Device and method for quickly repairing thermoplastic plastic automobile parts

A technology for auto parts and thermoplastics, which is applied in the field of rapid maintenance devices for thermoplastic auto parts, can solve the problems of secondary damage to bumpers, labor and material resources, and achieve simple operation, simple structure, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

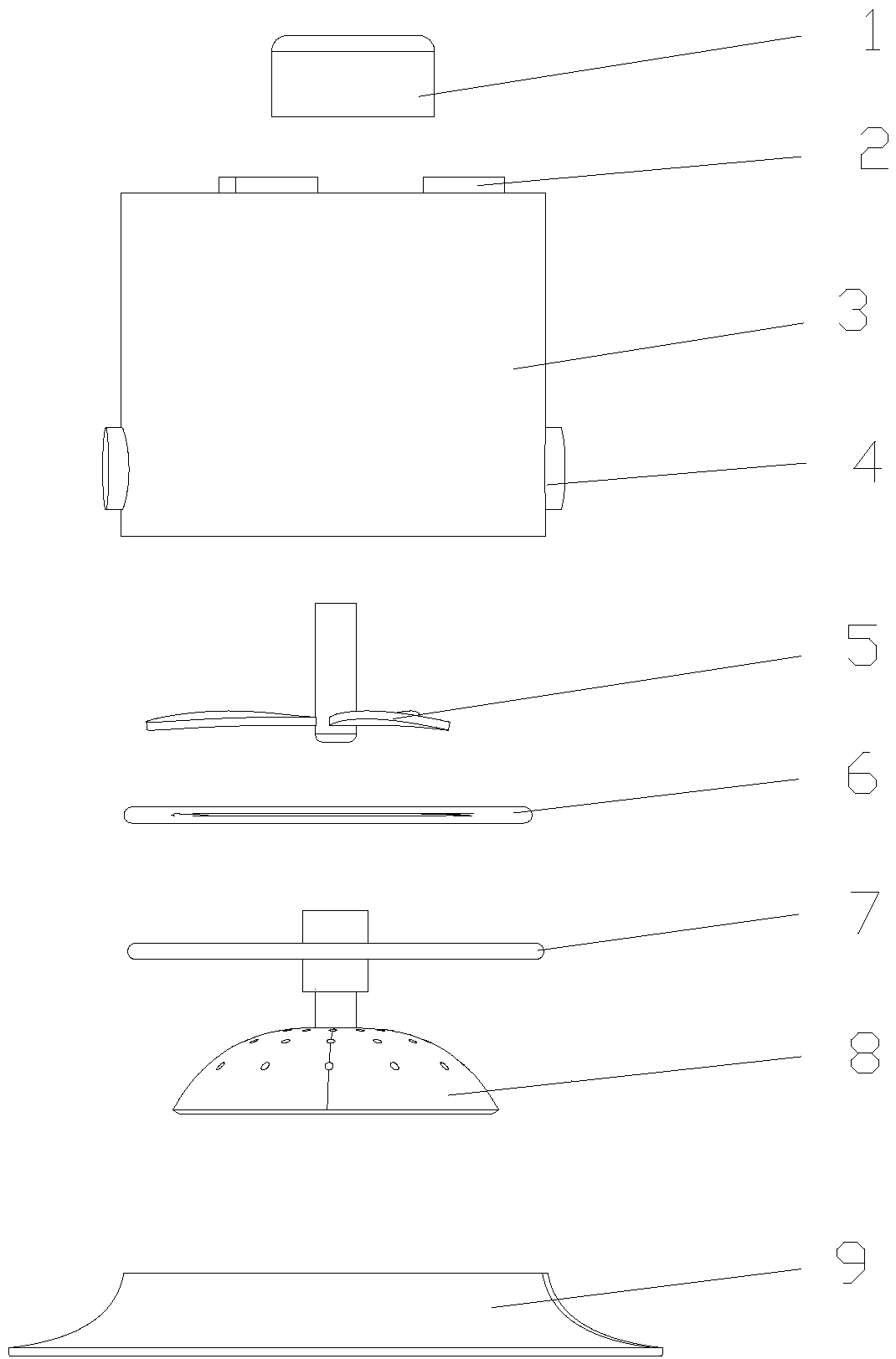

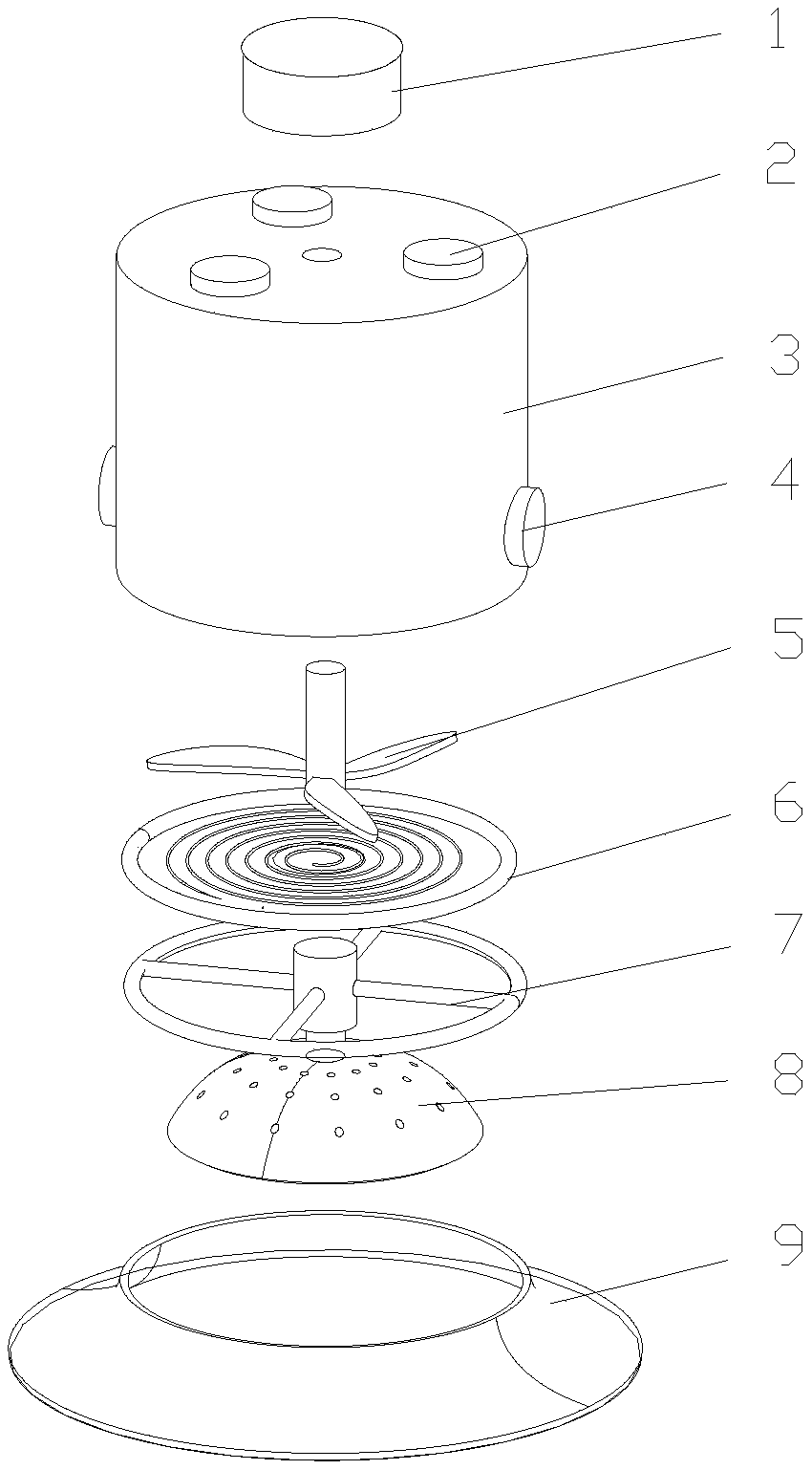

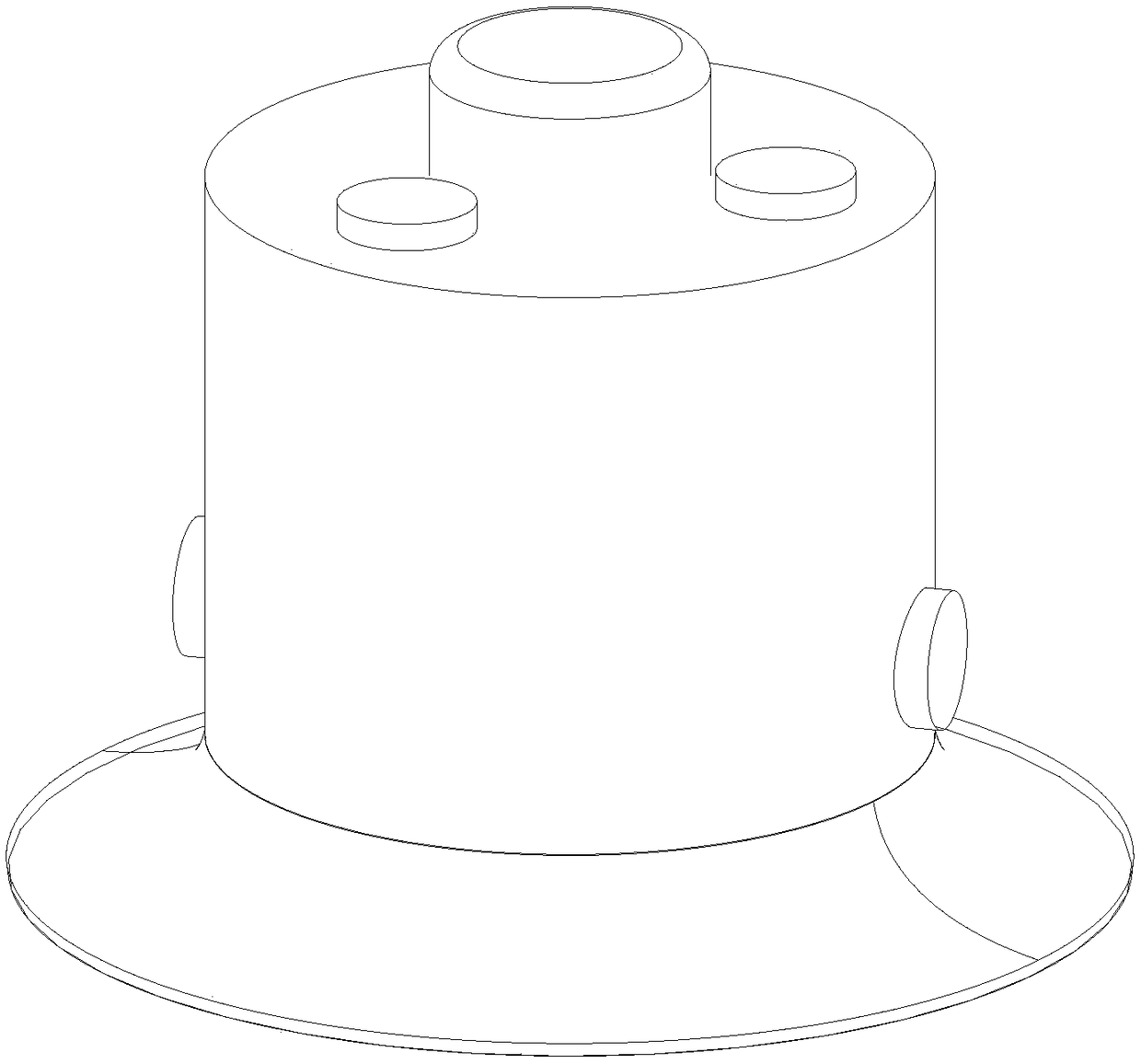

[0035] Such as Figure 1-5 shown. The invention discloses a rapid maintenance device for thermoplastic auto parts, which comprises a casing 3 with an open lower end;

[0036] A cup 9 for covering the area to be shaped of the thermoplastic auto parts 10 is installed at the lower end of the housing 3;

[0037] Inside the casing 3, the fan blade 5 driven by the motor 1, the disc-shaped heating wire assembly and the labyrinth cover 8 with air holes are sequentially arranged from top to bottom;

[0038] When the cup 9 covers the area to be shaped, the inside of the housing 3 is divided into an upper sealing cavity and a lower sealing cavity with the position of the fan blade 5 as a boundary; The valve 2 is equipped with a second valve 4 on the housing 3 corresponding to the lower sealing chamber;

[0039] When the motor 1 is rotating forward, the disc-shaped heating wire assembly is in the state of energizing and heating, and the first valve 2 and the second valve 4 are both in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com