Continuous rolling process for lithium-ion battery electrode and device thereof

A lithium-ion battery, rolling technology, applied in electrode manufacturing, presses, manufacturing tools, etc., can solve the problems of difficult operation, complicated methods, inconvenient continuous production, etc. simple effect

Inactive Publication Date: 2010-11-03

NINGBO VEKEN BATTERY

View PDF1 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that the key to the problem lies in the rebound of the electrode sheet. The method adopted in this patent is relatively complicated, difficult to operate, and more inconvenient for continuous production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

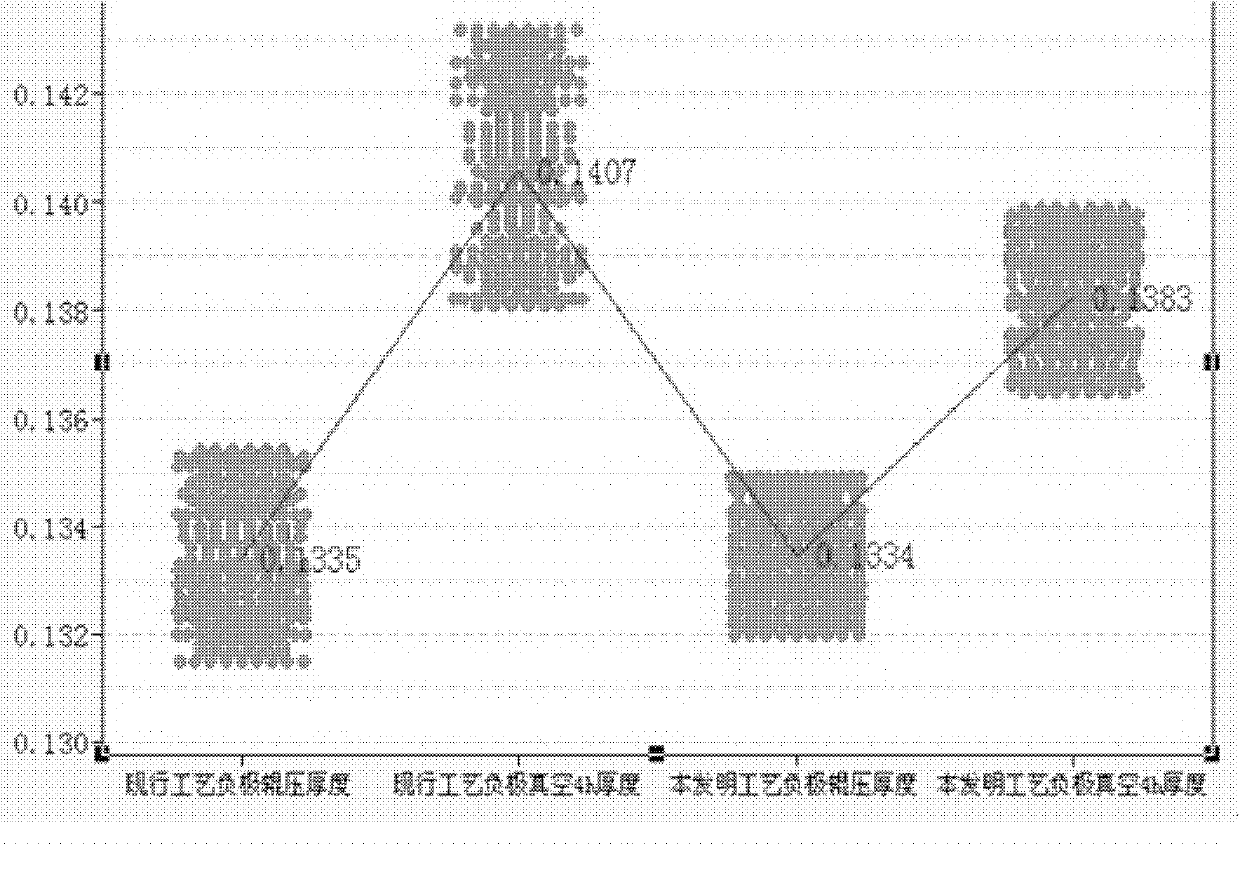

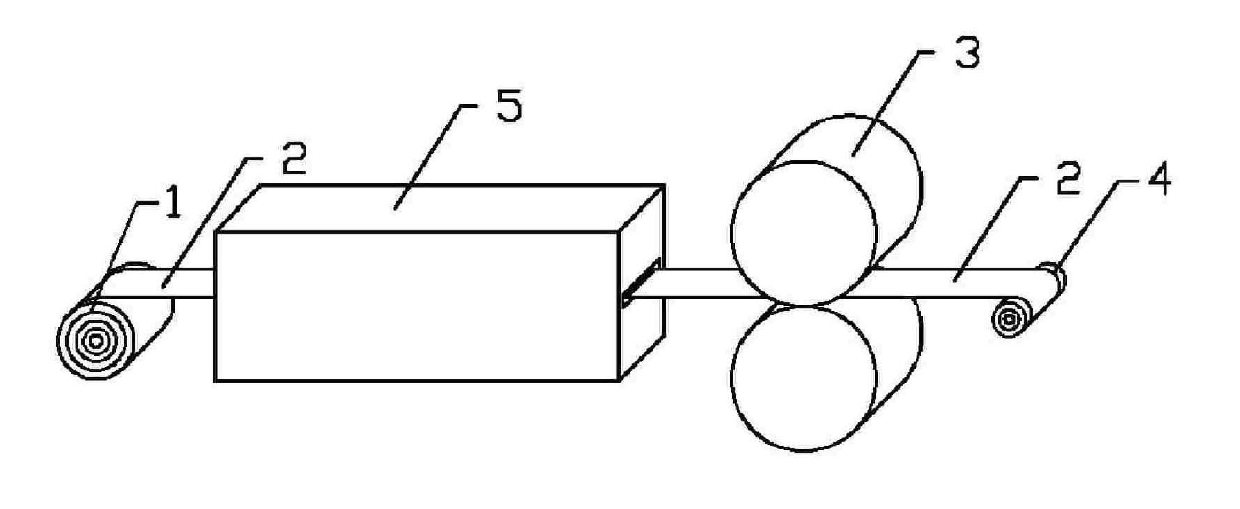

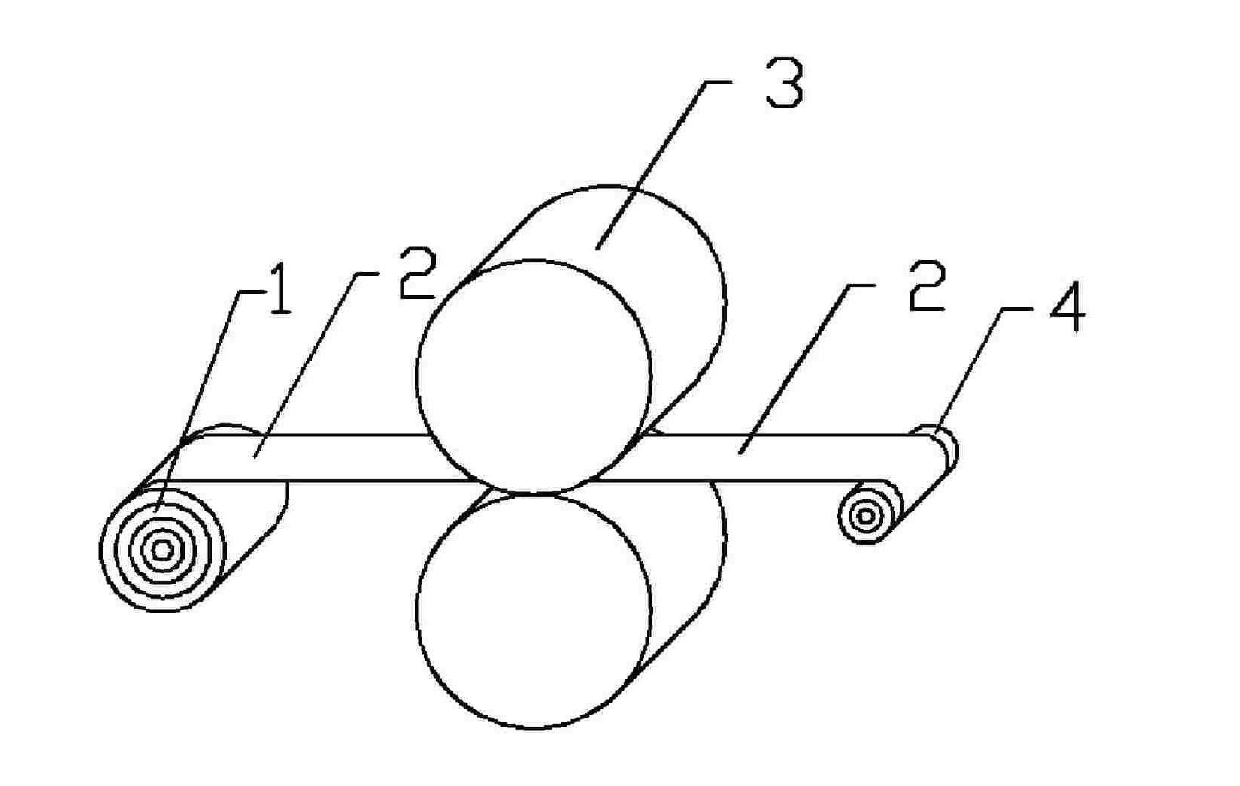

The invention discloses a continuous rolling process for a lithium-ion battery electrode and a device thereof. The process is characterized in that an electrode plate adopts a low-temperature hot rolling process. The used device is characterized in that a heating device is increased between an unrolling shaft and a roll. The process has the advantages of ensuring the dryness of the electrode, increasing the plasticity of the electrode plate, reducing the rebound rate of the rolled electrode plate and properly increasing the single-side density of the electrode plate, thereby promoting the volume rate capacity of the battery; and the device has a simple structure and convenient operation.

Description

technical field The invention belongs to the field of battery manufacturing, in particular to a lithium-ion battery electrode continuous rolling process and a device thereof. Background technique At present, the production method of lithium-ion battery electrodes is roughly to first uniformly coat the stirred positive and negative electrode slurry (mainly including positive and negative electrode active materials, binders, conductive agents, solvents, etc.) Aluminum foil or aluminum mesh, the negative electrode is copper foil or copper mesh), and then the solvent is baked out by baking to obtain a dry electrode; then the electrode is compacted by a roller press (see Figure 1), and then the electrode is cut into Small strips of specified length and width are finally welded to the drainage body (the positive pole is an aluminum strip, the negative pole is a nickel strip or a copper strip or a copper-nickel composite strip), so that the final electrode has been obtained. Howev...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/04B30B3/00

CPCY02E60/10

Inventor 曹长河姚宇均潘美姿席敏杰王从伟曹国瑞

Owner NINGBO VEKEN BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com