Vanadium alloy

A vanadium alloy and alloy technology, applied in the field of vanadium alloys, can solve problems such as the inability to apply coatings, achieve excellent thermal shock resistance, increase service temperature, and low tritium permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Vanadium alloy of the present invention adopts following method to prepare:

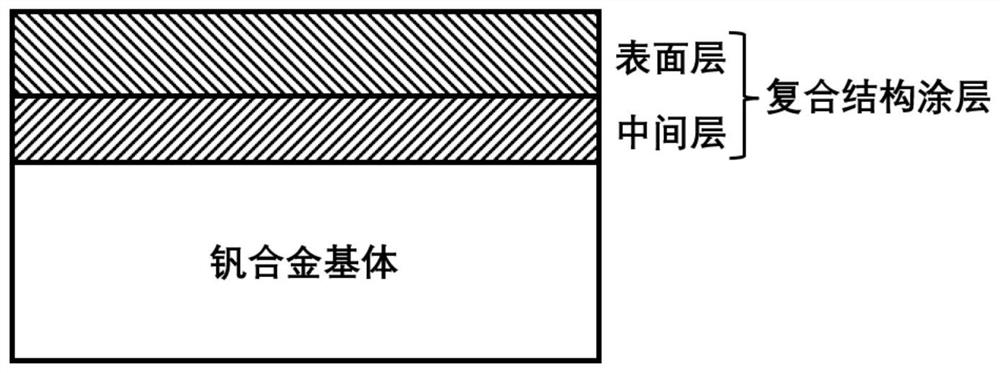

[0022] 1) The vanadium alloy-titanium composite material is prepared by diffusion welding the vanadium alloy and the titanium metal interlayer material by hot isostatic pressing, wherein the operating conditions of the hot isostatic pressing method are: high vacuum or inert gas atmosphere, temperature 900°C , pressure 2MPa, time 1h; 2) Apply 200-mesh enamel slurry on the surface of the metal titanium intermediate layer, dry and then fire, the firing conditions are: high vacuum or inert gas atmosphere, temperature 950°C , the time is 10 minutes, and the vanadium alloy coated with the composite structural coating of "vanadium alloy / metal titanium intermediate layer / enamel layer" is obtained.

[0023] The thickness of the metal titanium intermediate layer obtained above is 5000 μm, the thickness of the enamel surface layer is 100 μm, and the service temperature of the vanadium alloy is any temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com