Cork solid wood flooring and manufacturing method thereof

A technology for solid wood flooring and a manufacturing method, which is applied in the direction of manufacturing tools, treatment details of cork, wood compression, etc. Improved weather resistance, reduced hygroscopicity and internal stress, and improved dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: a kind of manufacture method of solid wood floor, is example with cork poplar floor manufacture method, it comprises the following steps successively:

[0048] (1) Wood making step: by the method of making wood by the poplar cork raw material, make the poplar cork floor blank that is 600mm long, 110mm wide, and 25mm thick;

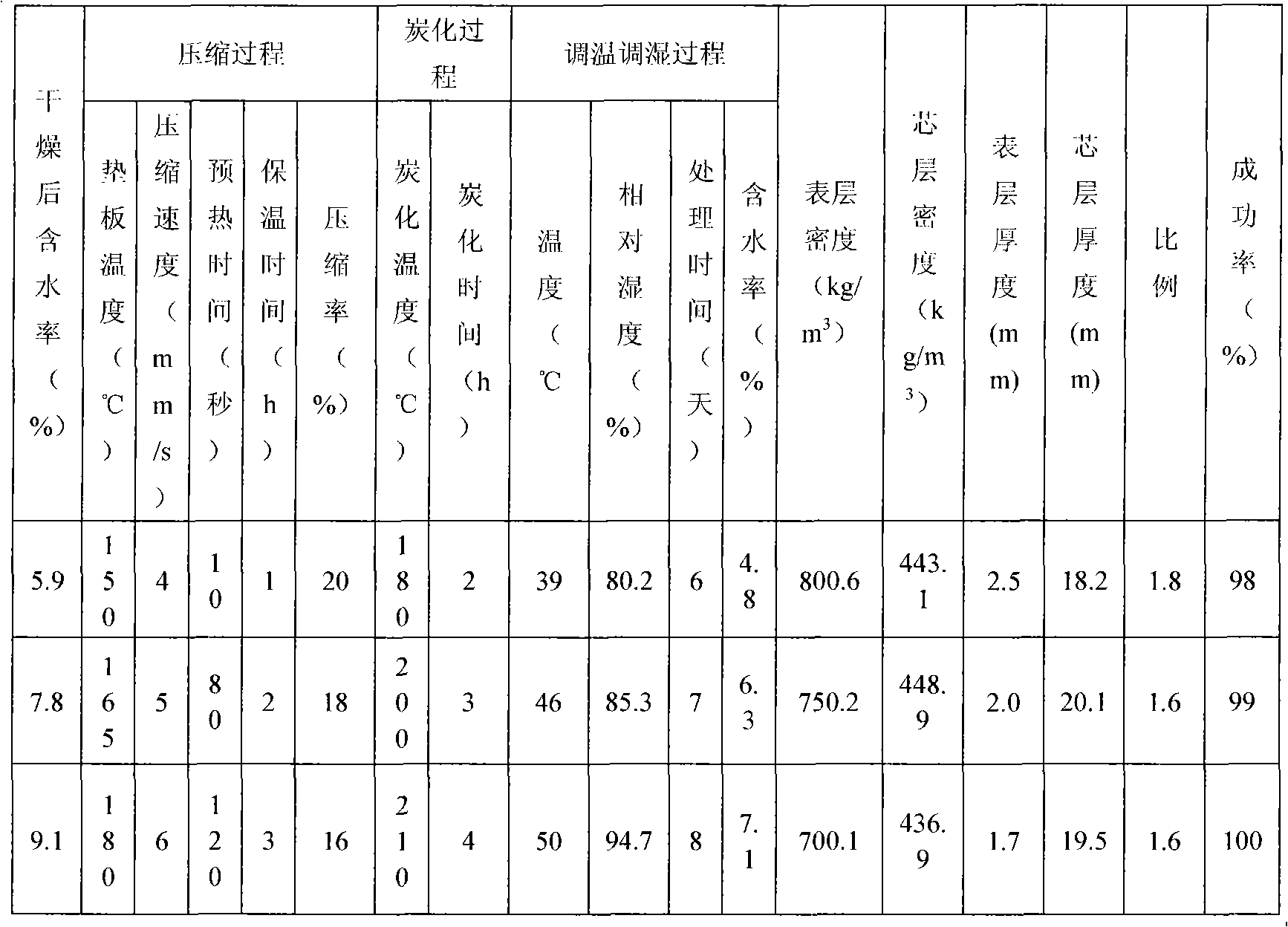

[0049] (2) Drying step: by drying the poplar cork floor blank, the dried poplar cork floor blank whose moisture content is reduced to a suitable value (see Table 1 for specific values) is obtained;

[0050] (3) Polishing step: carry out four-sided planing by the dry poplar cork floor blank by a four-side planer machine tool, and make a four-side polished dry poplar cork floor blank with a thickness of 20mm;

[0051] (4) Improvement step: the improved blank is obtained by functional improvement of the dry floor blank of poplar wood with four sides polished, and the functional improvement is wood compression carbonization method; the des...

Embodiment 2

[0059] Embodiment 2: a kind of manufacture method of solid wood floor, is example with cork fir floor manufacture method, it comprises the following steps successively:

[0060] (1) Timber making step: by the method for making timber by Chinese fir cork raw material, make the Chinese fir cork floor blank that is 1000mm long, 160mm wide, and 27mm thick;

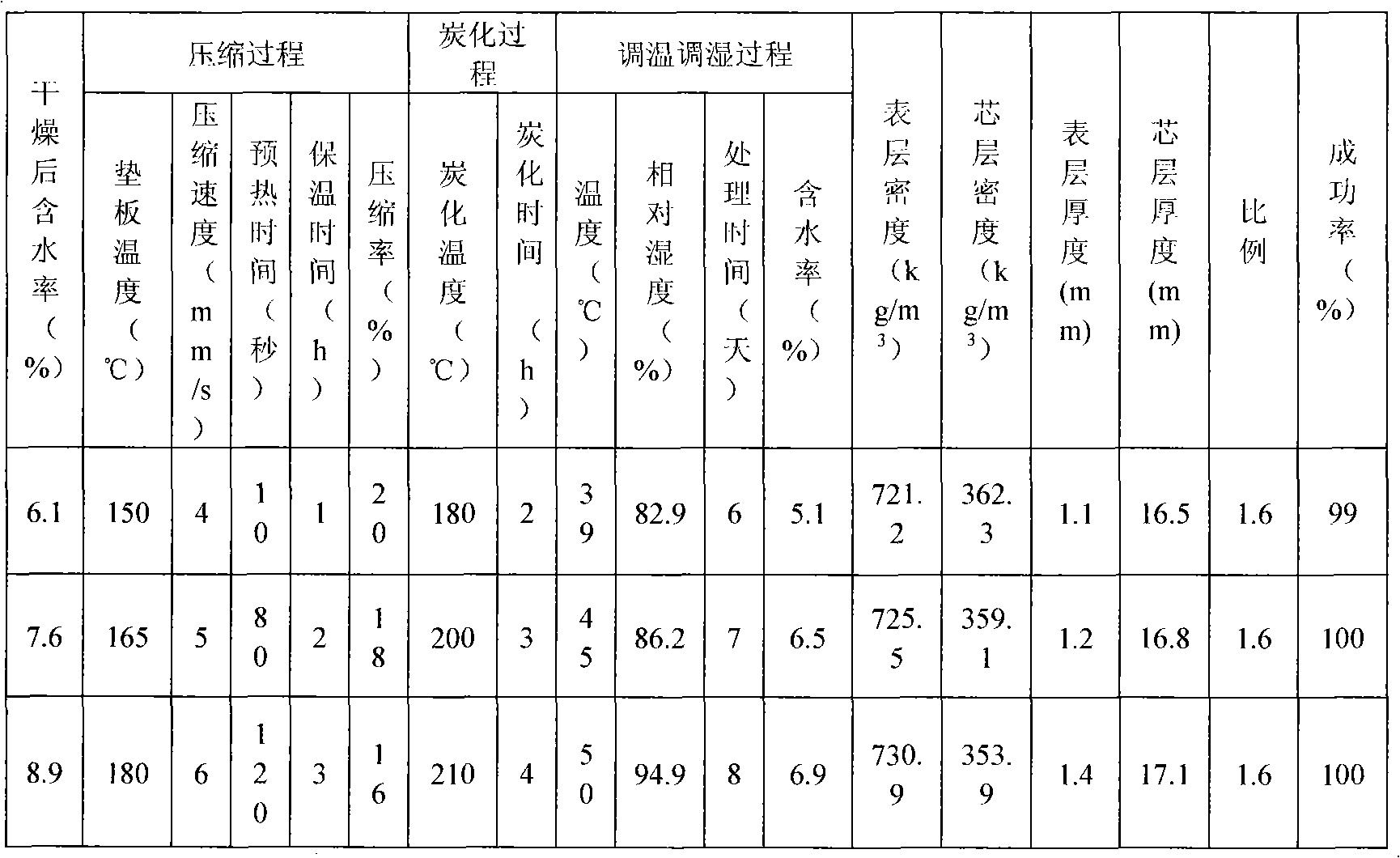

[0061] (2) Drying step: by drying the fir cork floor blank, the dried fir cork floor blank whose moisture content is reduced to a suitable value (see Table 2 for specific values) is obtained;

[0062] (3) Polishing step: carry out four-sided planing by four-sided planing machine tool by dry Chinese fir cork floor blank, make the four-sided polishing dry Chinese fir cork floor blank that thickness is 24mm;

[0063] (4) Improvement step: the improved blank is obtained by functional improvement of the four-sided polished Chinese fir dry floor blank, and the functional improvement is a wood compression carbonization method; the wo...

Embodiment 3

[0071] Embodiment 3: a kind of manufacture method of solid wood floor, take cork paulownia floor manufacture method as example, it comprises the following steps successively:

[0072] (1) Timber making step: the paulownia cork floor blank with a length of 2000mm, a width of 200mm and a thickness of 32mm is obtained by the paulownia cork raw material through the method of timber manufacture;

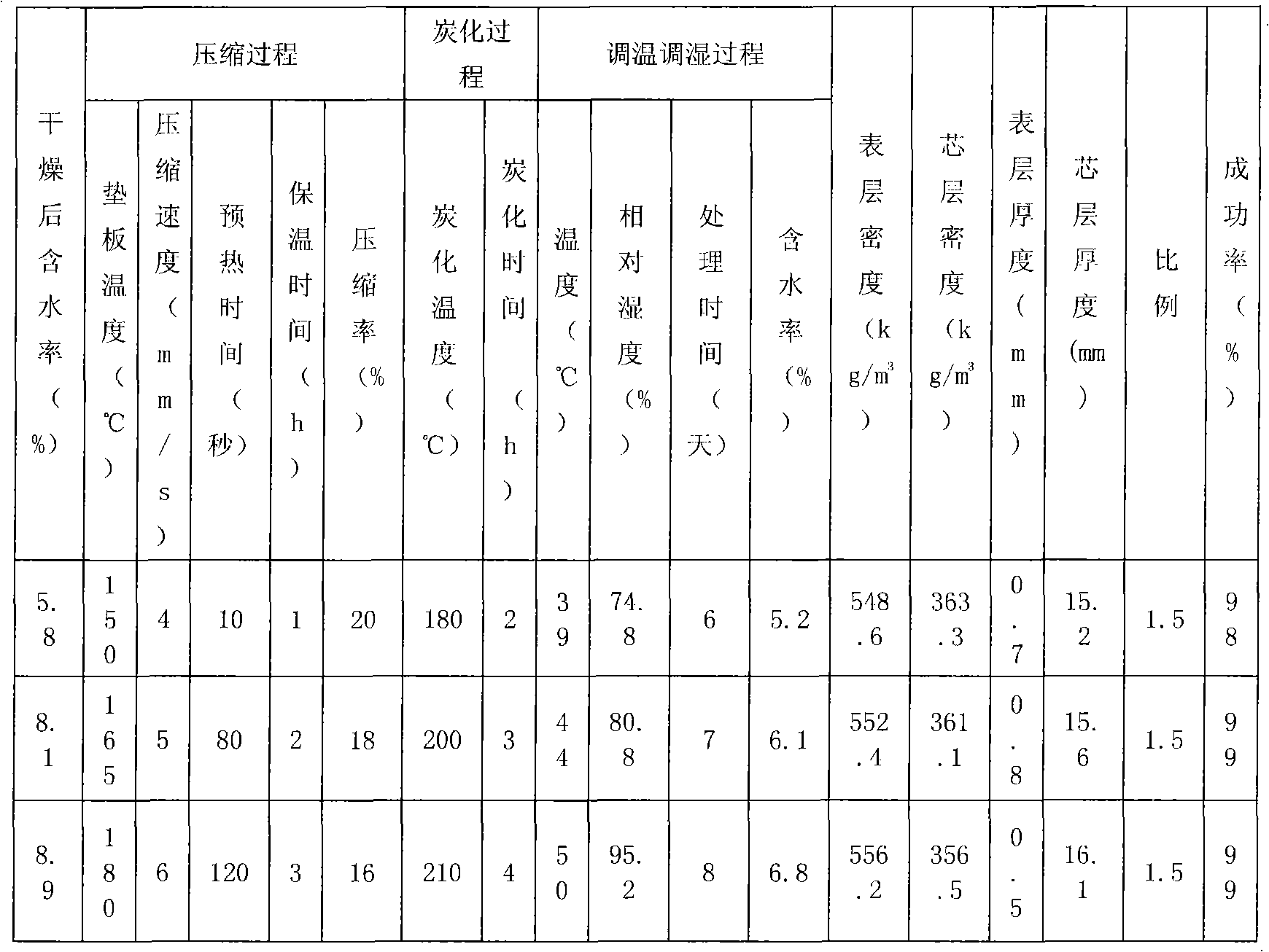

[0073] (2) Drying step: by drying the paulownia cork floor blank, the dry paulownia cork floor blank that the moisture content is reduced to a suitable value (see Table 3) is obtained;

[0074] (3) Polishing step: carry out planing on all sides by the dry paulownia cork floor blank by a four-side planer machine tool, and make a four-side polished dry paulownia cork floor blank with a thickness of 27mm;

[0075] (4) Improvement step: the improved blank is obtained by functional improvement of the four-sided polished paulownia dry floor blank, and the functional improvement is a wood compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com