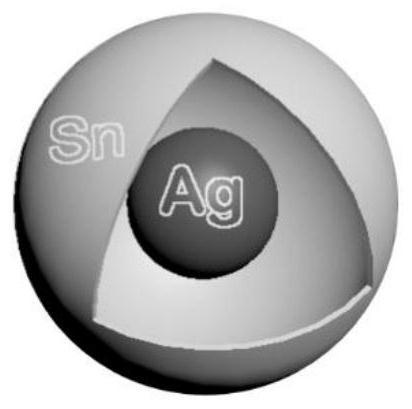

Preparing method of nano metal solder paste for Ag-Sn core-shell structure and application thereof

A nano-metal, core-shell structure technology, applied in metal processing equipment, metal processing, welding equipment, etc., can solve the problems of high sintering temperature, high cost of nano-silver, low service temperature of solder paste sintering materials, etc., to reduce Cost price, improve the quality of use, reduce the effect of electromigration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Using deionized water at room temperature to ultrasonically wash the nano-silver at 20 KHz for 15 minutes, to obtain the nano-silver washed with deionized water.

[0034] (2) Add the nano-silver powder washed with deionized water into acetone (acetone is volatile), and use an ultrasonic cleaner with a temperature of 25°C at 30KHz to process the acetone solution containing silver powder for 10 minutes to obtain the acetone solution containing silver powder after ultrasonic .

[0035] (3) Naturally volatilize the acetone in the acetone solution containing the silver powder at room temperature to obtain dry silver powder to be coated.

[0036] (4) Add sodium hydroxide to deionized ice water to obtain an alkaline solution, adjust the solution to PH=12, add sodium borohydride to the alkaline solution to obtain a concentration of 1×10 -2 mol / L sodium borohydride reducing solution.

[0037] (5) Using a magnetic stirrer at a stirring speed of 300 r / min, the obtained dried...

Embodiment 2

[0040] A preferred embodiment comprises the following preparation steps:

[0041] (1) Using deionized water at room temperature to ultrasonically wash the nano-silver at 20 KHz for 15 minutes, to obtain the nano-silver washed with deionized water.

[0042] (2) Add the nano-silver powder washed with deionized water into acetone (acetone is volatile), and use an ultrasonic cleaner with a temperature of 25°C at 30KHz to process the acetone solution containing silver powder for 10 minutes to obtain the acetone solution containing silver powder after ultrasonic .

[0043] (3) Naturally volatilize the acetone in the acetone solution containing the silver powder at room temperature to obtain dry silver powder to be coated.

[0044] (4) Add sodium hydroxide to deionized ice water to obtain an alkaline solution, adjust the solution to PH=12, add sodium borohydride to the alkaline solution to obtain a concentration of 1×10 -2 mol / L sodium borohydride reducing solution.

[0045] (5) U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com