Alkali-free liquid setting accelerator for shotcrete and preparation method thereof

A technology of sprayed concrete and accelerator, applied in the field of building materials, can solve the problems of high alkali content, strong corrosion, strength loss, etc., and achieve the effects of low rebound rate, stable performance and small dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

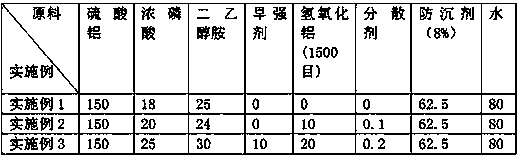

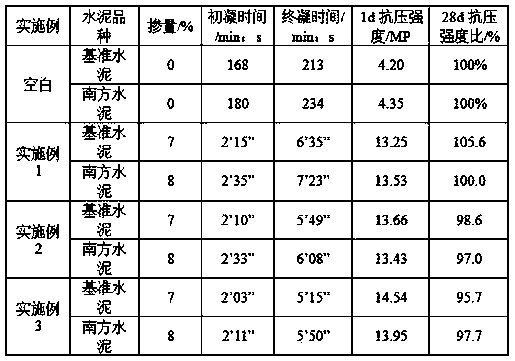

Embodiment 1

[0025] A kind of non-alkali liquid quick-setting agent for shotcrete, the weight ratio of each raw material is as shown in table 1, wherein aluminum sulfate contains the industrial grade aluminum sulfate of eighteen crystal waters, the mass percentage of aluminum oxide ≥ 15.8%; The regulator is concentrated phosphoric acid, industrial grade, with a mass percentage ≥ 85%; aluminum hydroxide is activated aluminum hydroxide with a mesh number of 1500; alcohol amine is diethanolamine; dispersant is polycarboxylate water reducer; early strength agent It is sodium nitrate; the anti-sedimentation agent is hydrated magnesium silicate colloid with a mass content of 8%.

[0026] The preparation method of the alkali-free liquid quick-setting agent for shotcrete specifically comprises the following steps:

[0027] (1) Weigh each raw material according to the weight ratio;

[0028] (2) First add water to the four-necked flask, start stirring, add dispersant, anti-sedimentation agent and a...

Embodiment 2

[0034] A kind of non-alkali liquid quick-setting agent for shotcrete, the weight ratio of each raw material is as shown in table 1, wherein aluminum sulfate contains the industrial grade aluminum sulfate of eighteen crystal waters, the mass percentage of aluminum oxide ≥ 15.8%; Regulator is concentrated phosphoric acid, industrial grade, mass percentage ≥ 85%; aluminum hydroxide is activated aluminum hydroxide with a mesh number of 1500; alcohol amine is triethanolamine; dispersant is polycarboxylate water reducer; early strength agent It is calcium formate; the anti-settling agent is hydrated magnesium silicate colloid with a mass content of 8%.

[0035] The preparation method of the alkali-free liquid quick-setting agent for shotcrete specifically comprises the following steps:

[0036] (1) Weigh each raw material according to the weight ratio;

[0037] (2) First add water to the four-necked flask, start stirring, add dispersant, anti-sedimentation agent and acid regulator ...

Embodiment 3

[0043] A kind of non-alkali liquid quick-setting agent for shotcrete, the weight ratio of each raw material is as shown in table 1, wherein aluminum sulfate contains the industrial grade aluminum sulfate of eighteen crystal waters, the mass percentage of aluminum oxide ≥ 15.8%; The regulator is concentrated phosphoric acid, industrial grade, with a mass percentage ≥ 85%; aluminum hydroxide is activated aluminum hydroxide with a mesh number of 1500; alcohol amine is diethanolamine; dispersant is polycarboxylate water reducer; early strength agent It is calcium formate; the anti-settling agent is hydrated magnesium silicate colloid with a mass content of 8%.

[0044] The preparation method of the alkali-free liquid quick-setting agent for shotcrete specifically comprises the following steps:

[0045] (1) Weigh each raw material according to the weight ratio;

[0046] (2) First add water to the four-necked flask, start stirring, add dispersant, anti-sedimentation agent and acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com