A system and method for water-vapor phase change coupled with low-temperature electrostatic precipitator to remove fine particles

A water vapor phase change, low and low temperature technology, applied in the field of flue gas purification, can solve the problems of poor dust removal performance, achieve the effects of strengthening adhesion, reducing jet resistance, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

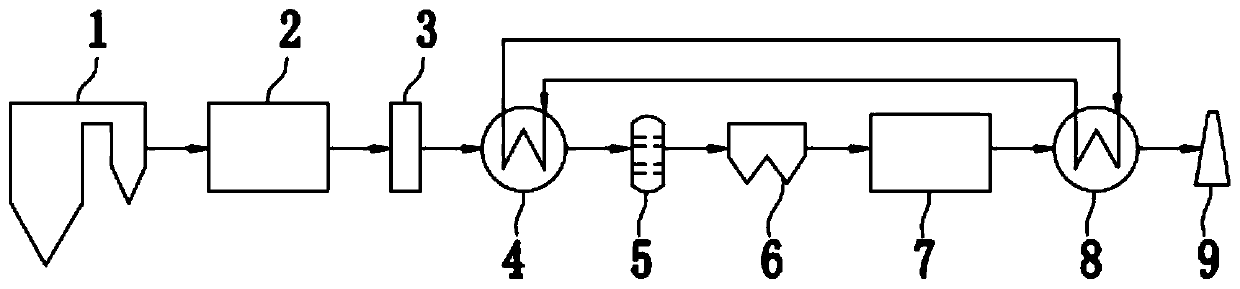

[0048] A water vapor phase change coupled low-temperature electrostatic precipitator system for removing fine particles, such as figure 1 As shown, it includes a denitration reactor 2, an air preheater 3, a heat recovery device 4, a low and low temperature electric precipitator 6, a desulfurization tower 7 and a reheater 8 connected in sequence through the flue, and the denitration reactor 2 is connected with the boiler 1, the reheater 8 is connected to the chimney 9, and the phase change chamber that promotes the growth of fine particles in the flue gas is connected between the heat recovery device 4 and the low-temperature electrostatic precipitator 6 5.

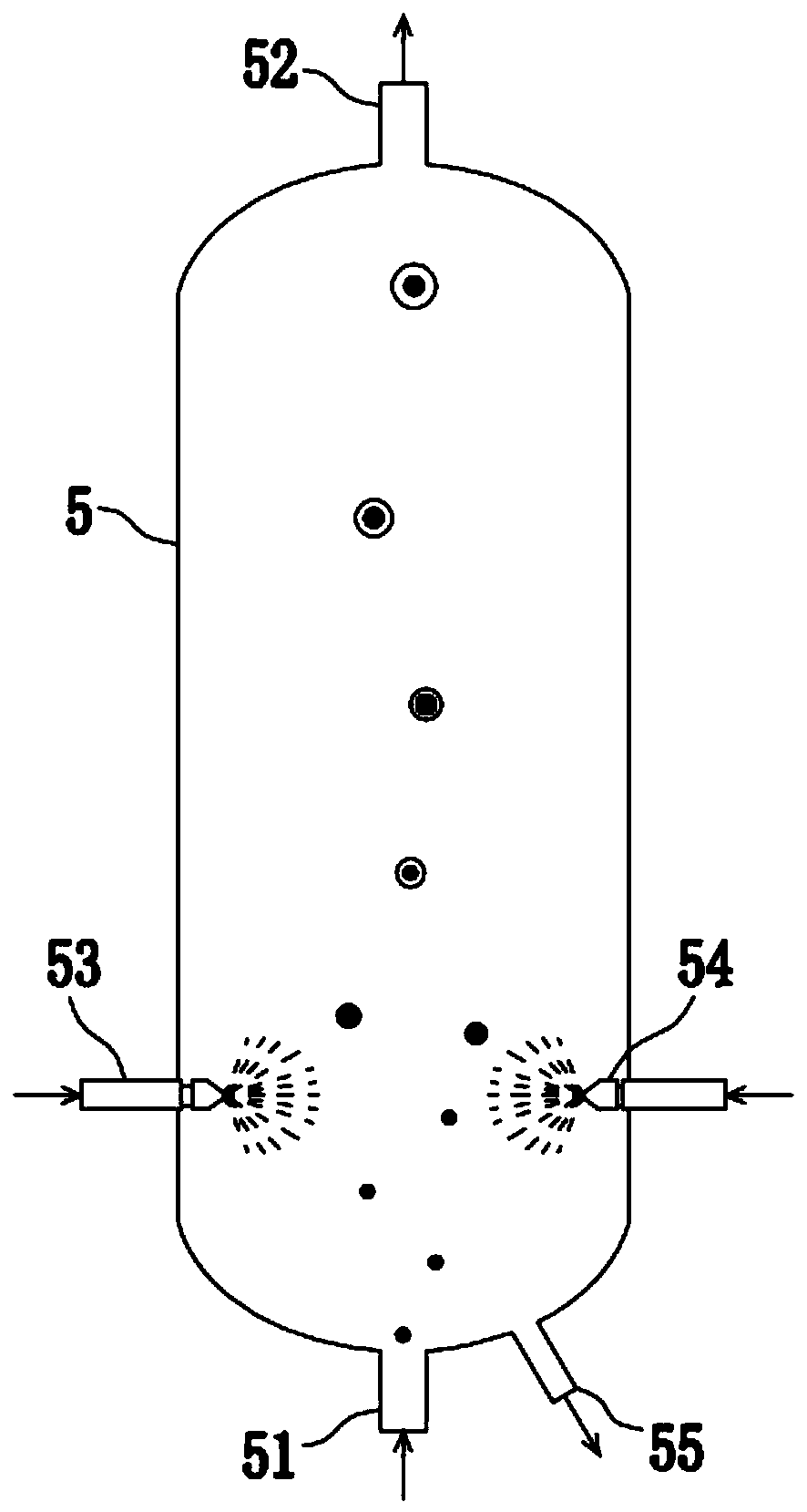

[0049] Such as figure 2 As shown, the phase change chamber 5 includes a flue gas inlet 51, a flue gas outlet 52, a condensed water discharge port 55 and several steam inlets 53, and the flue gas inlet 51 and the condensed water discharge port 55 are all arranged on the At the bottom of the phase change chamber 5, the co...

Embodiment 2

[0056] In this embodiment, a system for water vapor phase change coupled with low and low temperature electrostatic precipitator to remove fine particles, the basic structure is the same as that of Embodiment 1, the differences and improvements are as follows: figure 2 As shown, the steam inlet 53 is provided with an atomizing nozzle 54, so that what passes into the phase change chamber 5 can be water vapor or liquid water. When water is passed into the phase change chamber 5 Instead of steam, the atomizing nozzle 54 can atomize water to form water mist to promote the combination of water and particles; use liquid cold water atomization to combine with flue gas to cool the flue gas, and at the same time through heat transfer The mass transfer process makes it easier to reach supersaturated water vapor conditions.

Embodiment 3

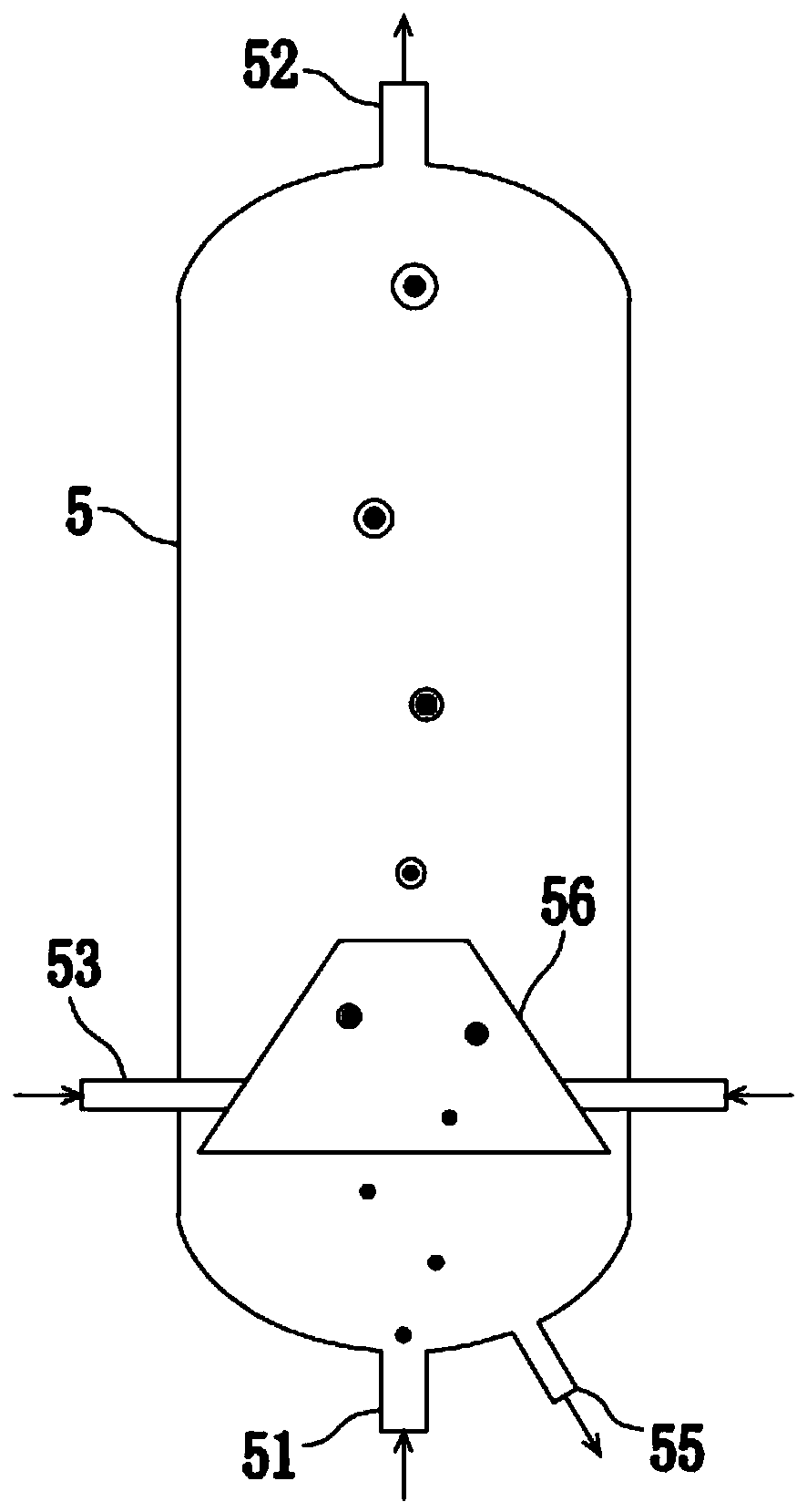

[0058] In this embodiment, a system for water vapor phase change coupled with low-temperature electrostatic precipitator to remove fine particles, the basic structure is the same as that of Embodiment 1 or 2, the differences and improvements are as follows: image 3 As shown, the phase change chamber 5 is provided with a swirl device 56 for enhancing the mixing of smoke and water vapor, and the particles and water vapor are fully mixed by generating a swirling air flow. The swirl device 56 is also made of low surface energy materials , to prevent steam from condensing on the surface of the cyclone device 56, causing waste of steam and increasing energy consumption. In this embodiment, the lining material of the cyclone device 56 is polytetrafluoroethylene. Such as image 3 , 4 As shown, the swirl device 56 is in the shape of an inverted funnel, and the steam inlet 53 and the upper port of the swirl device 56 are arranged in a tangential circle, which can reduce the jet resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com