Manufacturing method of three-dimensional woven composite material hollow spiral spring

A helical spring and three-dimensional weaving technology, applied in the direction of coating, etc., can solve problems such as short life, poor impact resistance, and mismatching mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention provides a method for manufacturing a three-dimensional braided composite material hollow coil spring, which is described in a preferred embodiment, which includes the following steps:

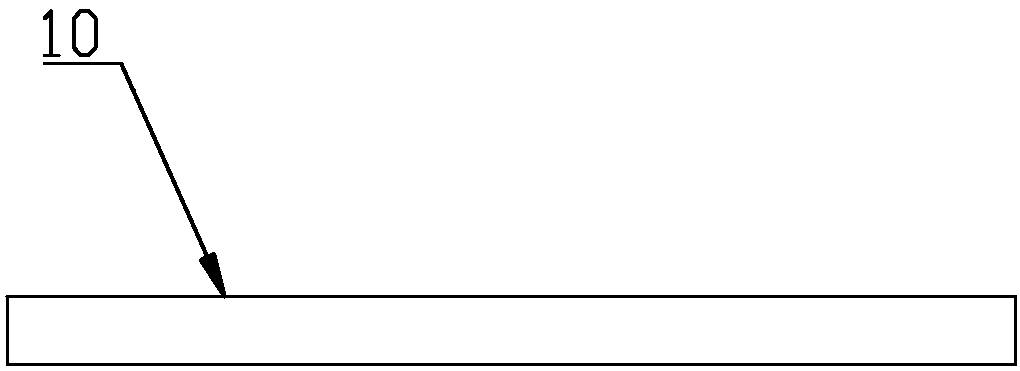

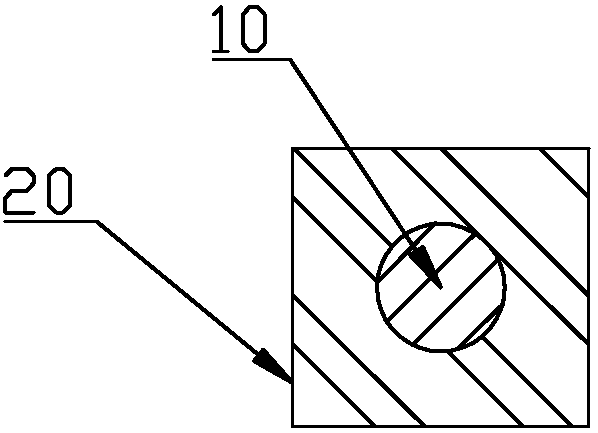

[0045] One, use carbon fiber, glass fiber, aramid fiber, super strong polyethylene fiber, silicon carbide fiber or silicon nitride fiber and other spinnable and braidable fibers, with a strip-shaped low-melting point alloy as the mandrel 10, in the mandrel 10 A three-dimensional braided tube 20 is braided on the outer surface with a three-dimensional braiding process, and the mandrel 10 and the three-dimensional braided tube 20 form a strip-shaped preform; as figure 1 , figure 2 As shown, in this embodiment, the outer section of the strip-shaped preform is square, and the inner section is circular (the shape is not limited);

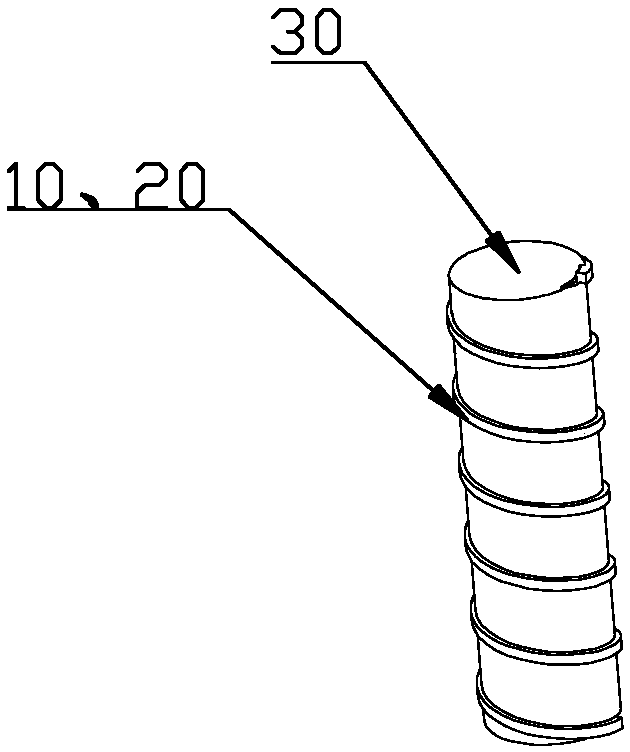

[0046] Two, such as image 3 As shown, the strip-shaped preform is wound onto the inner mold 30, wherein the inner mold 30 is cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com