Ruthenium-containing multi-component TiAl alloy suitable for temperature of 800 DEG C

A multi-component and alloy technology, applied in the field of ruthenium-containing multi-component TiAl alloy, can solve the problem of increasing the service temperature of multi-component TiAl alloy, which has not yet been seen, and achieve the effect of improving high-temperature performance and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

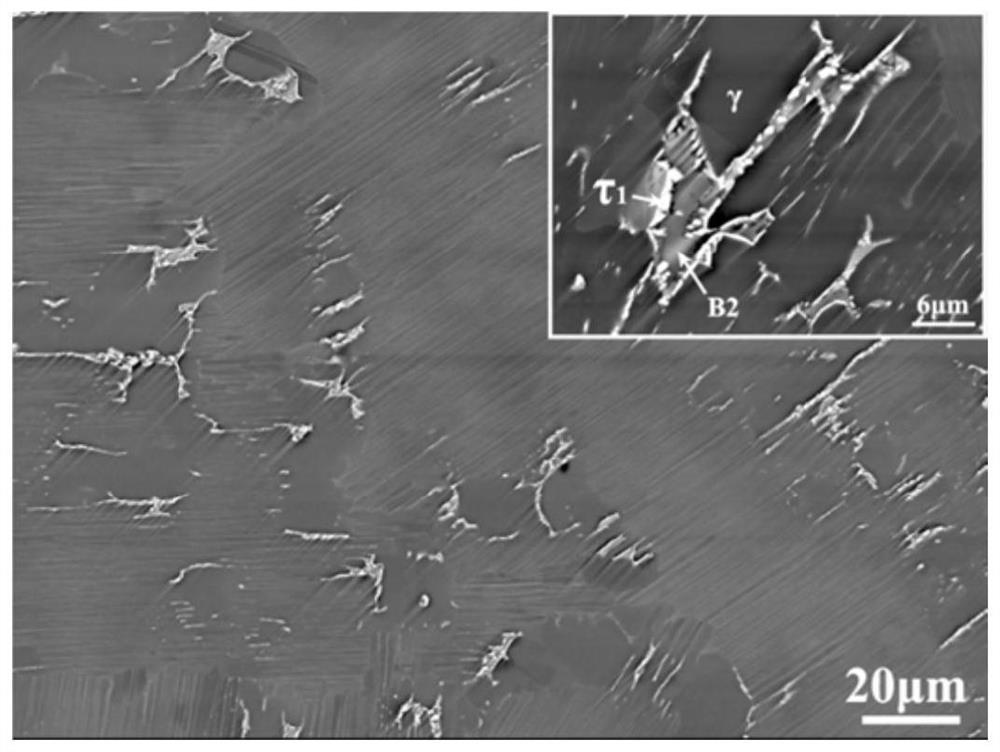

[0025] The composition of the present embodiment alloy is Ti-48Al-4Nb-2Cr-1.0Ru alloy, and specific implementation method is as follows: (1) sponge titanium, high-purity aluminum, aluminum-chromium master alloy, aluminum-niobium master alloy and high-purity ruthenium powder are formulated (2) Put the raw material weighed in step 1 into a vacuum non-consumable arc melting furnace; (3) After each smelting is completed, turn over and continue smelting, repeating 4 times to ensure the uniformity of the ingredients. The SEM photo of the as-cast structure of Ti-48Al-4Nb-2Cr-1.0Ru alloy is as follows figure 1 As shown, it is mainly composed of α 2 / γ lamellar clusters, with Ru-rich B2 phase and fine granular τ at the boundary and inside of the lamellar clusters 1 phase out. These tiny tau 1 Phase can be used as the second phase particle strengthened alloy.

Embodiment 2

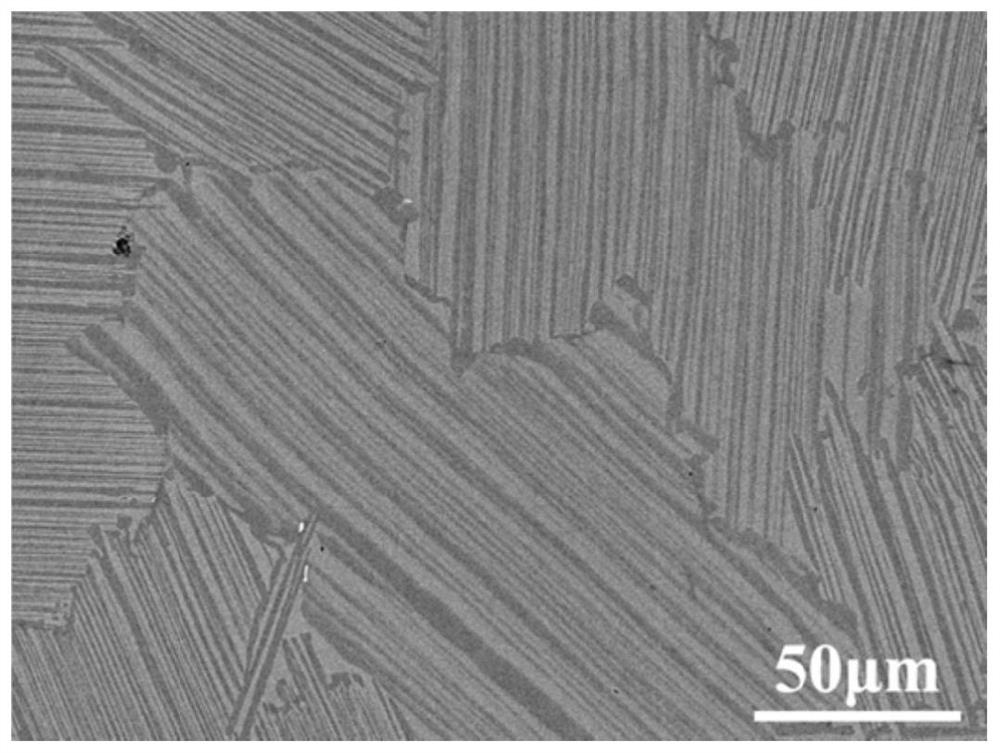

[0027] The composition of the present embodiment alloy is Ti-48Al-4Nb-2Cr-0.3Ru alloy, and specific implementation method is as follows: (1) sponge titanium, high-purity aluminum, aluminum-chromium master alloy, aluminum-niobium master alloy and high-purity ruthenium powder are formulated according to (2) Put the raw material weighed in step 1 into a vacuum non-consumable arc melting furnace; (3) After each smelting is completed, turn over and continue smelting, repeating 4 times to ensure the uniformity of the ingredients. The SEM photo of the as-cast structure of Ti-48Al-4Nb-2Cr-0.3Ru alloy is as follows figure 2 As shown, it is mainly composed of α 2 / γ lamellar group structure, because the alloying elements are completely dissolved, no precipitated phase in Example 1 is seen at the boundary and inside of the lamella group.

Embodiment 3

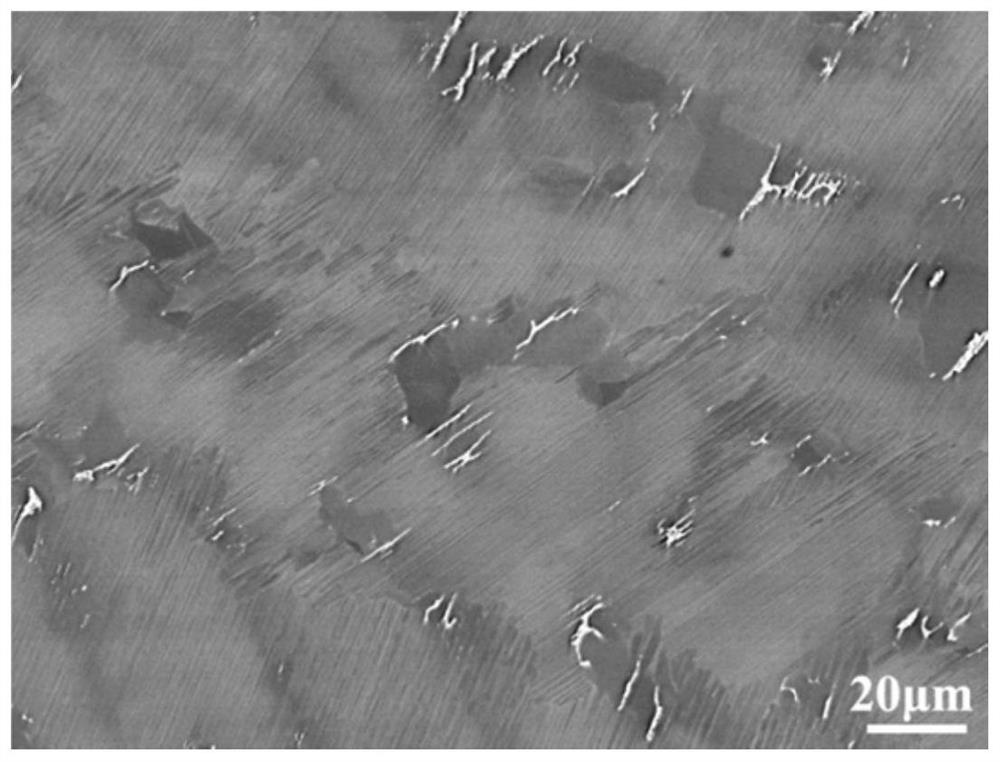

[0029] The composition of present embodiment alloy is Ti-47Al-4Nb-2Cr-0.5Ru alloy, and specific implementation method is as follows: (1) sponge titanium, high-purity aluminum, aluminum-niobium master alloy and high-purity ruthenium powder are weighed by proportioning; ( 2) Put the raw materials weighed in step 1 into a vacuum non-consumable arc melting furnace; (3) After each smelting, turn over and continue smelting, repeating 4 times to ensure the uniformity of the ingredients. The SEM photo of the as-cast structure of Ti-47Al-4Nb-2Cr-0.5Ru alloy is as follows image 3 As shown, similar to Example 1, its organization is mainly composed of α 2 / γ lamellar group structure, Ru-rich phase precipitates at the boundary and inside of the lamella group, but its content is obviously lower than that of the alloy described in Example 1.

[0030] The service temperature of the Ti-48Al-4Nb-2Cr alloy without adding Ru element is below 750°C. Comparing it with the alloys prepared in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com