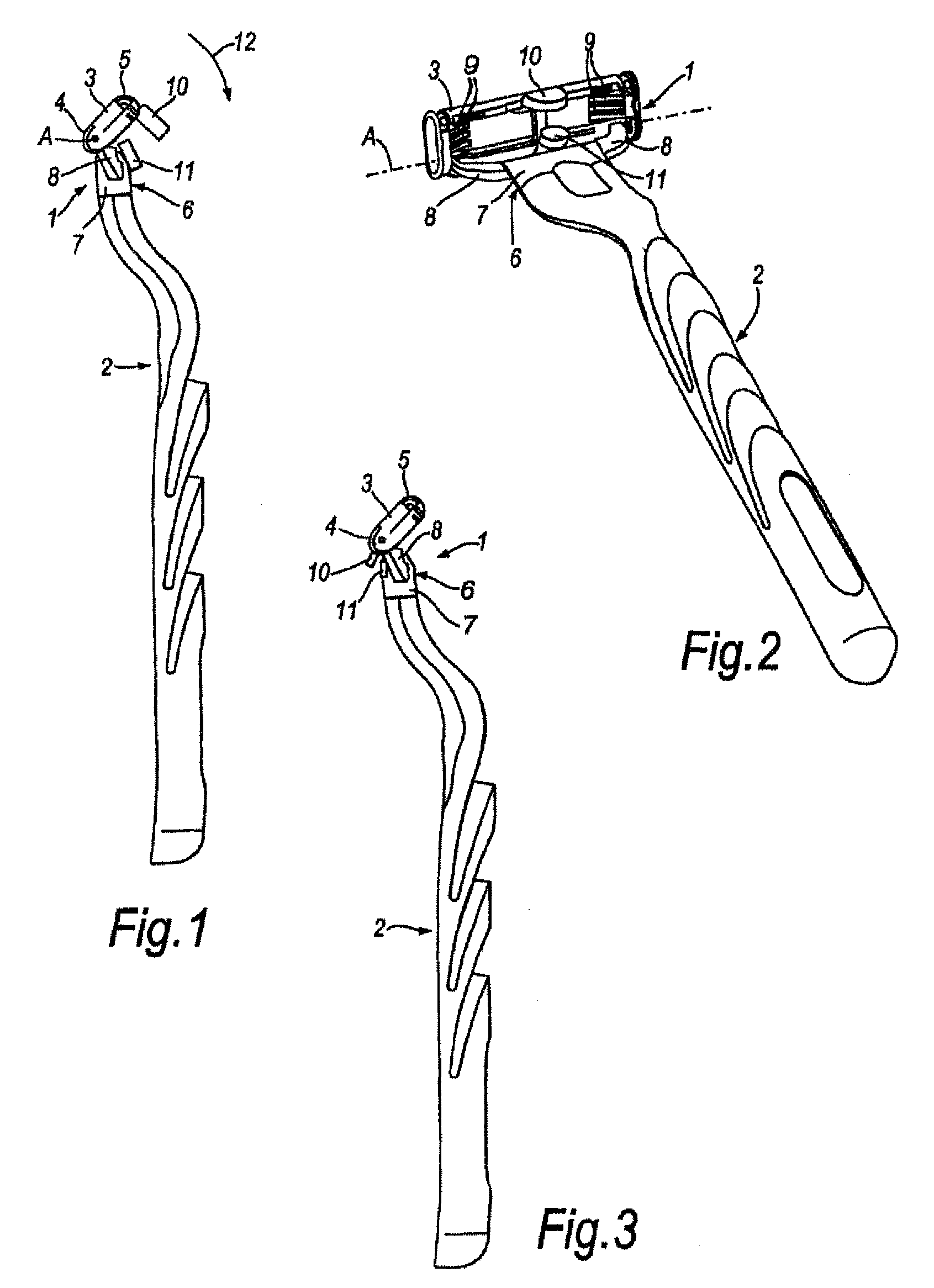

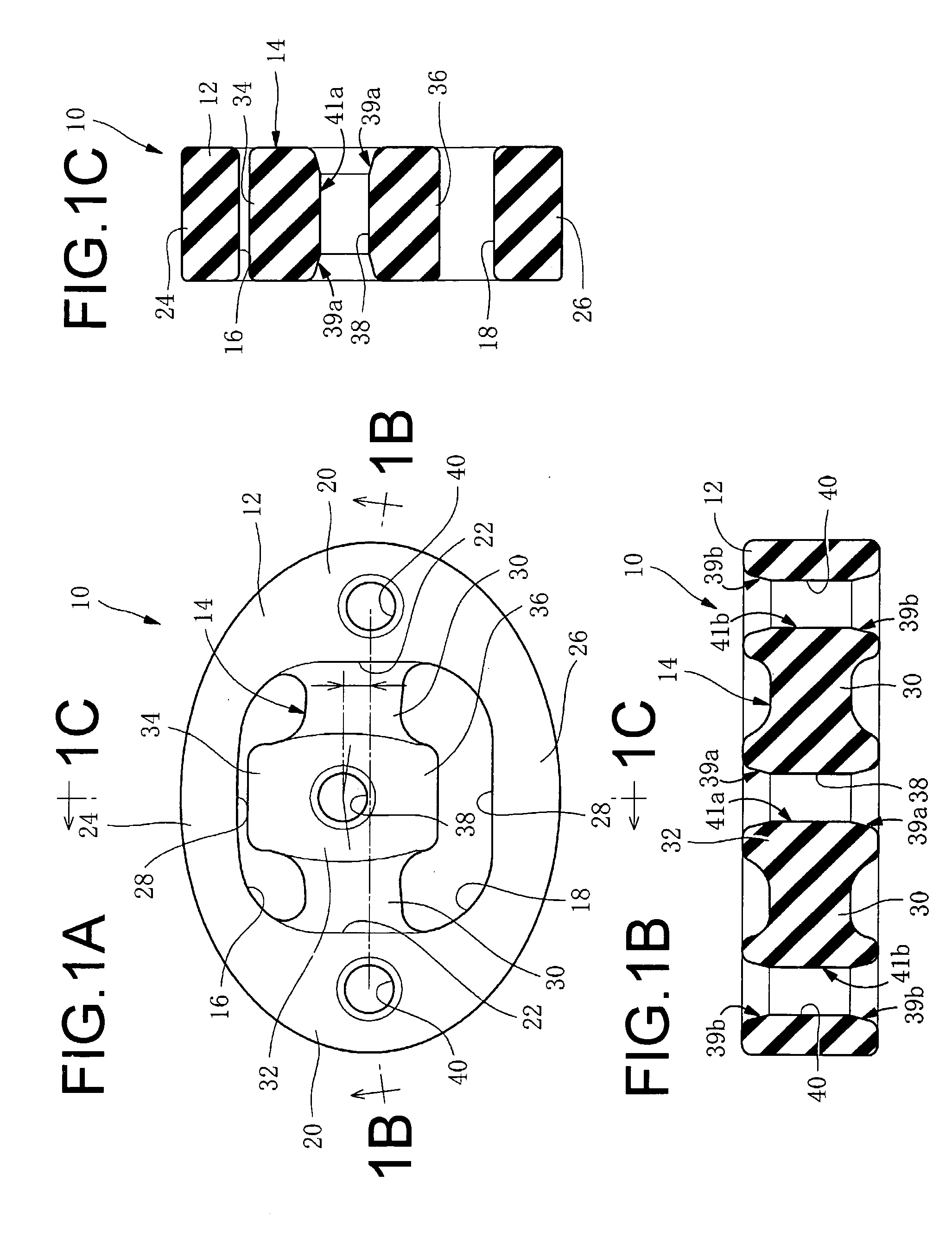

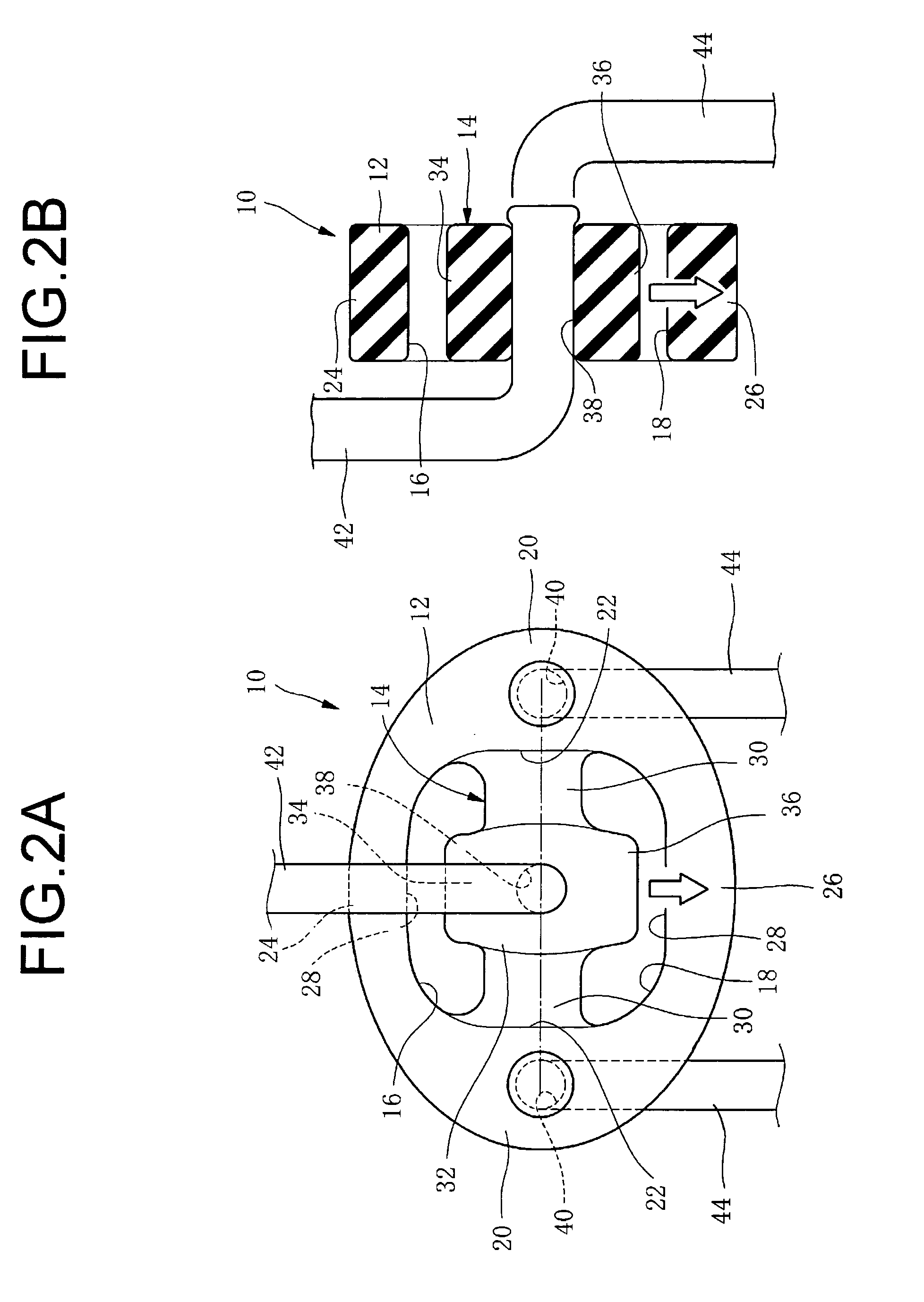

Safety razors

ActiveUS7895754B2Reduced strengthIncrease the spring rateMetal working apparatusRest positionEngineering

A safety razor blade unit mounted for pivotal movement relative to a razor handle is biased to a normal rest position by a magnetic return force generated by a pair of magnets that are so disposed that the return force increases as the pivotal displacement of the blade unit from the rest position increases.

Owner:THE GILLETTE CO

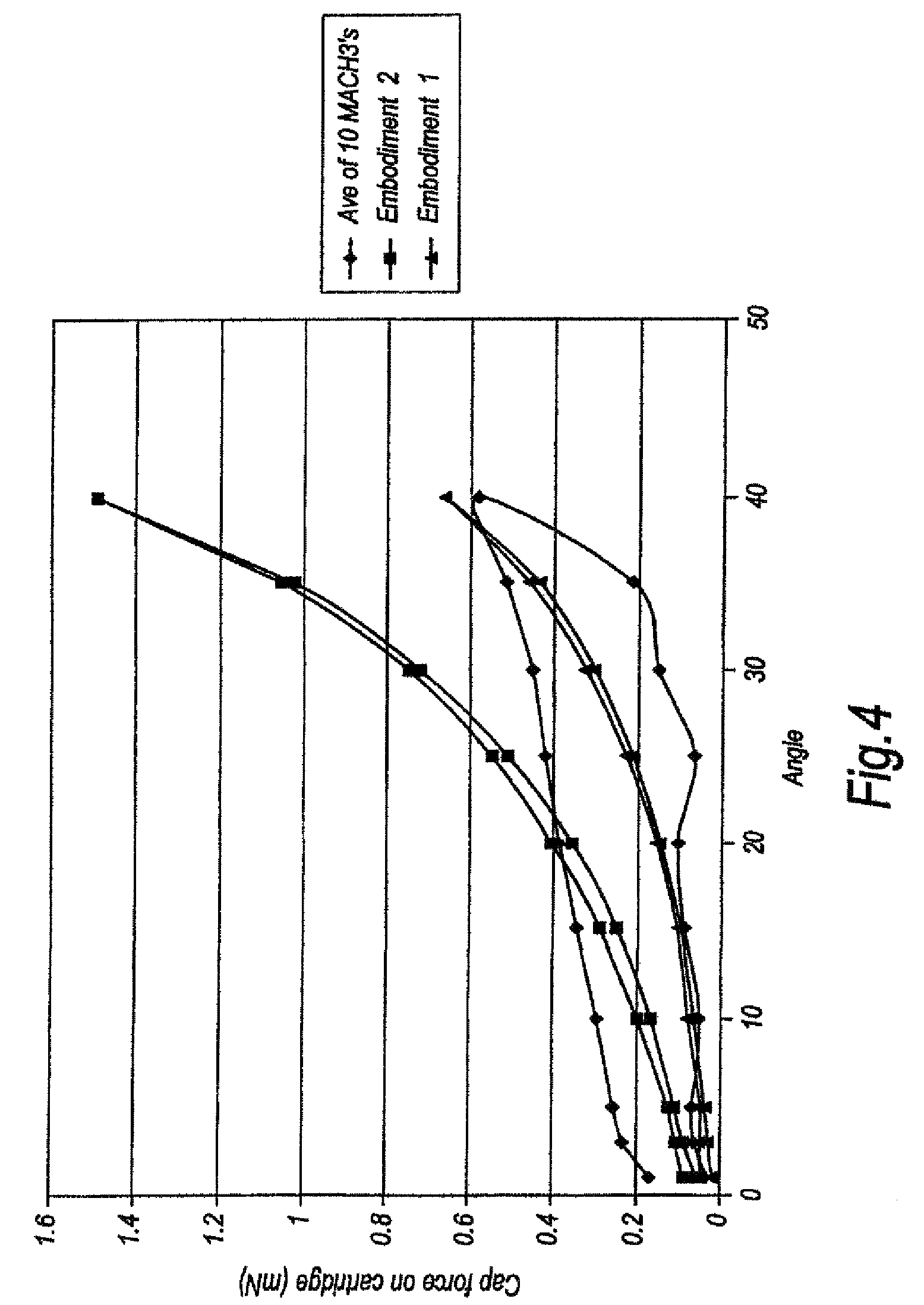

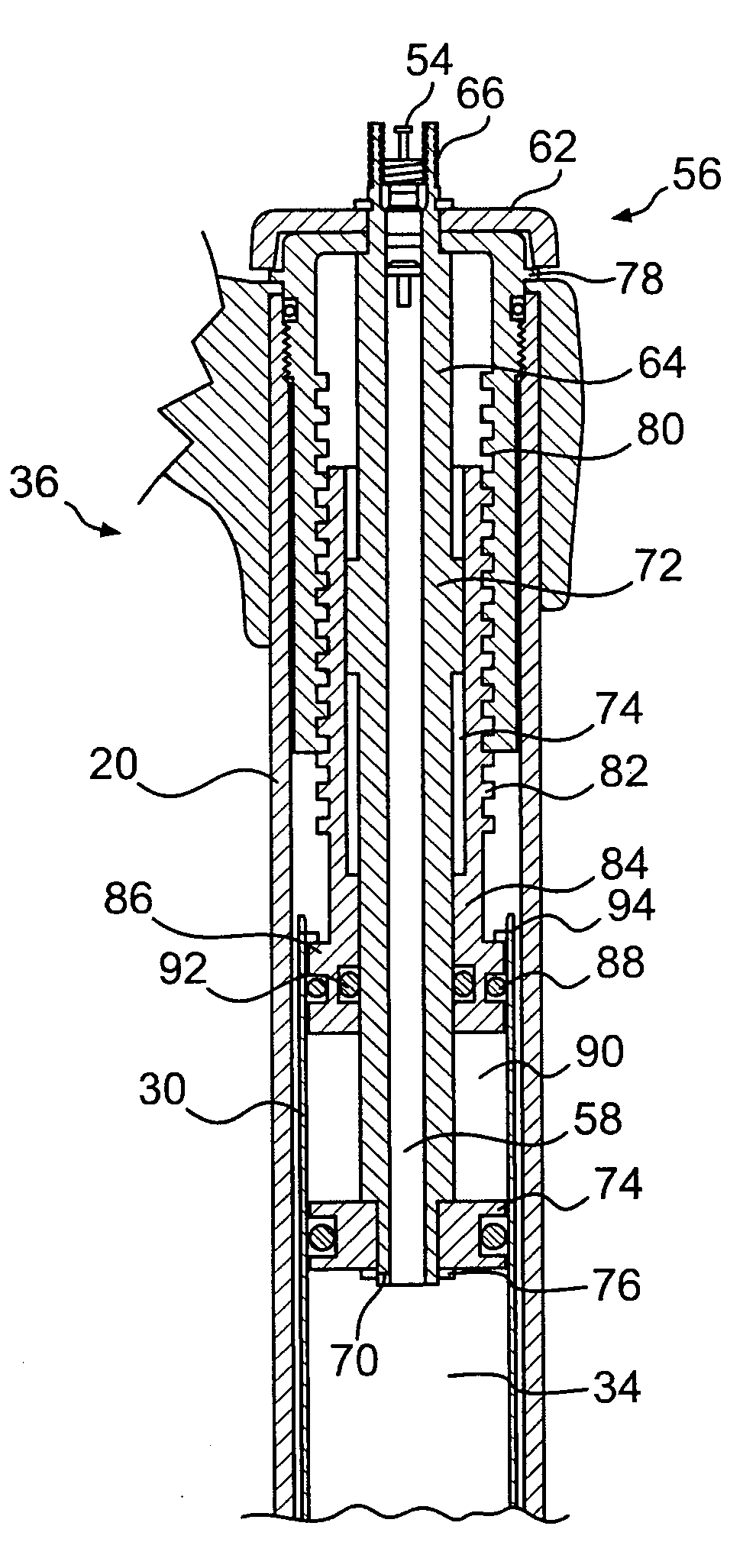

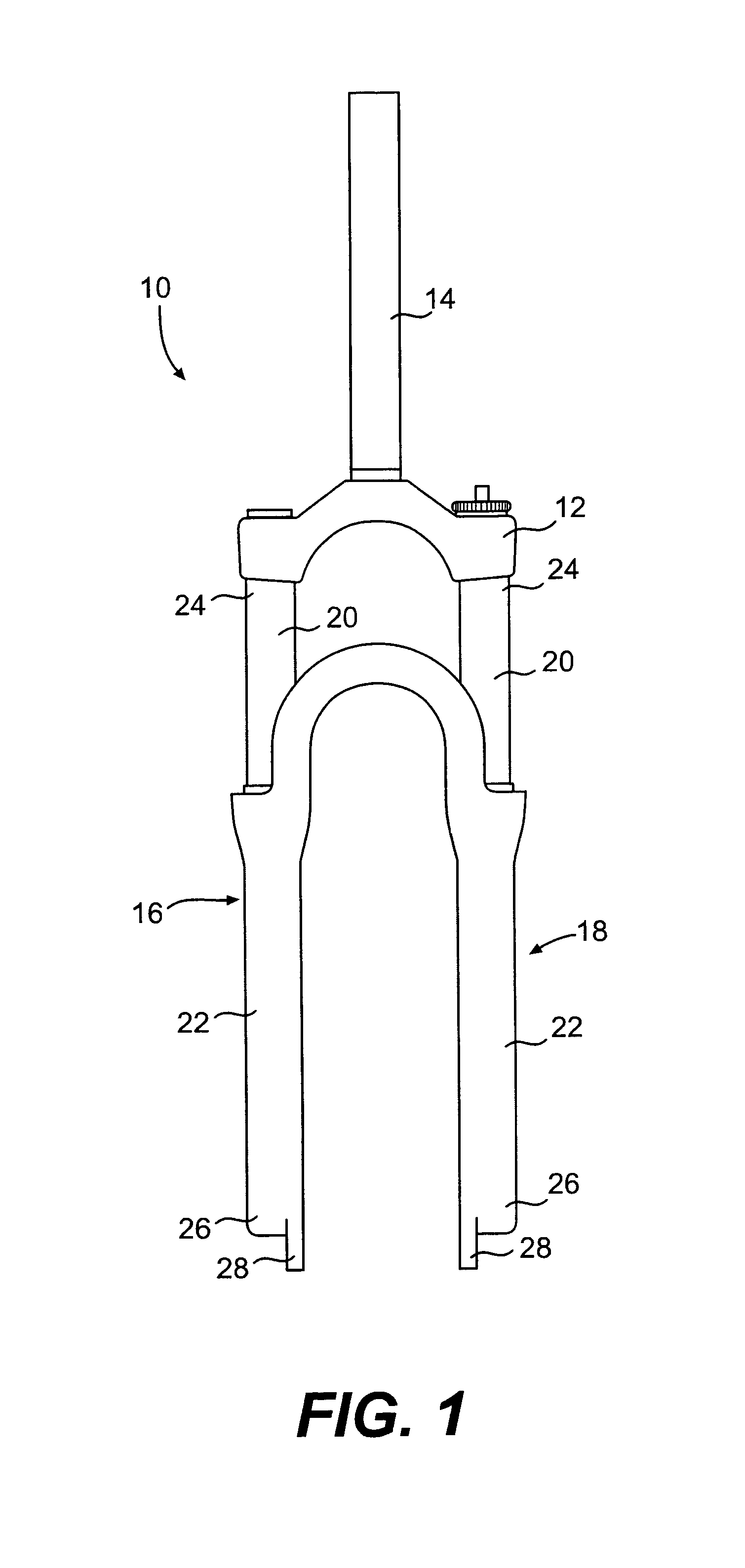

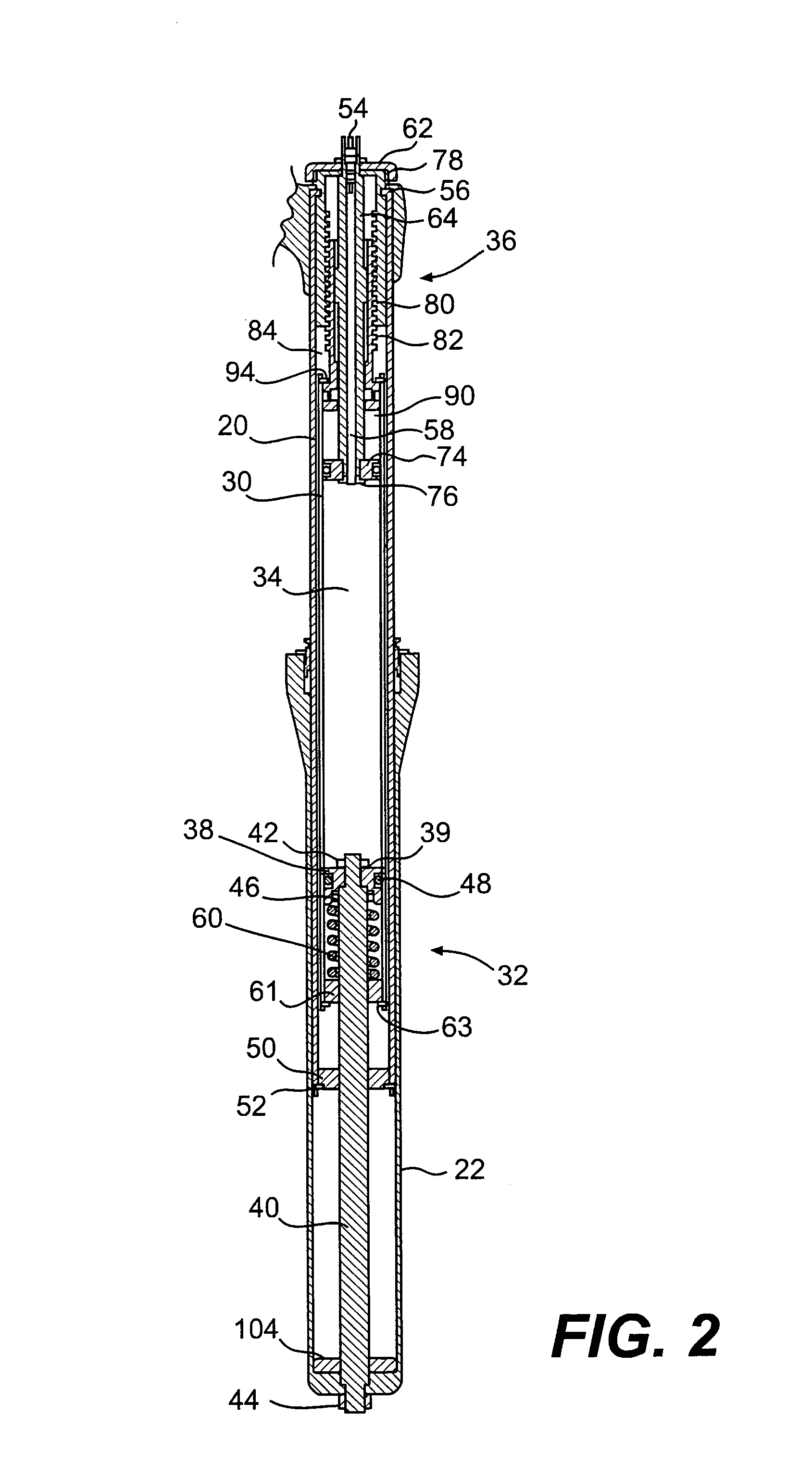

Adjustable gas spring suspension system

ActiveUS7195234B2High rebound rateSoft spring ratePassenger cyclesWheel based transmissionAxial displacementGas spring

Owner:SRAM CORPORATION

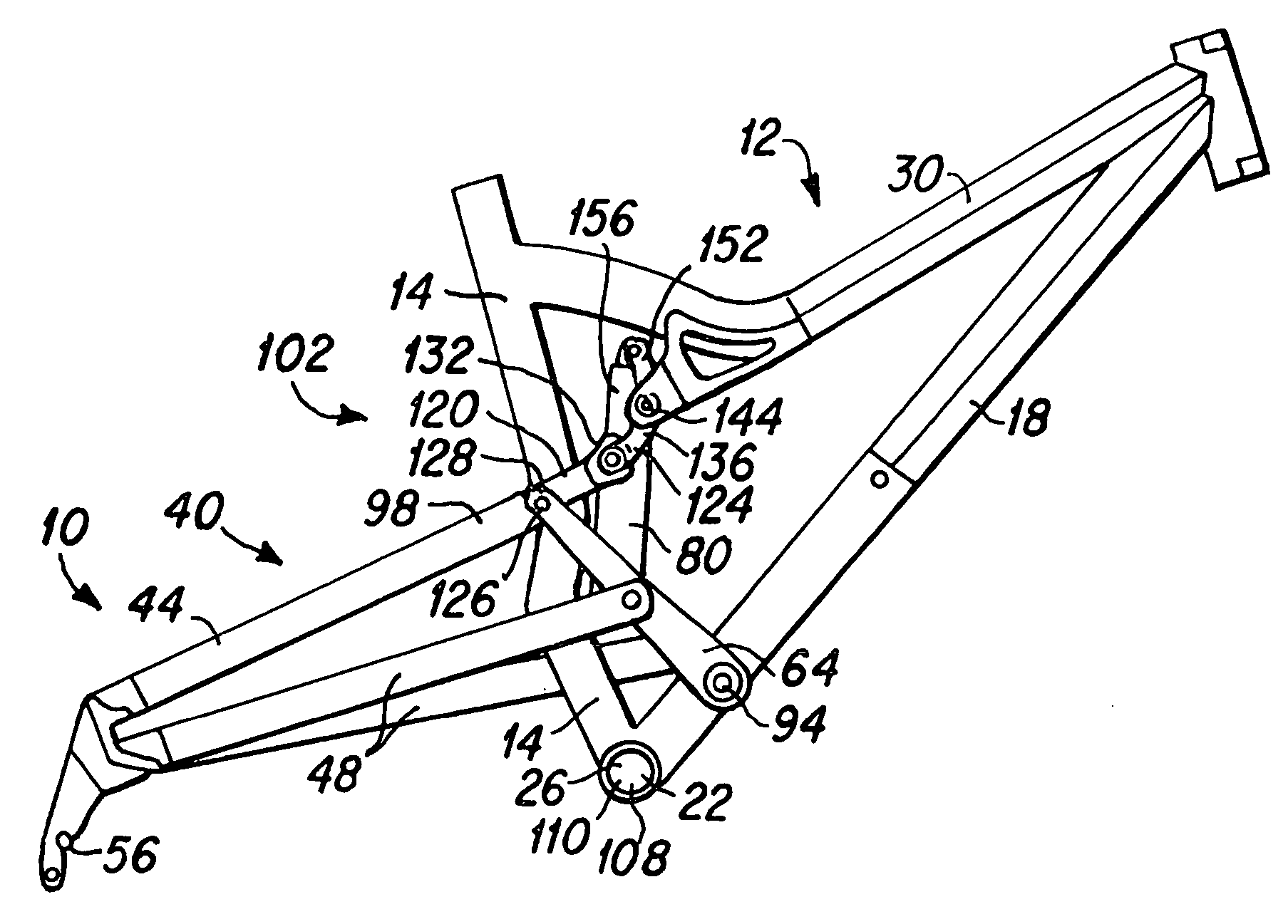

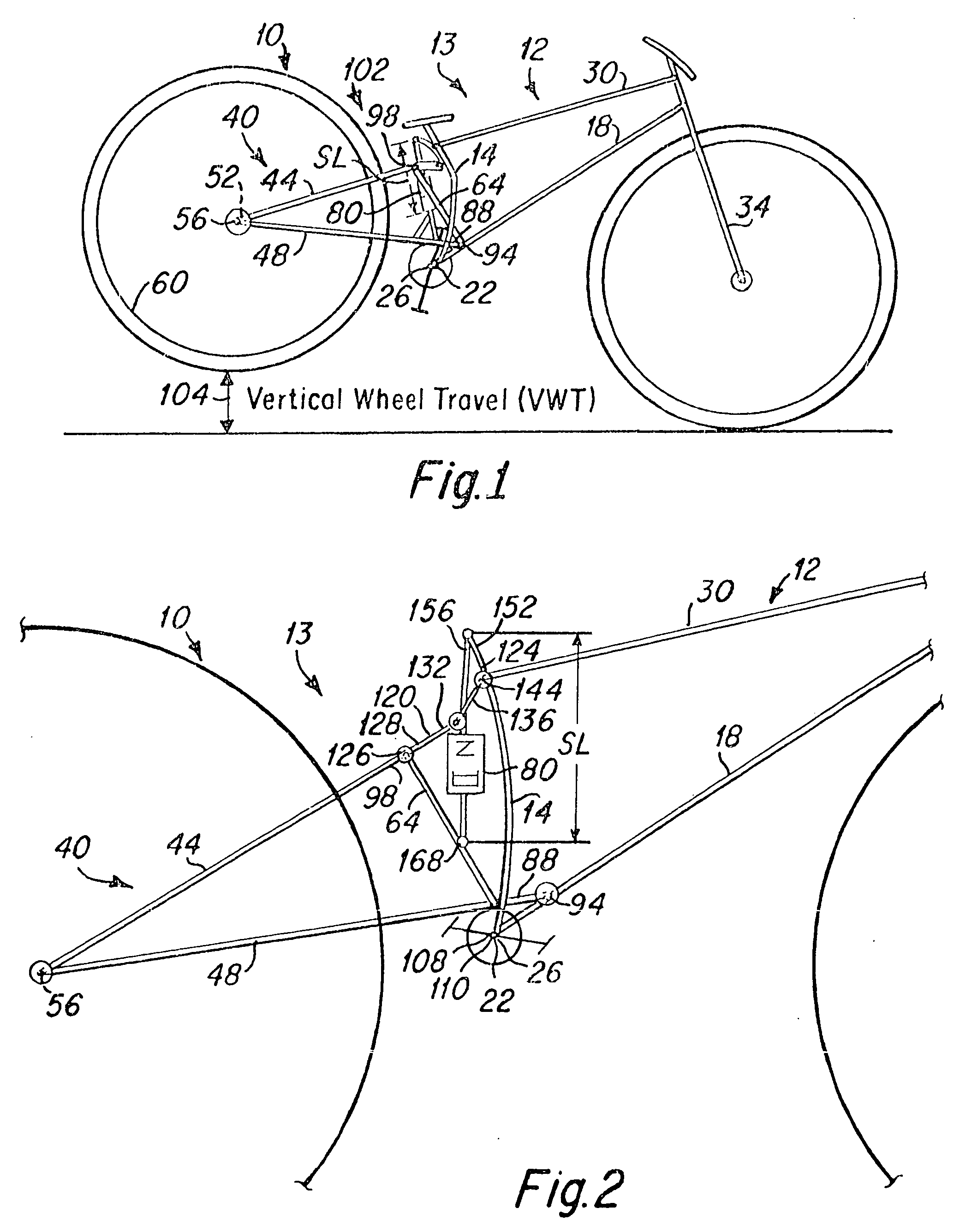

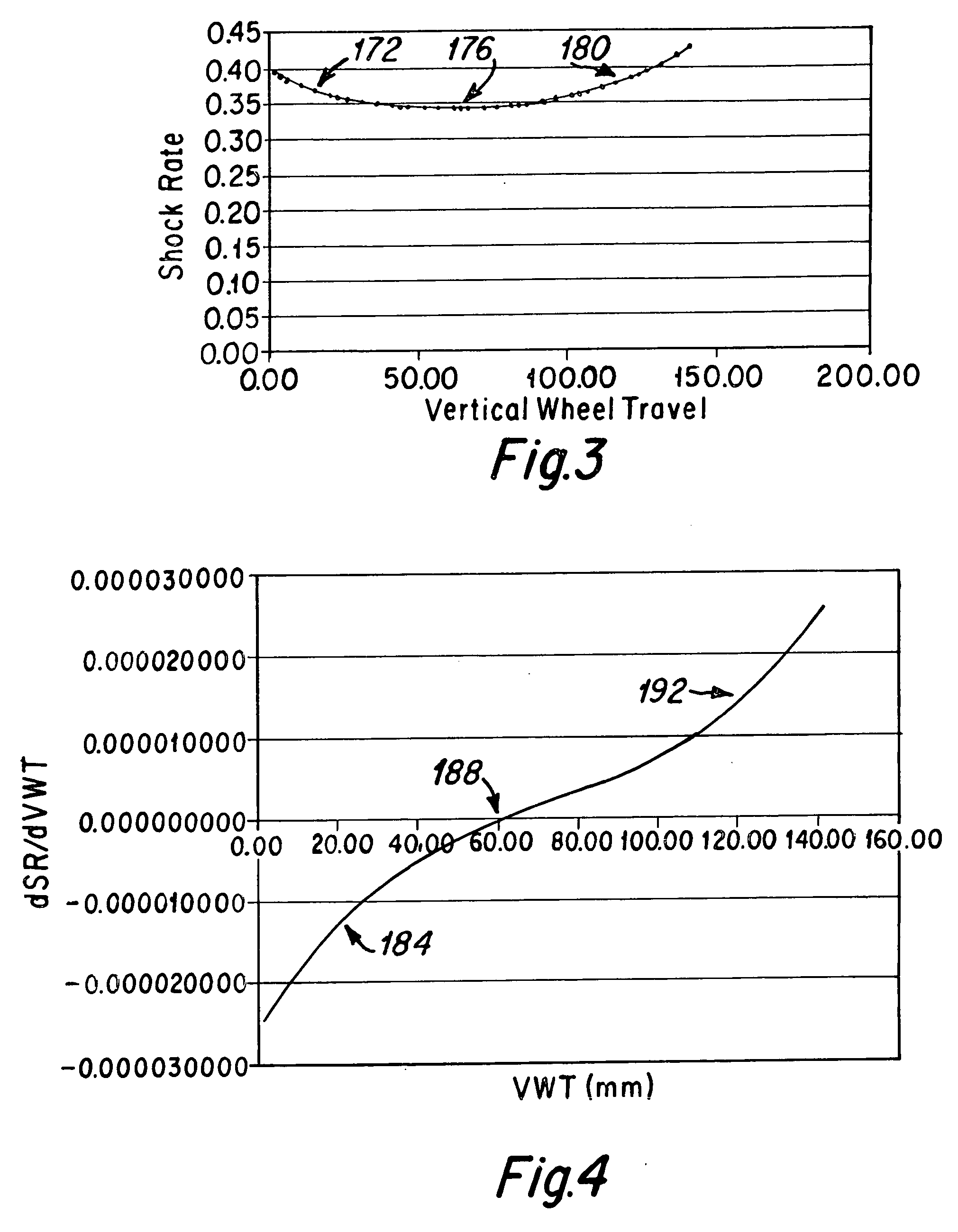

Bicycle rear wheel suspension system with controlled variable shock rate

ActiveUS20070108725A1Great tractionEasy to controlPassenger cyclesChildren cyclesVehicle frameControl variable

The present invention is a bicycle including a bicycle frame and a rear wheel suspension system that is attached to the frame. The rear wheel suspension system includes a rear wheel swingarm and a shock absorber that is engaged to the swingarm to control the motion of a rear wheel of the bicycle. A change in the vertical wheel travel (ΔVWT) of the rear wheel is related to a change in the length of the shock absorber (ΔSL), providing a shock rate (SR) according to the relationship: SR=ΔSL / ΔVWT. The shock rate (SR) changes throughout the vertical wheel travel of the rear wheel, such that the change in the shock rate dSR / dVWT has a change in sign as the rear wheel travels through its vertical wheel travel. The shock rate may at first decrease in value and subsequently increase, or initially increase in value and subsequently decrease throughout the vertical wheel travel of the rear wheel. In various exemplary embodiments the swingarm may be attached to the frame at a single pivot point or through a linkage system.

Owner:SANTA CRUZ BICYCLES

Seat suspension assembly for a two-wheeler

InactiveUS6270065B1Increase the spring rateVehicle seatsPassenger cyclesMechanical engineeringEngineering

A seat suspension assembly for a bicycle has a movable and cushioning intermediate section between a lower seat post part and an upper seat attachment part. The intermediate section comprises parallel bars journalled to a head on top of the seat post, and to the seat attachment part. A springing mechanism is equipped with a system for adjusting the effective spring rate of the springing mechanism.

Owner:CATO HALS DESIGN

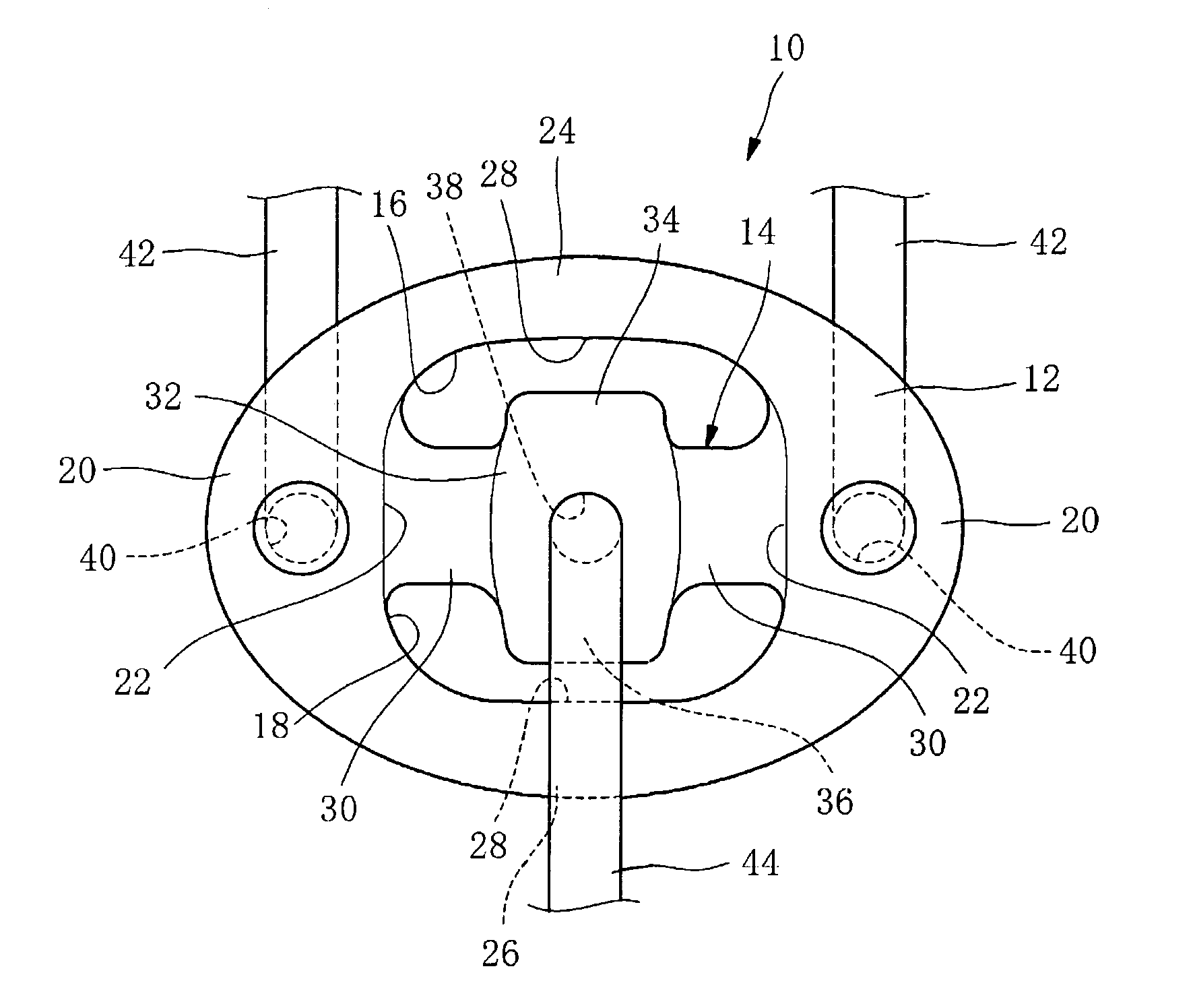

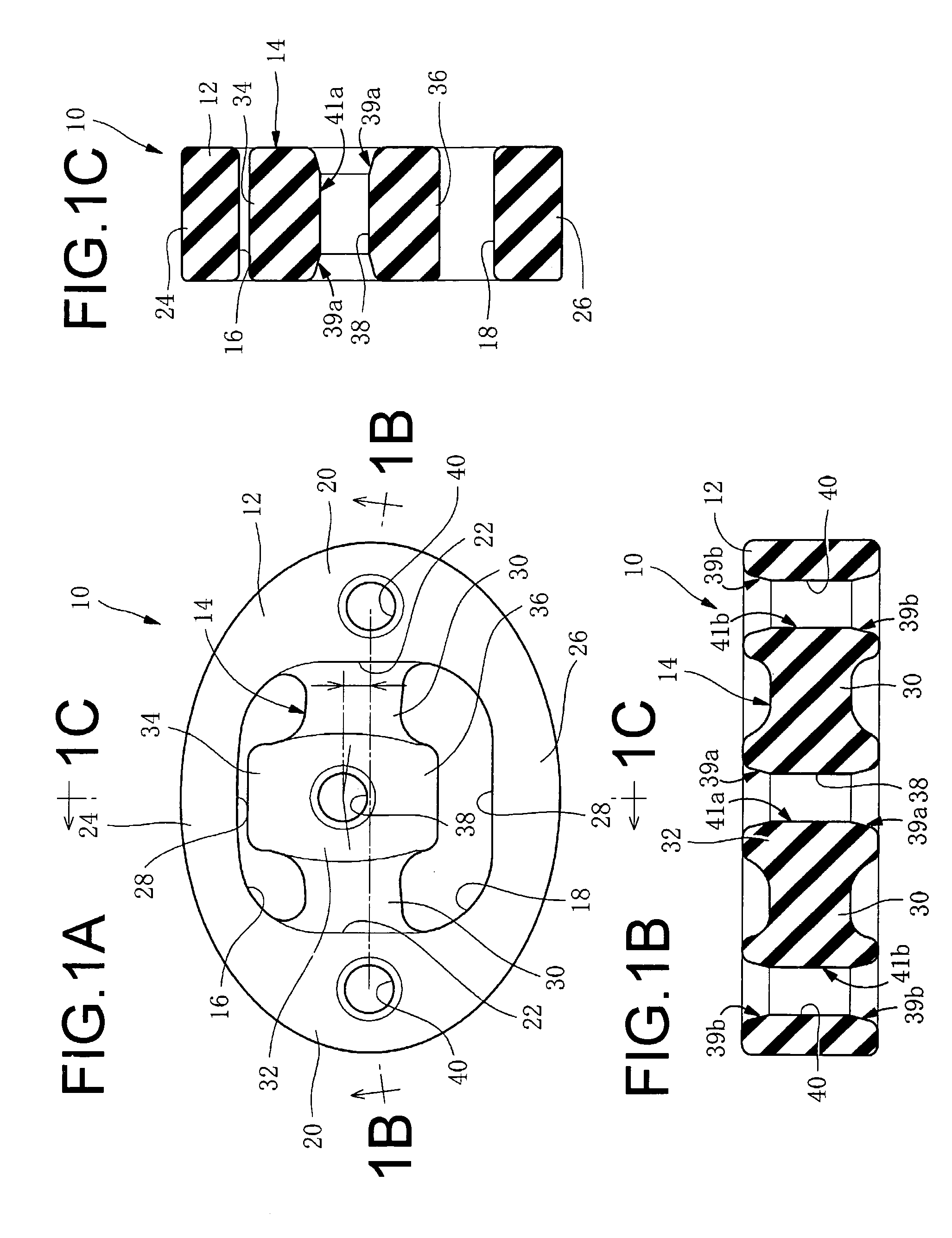

Muffler hanger

ActiveUS7637472B2Reduce the spring rateIncrease the spring rateExhaust apparatusPipe elementsEngineeringMuffler

A muffler hanger including: a rubber annular portion; a rubber arm constituting an elastic support portion for the muffler; an upper space and a lower space for permitting deformation of the rubber arm; a first mounting hole disposed in a center of the rubber arm in a vehicle left-right direction to extend in a vehicle front-back direction when installed on the vehicle, and attached in a mated condition to a support pin provided on one of a muffler side and a vehicle body side; and a pair of second mounting holes disposed at locations away to right and left sides from the first mounting hole to extend in the front-back direction, and attached in a mated condition to support pins on the other side. The first and second mounting holes are arranged to form a row in the left-right direction, with positional relationships such that when installed on the vehicle the holes overlaps one another as viewed in the left-right direction.

Owner:HONDA MOTOR CO LTD +1

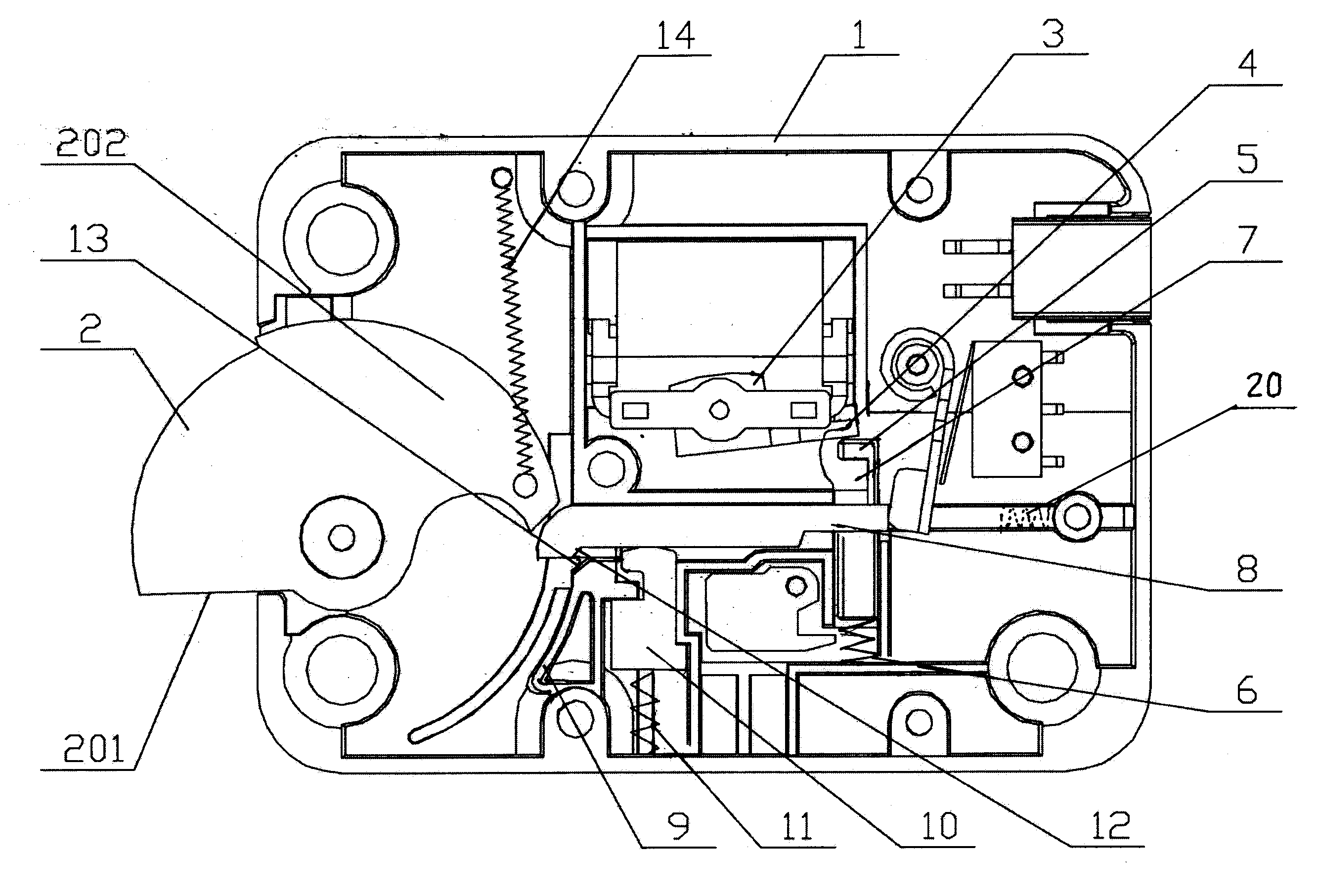

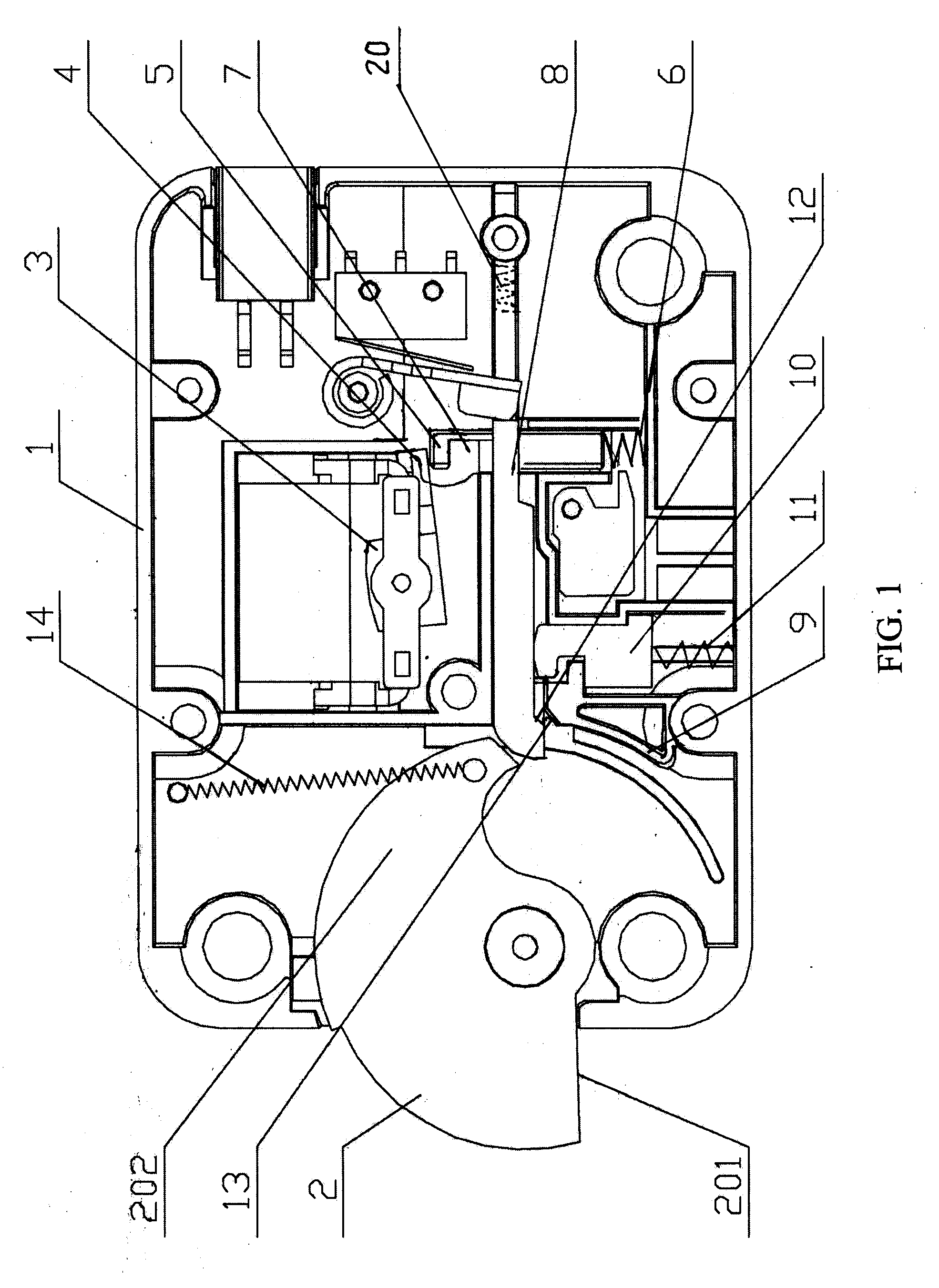

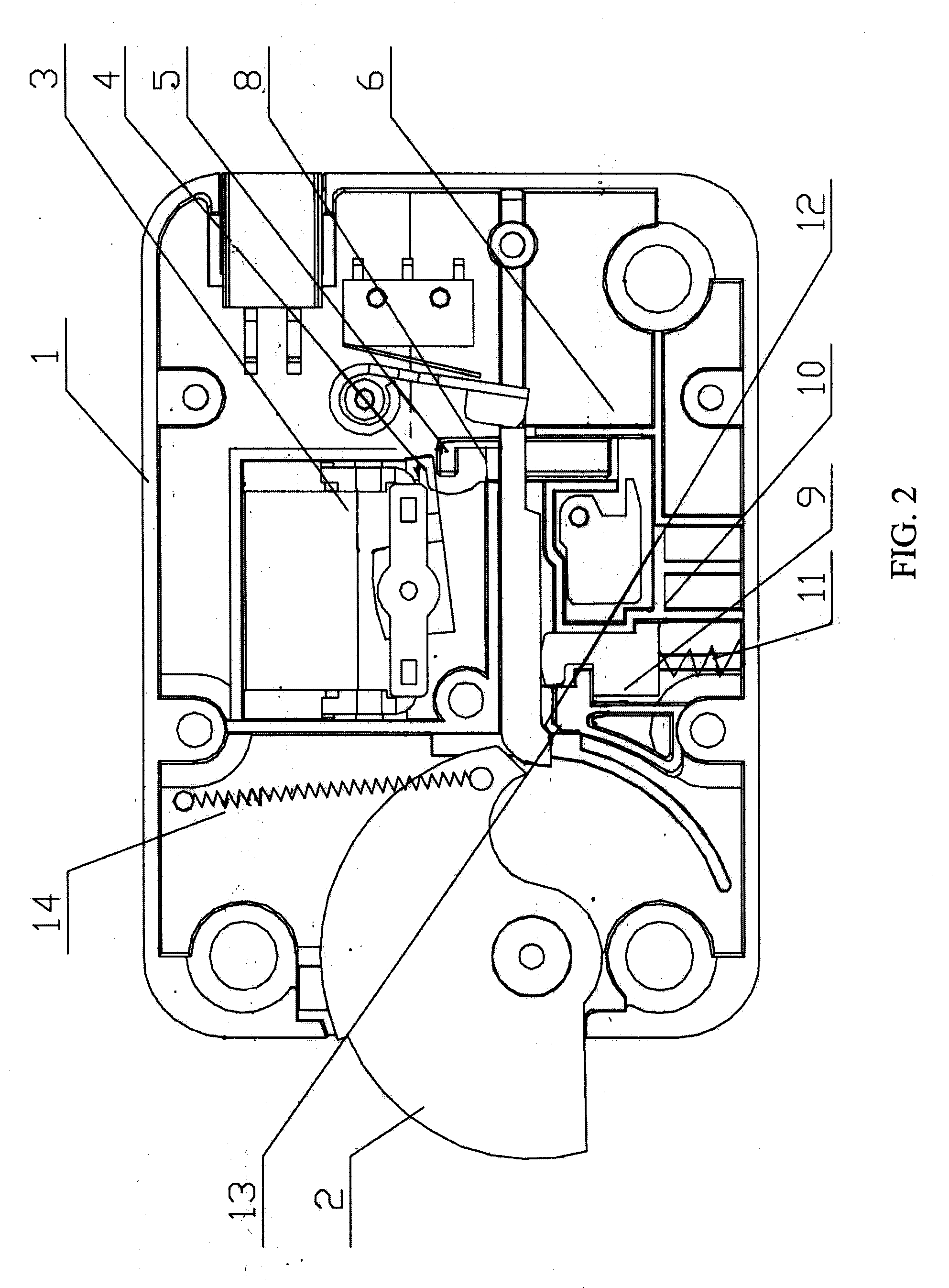

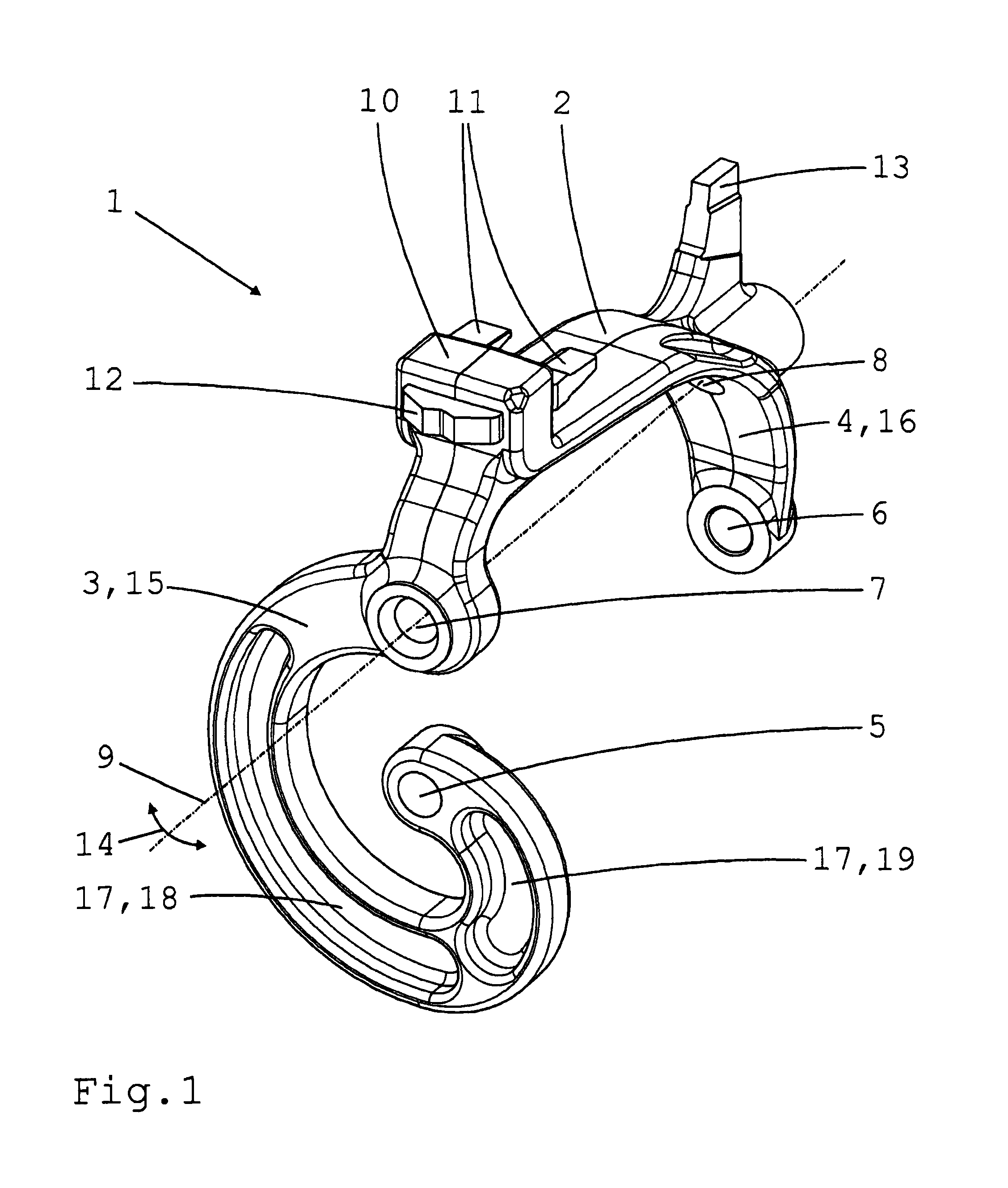

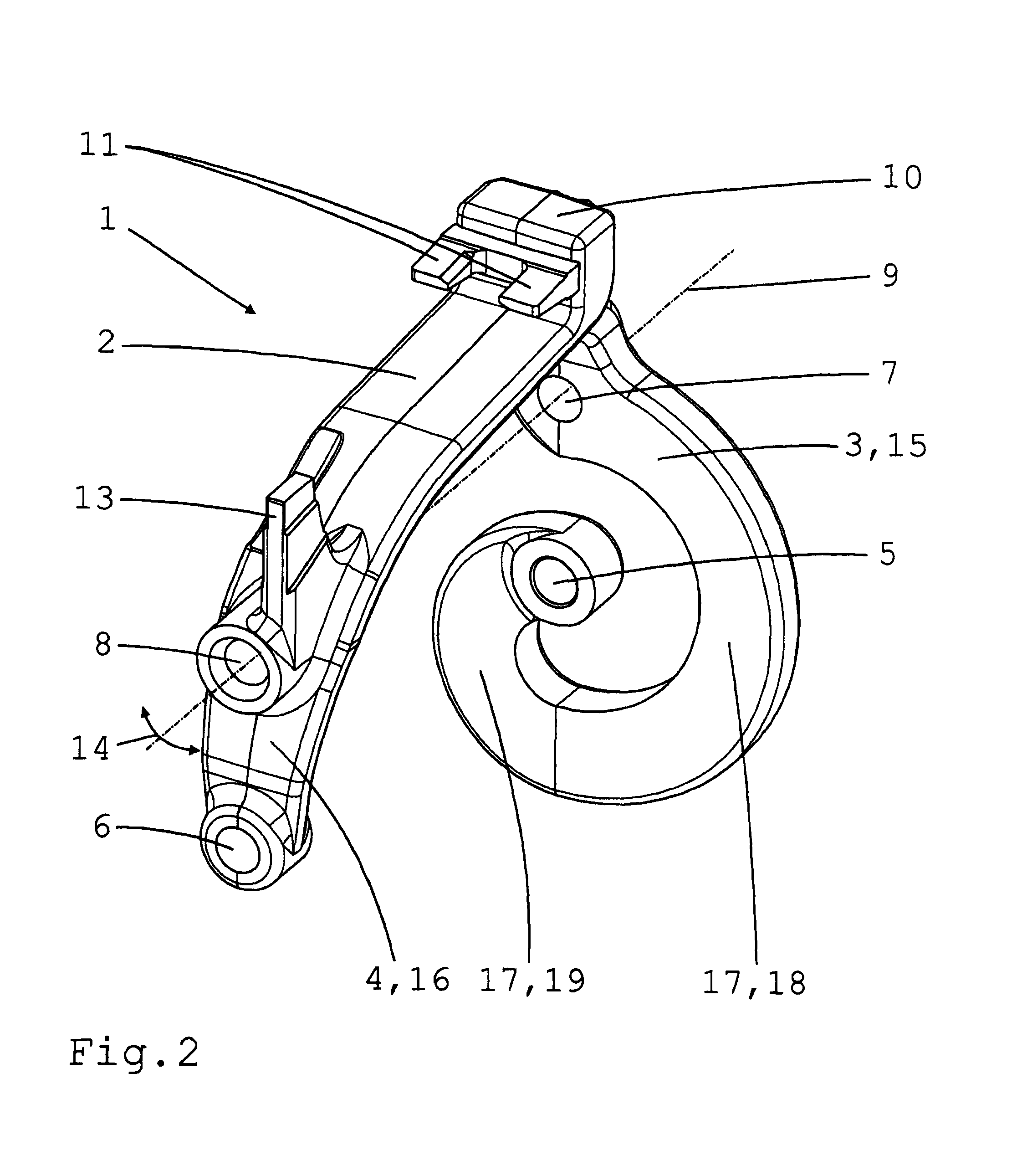

Electromagnetic Lock with Strong Anti-impact Ability

InactiveUS20080073916A1Safety grade be increaseReduce forceNon-mechanical controlsConstruction fastening devicesElectromagnetic lockEngineering

The present invention resolves the problem that a lockpin is easy to broken in current electromagnetic lock, find a good structure for greatly improving the capability of the electromagnetic lock against a very strong impact from outside. The new structure can transfer the outside force to a reinforced rib on the lock shell. The new electromagnetic lock comprises a lock shell (1), an arc style bolt (2), an electromagnet (3), an implemental part (4) of the electromagnet (3) connecting with one end of the lockpin (5), a unlock slot (7) is on the lockpin (5), a slipping block (8) is installed in a slipping slot against the lockpin, other end of this slipping block is against the bolt tail (202) of the arc style bolt. A second spring (20) is installed between the bottom of the slipping slot and the slipping block (8), the second spring (20) forces the slipping block (8) to contact the bolt tail (202) of arc style bolt. The structure of the new electromagnetic lock is simple, the manufacturing process is easy, and the new electromagnetic lock can resist relatively stronger wallop.

Owner:MIN HAO

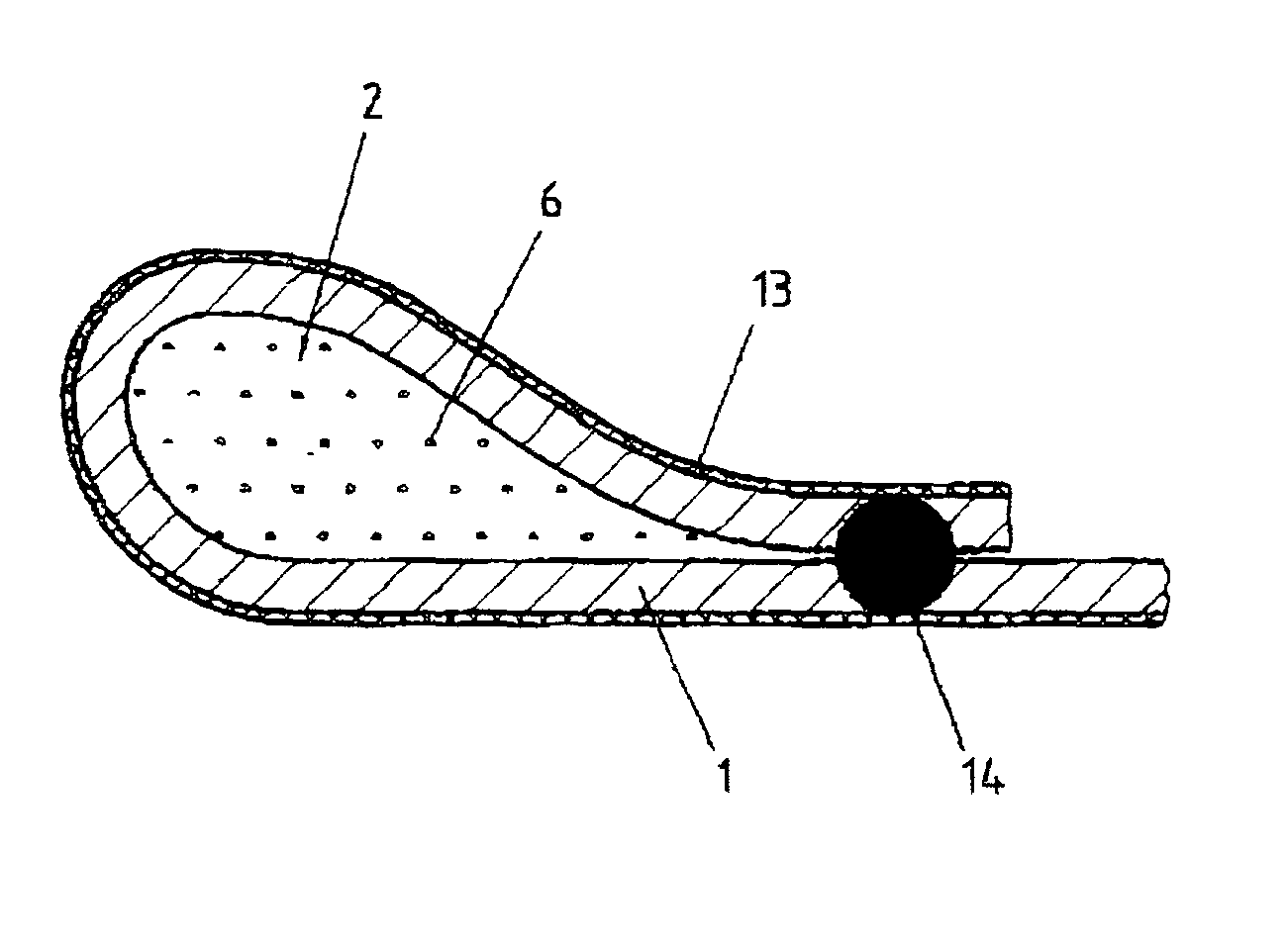

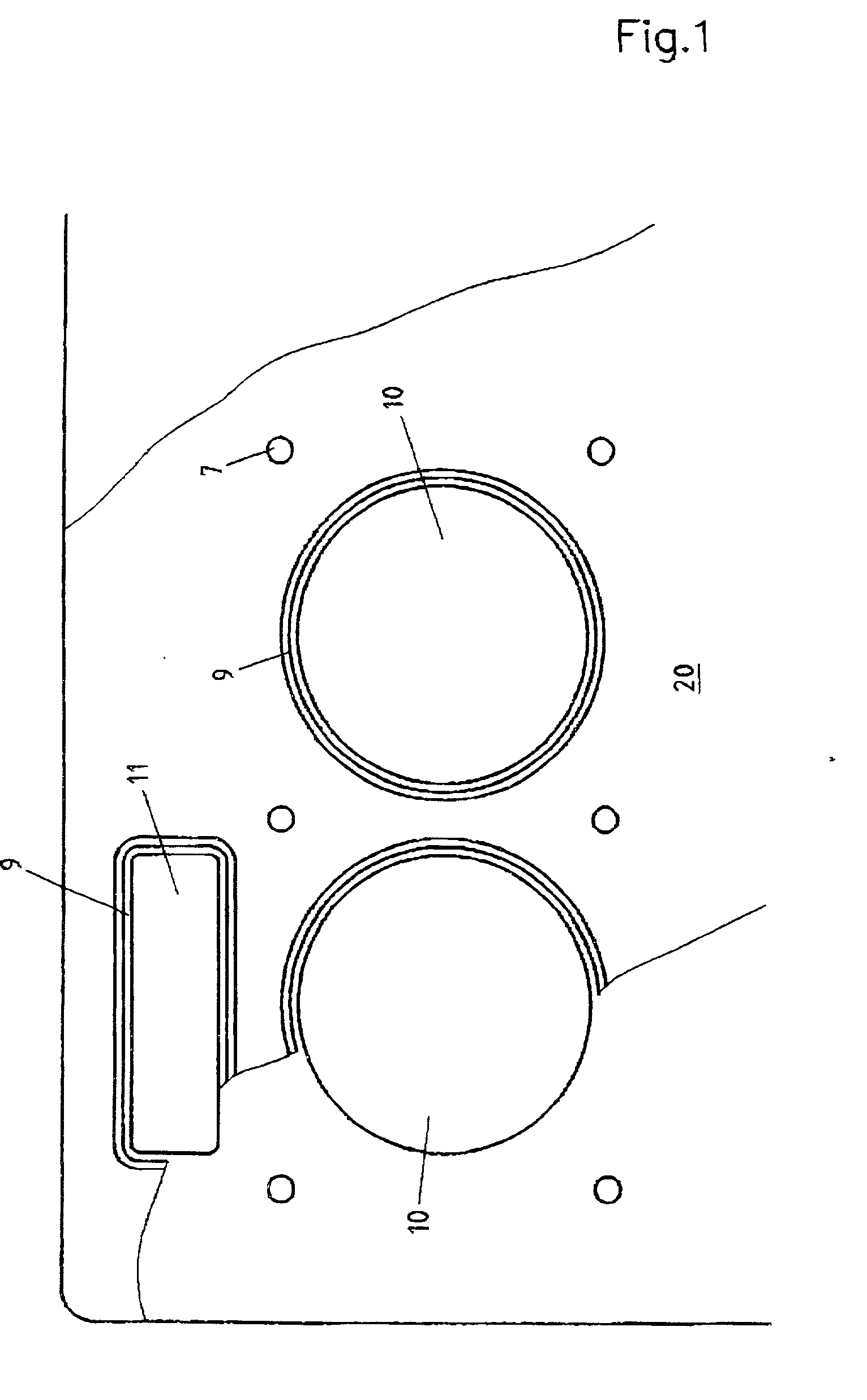

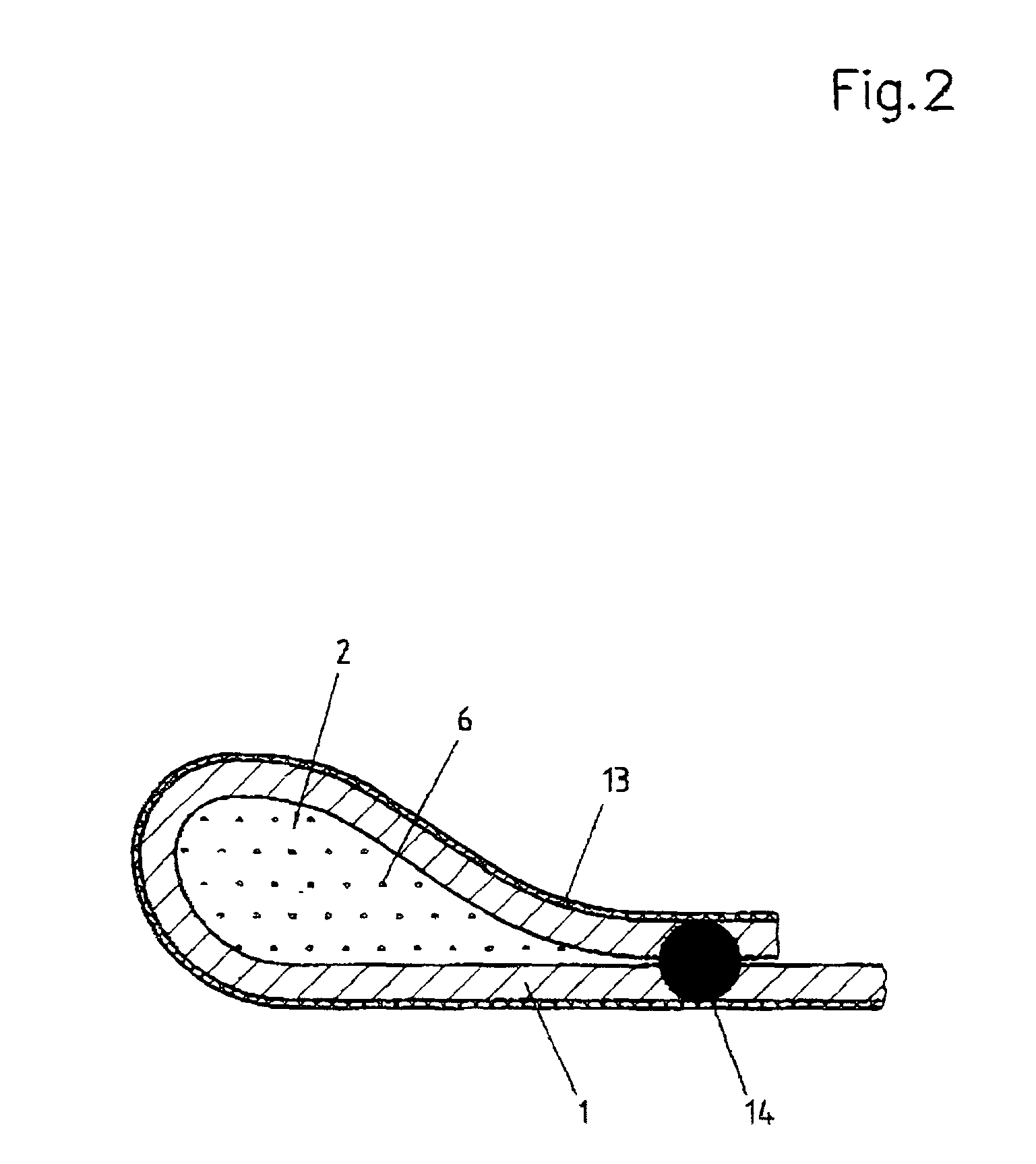

Flat gasket for a reciprocating engine or a driven machine

InactiveUS20020170521A1Improve sealingExtended service lifeEngine sealsCylinder headsElastomerCylinder head

A flat gasket for a reciprocating engine or a driven machine including at least one metal sheet 0.05 to 0.5 mm thick which is provided with a coating of an elastomer film at least on the sides facing outward in at least one sealing area and has an edge area, formed by the outer contour and / or at least one cylinder bore and / or a water and / or oil passage in the cylinder head, adjacent to at least one peripheral self-contained cavity, and the cavity is filled completely with a hydraulic medium.

Owner:CARL FREUDENBERG KG

Muffler hanger

ActiveUS20090001242A1Ensure durabilitySufficient space utilizationExhaust apparatusPipe elementsEngineeringMuffler

A muffler hanger including: a rubber annular portion; a rubber arm constituting an elastic support portion for the muffler; an upper space and a lower space for permitting deformation of the rubber arm; a first mounting hole disposed in a center of the rubber arm in a vehicle left-right direction to extend in a vehicle front-back direction when installed on the vehicle, and attached in a mated condition to a support pin provided on one of a muffler side and a vehicle body side; and a pair of second mounting holes disposed at locations away to right and left sides from the first mounting hole to extend in the front-back direction, and attached in a mated condition to support pins on the other side. The first and second mounting holes are arranged to form a row in the left-right direction, with positional relationships such that when installed on the vehicle the holes overlaps one another as viewed in the left-right direction.

Owner:HONDA MOTOR CO LTD +1

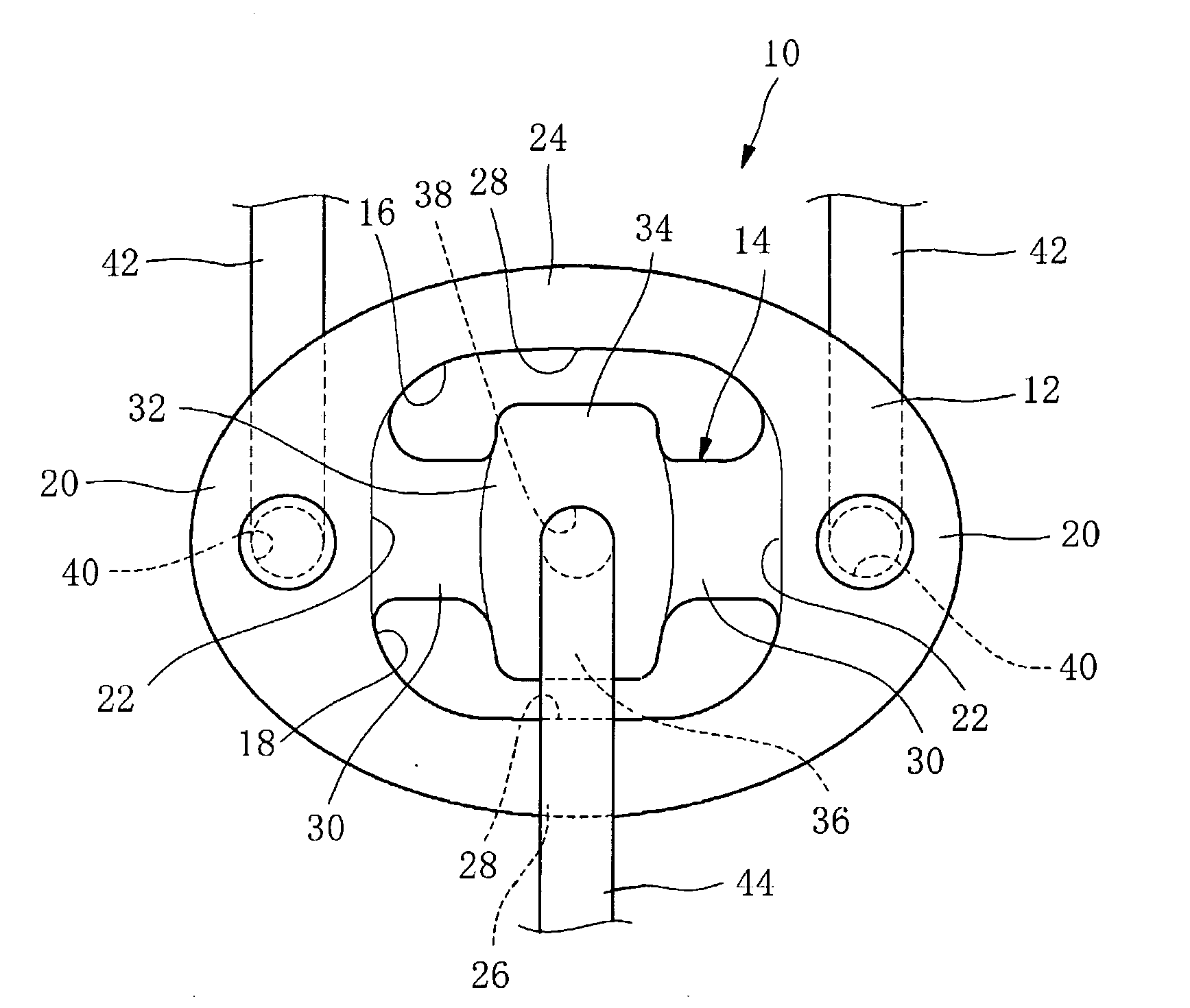

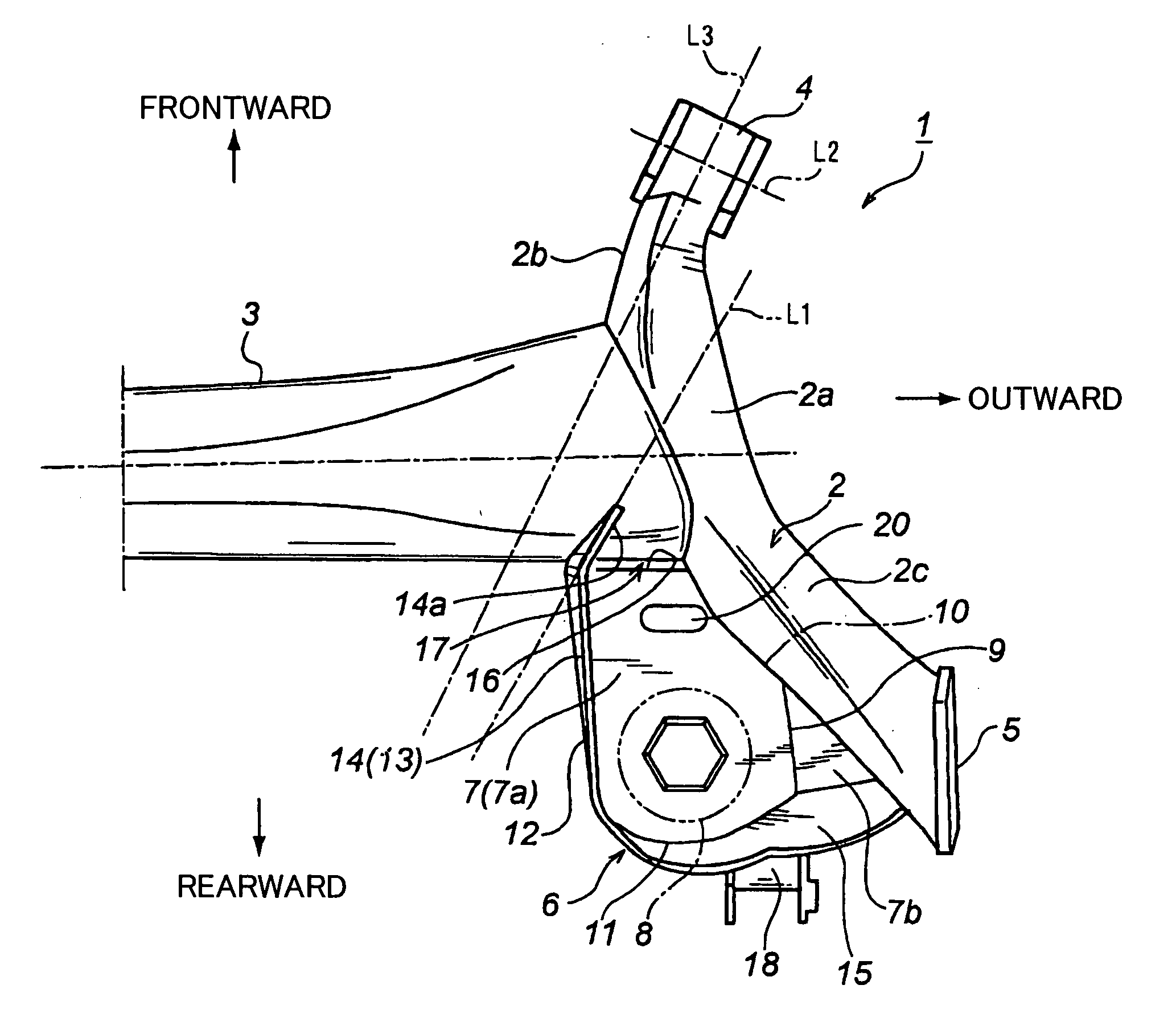

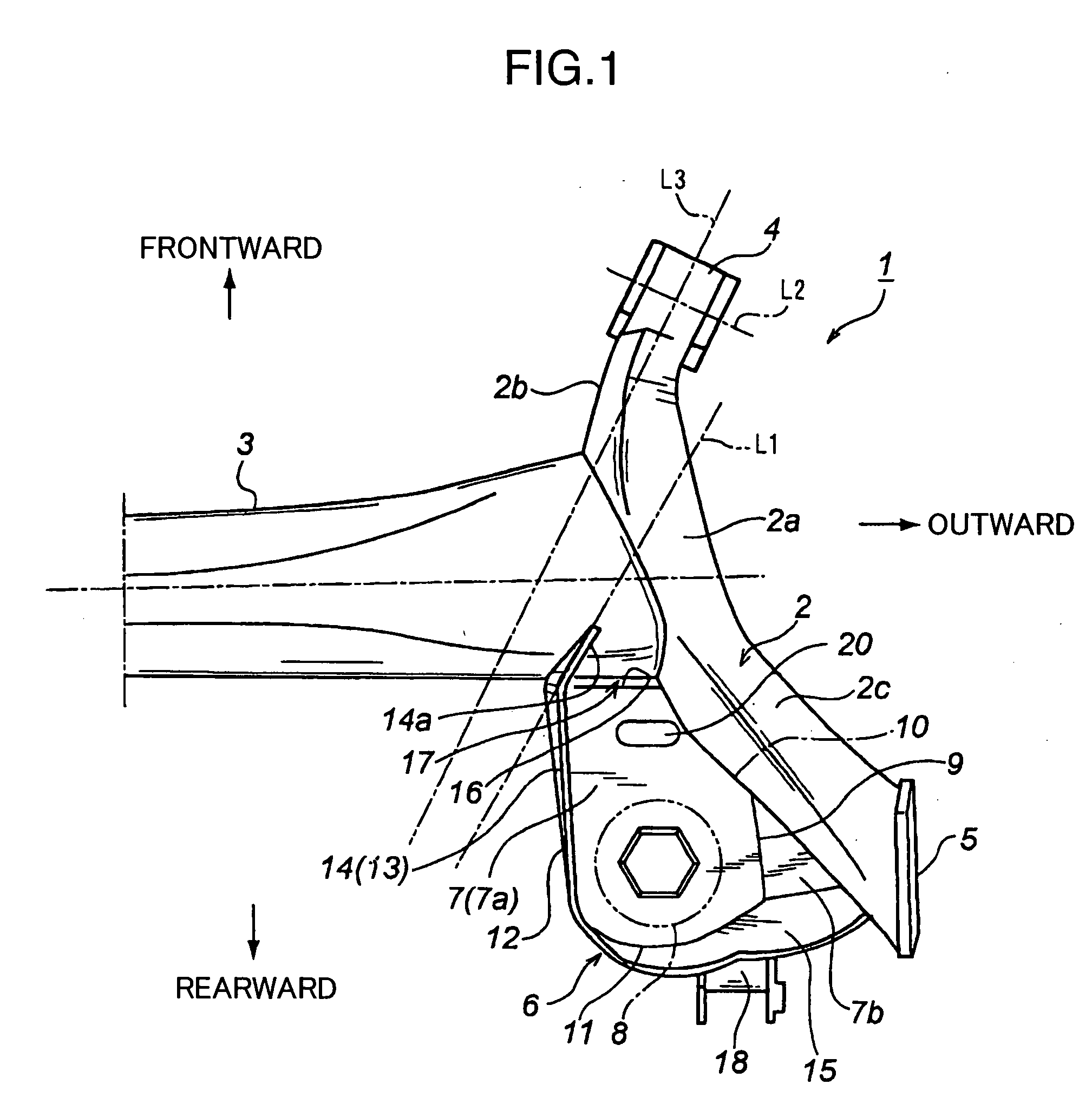

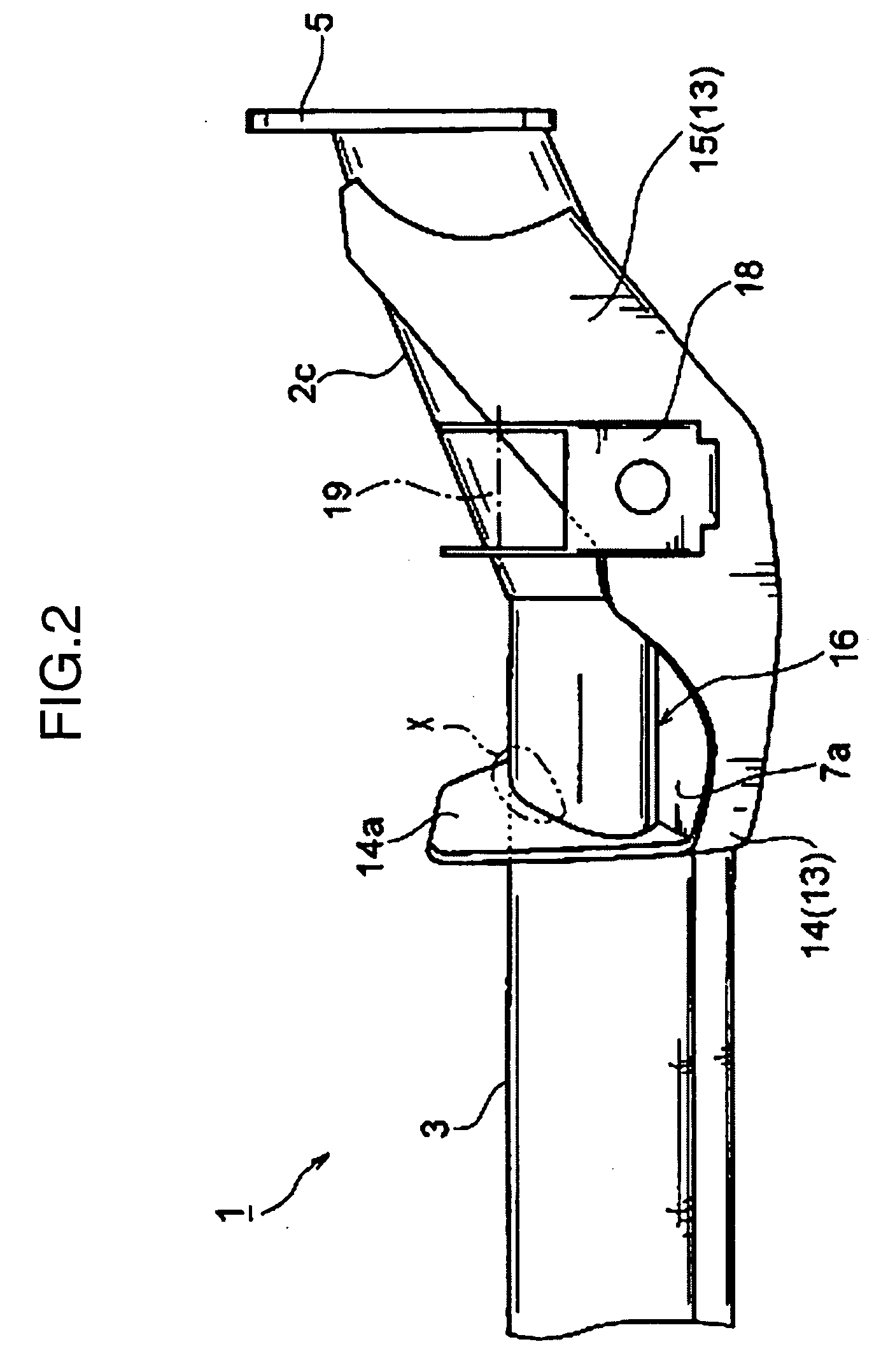

Torsion beam type rear suspension

InactiveUS20060220339A1Improve supportIncrease rigidityInterconnection systemsWheel manufactureEngineeringCoil spring

Disclosed is a torsion beam type rear suspension which comprises a pair of right and left trailing arms (2), a torsion beam (3), and a spring seat (6) disposed in a corner region defined at a junction between each of the lateral ends of the torsion beam and a rear portion (2c) of a corresponding one of the trailing arms to form a mounting seat for a coil spring (8). A vertical flange (13) is formed along a laterally inner edge (12) of the spring seat to have a longitudinally front edge extending vertically along a rear side surface of the torsion beam. The spring seat has a first region (7b) of disposed opposed to the corresponding trailing arm and fixed thereto approximately in its entirety, and a second region (16) disposed opposed to the torsion beam and fixed thereto only through the vertical flange. The torsion beam type rear suspension of the present invention can improve the supporting rigidity of the spring seat relative to a coil spring without increasing the rigidities of the spring seat and trailing arm themselves, while allowing the risk of stress concentration occurring at an end of the torsion beam to be reduced, so as to achieve increased chassis rigidity and adequately maintain suspension functions.

Owner:MAZDA MOTOR

Safety Razors

ActiveUS20070017099A1Reduced strengthIncrease the spring rateMetal working apparatusRest positionKnife blades

A safety razor blade unit mounted for pivotal movement relative to a razor handle is biased to a normal rest position by a magnetic return force generated by a pair of magnetic that are so disposed that the return force increases as the pivotal displacement of the blade unit from the rest position increases.

Owner:THE GILLETTE CO

Wheelset to side frame interconnection for a railway car truck

A railway car truck incorporating an interconnection between the side frame and bearing adapter is characterized by a low lateral spring constant relative to the longitudinal spring constant. The interconnection provides a proportional restoring force with minimal internal friction and hysteresis. In embodiments, the interconnection comprises compressed elastomeric members positioned between the thrust lug of the side frame and the bearing adapter in the longitudinal direction and a low friction interface between the roof of the pedestal jaw and the top of the bearing adapter.

Owner:STRATO AG

Pull arrangement with reversing tension spring

ActiveUS20100007254A1Increase the spring rateReduce the spring rateLiquid resistance brakesBuilding braking devicesRest positionTorsion spring

In a pull arrangement including a housing with a guide structure movably supporting a carrier element which has a park position at one end of the guide structure and a rest position at the other end and a reversing structure is provided at the other end of the guide structure and a tension spring extending around the reversing structure is connected with one end to the carrier element and the opposite end to the housing for moving the carrier element to the end position, the tension spring comprises an area of high spring stiffness where it extends around the reversing structure and an area of low spring stiffness where the spring is connected to the housing away from the reversing structure.

Owner:ZIMMER GUNTHER +1

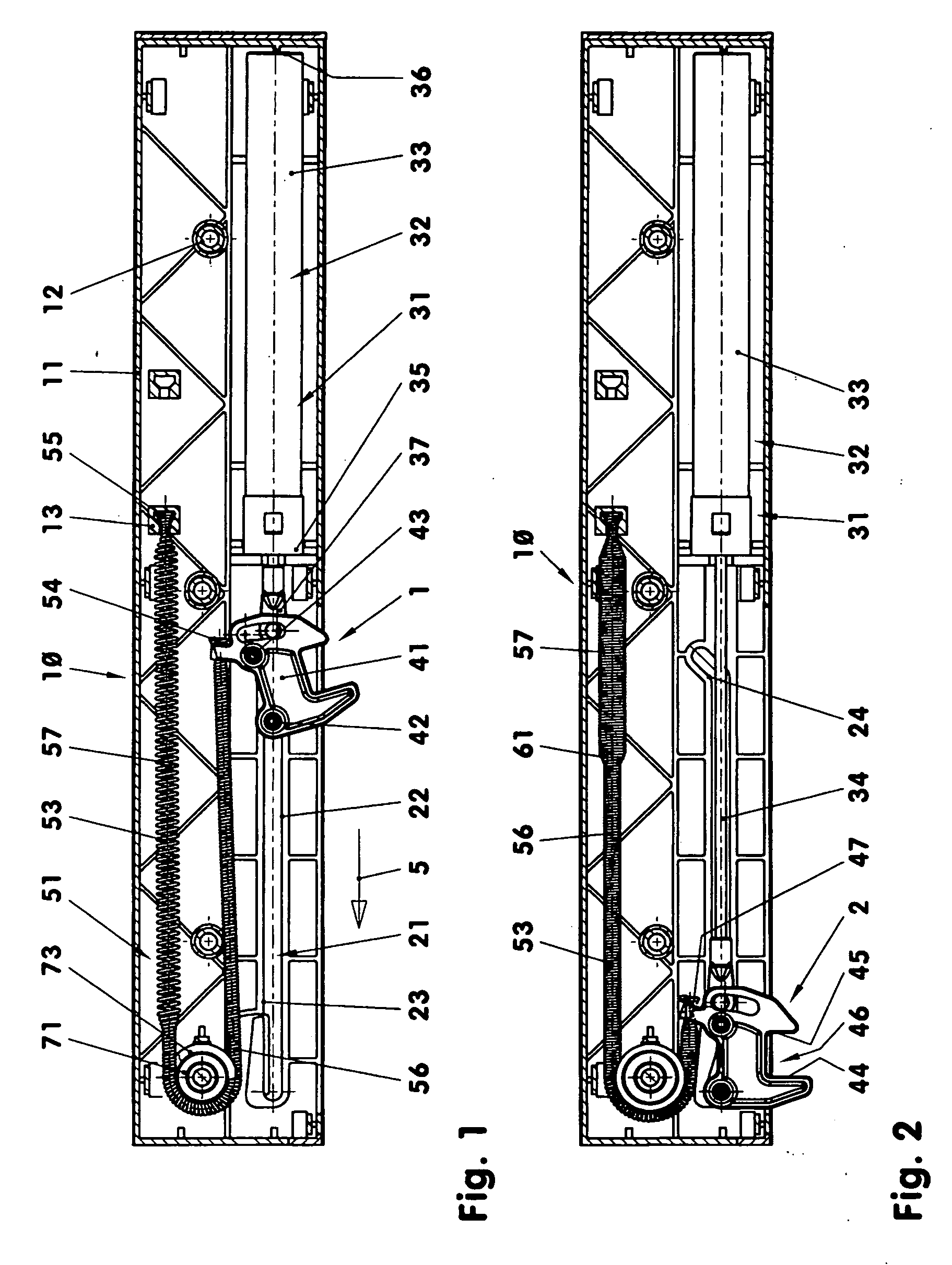

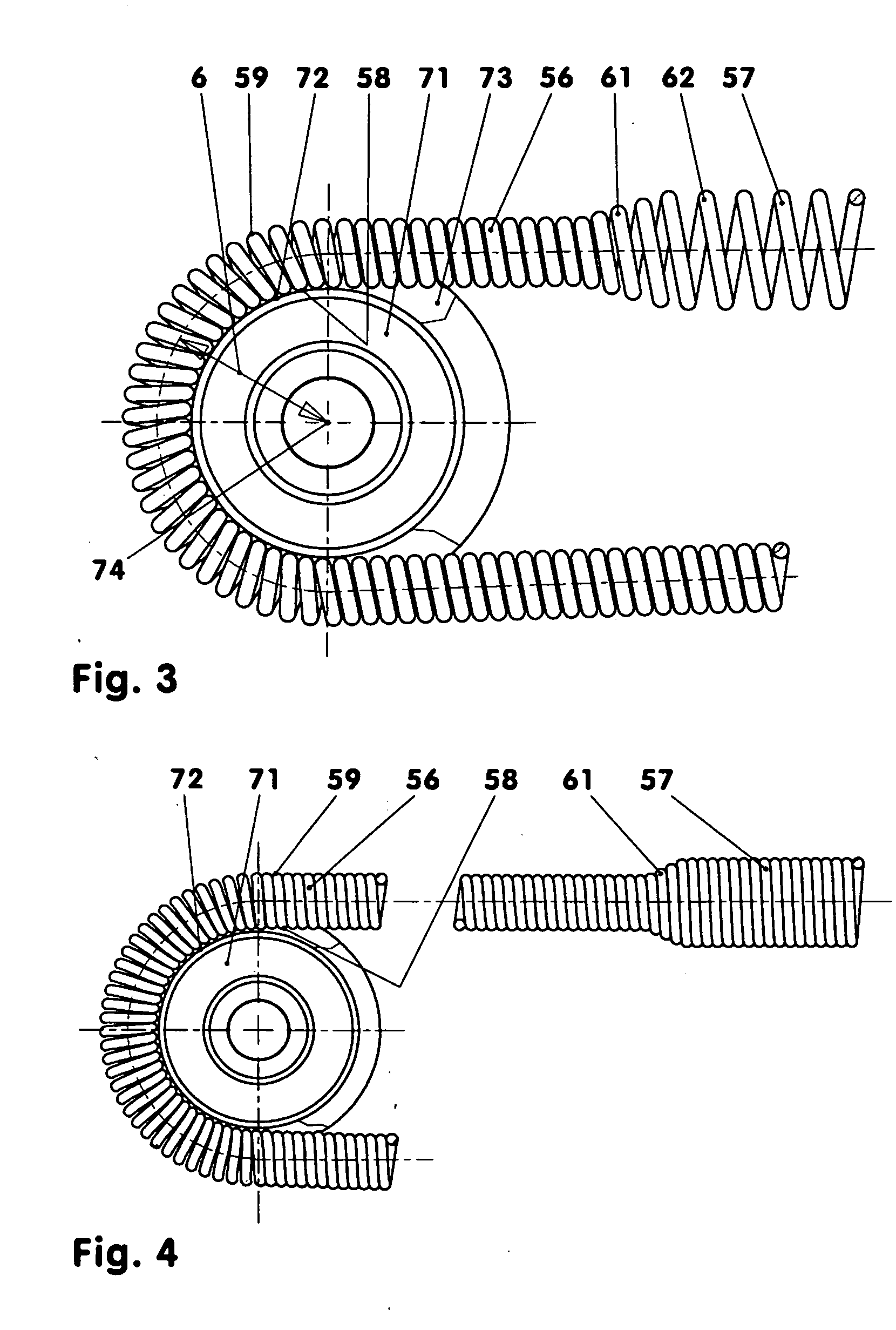

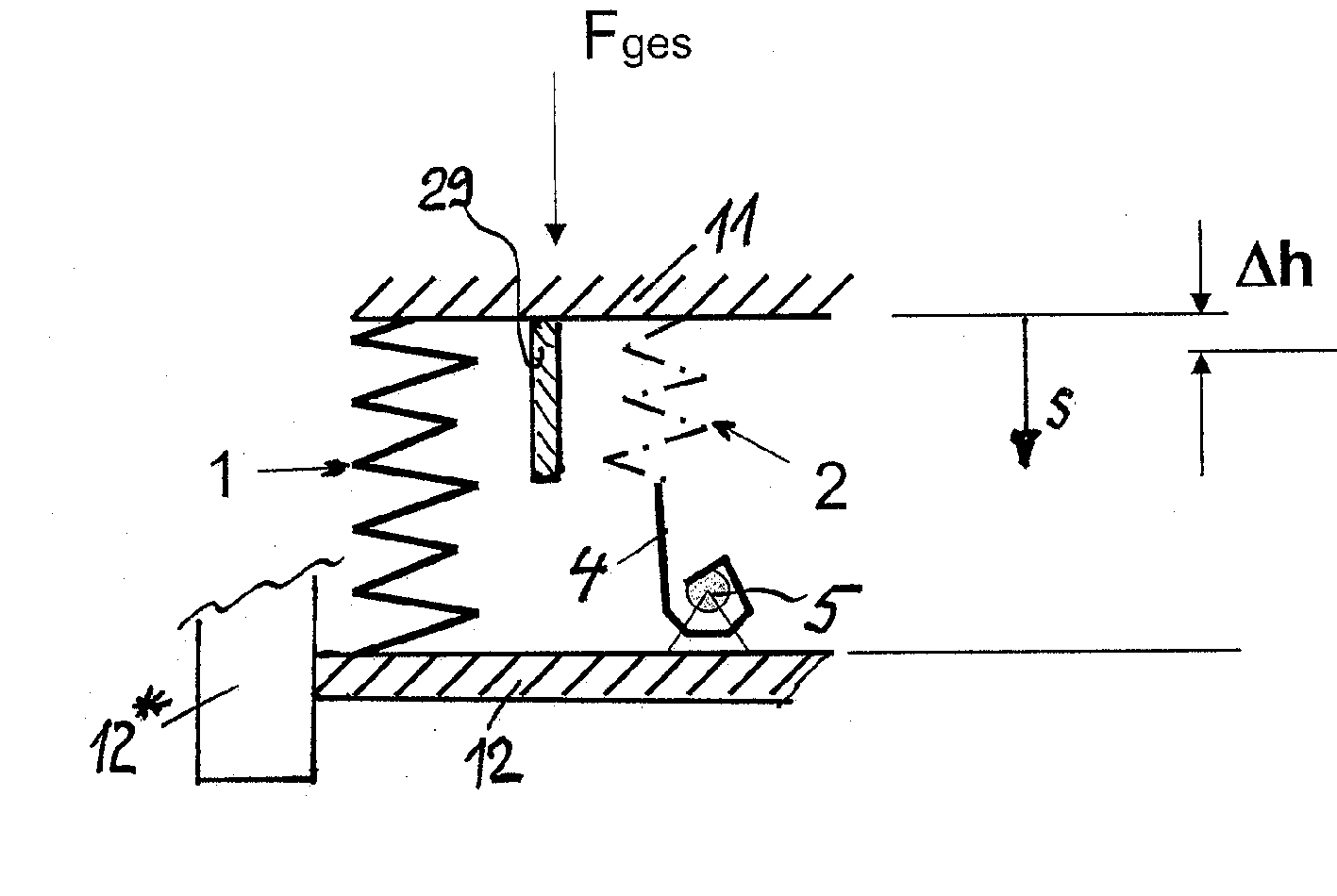

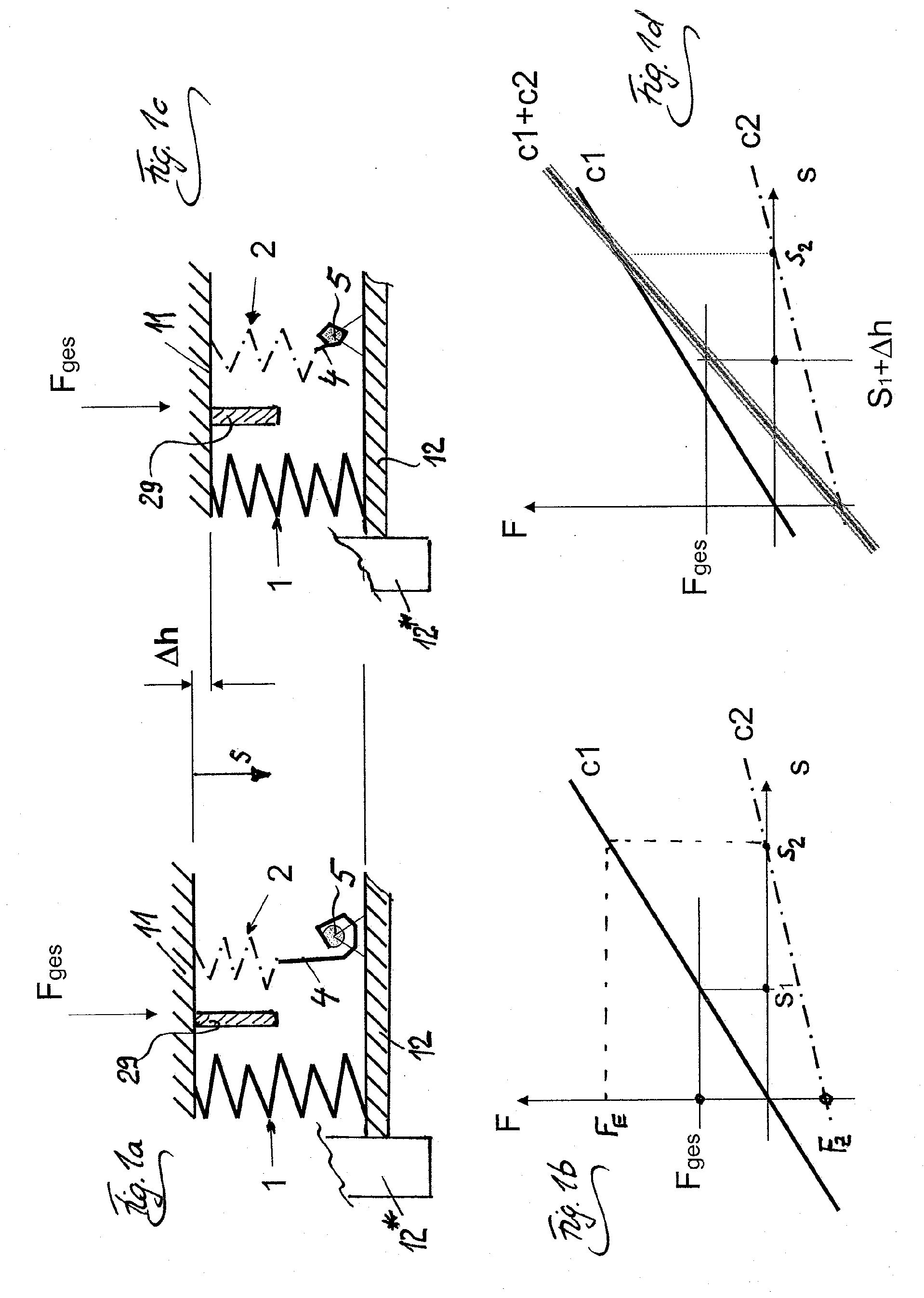

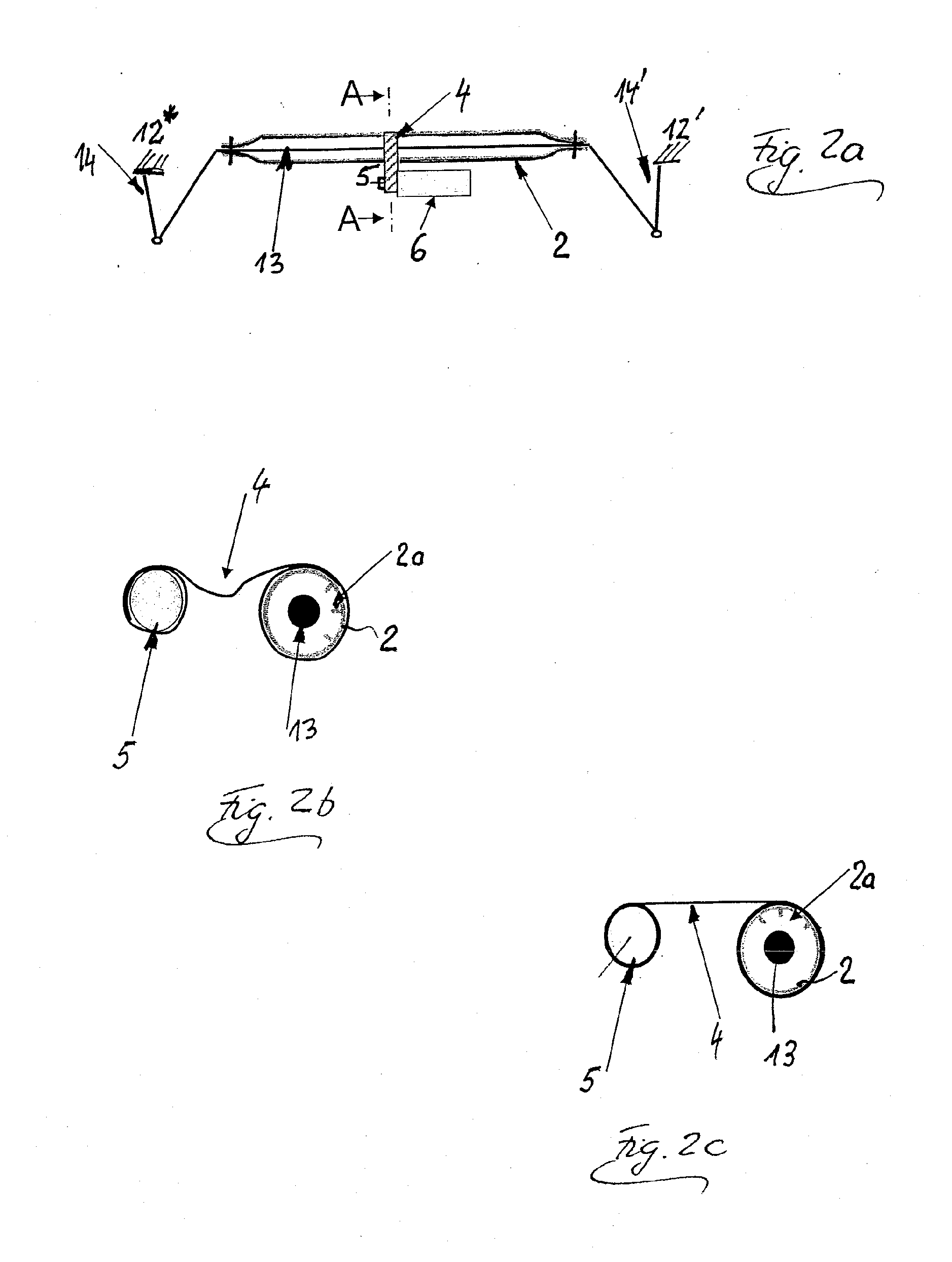

Spring System for a Vehicle Wheel Suspension System

ActiveUS20090000368A1Increase the spring rateHigh rebound rateEngine testingInterconnection systemsSpring systemPressure increase

The invention relates to a suspension system for a vehicle wheel suspension having a first spring element (1) in the end clamped between the vehicle body (11) and a vehicle wheel (12,12′) and a second or additional spring element (2,3) which in the end can be clamped between the vehicle body (11) and the vehicle wheel (12,12′) by the introduction of a tensile force by means of a mechanical tensioning element (4,5,6,20), which spring element (2,3) can thereby be connected parallel to the first spring element (1), while this additional spring element (2,3) is not active without tensile force introduced into the system, and furthermore having a pressure addition spring element (29) which, in the case of large spring excursions of the first spring element (1), becomes active by way of an end stop. In this case, the pressure addition spring element (29) is not activated with the introduction of the tensile force for activating the second or additional spring element (2). The spring rate of the second spring element (2) is preferably lower than that of the first spring element (1). Second or additional spring elements assigned to different wheels or axles of the motor vehicle can be activated or deactivated by means of a common mechanical tensioning element having a servo motor which can shorten or lengthen several tension devices connected with the additional spring elements and, for this purpose, can wind them onto reels or unwind them from the latter.

Owner:BAYERISCHE MOTOREN WERKE AG

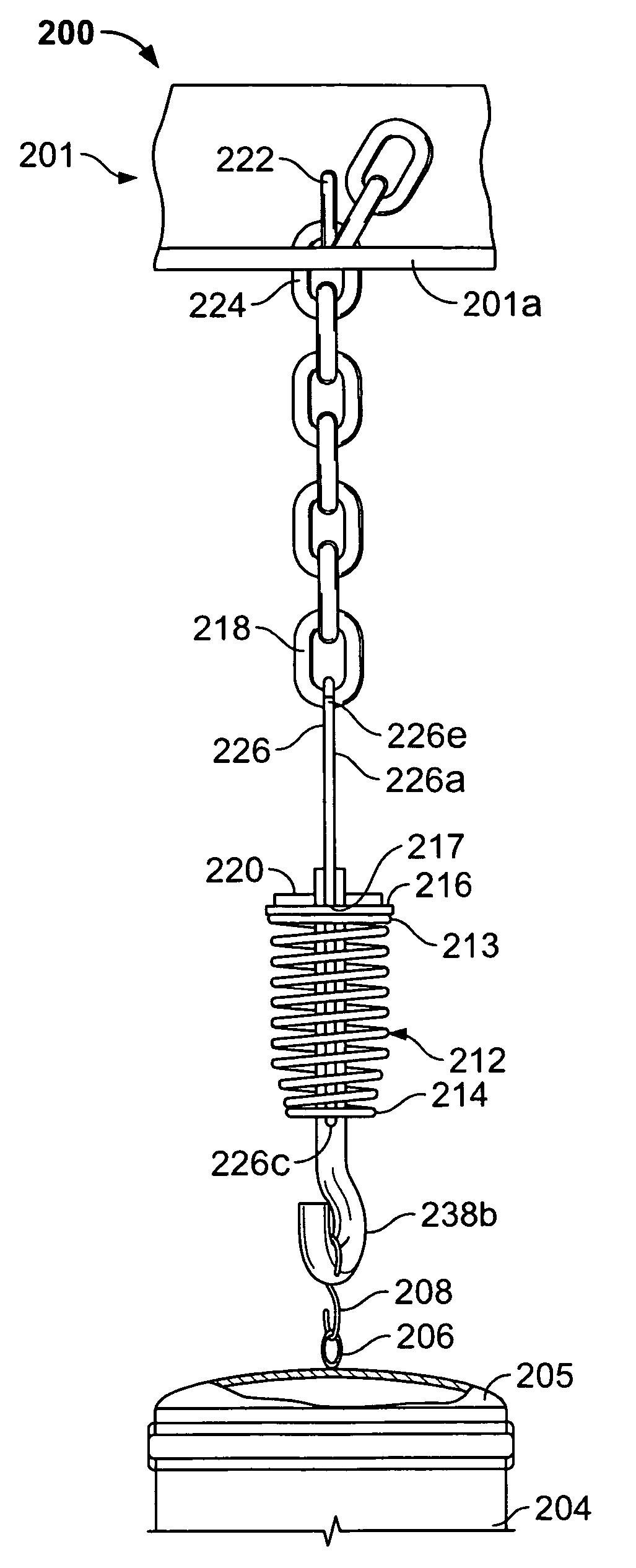

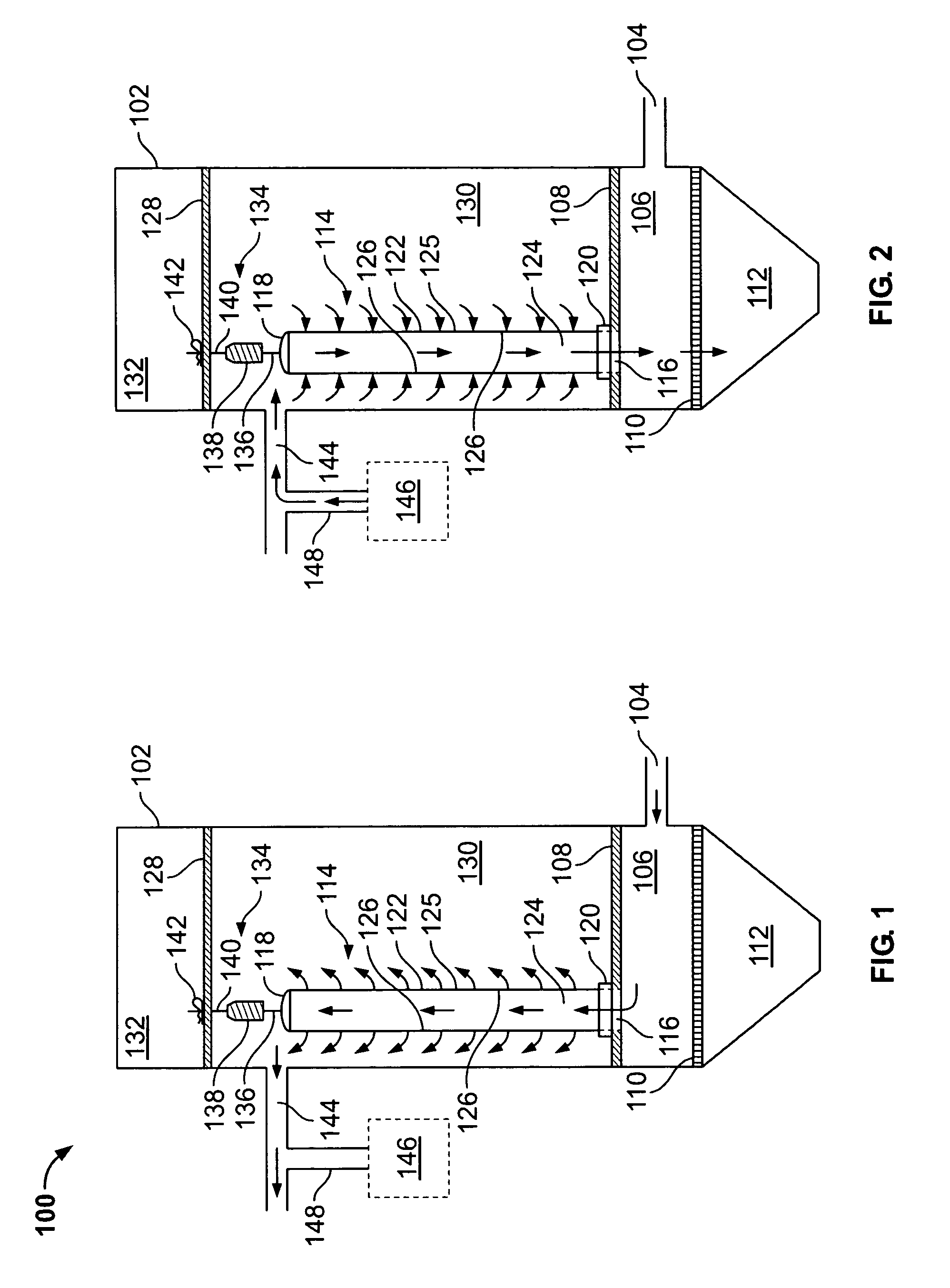

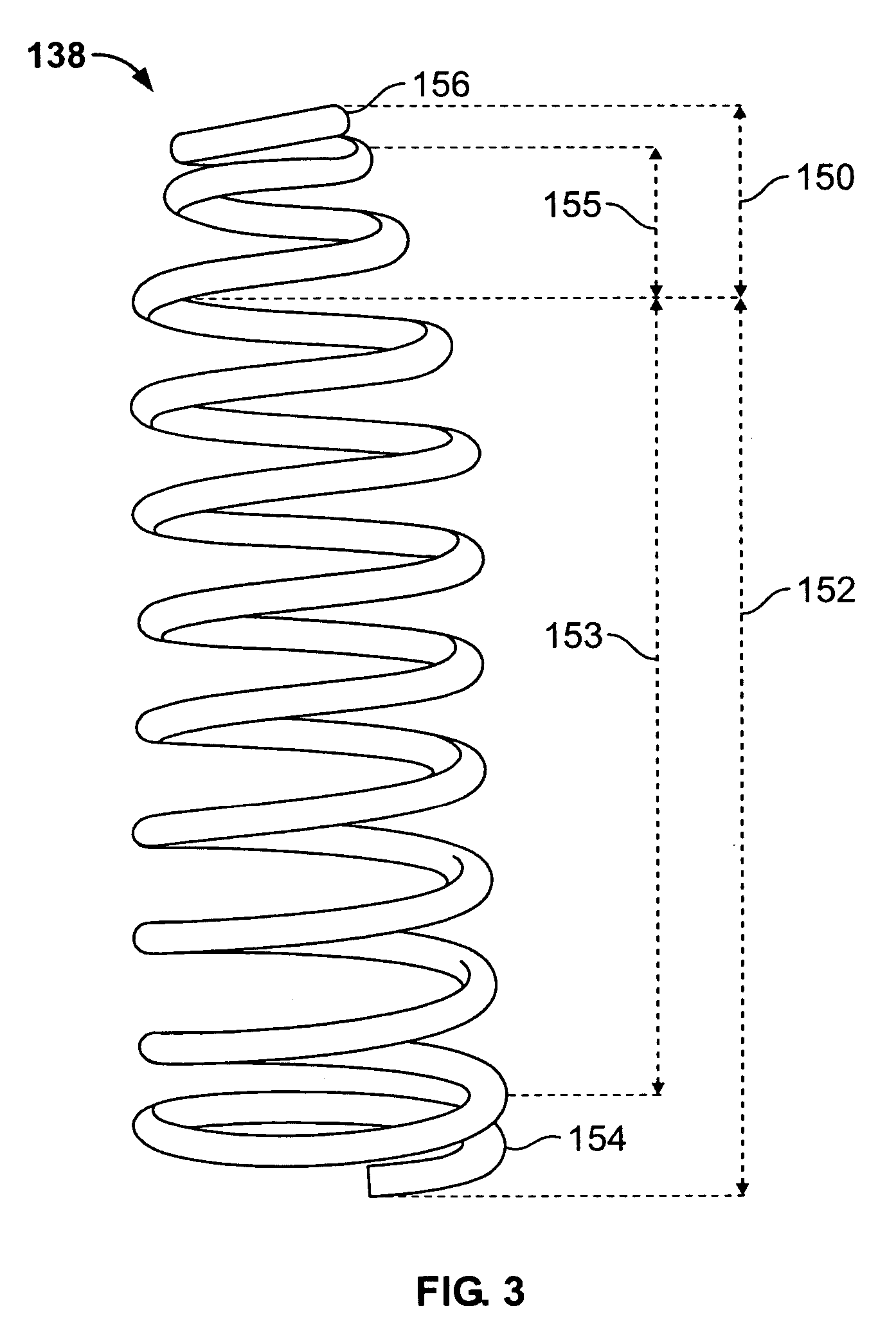

Methods and apparatus for manufacturing and assembling a baghouse bag filter tensioning assembly

ActiveUS7648563B2Convenient inductionIncrease the spring rateDispersed particle filtrationTransportation and packagingBaghouseEngineering

A method of assembling a baghouse bag filter tensioning assembly is provided. The assembly includes a compressible spring having a progressively increasing spring rate. The spring rate facilitates induction of a substantially constant spring tension over a range of pre-determined operating conditions. The method includes coupling the spring to a bag filter support frame and a bag filter. The method also includes compressing the spring into a pretensioned condition. The method further includes coupling a bag filter to a baghouse floor. The method also includes decompressing the spring such that a tension induced in the bag filter is substantially similar to the spring tension induced over a range of pre-determined operating conditions.

Owner:BHA ALTAIR

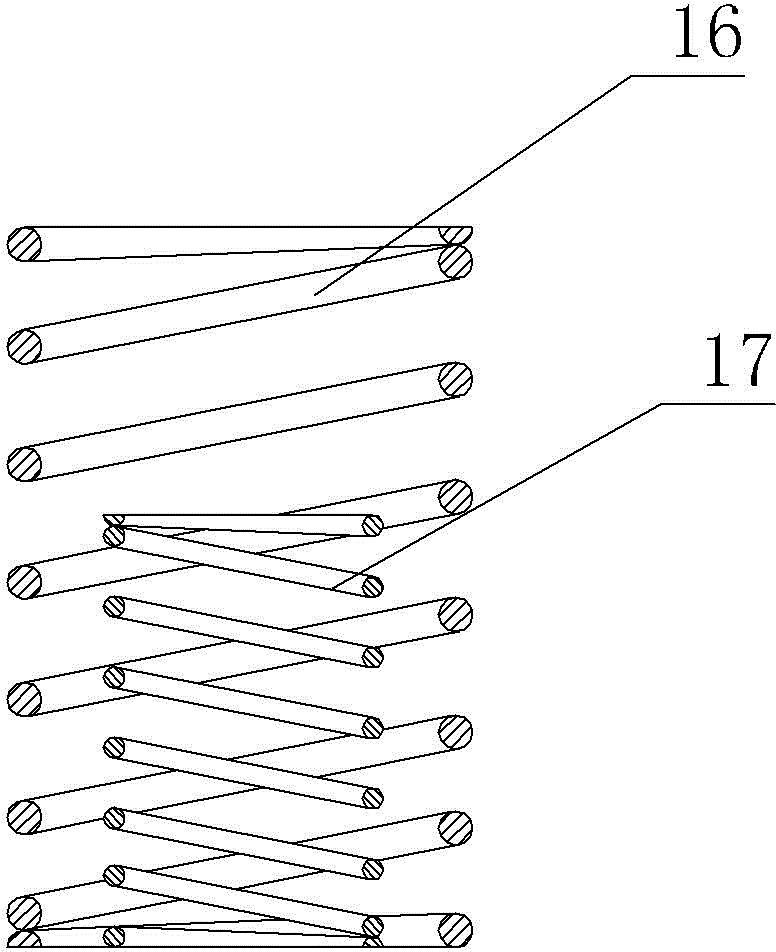

Manufacturing method of three-dimensional woven composite material hollow spiral spring

The invention provides a manufacturing method of a three-dimensional woven composite material hollow spiral spring. The manufacturing method comprises the following steps: first, using spinnable and weavable fiber to weave a three-dimensional braidd tube on the outer surface of a bent strip-type core model through the three-dimensional weaving technology so as to obtain a strip-type fabric preform; then, placing the strip-type fabric preform in a spiral space formed between an internal model and an external model; next, injecting basis material in the spiral space by adopting the vacuum assisted resin transfer molding process (VARTM), and adopting warming and pressurization to solidify the basis material and the three-dimensional braidd tube into the composite material spiral spring; and finally, removing the core model in the spiral spring to obtain the three-dimensional woven composite material hollow spiral spring. The three-dimensional woven composite material hollow spiral springmanufactured through the manufacturing method has the advantages of light weight, antifatigue, corrosion resistance and impact resistance of the composite material spiral spring to further improve theperformance including light weight and spring rigidity.

Owner:刘念

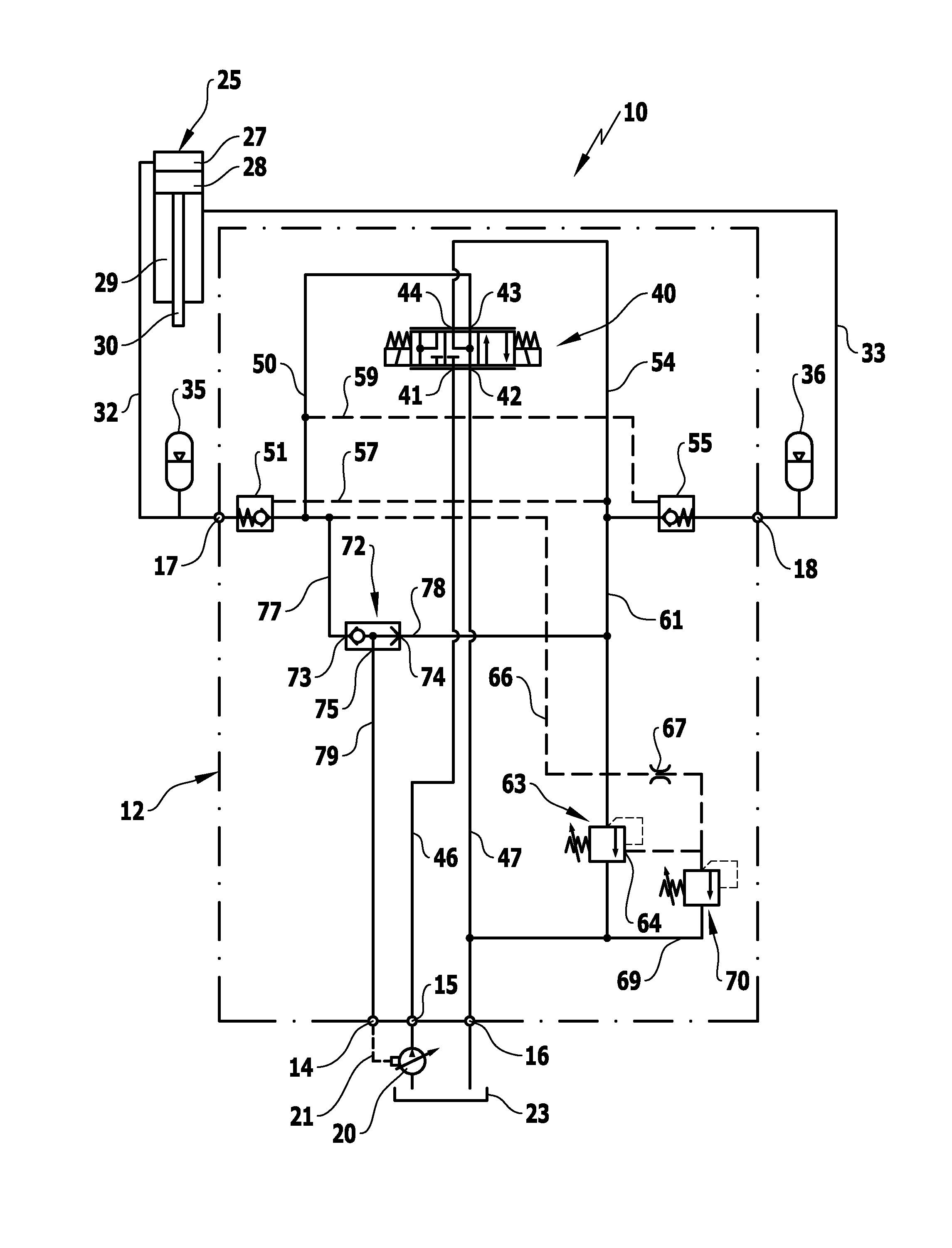

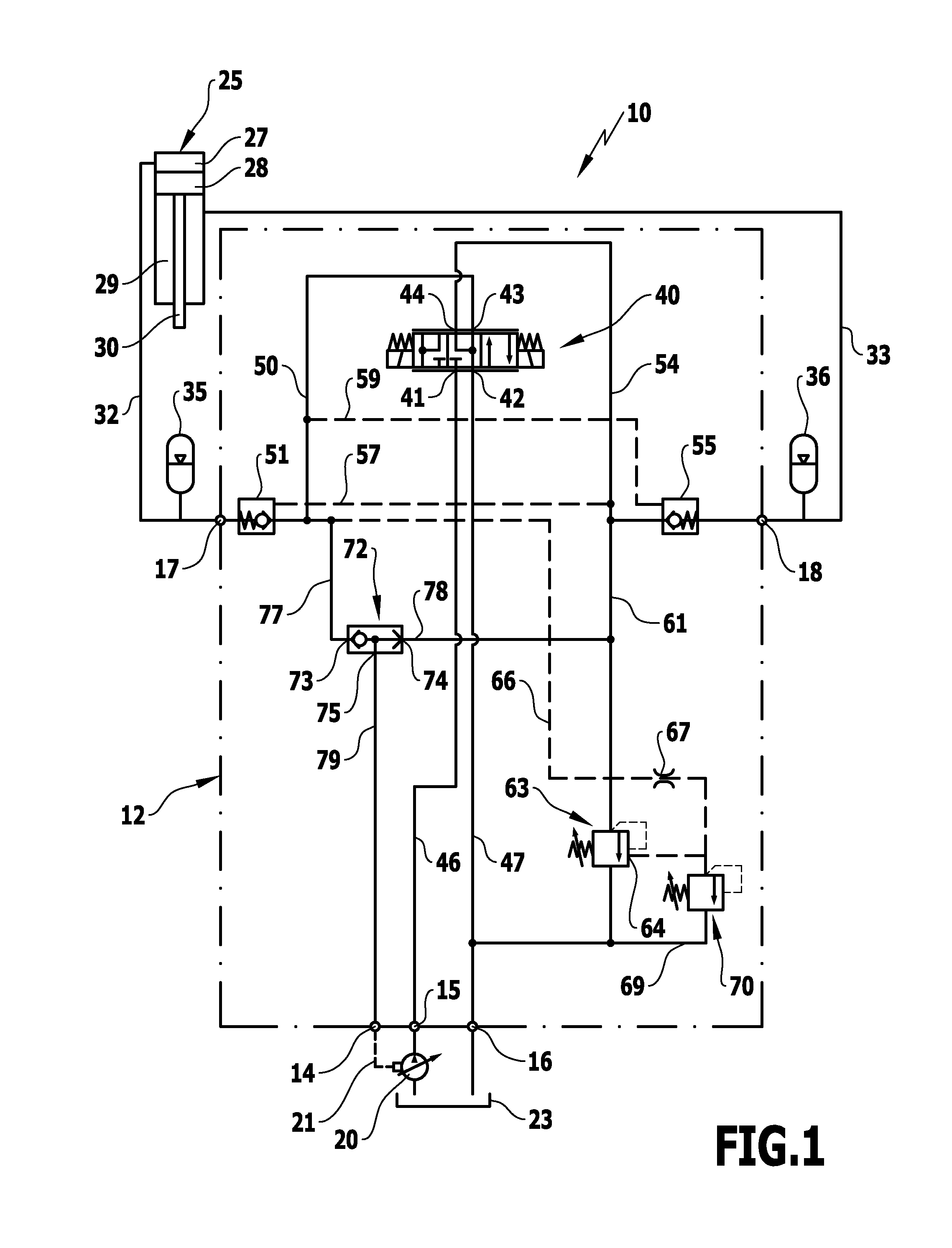

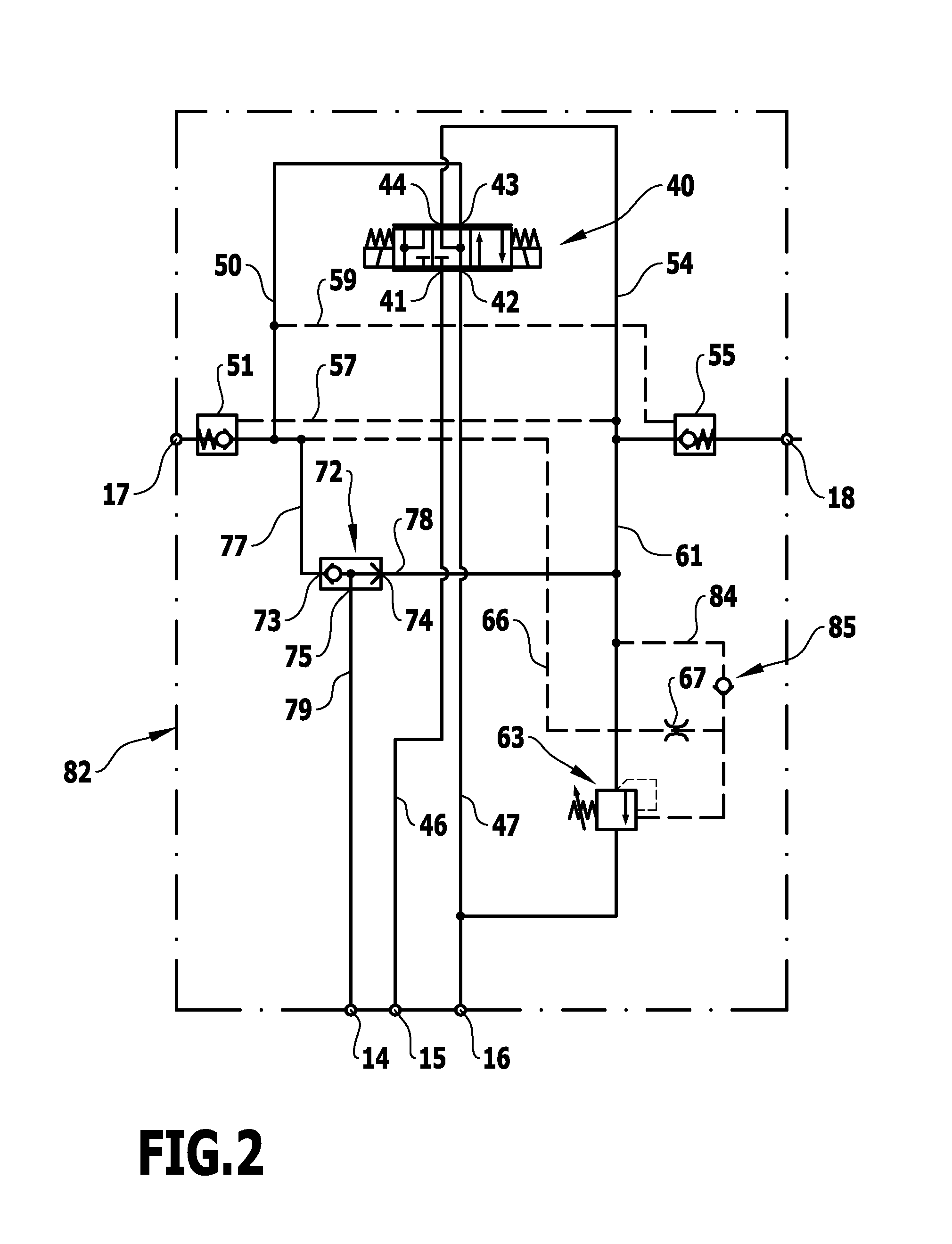

Control Arrangement For A Hydropneumatic Suspension System And Hydropneumatic Suspension System Comprising Such A Control Arrangement

ActiveUS20140015215A1Increase the spring rateControl outflowResilient suspensionsLine tubingHydropneumatic suspension

A control arrangement for a hydropneumatic suspension system and a hydropneumatic suspension system are provided. The control arrangement has a pressure supply connection, a return connection, a piston chamber connection adapted to be connected to the piston chamber of a suspension cylinder of the hydropneumatic suspension system, an annular chamber connection adapted to be connected to the annular chamber of the suspension cylinder, and at least one controllable valve arrangement comprising a plurality of switch positions via which the pressure supply connection and the return connection are connectable to the piston chamber connection and the annular chamber connection. The annular chamber connection is in flow connection with the return connection via a pressure-limiting line having a hydraulically controllable pressure-limiting element. The pressure-limiting element has a control input adapted to be acted upon via a control line by a control pressure which is limitable to a predefinable pressure limit.

Owner:ARGO HYTOS GRP AG

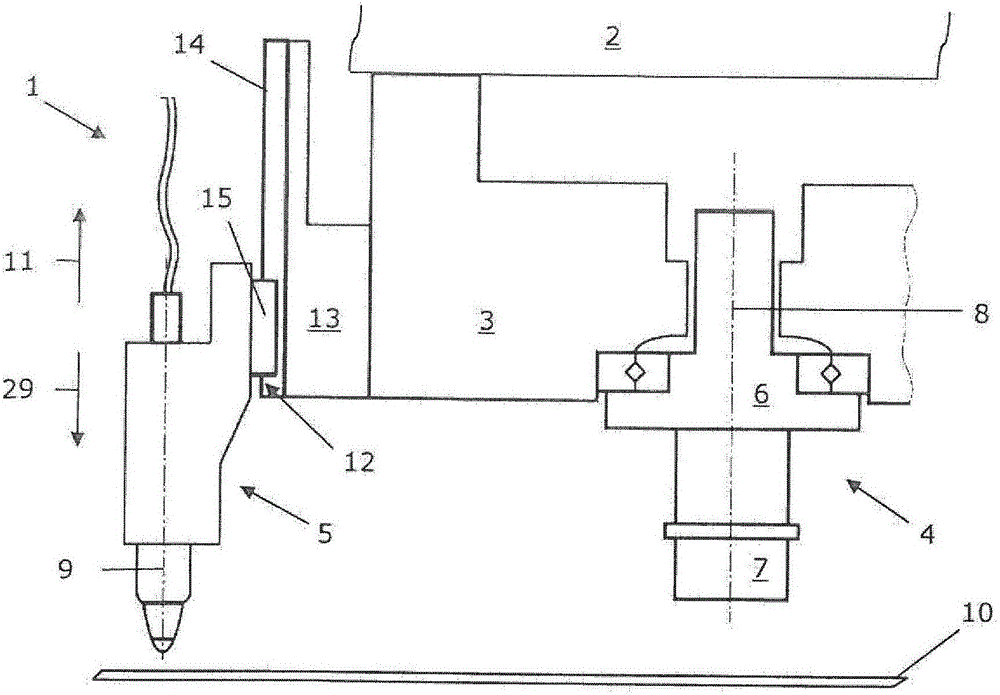

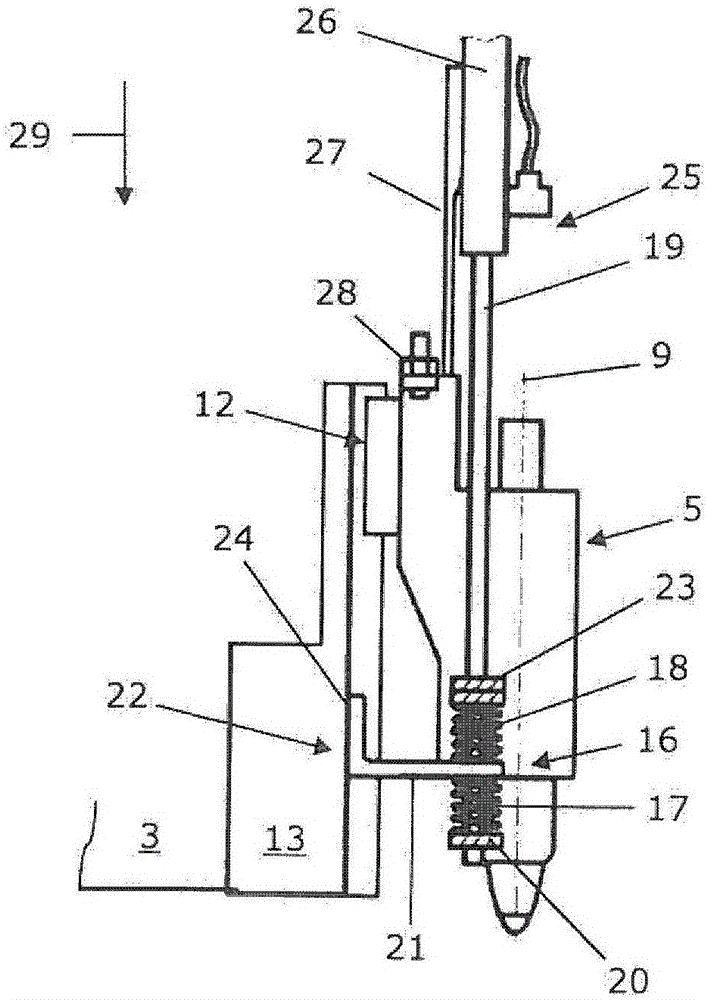

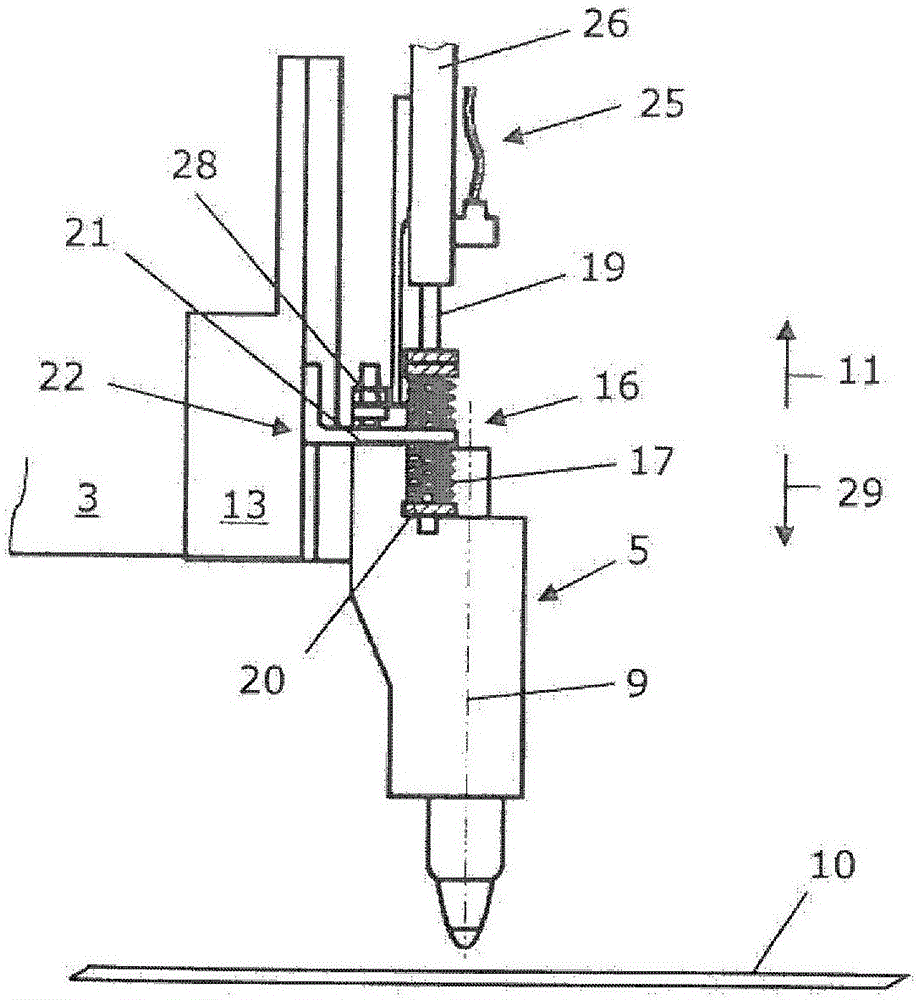

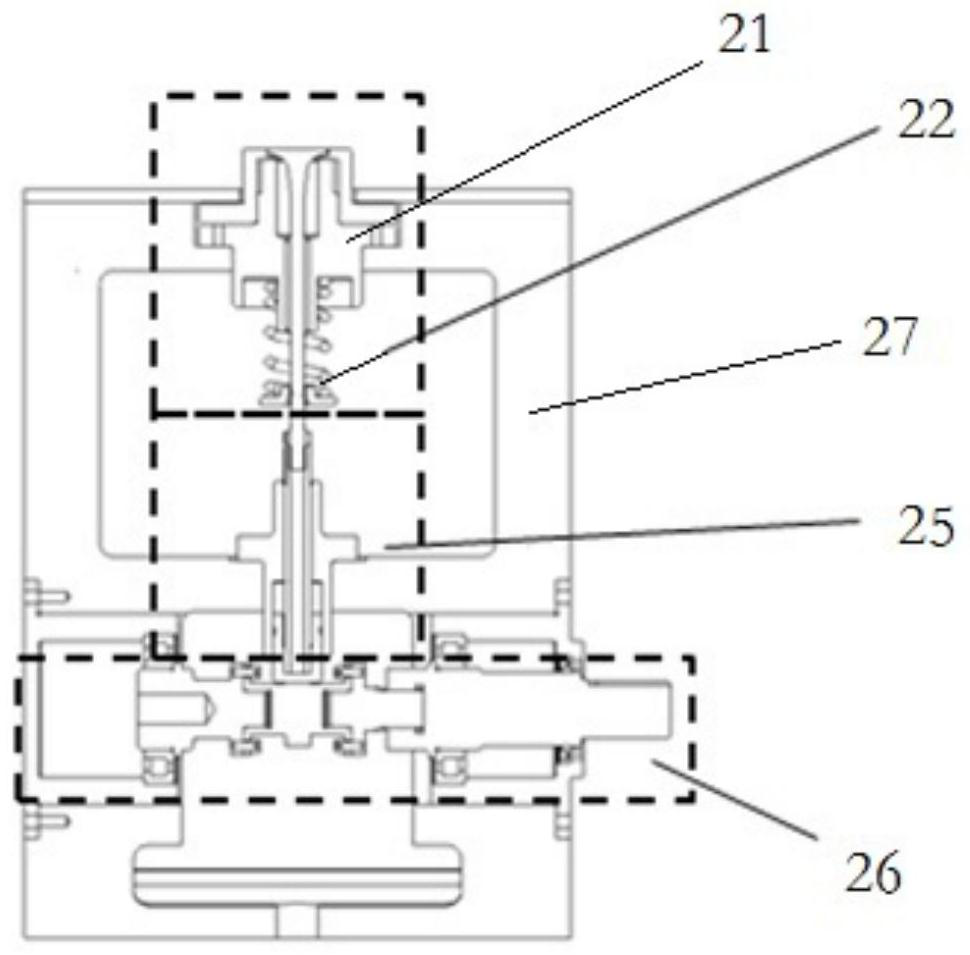

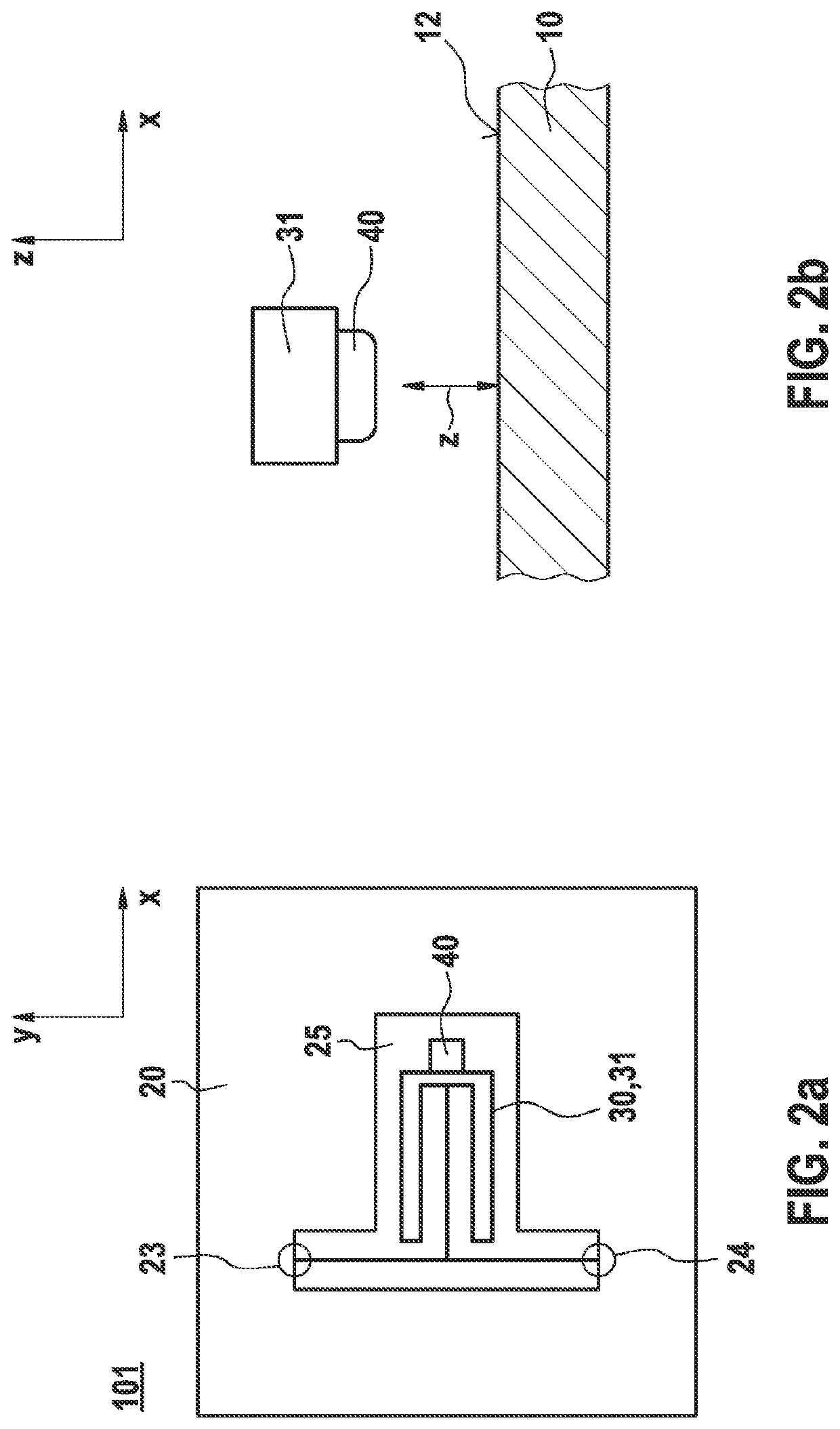

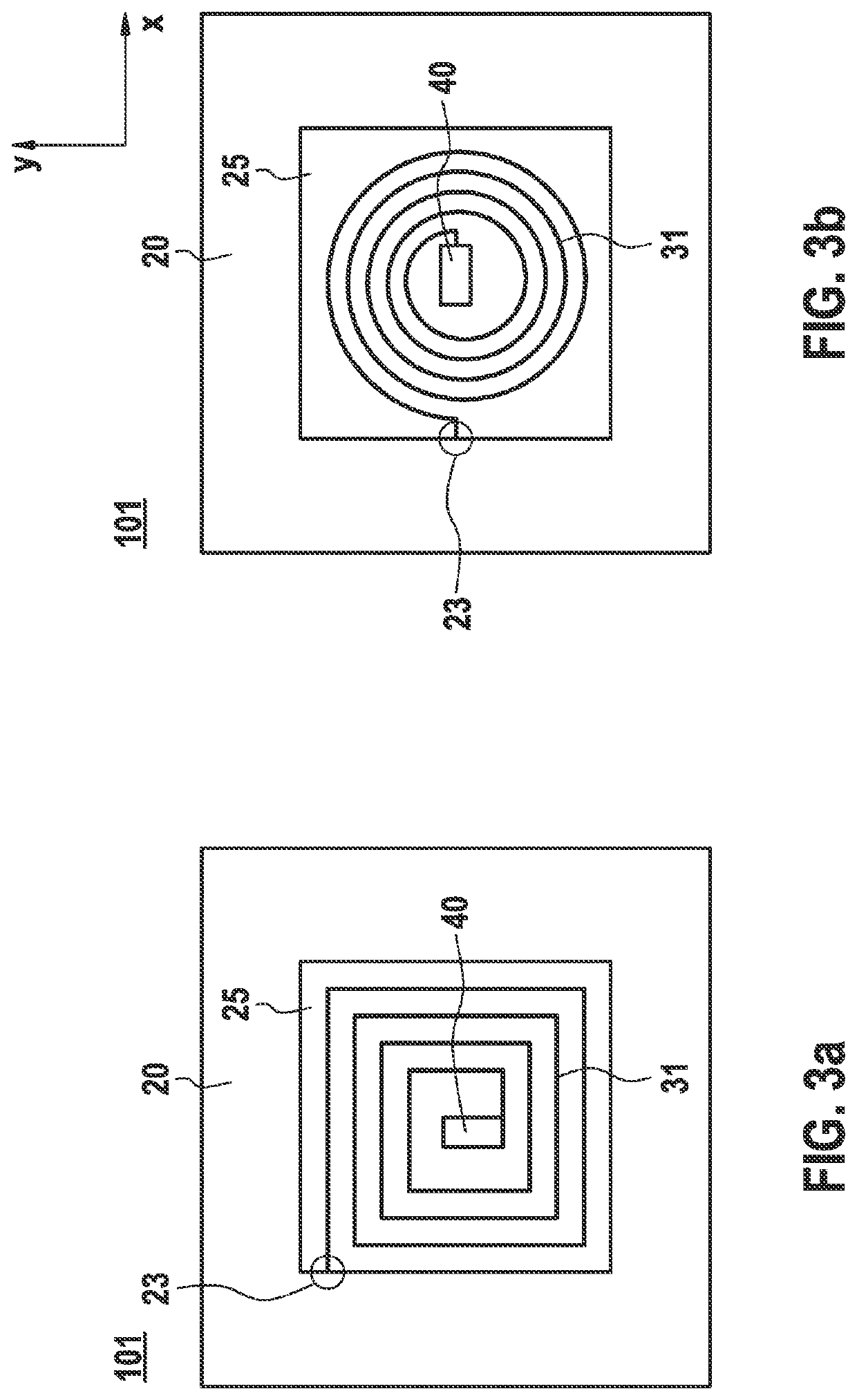

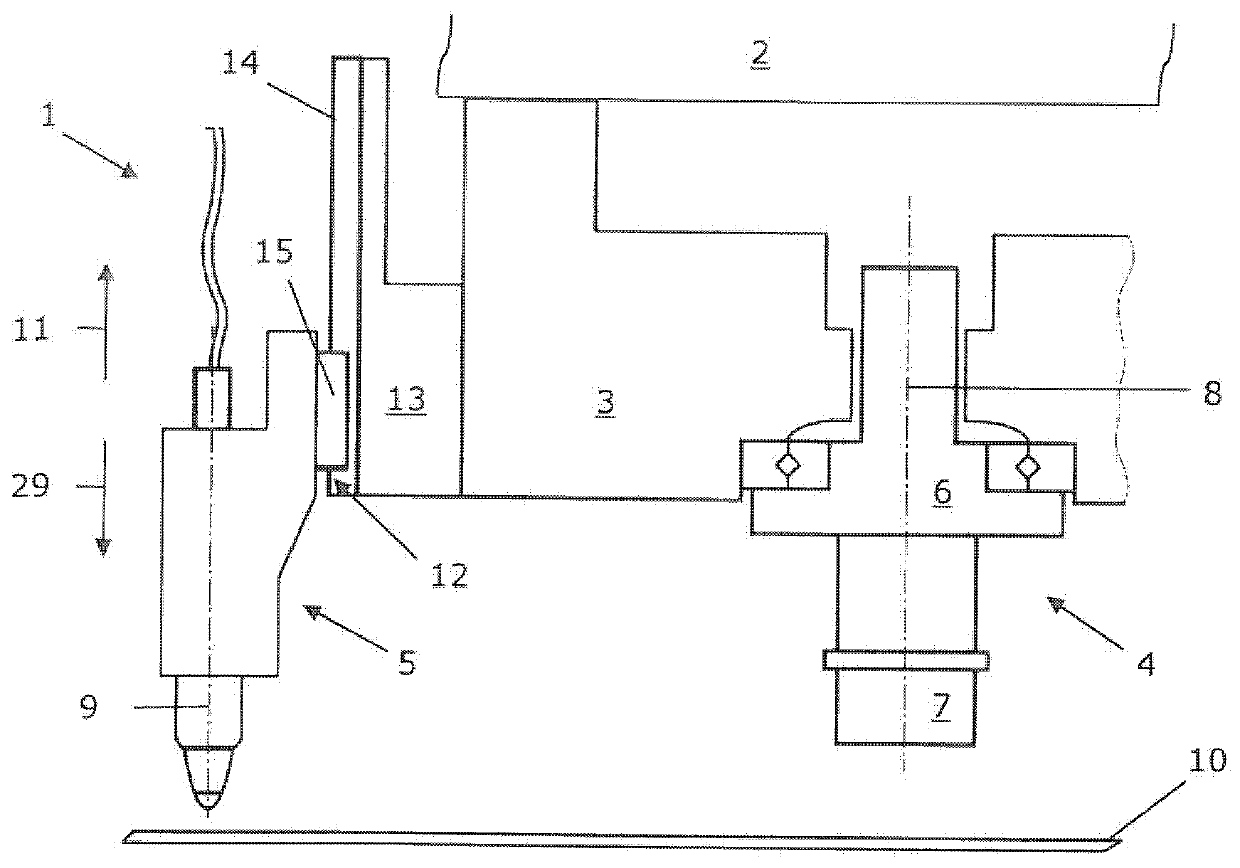

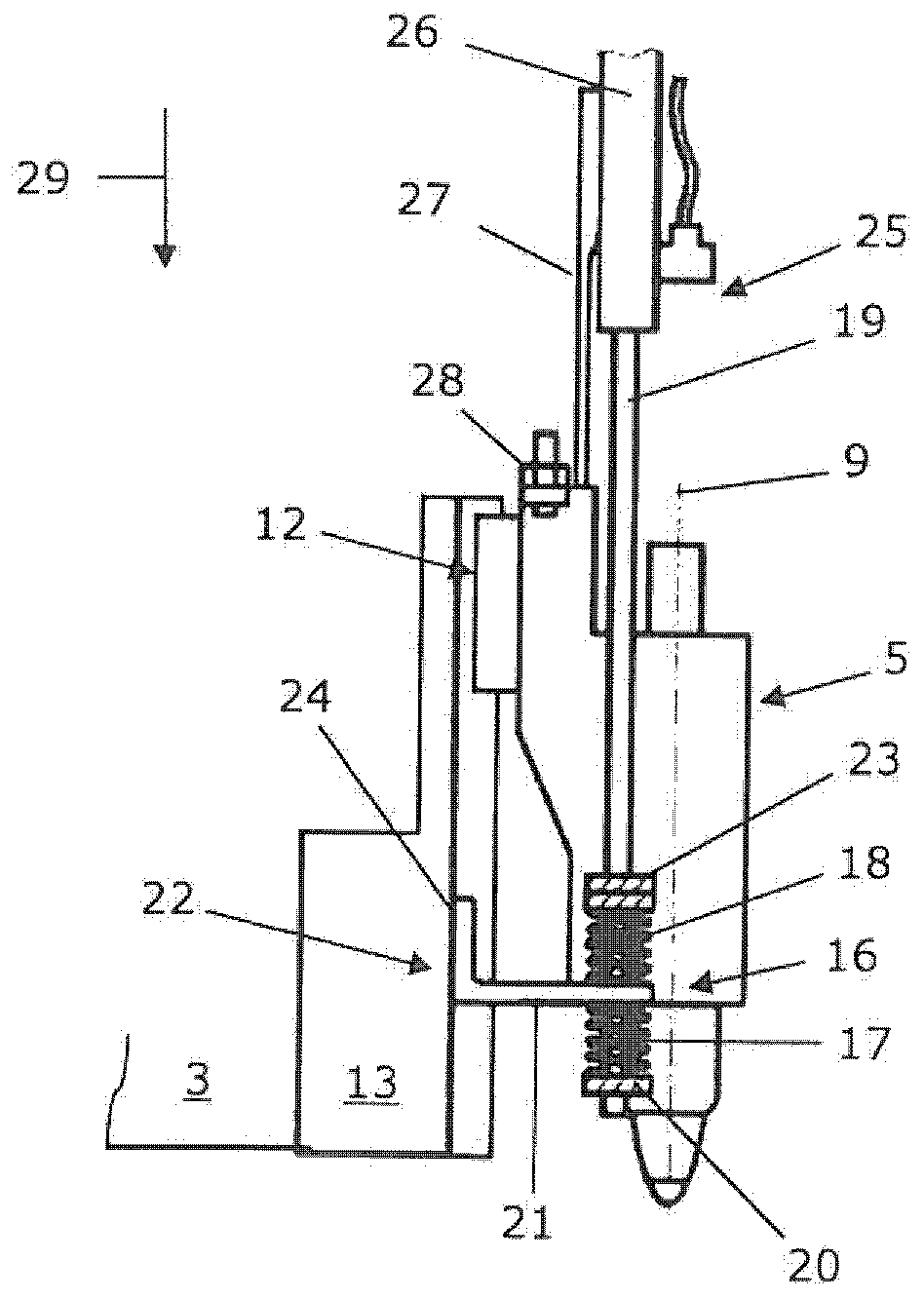

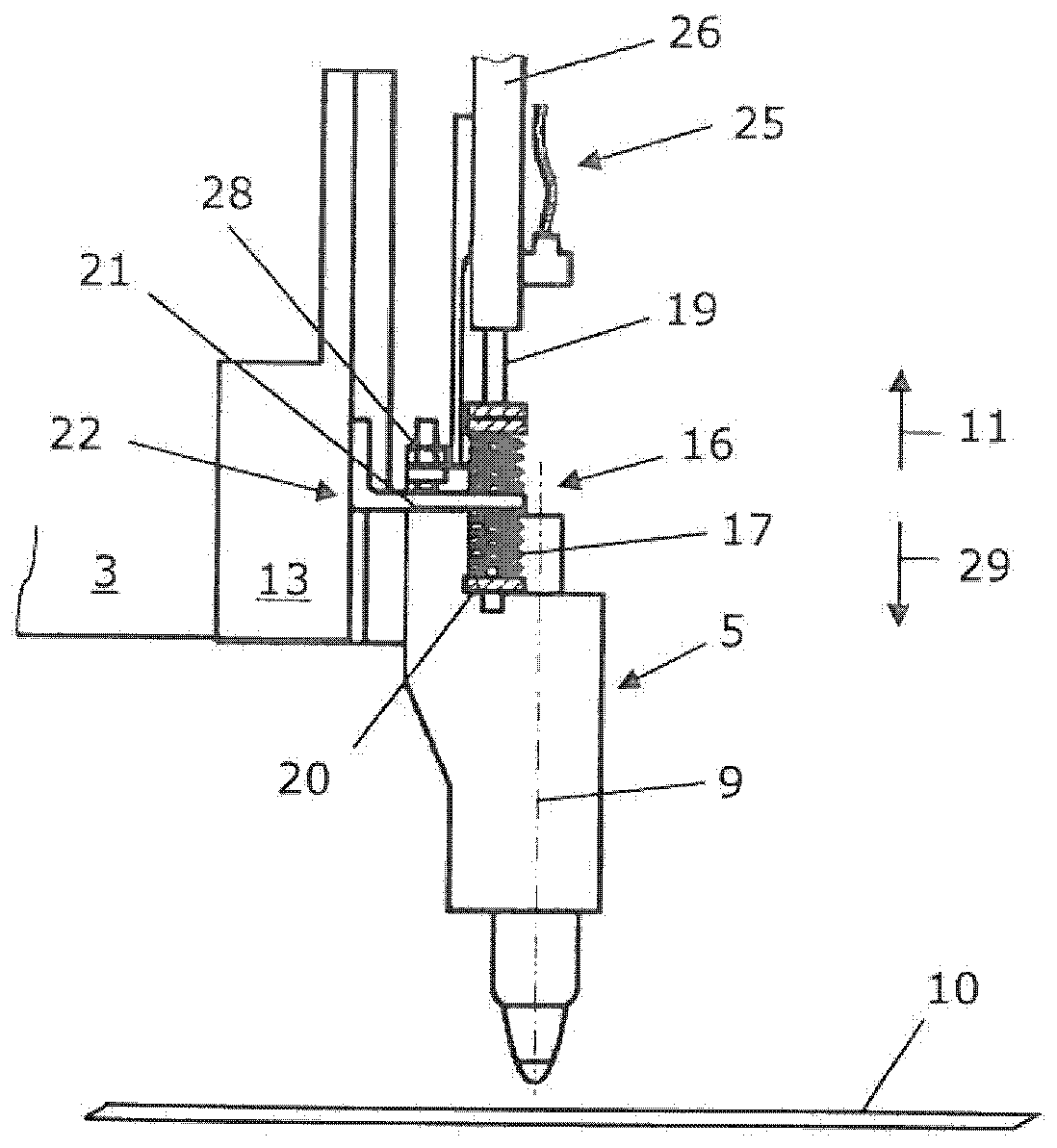

Machine tool with stamping device and laser processing device

ActiveCN106563947AAvoid negative effectsIncrease the spring rateWelding/cutting auxillary devicesOther manufacturing equipments/toolsPunchingLaser processing

A machine tool for machining workpieces, in particular sheet metal (10), comprises a support structure (3) as well as a punching device and a laser processing device (5), both of which are mounted on the support structure (3). A spring device (16) is provided between the punching device and the laser processing device (5) in order to prevent the laser processing device (5) from being stimulated to undesirable movements by the operation of the punching device. The suspension device (16) has a spring stiffness which can be adjusted by means of a laser feed device (25). By means of the laser feed device (25), the laser processing device (5) can be supplied to the workpiece with an activation movement into a functional position and also into a position remote from the functional position. The spring stiffness of the suspension device is adjusted by means of the laser feed device in such a way that a higher spring stiffness is assigned to the operating position of the laser processing device than the position of the laser processing device remote from the functional position.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

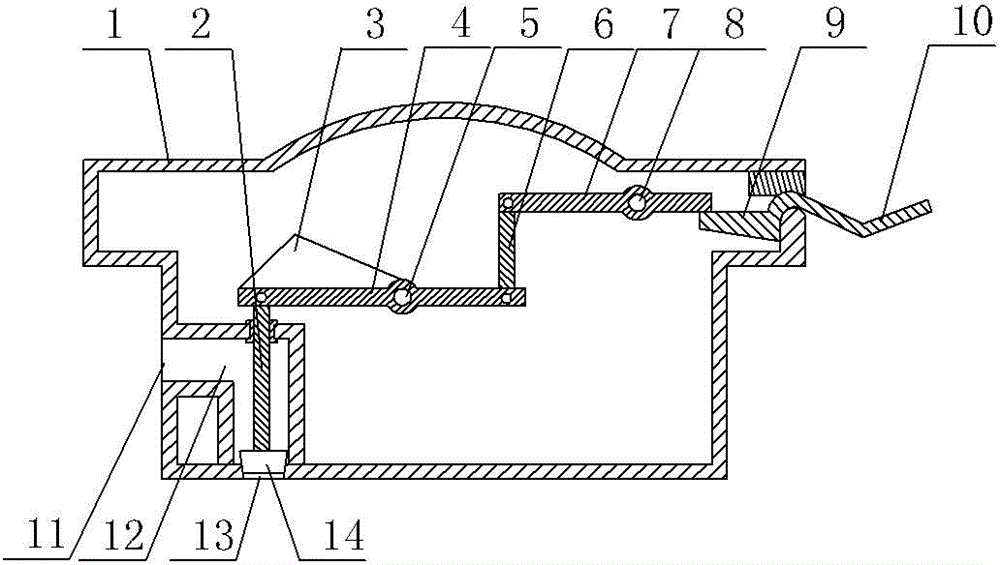

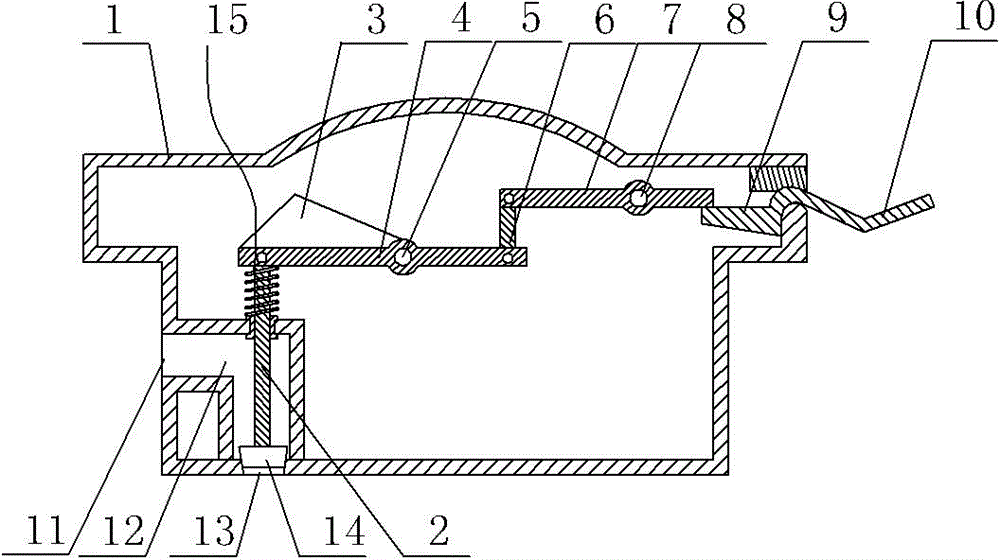

An opening/closing mechanism of a vacuum flask lid

InactiveCN105795901AIncrease the spring rateReduce falling speedCooking-vessel lids/coversWater-boiling vesselsEngineeringVacuum flask

The invention provides an opening / closing mechanism of a vacuum flask lid. The opening / closing mechanism enables boiled water remaining in a flask nozzle and a water outlet channel to flow back to an inner container of a flask body, so that the brewing and taste of beverages can be guaranteed when water is added next time. The opening / closing mechanism comprises a button, a first connecting rod, a second connecting rod, a first pressing rod, a second pressing rod and a rubber plug, wherein the button is connected with a push block; the push block is pressed against the lower portion of the outer end of the first connecting rod; the inner end of the first connecting rod is in hinge joint with the upper end of the first pressing rod; the lower end of the first pressing rod is in hinge joint with the outer end of the second connecting rod; the inner end of the second connecting rod is in hinge joint with the upper end of the second pressing rod; the rubber plug is fixed to the lower end of the second pressing rod; the second connecting rod is provided with a load bearing block; the first connecting rod and the second connecting rod are supported on a lid body via rotating shafts; the second connecting rod is located on the lower side of the first connecting rod. The opening / closing mechanism is characterized in that the side wall of the water outlet channel of the flask lid is provided with a buffer device which is pressed against the inner end of the second connecting rod.

Owner:WUXI FORMEN TECHN

Electric connector

InactiveCN1356745AHigh spring rateIncrease contact pressureCoupling contact membersClamped/spring connectionsEngineeringContact force

The present invention relates to an electrical connector which has a contact element, especially a socket contact point, and an additional spring element. Wherein the contact element has a contact zone formed by two contact legs and a bent spring area that applies a contact force to a mating contact element inserted into the contact zone, and the bent spring area connects to the legs. The additional spring element has two legs and a bridge which connects the legs. The contact force is increased through a simple and low-cost structure, that is the additional spring element is arranged relative to the contact element such that the stretching length of the additional spring element which is in the direction of the contact force is lager than the stretching length that is perpendicular to the contact force.

Owner:PHOENIX CONTACT GMBH & CO KG

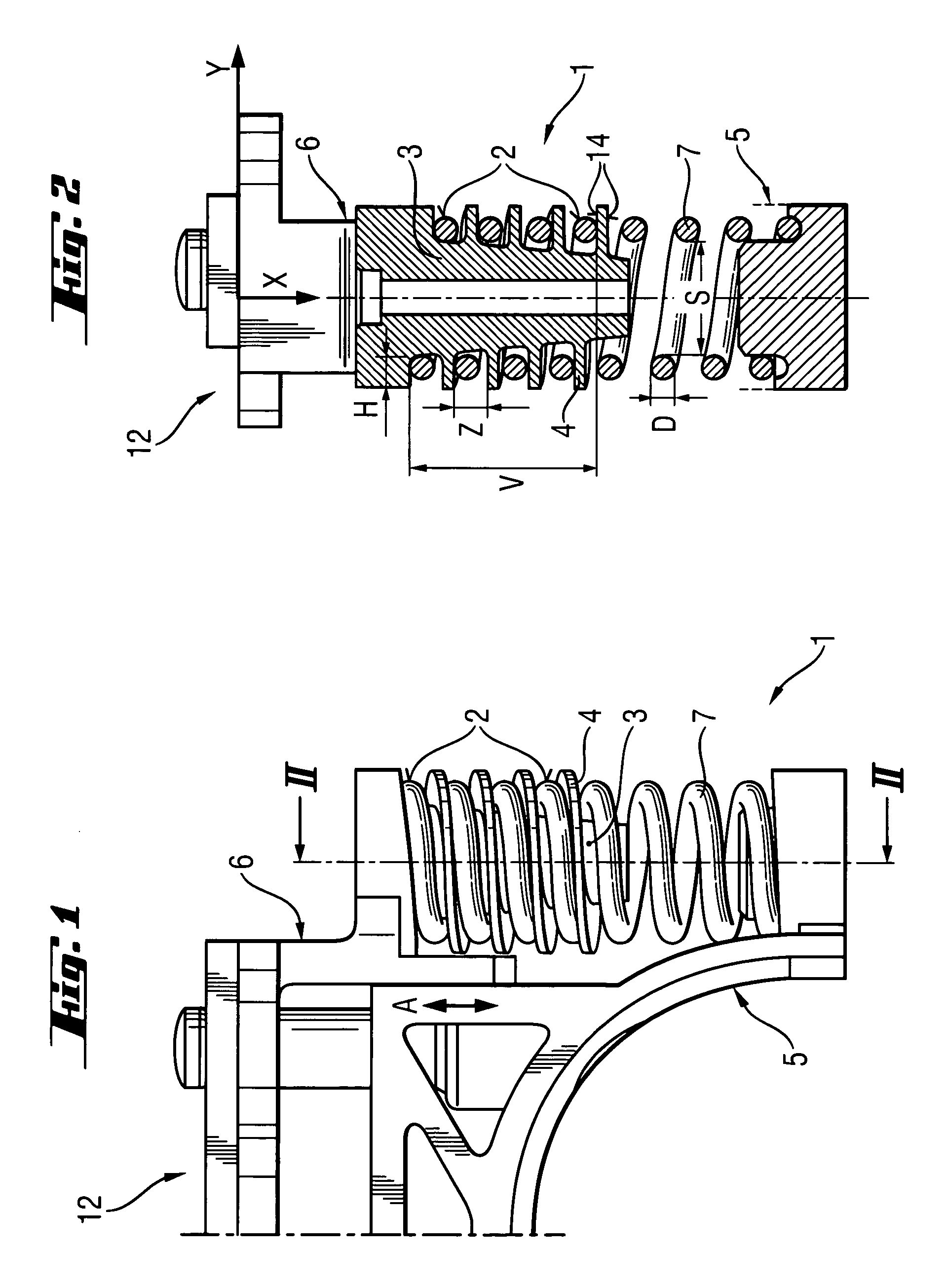

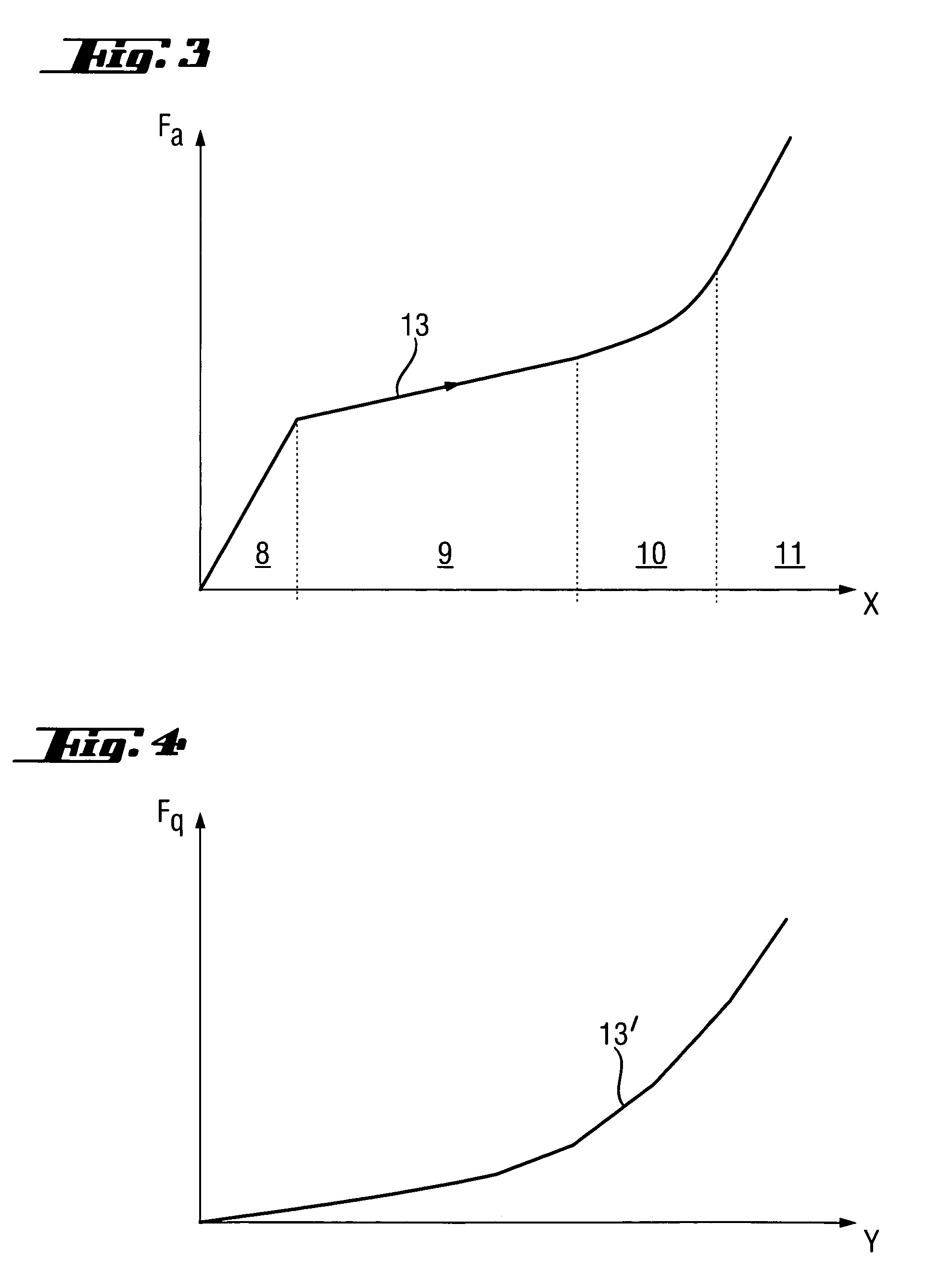

Vibrating hand-held power tool

InactiveUS8511658B2Increase the spring rateReduce the numberPortable framesPortable percussive toolsHand heldCoil spring

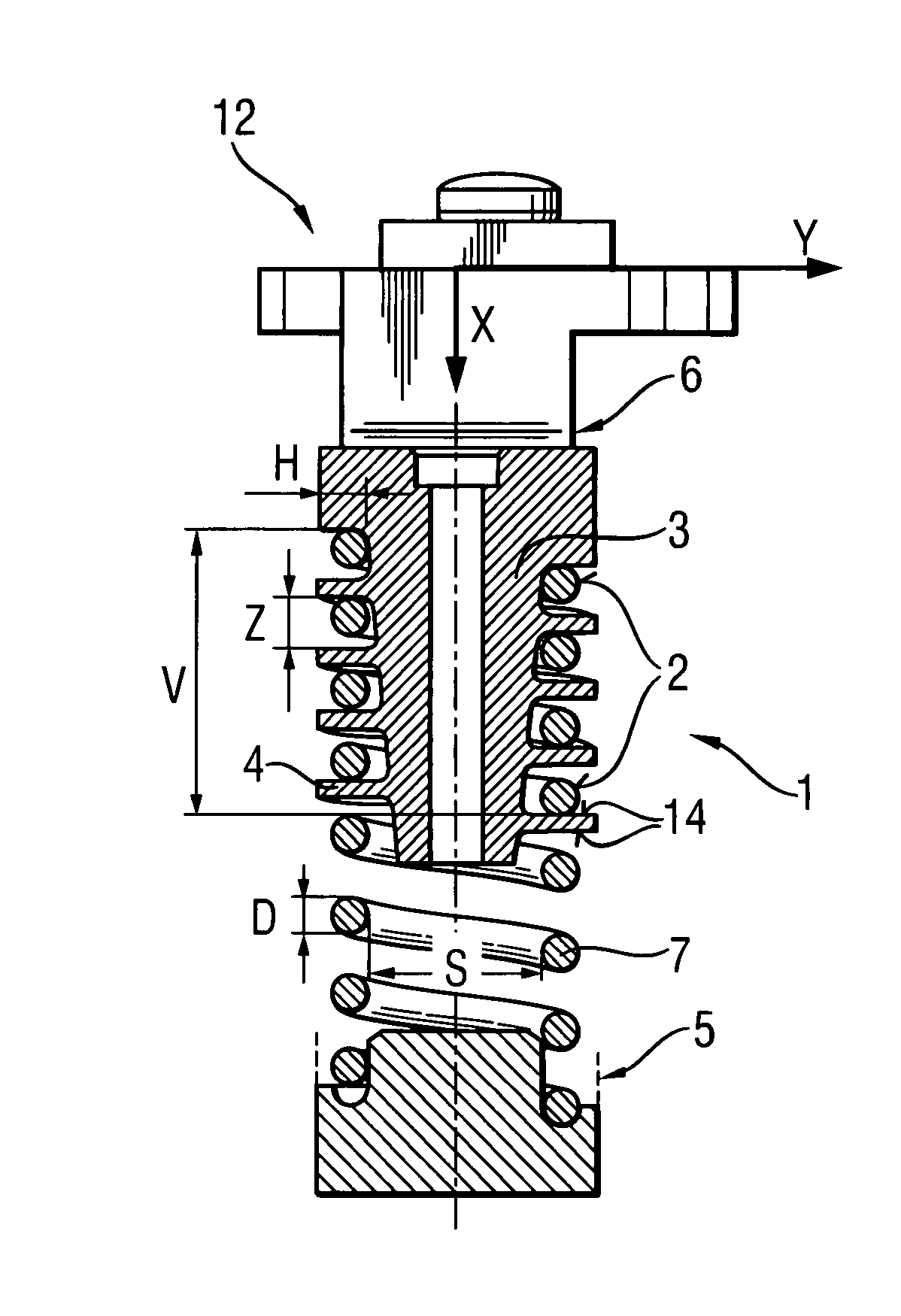

A hand-held power tool includes an antivibration element (1) for vibrationally decoupling a handle sub-assembly (6) from another sub-assembly (5) that vibrates along a vibration axis (A), and having a coil spring (7) oriented along the vibration axis (A), and a threaded plug (3) provided with an outer thread (4) longitudinally extending therealong, with the coil spring (7) having a plurality of windings (2) extending along a preload region (V) and screwed on the outer thread (4) under an axial compressive preload, and with the outer thread (4) having a between-flight width (Z) greater than a diameter (D) of the spring wire of which the coil spring (7) is formed.

Owner:HILTI AG

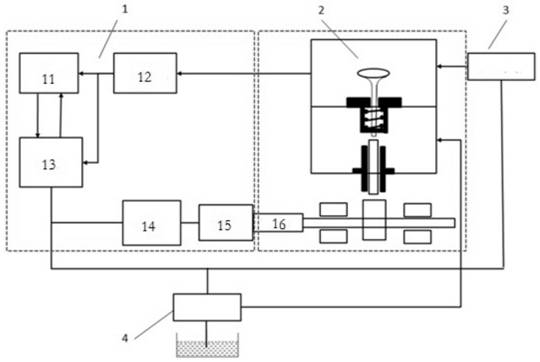

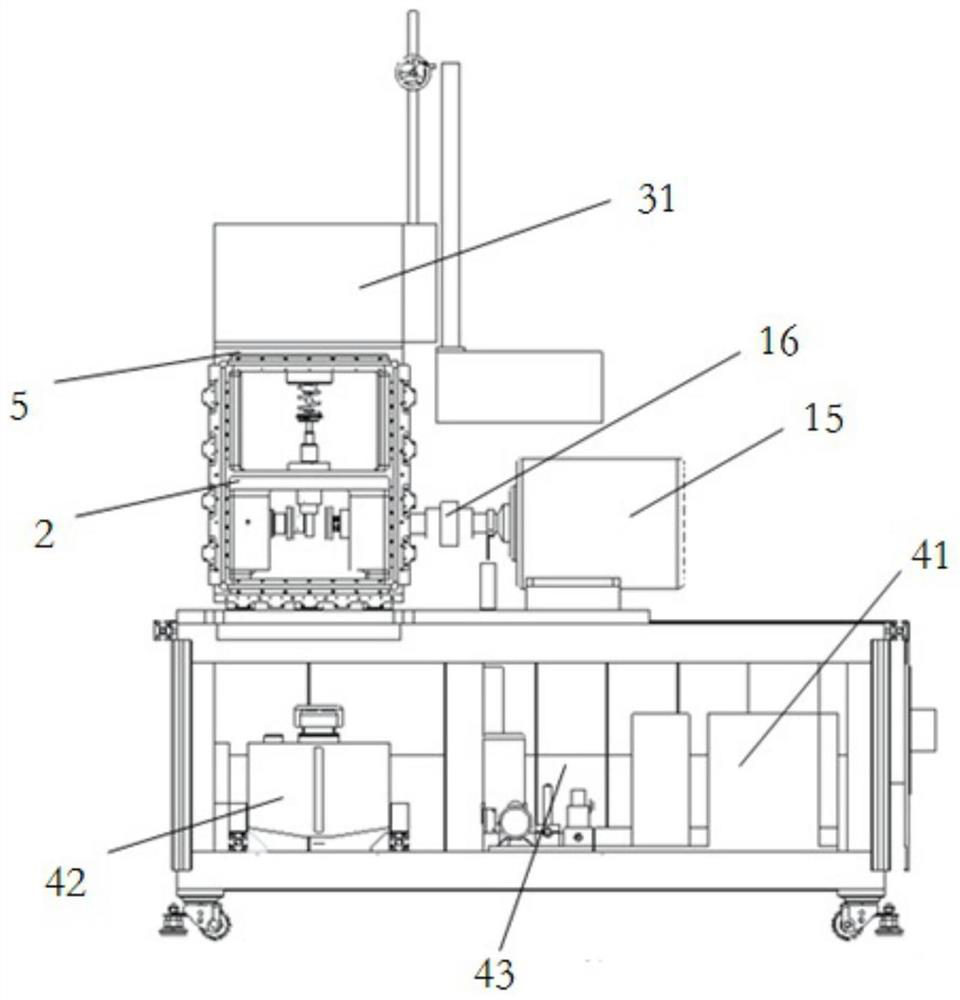

Enhanced wear test system with valve-valve seat ring

PendingCN112782017AIncrease seating forceIncrease preloadInvestigating abrasion/wear resistanceMatching testWorking temperature

The invention provides an enhanced wear test system with a valve-valve seat ring. The enhanced wear test system comprises a control system, a mechanical system, a heating system and a lubricating system. Compared with the prior art, the enhanced wear test system has the following advantages that the wear test system integrates a heating system, a lubricating system, a mechanical system and a control system, and mechanical load and thermal load can be simulated and loaded at the same time. An inverted valve-valve seat ring structure is adopted, the spring is strengthened, and the spring pre-tightening force and the spring rigidity are increased, so that the valve seating force is increased, the one-time abrasion test period is shortened to 7-10 hours, and the multi-scheme valve-seat ring matching test efficiency is greatly improved. A PLC is adopted to remotely control starting and stopping of the test bench, data acquisition and online monitoring of the operation state, man-machine separation is achieved, and the safety and reliability of the test process are improved. The resistance furnace capable of accurately controlling the heating temperature simulates a valve-seat ring working temperature field, so that a tested piece is in a high-temperature state in the whole test process.

Owner:CHINA NORTH ENGINE INST TIANJIN

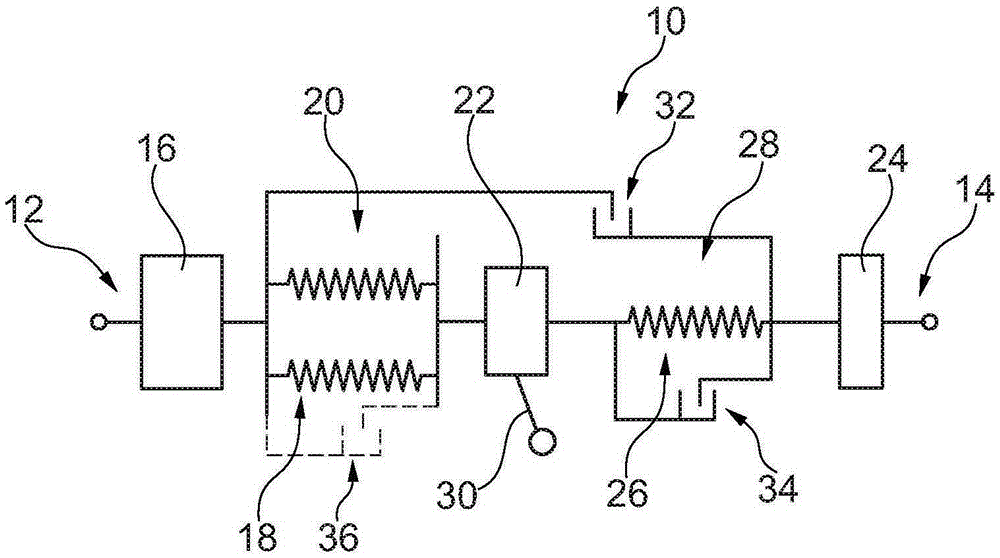

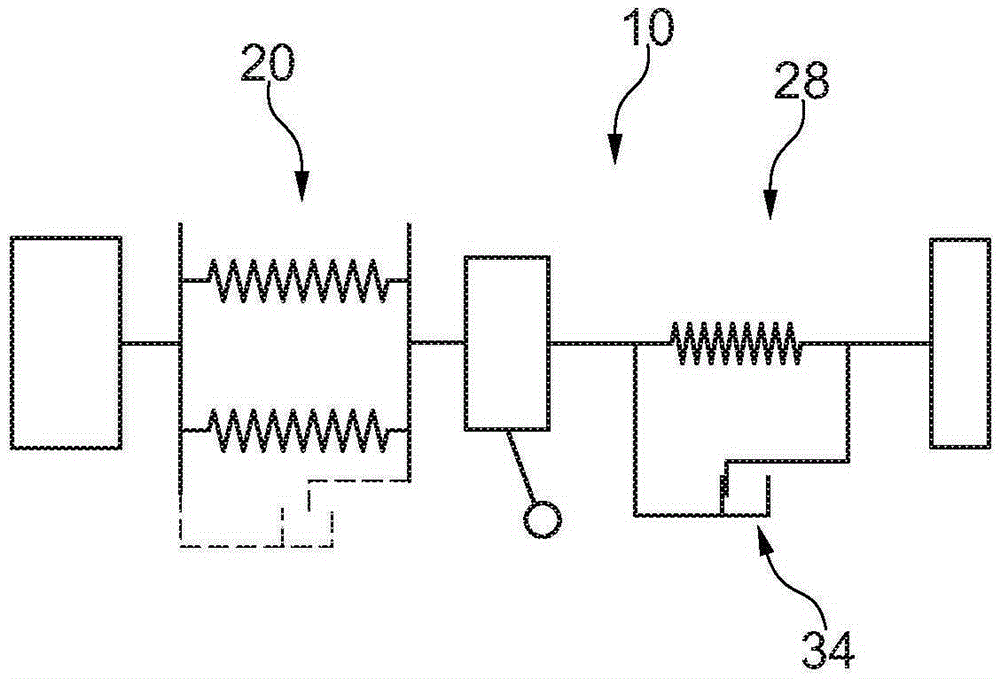

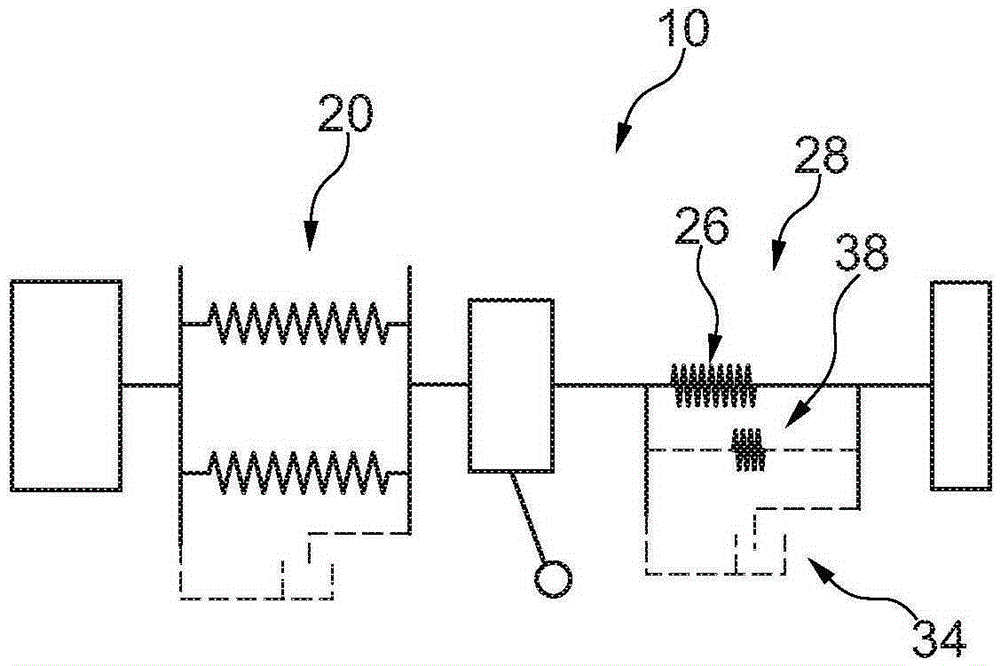

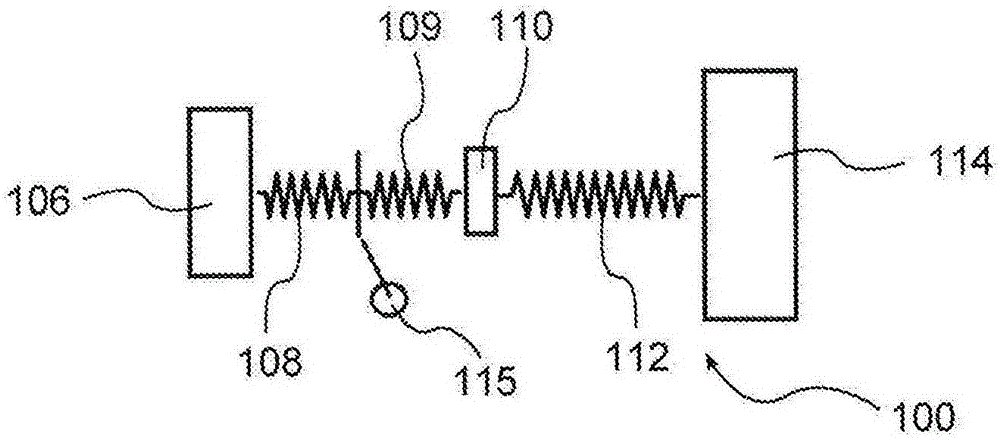

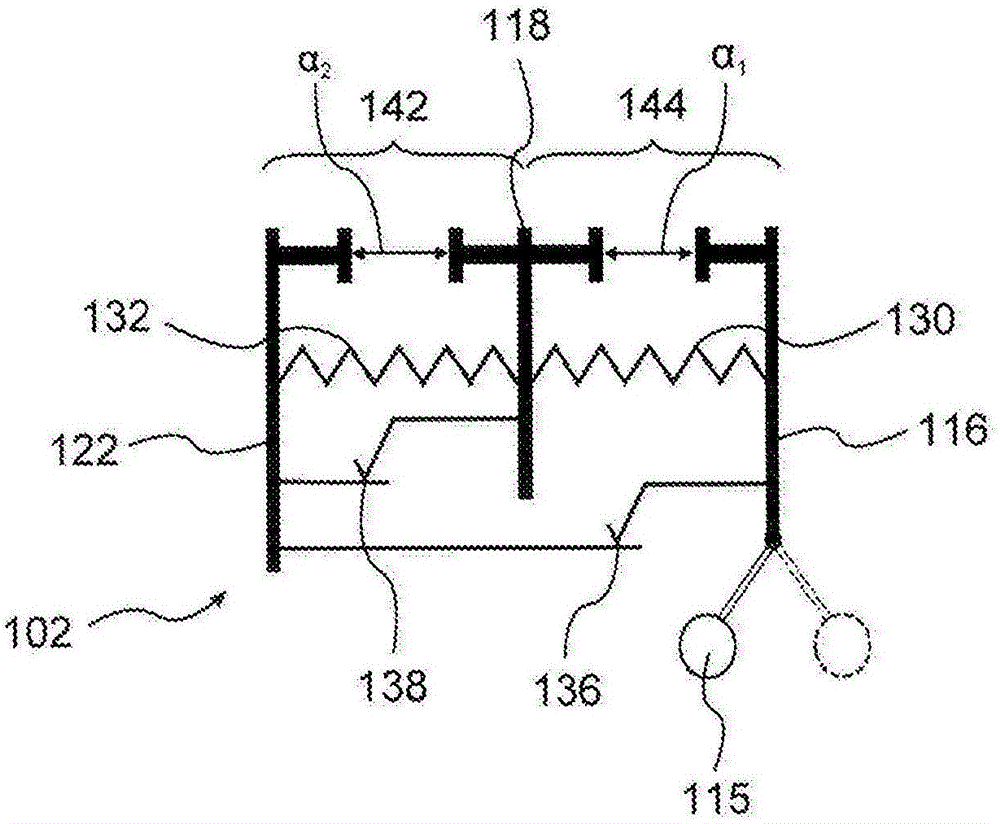

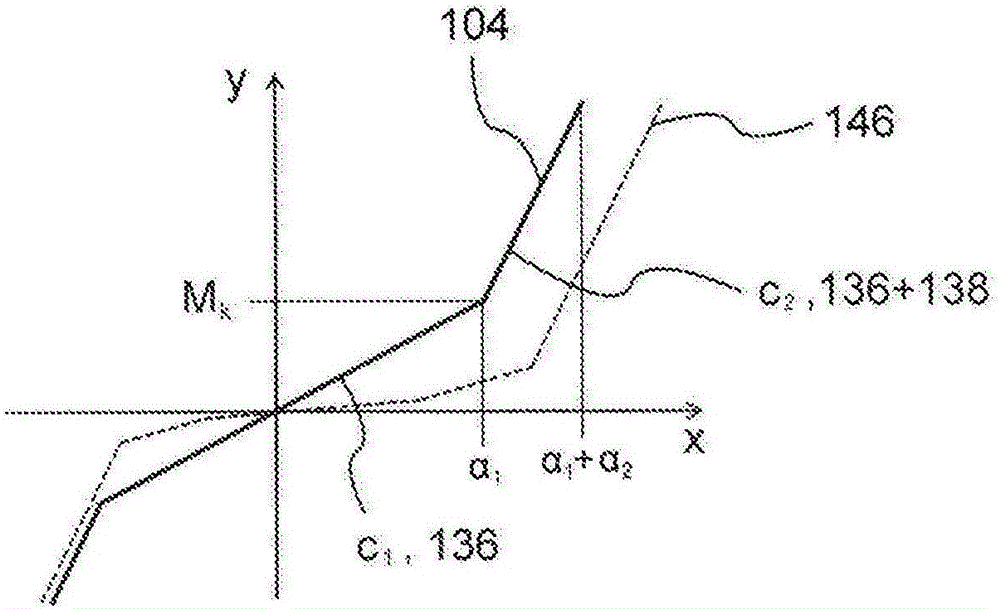

Damper device for a vehicle and method for designing a damper device

ActiveCN105209781ATo reverse the realizationIncrease the spring rateRotating vibration suppressionYielding couplingTorque transmissionDamper

The invention relates to a damper device, in particular a torsional vibration damper (11) for a vehicle, preferably for a torque transmission device (10) or a torque converter of a vehicle, for transmitting a torque between a drive side (12) and an output side (14) of the damper device, said damper device comprising: an input element (16), the rotation of which is restricted, in relation to an intermediate element (22) located downstream of the input element (16) in a torque transmission path, by the action of a first energy storage element (18), thus forming a first damping stage (20); and comprising an output element (24) located downstream of the intermediate element (22) in the torque transmission path, the rotation of said output element being restricted, in relation to the intermediate element (22), by the action of a second energy storage element (26), thus forming a second damping stage (28). The damper device, or the first damping stage (20) and / or the second damping stage (28) is or are designed such that the first damping stage and / or the second damping stage are substantially mechanically bypassed by means of a blocking action.

Owner:SCHAEFFLER TECH AG & CO KG

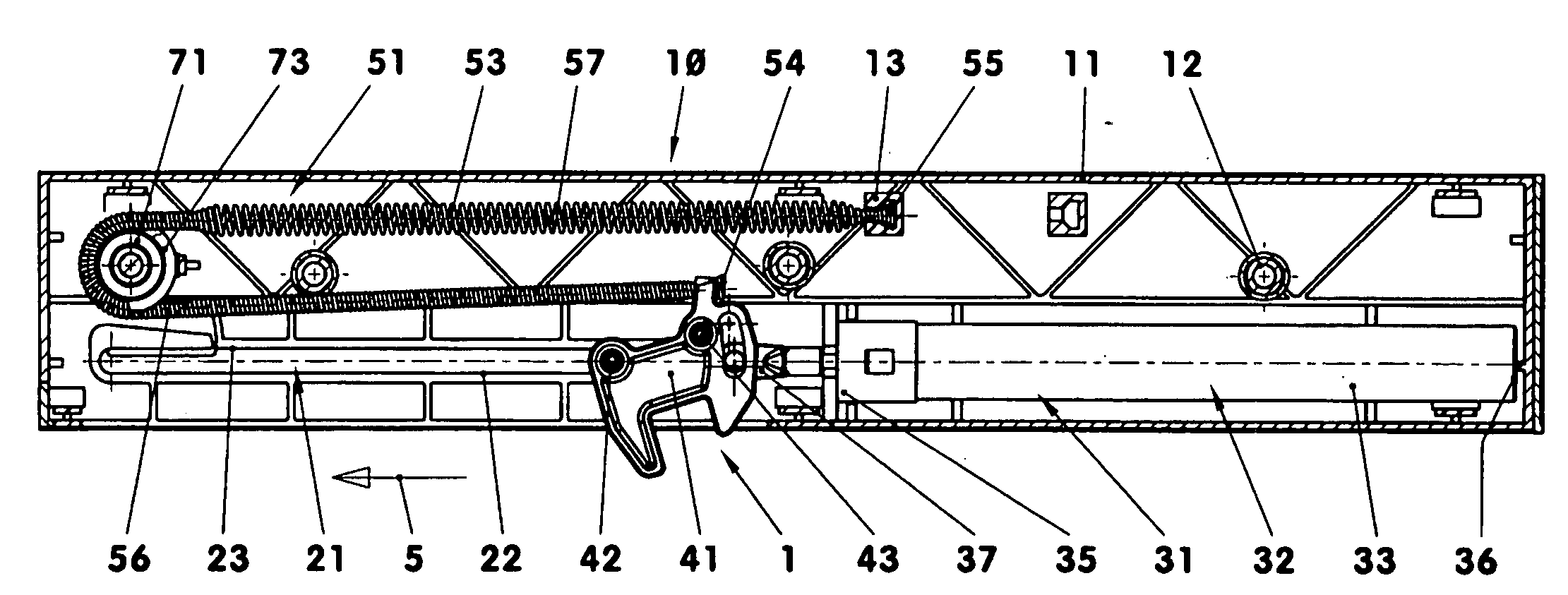

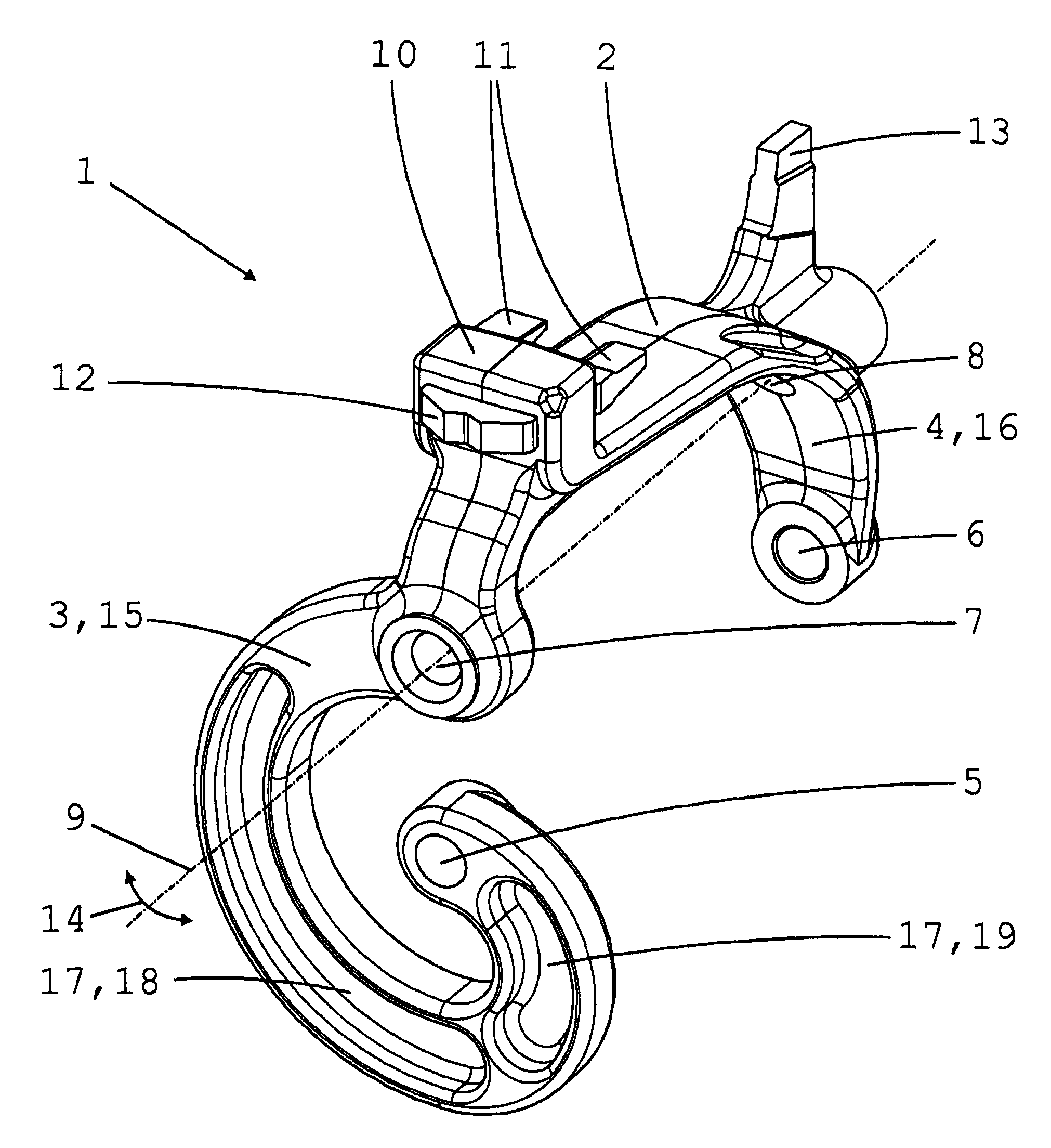

Shifting device for a manual transmission

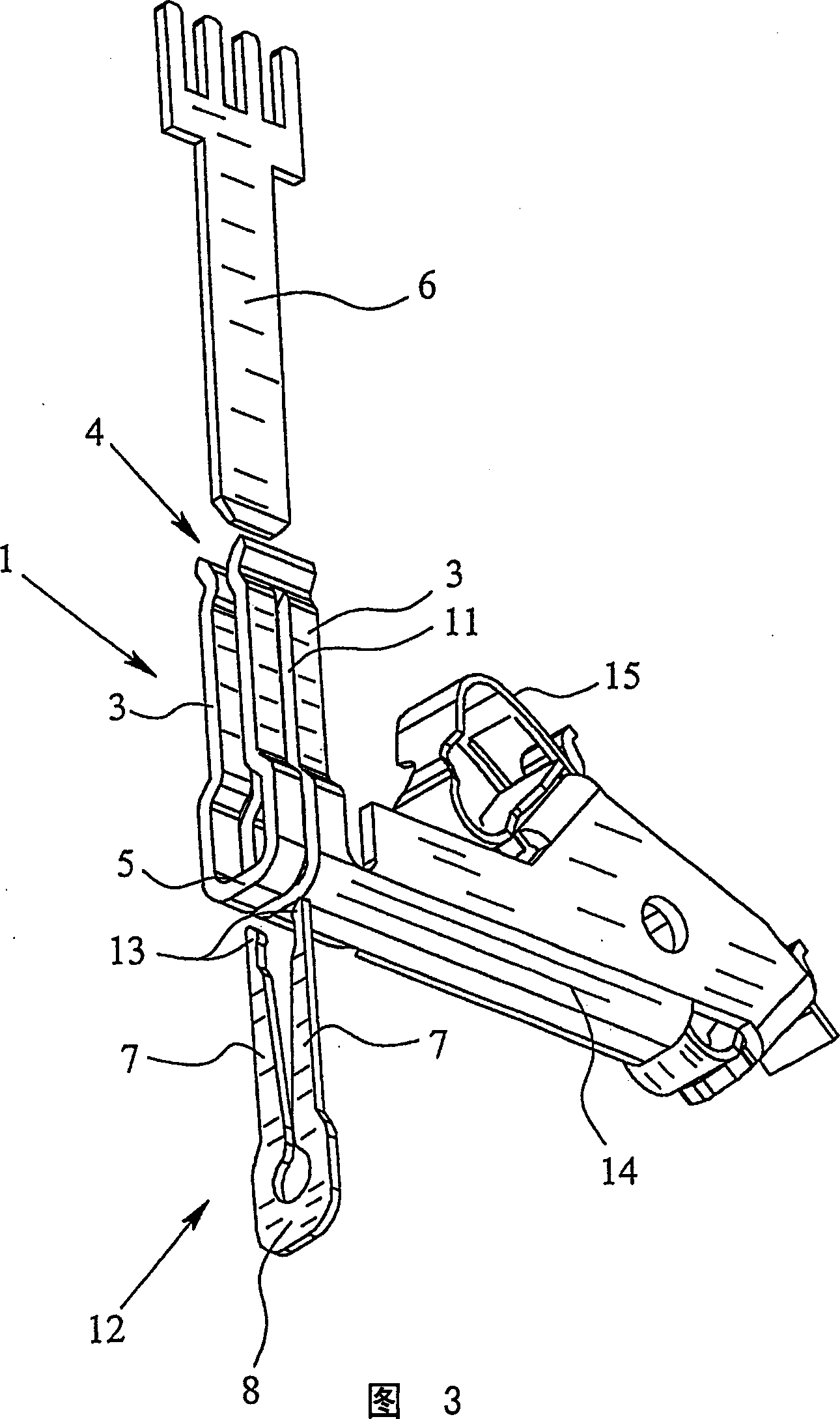

InactiveUS20100101354A1Reduce the spring rateProduced simply and inexpensivelyGearing controlWound springsTransverse axisEngineering

A shifting device for a manual transmission having a shift rocker formed by two rocker arms connected by a rocker bridge, which is arranged over a shift sleeve via two slide-blocks attached to a holder at the end of each rocker arm, which pivots about a transverse axis defined by bearing points. A carrier element is positioned off-center on the rocker bridge to engage with a shifting pin of a shifting shaft. The rocker arm closer to the carrier element has a lower elastic rigidity than the other rocker arm. To produce different spring rigidities, the rocker arm closer to the carrier element has the geometrical form of a spring element which is elastic in the pivoting direction. The, rocker arm farther away from the carrier element is a bracket with relatively greater elastic rigidity.

Owner:ZF FRIEDRICHSHAFEN AG

Clutch disk and friction clutch system

ActiveCN106461005AReduce friction and dampingIncrease the spring rateRotating vibration suppressionSpringsClutchDrive motor

The invention relates to a clutch disk (102) for a friction clutch system, particularly for a powertrain of an internal combustion engine-driven vehicle, said clutch disk (102) comprising a disk rotation axis; an input part (122), at least one intermediate part (118) and an output part (116), wherein the input part (122) and the at least one intermediate part (118) on one hand, and the at least one intermediate part (118) and the output part (116) on the other hand, can be rotated relative to each other to a limited extent; and a centrifugal force pendulum device (115) which is mounted on the output part (116), the clutch disk (102) having a characteristic line with a lower load range and an upper load range, and an increased spring stiffness being effective in the lower load range. The invention also relates to a friction clutch system, in particular for a powertrain of an internal combustion engine-driven motor vehicle, said friction clutch system comprising a clutch rotation axis, a housing, at least one pressure plate, at least one contact plate which can be axially moved relative to the pressure plate to a limited extent between an engaged actuation position and a disengaged actuation position for the purpose of actuation, and to at least one such clutch disk (102) which can be clamped between the at least one pressure plate and the at least one contact plate for frictional power transmission.

Owner:SCHAEFFLER TECH AG & CO KG

Micromechanical device including a stop spring structure

ActiveUS20210323809A1Reduce the spring rateIncrease the spring rateAcceleration measurement using interia forcesMovable microstructural devicesEngineeringMicromachinery

A micromechanical device including a substrate, a movable mass, and a stop spring structure, which includes a stop. The substrate includes a substrate surface in parallel to a main extension plane and the movable mass is situated movably above the substrate surface in relation to the substrate. The stop spring structure is connected to the movable mass. The stop is designed to strike against the substrate surface in the event of a deflection of the movable mass in a z direction, perpendicular to the main extension plane. The stop spring structure, at the location of the stop, includes a first spring constant, a second spring constant, in parallel to the main extension plane, and a third spring constant, in parallel to the main extension plane and perpendicular to the x direction. The first spring constant is greater than the second spring constant and / or is greater than the third spring constant.

Owner:ROBERT BOSCH GMBH

Machine tools including punching units and laser processing units

ActiveCN106563947BAvoid negative effectsIncrease the spring rateWelding/cutting auxillary devicesOther manufacturing equipments/toolsLaser processingPunching

A machine tool for machining workpieces comprising a support structure, a punching device mounted on the support structure, and a laser machining device mounted on the support structure. The machine tool includes a suspension device provided between the punching device and the laser machining device to reduce the laser machining device from being stimulated to move unintentionally due to the operation of the punching device. The suspension device has a spring rate which can be adjusted by a laser positioning device. The laser positioning device can move the laser machining device relative to the workpiece into a functional position and also into a position remote from the functional position. The spring rate of the suspension device is adjusted such that the functional position of the laser machining device is assigned a higher spring rate than that assigned to the position of the laser machining device remote from the functional position.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

Damping Valve For A Vibration Damper

ActiveUS20190301558A1Easy constructionAvoid knocking noiseSpringsShock absorbersVibration damperValve seat

A damping valve for a vibration damper includes a damping valve body with a through-channel whose outlet opening is at least partially closed by at least one elastically deformable valve disk. A further valve element is associated with the valve disk. This further valve element predetermines a defined lift behavior for the valve disk proceeding from a valve seat surface. The further valve element is formed by an elastic coating of the valve disk that exerts a varying supporting force with respect to the valve disk via the configuration of the top surface of the valve disk.

Owner:ZF FRIEDRICHSHAFEN AG

Shifting device for a manual transmission

InactiveUS8210067B2Great spring elasticityReduced cross sectionGearing controlWound springsTransverse axisEngineering

A shifting device for a manual transmission having a shift rocker formed by two rocker arms connected by a rocker bridge, which is arranged over a shift sleeve via two slide-blocks attached to a holder at the end of each rocker arm, which pivots about a transverse axis defined by bearing points. A carrier element is positioned off-center on the rocker bridge to engage with a shifting pin of a shifting shaft. The rocker arm closer to the carrier element has a lower elastic rigidity than the other rocker arm. To produce different spring rigidities, the rocker arm closer to the carrier element has the geometrical form of a spring element which is elastic in the pivoting direction. The, rocker arm farther away from the carrier element is a bracket with relatively greater elastic rigidity.

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com