Method for achieving electronic building brick high-temperature packaging by filling Sn-based solder with micro-nano metallic particles

A technology of metal particles and electronic components, applied in metal processing, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of high cost of nanomaterial preparation, device damage, long preparation time, etc., and achieve heat dissipation and electrical performance The effect of index improvement, high temperature resistance capability enhancement, and service temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

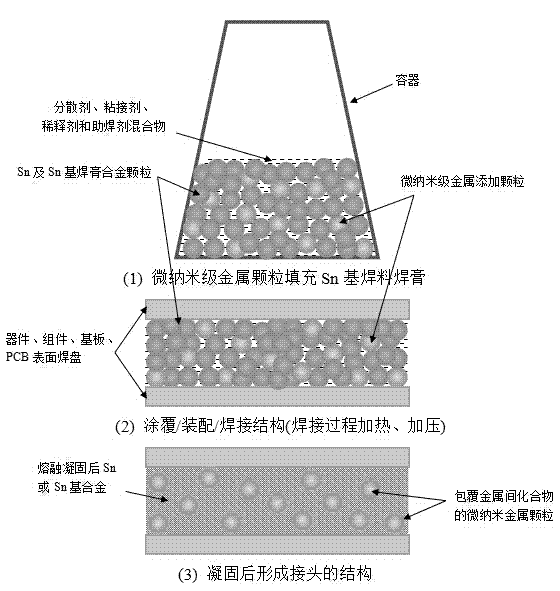

[0018] Such as figure 1 As shown, the micron-scale Cu metal particle filling Sn-based solder solder paste interconnection joint formation method comprises the steps:

[0019] Step 1: preparing Cu particles with a diameter of about 20 μm;

[0020] Step 2: Mix the above micron-sized Cu particles with the dispersant methyl amyl alcohol, the binder α-terpineol, the diluent terpineol, and the flux rosin in an appropriate amount, and the mixing mass ratio is 80:4:6:4: 6;

[0021] Step 3: Mix the above Cu particle mixture with Sn3.5wt.%Ag solder paste, the Cu particle mixture accounts for 50% of the total mass of the final solder paste mixture;

[0022] Step 4: Use 200W ultrasonic vibration for 80 minutes to make the Cu particles uniformly dispersed in the mixture prepared in Step 3 to make a micron-sized metal particle filled Sn-based solder paste;

[0023] Step 5: Place the Sn-based solder paste filled with the above micron-sized metal particles on the substrate by the screen pr...

Embodiment 2

[0026] The nanoscale Ag metal particle filling Sn-based solder paste interconnection joint forming method comprises the following steps:

[0027] Step 1: preparing Ag particles with a diameter of about 100 nm;

[0028] Step 2: mix the above nano-Ag particles with dispersant triethylhexyl phosphoric acid, binder α-terpineol, diluent alcohol, flux rosin in an appropriate amount, and the mixing ratio is 85:3:4:4:4;

[0029] Step 3: Mix the above nanoscale Ag particle mixture with Sn0.7wt.%Cu solder paste, the Ag particle mixture accounts for 30% of the total mass of the final solder paste mixture;

[0030] Step 4: Use 150W ultrasonic vibration for 120 minutes to make the Ag particles uniformly dispersed in the mixture prepared in Step 3 to make nano-scale Ag metal particles filled with Sn-based solder paste;

[0031] Step 5: Fill the above nano-scale Ag metal particles with Sn-based solder paste by dispensing method, complete the alignment of the pads of the parts to be soldered...

Embodiment 3

[0033] Embodiment 3: The method for forming interconnection joints filled with Sn-based solder paste by nano-scale Cu metal particles comprises the following steps:

[0034] Step 1: Prepare Cu particles with a diameter of about 500 nm;

[0035]Step 2: Mix the above micron-sized Cu particles with the dispersant methyl amyl alcohol, the binder α-terpineol, the diluent terpineol, and the flux rosin in an appropriate amount, and the mixing mass ratio is 82:4:5:4: 5;

[0036] Step 3: mixing the above Cu particle mixture with pure Sn solder paste, the Cu particle mixture accounts for 60% of the total mass of the final solder paste mixture;

[0037] Step 4: Use 180W ultrasonic vibration for 100 minutes to make Cu particles uniformly dispersed in the mixture prepared in Step 3 to make nano-scale metal particles filled Sn-based solder paste;

[0038] Step 5: Place the above nanoscale metal particles filled Sn-based solder paste on the substrate by screen printing method, complete the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com