An opening/closing mechanism of a vacuum flask lid

A technology of opening and closing structure and pot lid, which is applied in the direction of boiling water utensils and cooking utensil lids, etc. It can solve the problems of lowering the water temperature and affecting the brewing and taste of drinks, so as to avoid mutual jamming, ensure brewing and taste, The effect of increasing spring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

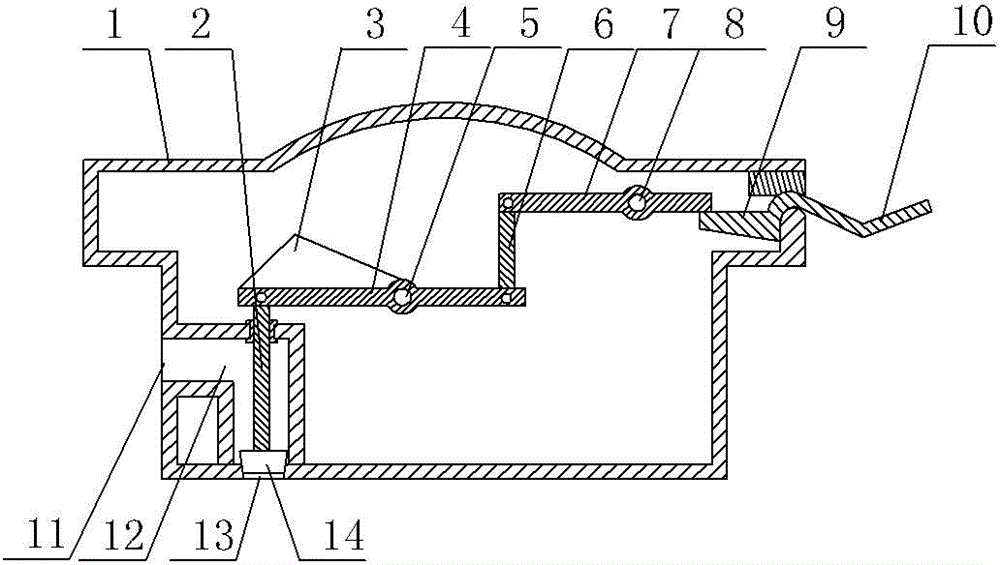

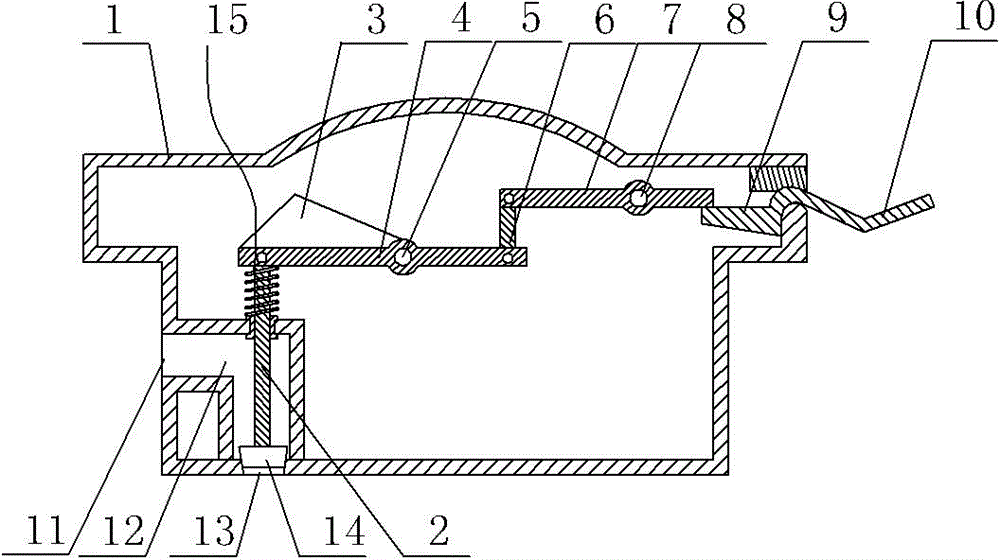

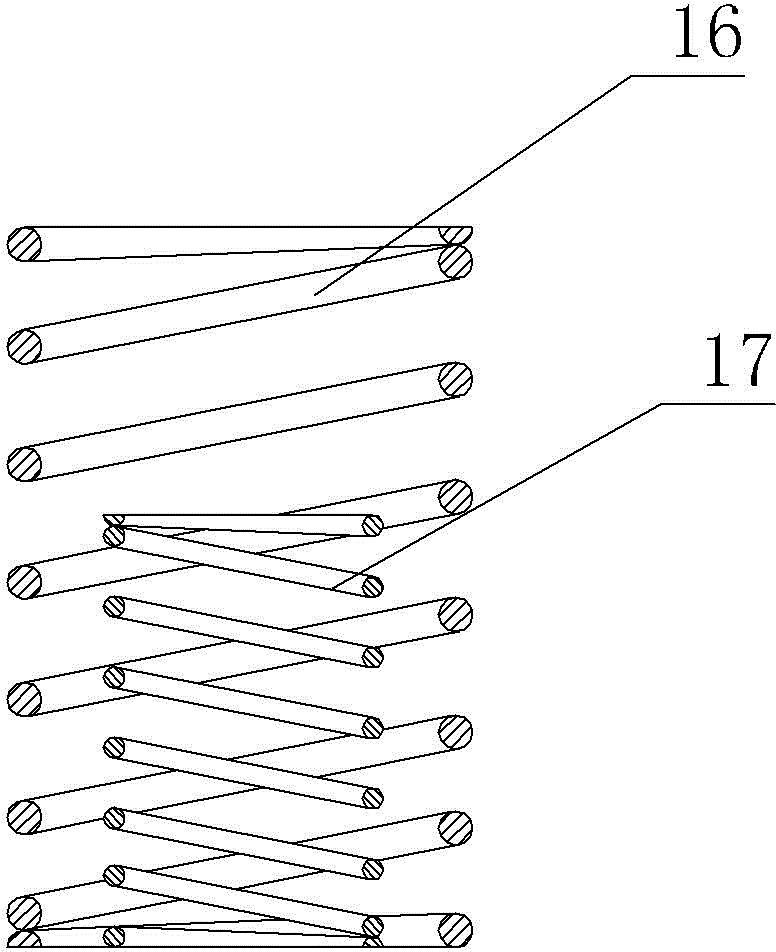

[0012] like Figure 2 to Figure 3 As shown, the pot lid 1 is provided with a water outlet channel 12 communicating with the inner tank of the kettle body and the spout, and an opening and closing mechanism for opening and closing the water outlet channel 12. The upper end of the water outlet channel 12 is provided with a water outlet connected to the spout. 11. Its lower end is provided with a water inlet 13 communicating with the inner tank of the pot body. The opening and closing mechanism includes a button 10, a first connecting rod 7, a second connecting rod 4, a first pressing rod 6, a second pressing rod 2 and a rubber plug 14. The button 10 is connected to the shift block 9, and the shift block 9 abuts against the lower part of the outer end of the first connecting rod 7, the inner end of the first connecting rod 7 is hinged with the upper end of the first pressing rod 6, and the lower end of the first pressing rod 6 is connected to the lower end of the first pressing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com