Brush-type spraying device for concrete sprayers

A technology of concrete spraying machine and spraying device, which is applied in the direction of spraying device, liquid spraying device, shaft equipment, etc., which can solve the problems of low construction efficiency, low concrete utilization rate, and negative impact on the health of construction workers, so as to improve the utilization rate and work efficiency, the spray direction is easy to control, and the effect of reducing the possibility of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

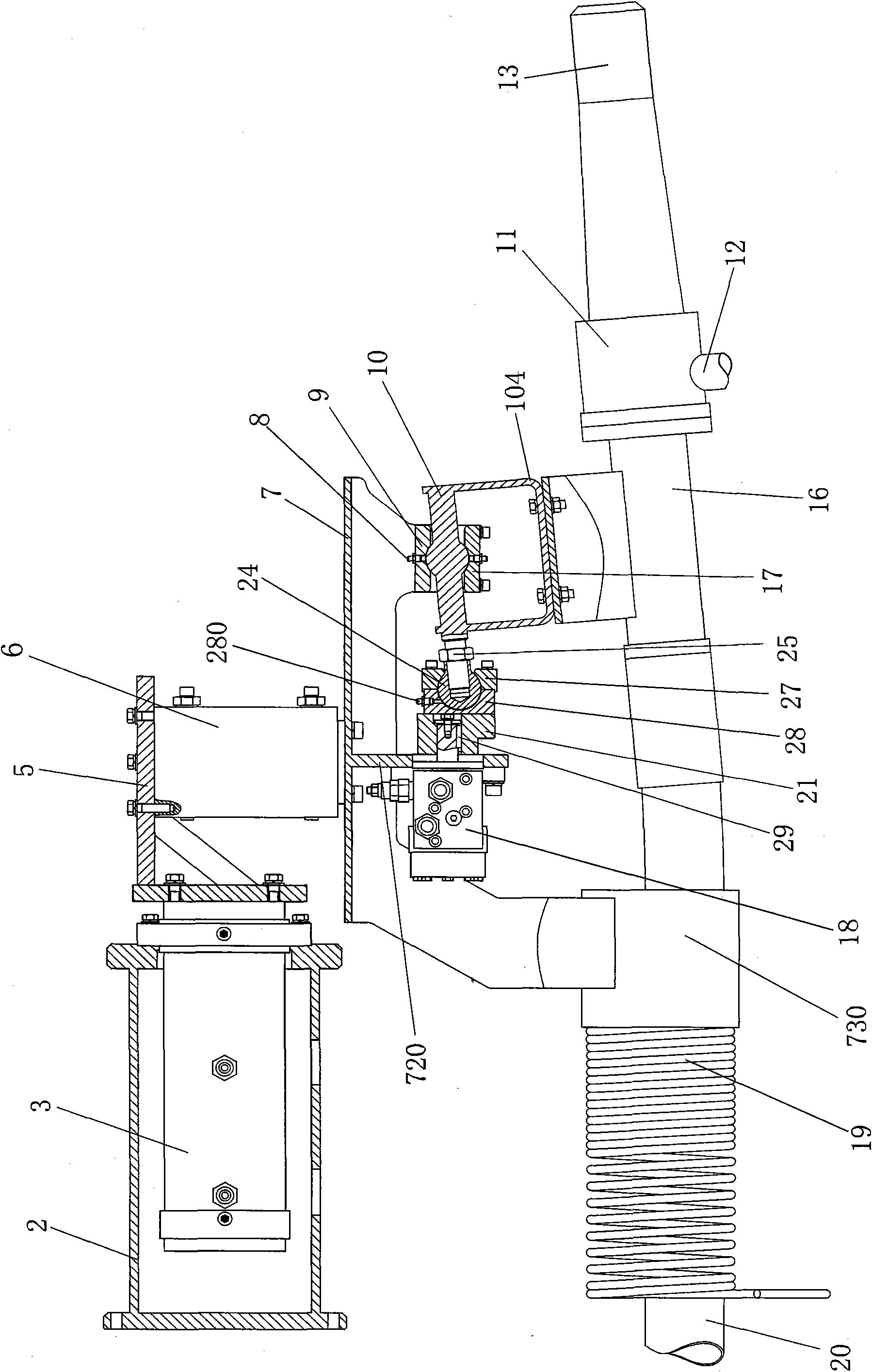

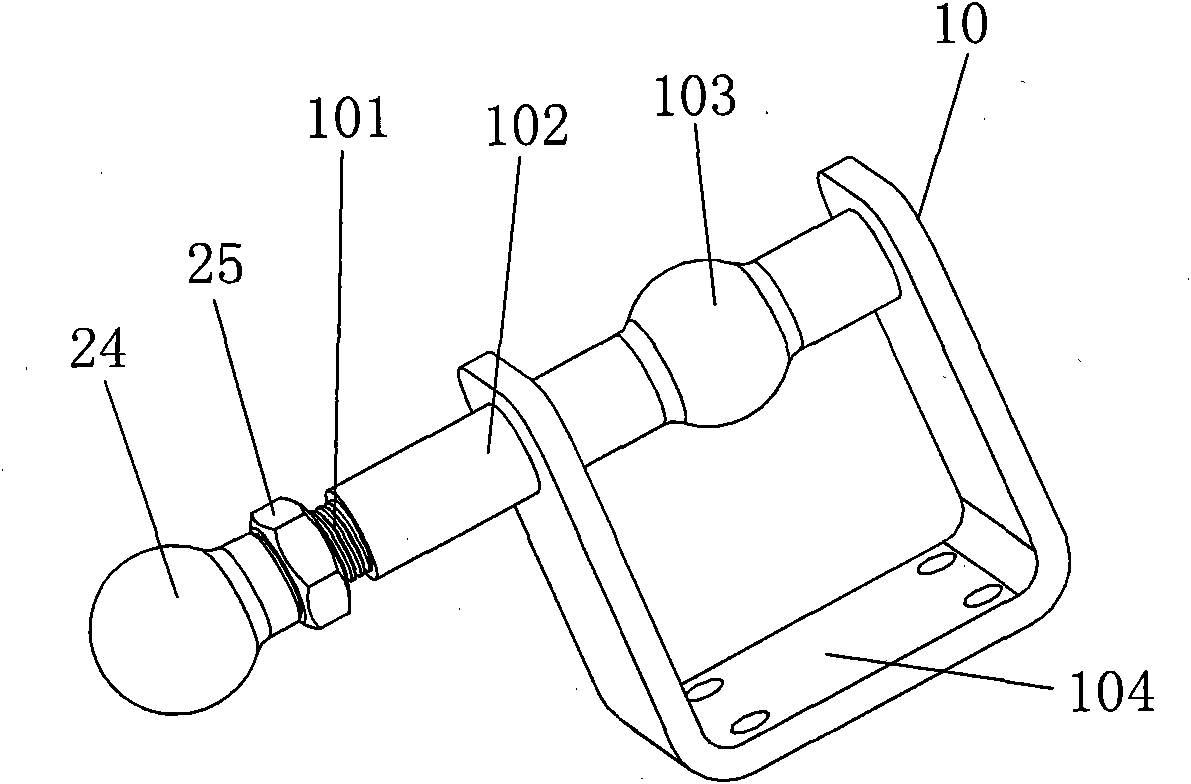

[0040] Such as figure 1 , figure 2 , image 3 The joint bearing of this embodiment includes a ball sleeve fixed body 28 connected to the eccentric disc 21, a ball sleeve 24 located in the ball sleeve fixed body 28 and connected with the extended end of the swing shaft 102, used for fixing the ball sleeve 24 and connecting with the ball The ball sleeve fixing cover 27 connected with the sleeve fixing body 28 is provided with a ball sleeve lubricating assembly 280 on the ball sleeve fixing body 28 . The ball socket fixed body 28 is integrated with the ball socket fixed cover 27 to form a ball joint overcoat. The protruding end of the swing shaft 102 is a threaded section 101 , and the ball sleeve 24 and the threaded section 101 are fixed by a locking nut 25 .

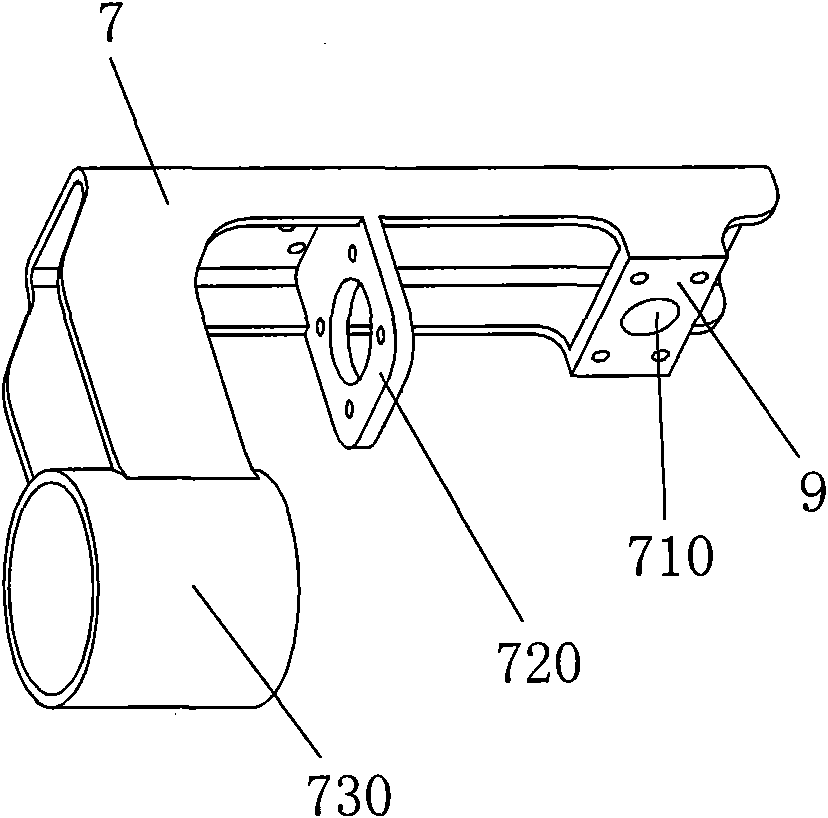

[0041] The spherical hinge structure of this embodiment includes a spherical protrusion 103 arranged on the swing shaft 102, a spherical crown-shaped recess 710 arranged on the hinge seat 9 of the brush frame, and a s...

Embodiment 2

[0044] Such as Figure 4 , Figure 5 , Image 6 In this embodiment, the joint bearing includes a ball joint rod 214 fixed on the eccentric disk 21 and a dimple 105 provided on the protruding end of the swing shaft 102 . The ball head of the ball joint rod 214 is located in the dimple 105 . Of course, in this example, the ball head lever 214 can also be arranged on the protruding end of the swing shaft 102 , and the pit 105 can be arranged on the eccentric disk 21 .

[0045] All the other structures are the same as in Embodiment 1.

Embodiment 3

[0047] Such as Figure 7 , Figure 8 , the ball hinge structure of this embodiment includes a spherical step hole 106 arranged on the swing shaft 102, a ball-end boom 31 fixed on the hinge seat 9 of the brush frame, and the ball head of the ball-end boom 31 is located on the spherical step Inside the hole 106.

[0048] All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com