Wort oxygenating equipment system and control method thereof

A control method and wort technology, applied in biochemical equipment and methods, wort preparation, biochemical instruments, etc., can solve problems affecting the stability of the fermentation process, fast sugar reduction rate of the main fermentation, poor beer maturity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

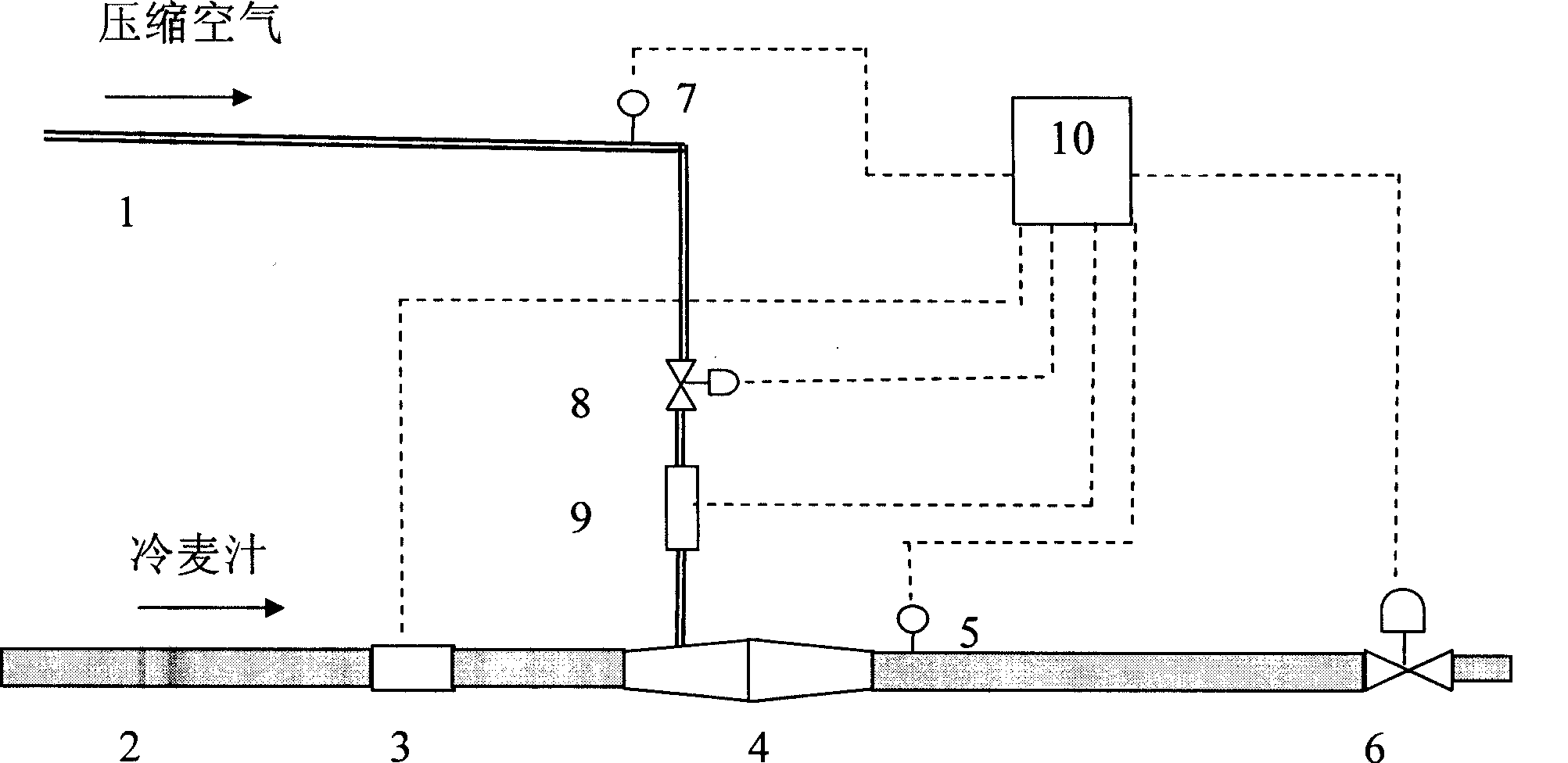

[0028] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. The configuration diagram is as follows figure 1 , that is, the wort oxygenation equipment system of the present invention includes a wort flowmeter, an air flowmeter, an air pressure gauge, a controller, an air regulating valve, a wort oxygenator, a wort pressure gauge and a backup valve, so The wort flowmeter is arranged on the wort pipeline entering the oxygenator, and the air pressure gauge, air regulating valve and air flowmeter are connected in series on the air pipeline entering the oxygenator, and connected in parallel with the wort flowmeter, The wort pressure gauge and backup pressure valve are arranged on the wort pipeline at the outlet of the oxygenator, and the wort pressure gauge is located at the front end of the backup pressure valve. The controller is respectively connected with the above-mentioned air pressure gauge, wort flowmeter, air r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com