Heat sink assembly and connecting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

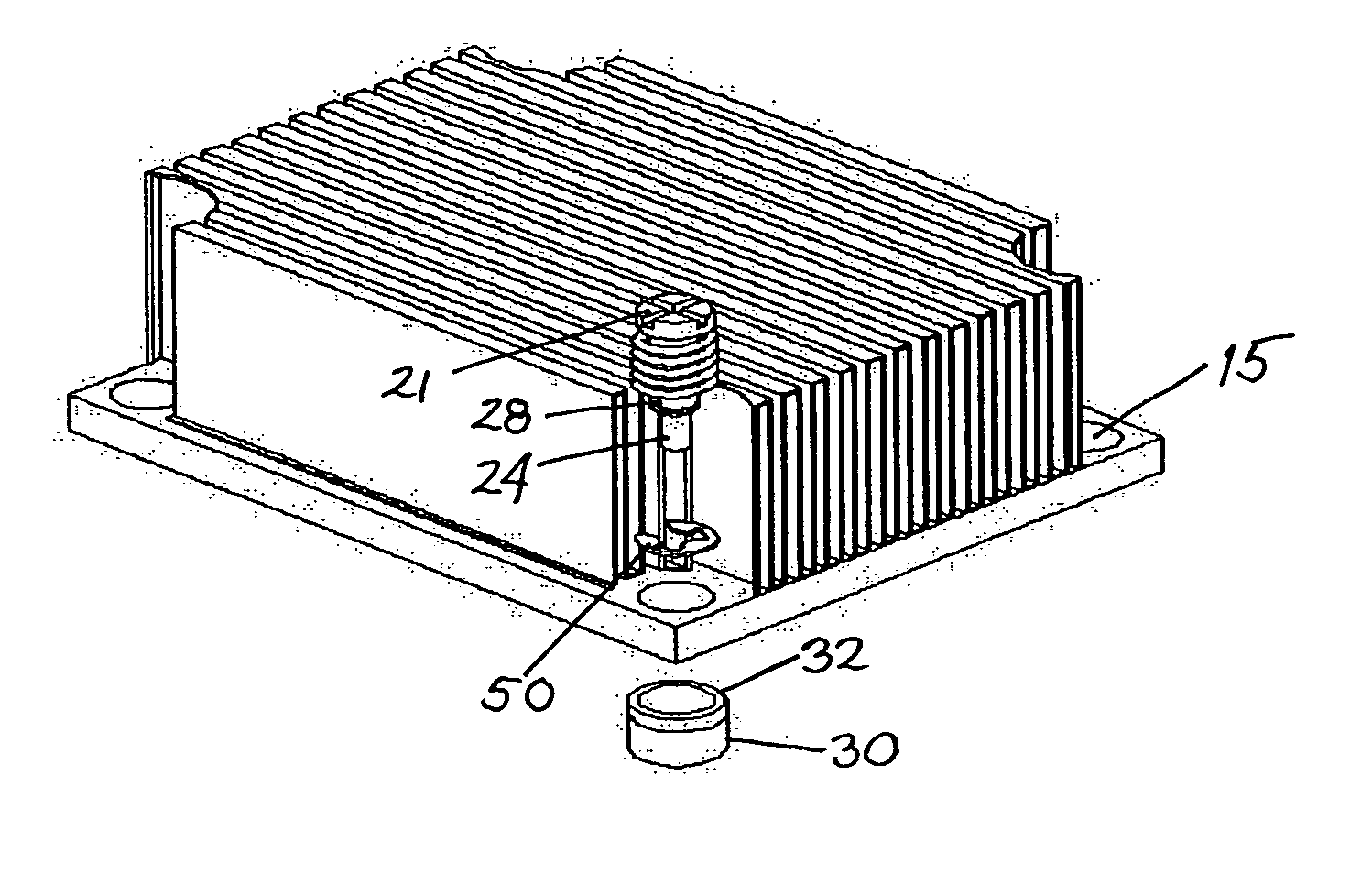

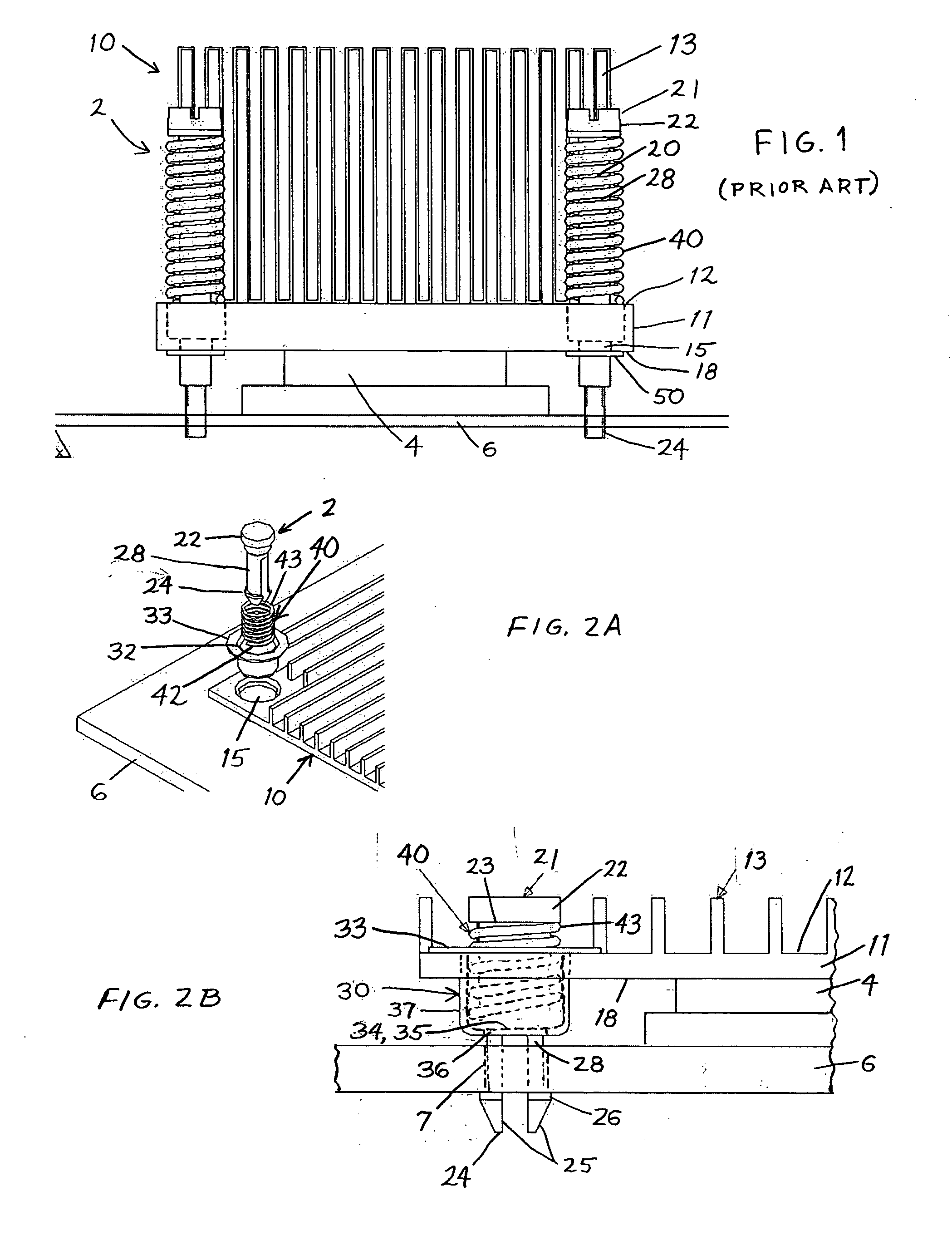

[0024]FIGS. 2A and 2B show connecting device 2 for fastening a heat sink 10 against an electronic device 4 mounted to a printed circuit board 6. The heat sink 10 includes a base plate 11 having a top surface 12 provided with fins 13 which are interrupted around a mounting aperture 15. The opposed bottom surface 18 is received against the electronic device 4. The heat sink is preferably made of aluminum, copper, graphite, or thermally conductive plastic, and may be extruded, machined, cast, or molded.

[0025] The connecting device 2 includes a mechanical fastener 20, a cup member 30, and a spring 40. The mechanical fastener 20 has a first end 21, a second end 24, and a shank 28 extending between said ends. The first end 21 is provided with a head 22 which forms a shoulder 23 facing the second end 25. The second end 24 is provided with resilient mounting prongs 25 having barbs 26 which engage the printed circuit board 6. The fastener may be made of steel, brass, or aluminum, but may als...

second embodiment

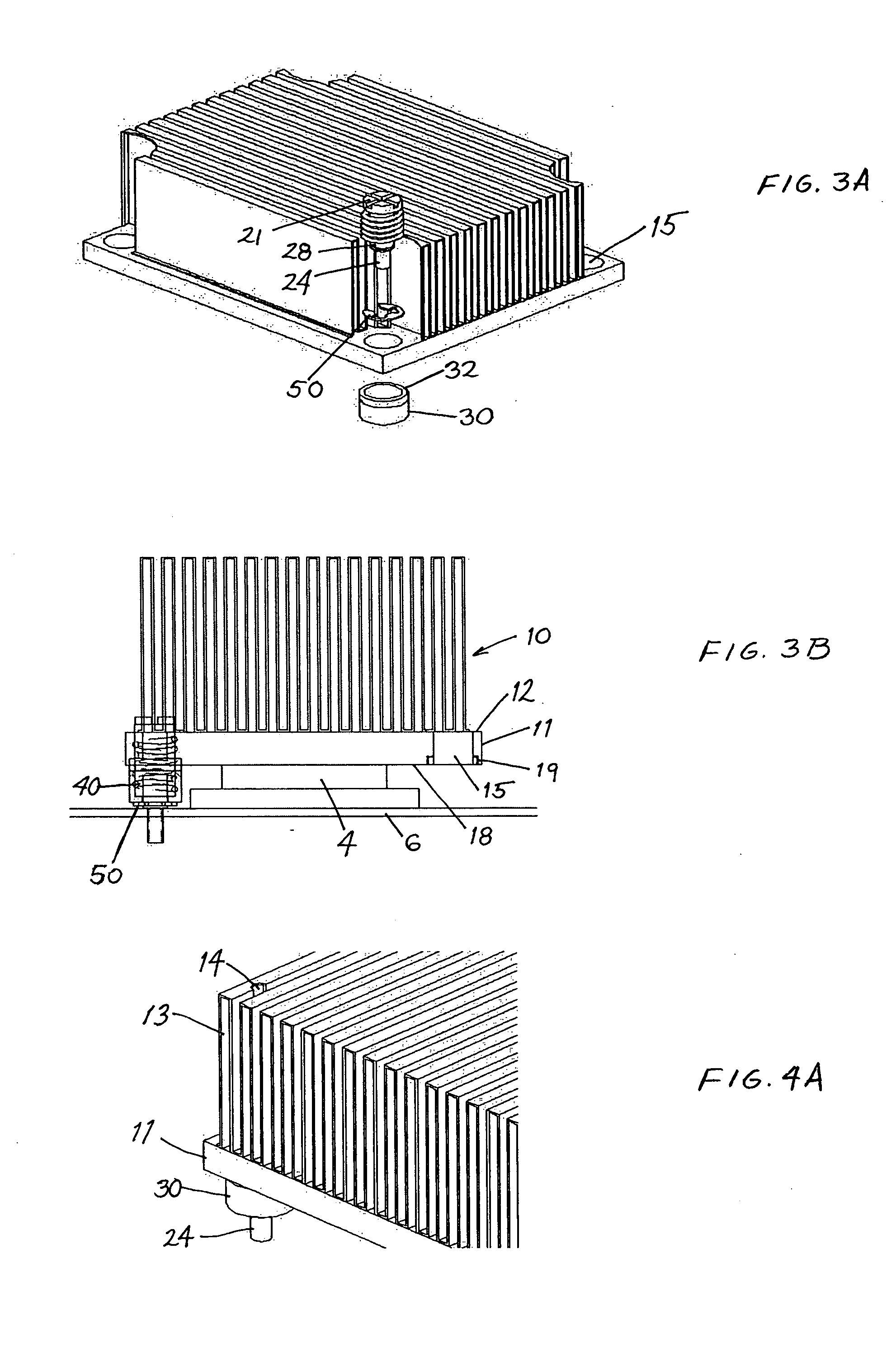

[0029]FIGS. 3A and 3B show the connecting device 2, wherein the cup member 30 is not provided with a flange around the lip 32. Rather, the bottom surface 18 of the heat sink base plate 11 is provided with a countersink 19 around the aperture 15, and the lip 33 is fit into the countersink 19. Alternatively, the cylindrical wall 37 of the cup member 30 may be provided with a shoulder which limits travel in aperture 15 in the base plate 11. The cup member 30 may be press fit, threaded, soldered, brazed, glued, or otherwise attached to the bottom surface of the base plate. The features of the fastener 20 and spring 40 are essentially as described in conjunction with the embodiment of FIGS. 2A and 2B. A retainer 50 in the form of a C-clip is provided to hold the fastener 20, cup member 30, and spring 40 together as a unit which may be pre-assembled to the heat sink 10 prior to assembling to the PCB 6.

third embodiment

[0030]FIGS. 4A and 4B show connecting device which is substantially similar to the second embodiment, but modified for use with an alternative printed circuit board 6 having an aperture 15 which is substantially closed at the top surface 12. Here the shank 28 and spring 40 are somewhat shorter than in the connecting device used with the heat sink 10 of FIGS. 2A and 2B. The first end 21 of the fastener is located in a pocket below the top surface and accessible only via an access hole 16 located centrally of the aperture 15. The advantage here, is that the heat sink fins 13 need not be interrupted above the connector, which can be accessed by a tool received between the fins 13. The fins may, however, be provided with at least one notch 14 to provide sufficient clearance for the tool, which may be a hex key.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com