Low-cost SiZrOC ceramic material and preparation method thereof

A ceramic material, low-cost technology, applied in the field of high-temperature structural ceramics, can solve problems such as poor thermal stability, and achieve the effects of low price, simple preparation method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

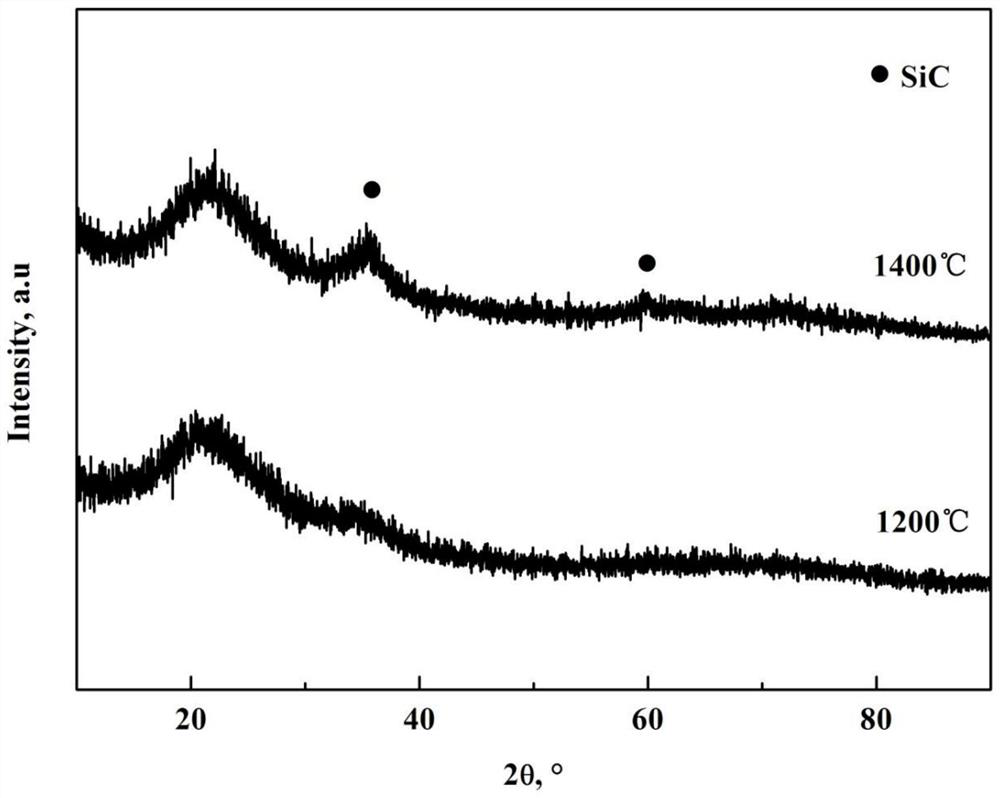

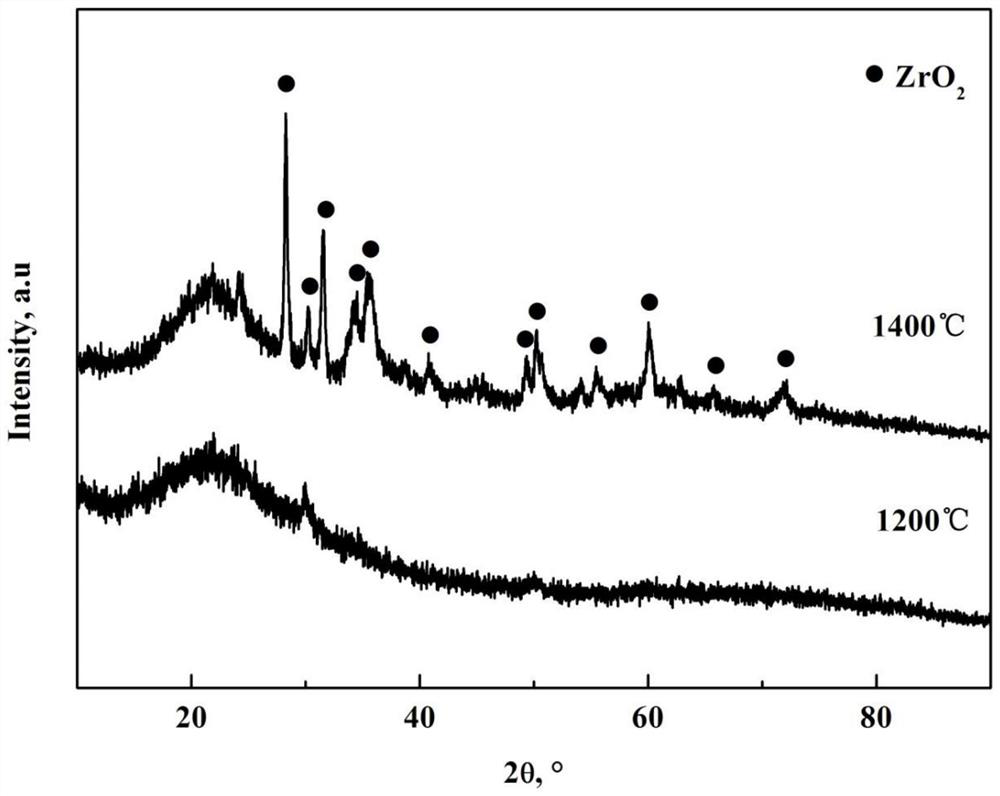

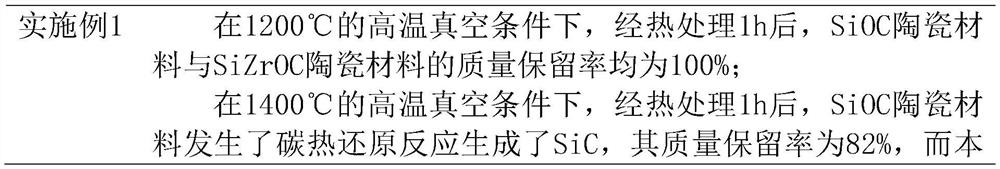

Embodiment 1

[0025] A preparation method of low-cost SiZrOC ceramic material, comprising the following steps:

[0026] 1) Preparation of zirconium sol:

[0027] Under constant temperature conditions of 40°C, take 4g ZrOCl 2 ·8H 2 O was dissolved in 20g ethanol, and magnetically stirred for 20min after adding 5g acetylacetone therein, to obtain zirconium sol;

[0028] Take 50g of MK silicone resin and dissolve it in 50g of ethanol to prepare a 50% MK silicone resin ethanol solution;

[0029] 2) Preparation of gel: Mix the prepared MK silicone resin ethanol solution and zirconium sol, add 2.7g of polyethylene glycol, and let it stand for 6 hours to form a gel;

[0030] 3) Preparing the precursor: heating the obtained gel to 150° C. in a drying oven, and drying for 10 hours to obtain a zirconium-modified polysiloxane precursor;

[0031] 4) Preparation of SiZrOC ceramic material: The obtained zirconium-modified polysiloxane precursor was placed in an inert gas atmosphere at 1000° C. for cr...

Embodiment 2

[0034] A preparation method of low-cost SiZrOC ceramic material, comprising the following steps:

[0035] 1) Preparation of zirconium sol:

[0036] Under constant temperature conditions of 50°C, take 10g ZrOCl 2 ·8H 2 O was dissolved in 35g of ethanol, and magnetically stirred for 15min after adding 6.2g of acetylacetone therein, to obtain a zirconium sol;

[0037] Take 30g of MK silicone resin and dissolve it in 70g of ethanol to prepare a 30% MK silicone resin ethanol solution;

[0038] 2) Gel preparation: the prepared MK silicone resin ethanol solution was mixed with zirconium sol, 4g of polyethylene glycol was added, and after standing for 9 hours, a gel was formed;

[0039] 3) Preparing the precursor: heating the obtained gel to 200° C. in air, and drying for 4 hours to obtain a zirconium-modified polysiloxane precursor;

[0040] 4) Preparation of SiZrOC ceramic material: The obtained zirconium-modified polysiloxane precursor was placed in a high-temperature inert gas...

Embodiment 3

[0043] A preparation method of low-cost SiZrOC ceramic material, comprising the following steps:

[0044] 1) Preparation of zirconium sol:

[0045]Under constant temperature conditions of 45°C, take 30g ZrOCl 2 ·8H 2 O was dissolved in 60g of ethanol, and magnetically stirred for 10min after adding 9.3g of acetylacetone therein to obtain a zirconium sol; 40g of MK silicone resin was dissolved in 60g of ethanol to prepare a 40% MK silicone resin ethanol solution;

[0046] 2) Gel preparation: the prepared MK silicone resin ethanol solution was mixed with zirconium sol, 12 g of polyethylene glycol was added thereto, and after standing for 28 hours, a gel was formed;

[0047] 3) Preparing the precursor: heating the obtained gel to 220° C. in air, and drying for 6 hours to obtain a zirconium-modified polysiloxane precursor;

[0048] 4) Preparation of SiZrOC ceramic material: The obtained zirconium-modified polysiloxane precursor was placed in a high-temperature inert gas atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com