Double-M-shaped electric heating device for multicore fiber fusion

An electric heating device and multi-core optical fiber technology, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of narrow flame temperature adjustment range, low output, and safety of gas combustion system, and achieve a small temperature fluctuation range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the drawings.

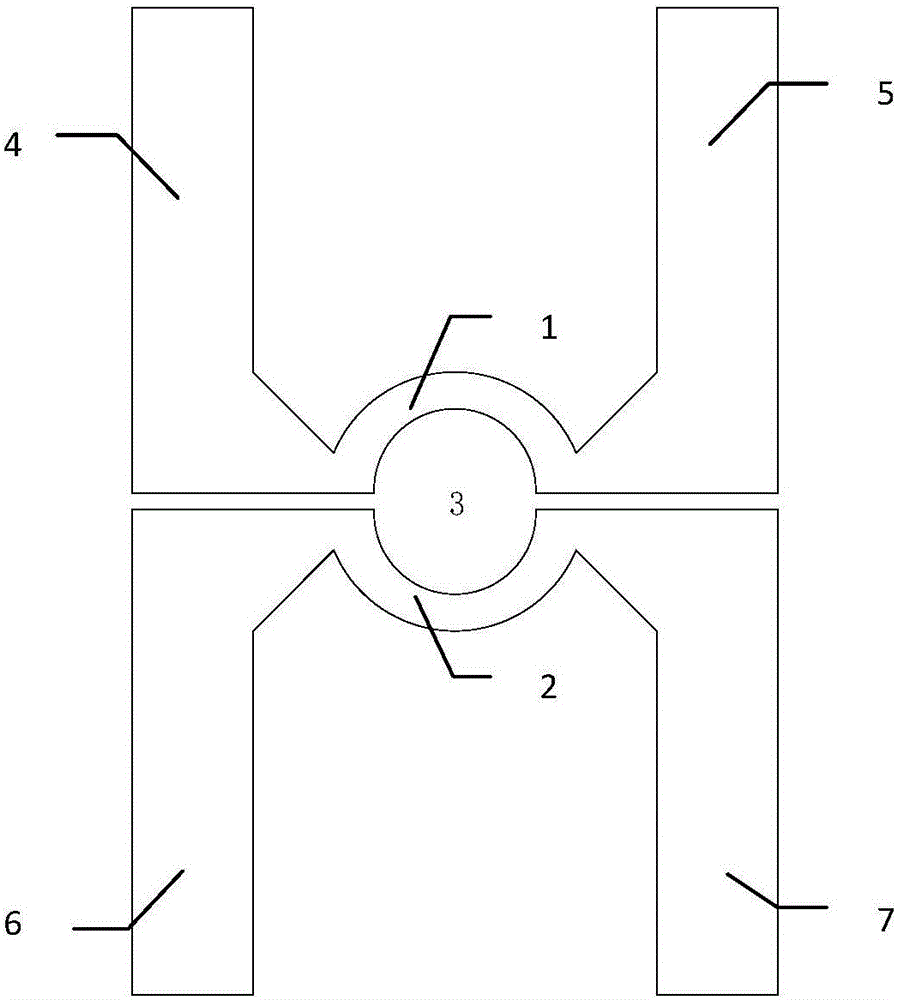

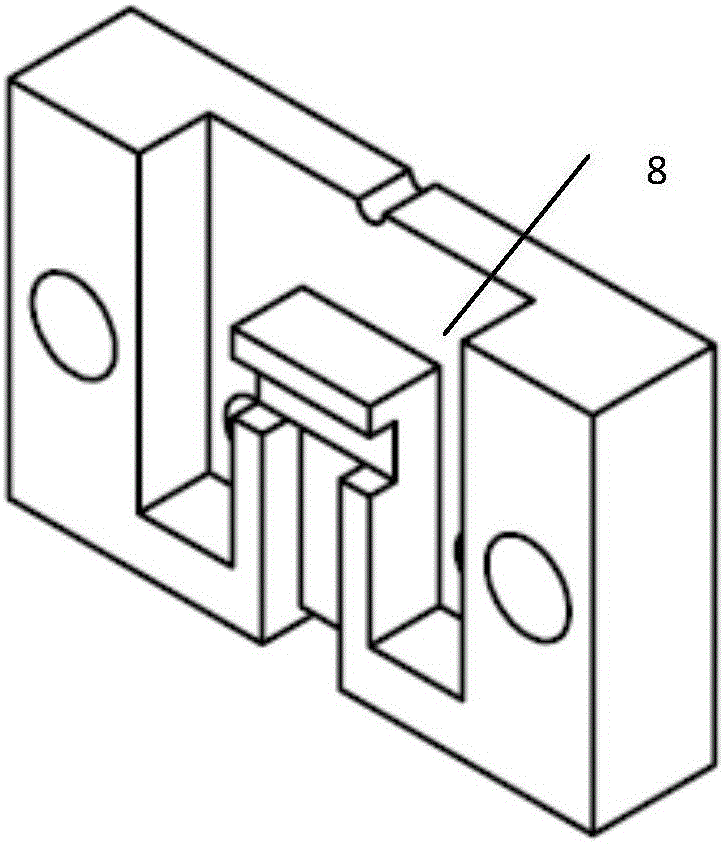

[0026] The present invention relates to a double M-shaped electric heating element used for fusion of multi-core optical fibers, which is characterized in that: the double M-shaped heating element is composed of two identical M-shaped graphite heating elements 1 and 2 graphite heating elements. 3 is the heating area, and the four legs of the double M are electrodes for loading current. Applying it to electric heating system has the following advantages:

[0027] (1) The heating power can be easily controlled. As long as one or more of the three parameters of current, voltage or heating body resistance is changed arbitrarily, the heating power can be changed, and a more ideal temperature field can be easily obtained;

[0028] (2) Small influence from the external environment, small temperature fluctuation range, easy control and high control accuracy;

[0029] (3) By changing the size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com