Wide temperature region viscosity corrosion resisting solid self-lubricating coating and preparation method thereof

A solid self-lubricating, wide temperature range technology, applied in the coating, metal material coating process, fusion spraying, etc., to achieve the effect of small fluctuation range, improve the working environment, and increase the service temperature of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030]The preparation method of the wide temperature range anti-sticking and corrosion self-lubricating coating in this embodiment, the specific steps are as follows:

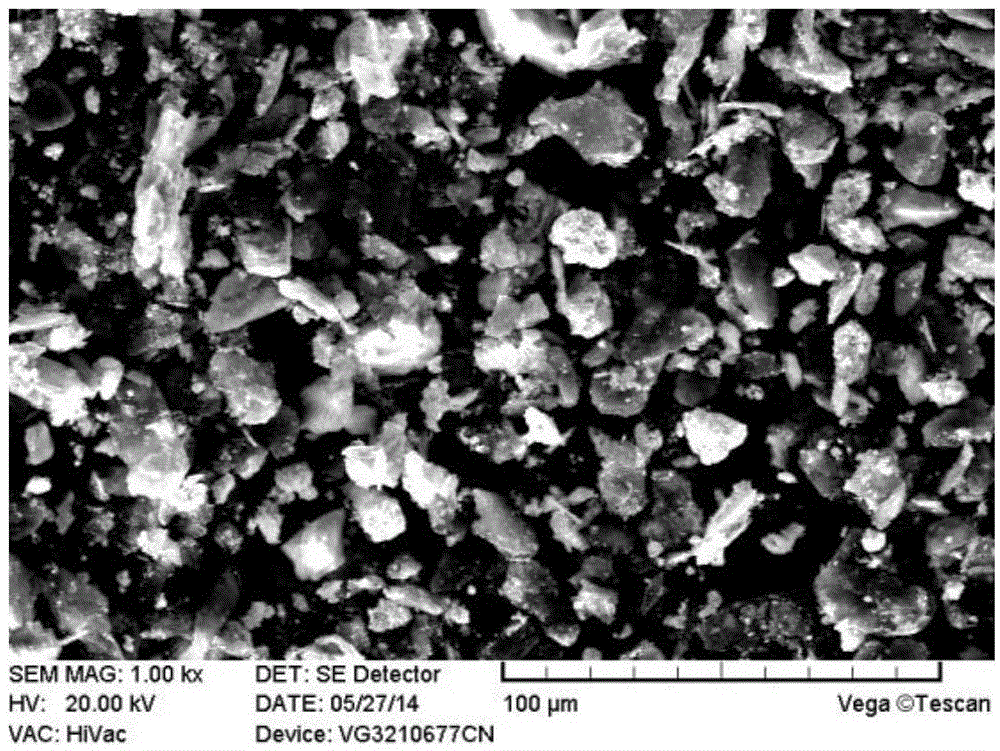

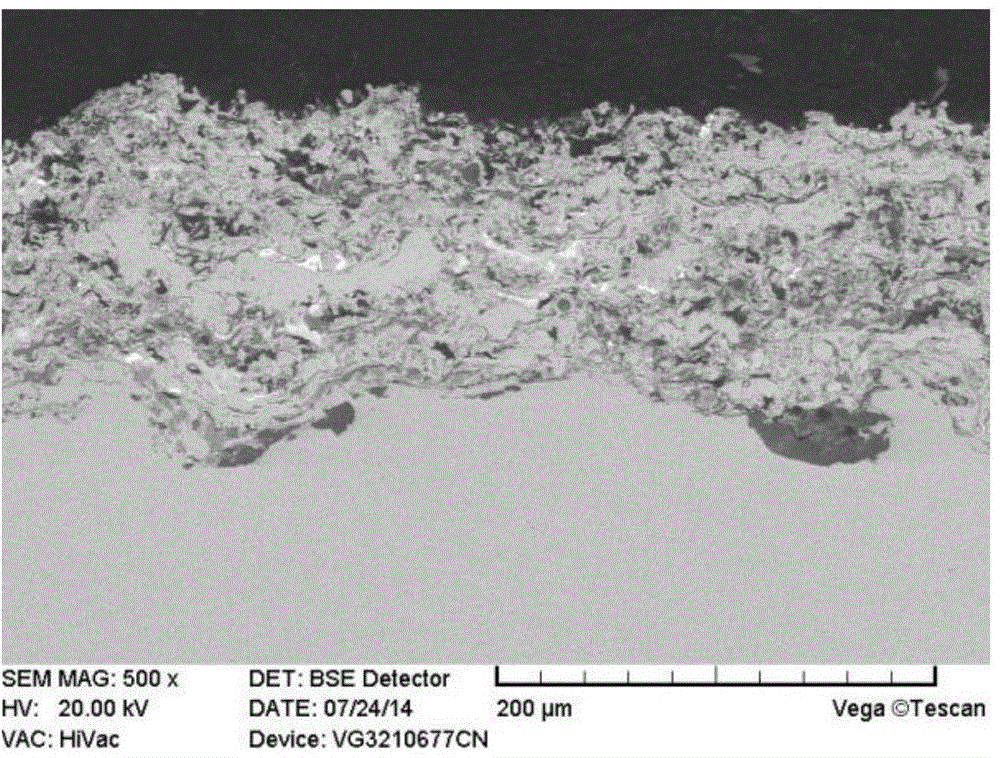

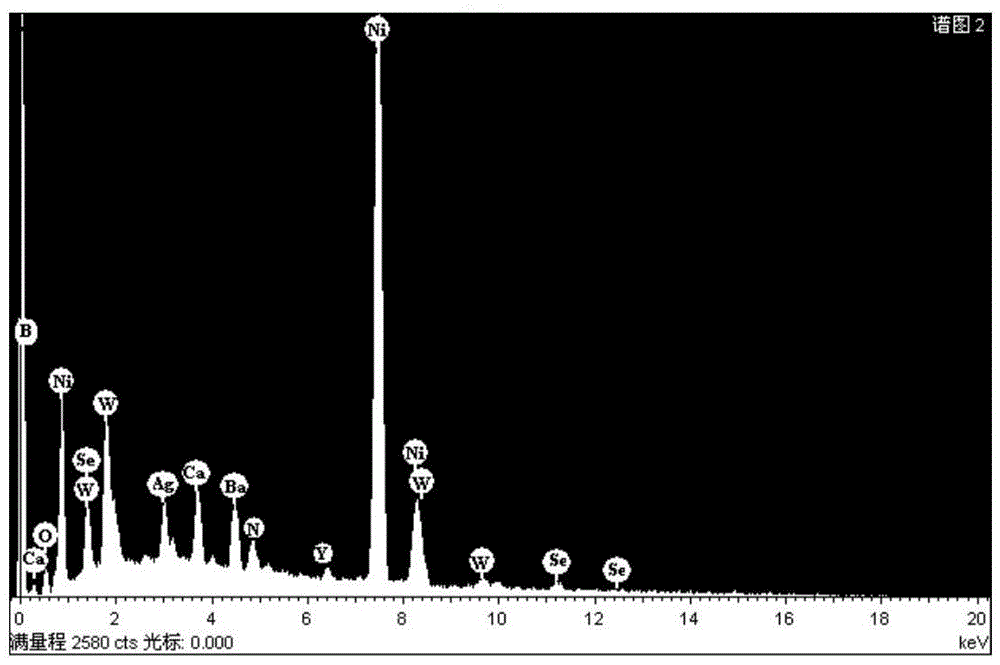

[0031] Step 1: dispensing of self-lubricating composite powder. Nano Ni powder: 240g, particle size is 0.6μm; WSe 2 Powder: 60g, the powder particle size is 5-15μm; Ag powder: 12g, the powder particle size is 5-20μm; Y powder: 12g, the powder particle size is 5-30μm; CaF 2 ·BaF 2 Eutectic powder: 60g, the powder particle size is 20-80μm; hBN powder: 20g, the powder particle size is 1-3μm.

[0032] Stir and mix the four weighed powders mechanically; weigh 10g of polyvinyl alcohol, put it in a heating pot, add an appropriate amount of water, heat, add the mixed powder into the solution, adjust the electric furnace to continue heating and stir continuously. After the solution is dried, continue to sinter, heat to 500°C and keep for 2 hours until it becomes a block, then break the block, take it out and put it i...

specific Embodiment 2

[0046] The preparation method of the wide temperature range anti-sticking and corrosion self-lubricating coating in this embodiment, the specific steps are as follows:

[0047] Step 1: dispensing of self-lubricating composite powder. Nano-Ni powder: 276g, particle size is 0.6μm; WSe 2 Powder: 60g, the powder particle size is 5-15μm; Ag powder: 12g, the powder particle size is 5-20μm; Y powder: 12g, the powder particle size is 5-30μm; CaF 2 ·BaF 2 Eutectic powder: 40g, the powder particle size is 20-80μm.

[0048] Stir and mix the four weighed powders mechanically; weigh 10g of polyvinyl alcohol, put it in a heating pot, add an appropriate amount of water, heat, add the mixed powder into the solution, adjust the electric furnace to continue heating and stir continuously. After the solution is dried, continue to sinter, heat to 500°C for 2 hours until it becomes a block, then break the block, take it out and put it into a grinding bowl for grinding, and pass through a 100-mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com