High-performance chlorine-free alkali-free liquid accelerating agent

A liquid quick-setting agent, high-performance technology, used in the field of concrete quick-setting agent, chlorine-free and alkali-free liquid quick-setting agent, can solve the problems of poor material compatibility, high production cost, strong corrosion, etc., to achieve long storage period , The effect of low production cost and low rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

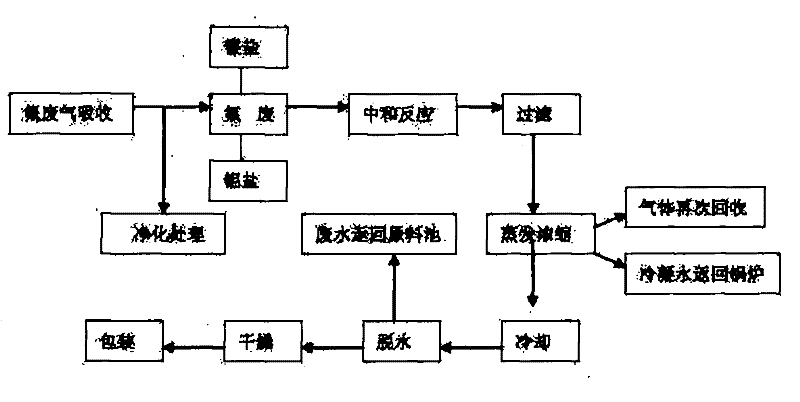

Method used

Image

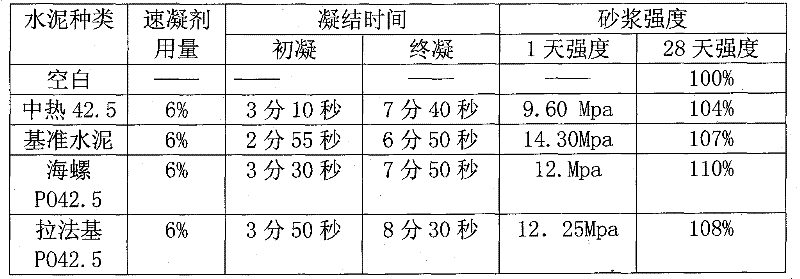

Examples

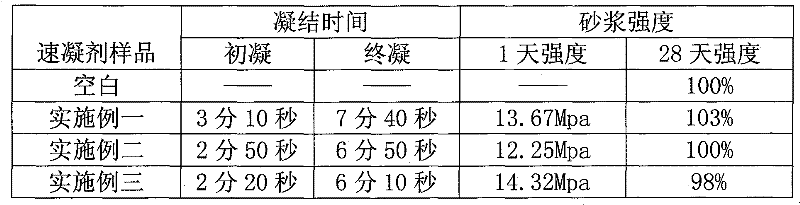

Embodiment 1

[0022] Embodiment one: to produce 1000kg of high-performance chlorine-free and alkali-free liquid accelerator, 500kg of water, 150kg of magnesium aluminum fluoride, 300kg of aluminum sulfate, and 50kg of monoethanolamine are needed; production steps: 500kg of water is added to the mixing tank, and 150kg of fluorine is added Stir and dissolve magnesium and aluminum, add 50kg of monoethanolamine, and add 300kg of aluminum sulfate while stirring, and stir until dissolved to obtain the finished product.

Embodiment 2

[0023] Embodiment two: produce 500kg of high-performance chlorine-free and alkali-free liquid quick-setting agent, need water 285kg, magnesium aluminum fluoride 100kg, aluminum sulfate 100kg, diethanolamine 15kg; Production step is with embodiment one.

Embodiment 3

[0024] Embodiment three: produce 1000kg of high-performance chlorine-free and alkali-free liquid quick-setting agent, need water 440kg, magnesium aluminum fluoride 100kg, aluminum sulfate 400kg, diethanolamine 50kg, phosphoric acid 10kg; Production step: 440kg water is added in the mixing tank, Add 100kg of magnesium aluminum fluoride and stir to dissolve, add 50kg of diethanolamine, add 400kg of aluminum sulfate while stirring, stir until dissolved, and then add 10kg of phosphoric acid as a stabilizer to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com