Motor heating control method, controller and system based on look-up table and closed-loop control

A motor controller and heating control technology, applied in the direction of controlling electromechanical brakes, control systems, controlling generators, etc., can solve the problems of continuous control, the inability to realize the adjustment and control of the heating power of the motor, and the inability to realize the heating power of the motor, etc., to achieve To achieve the effect of continuous control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

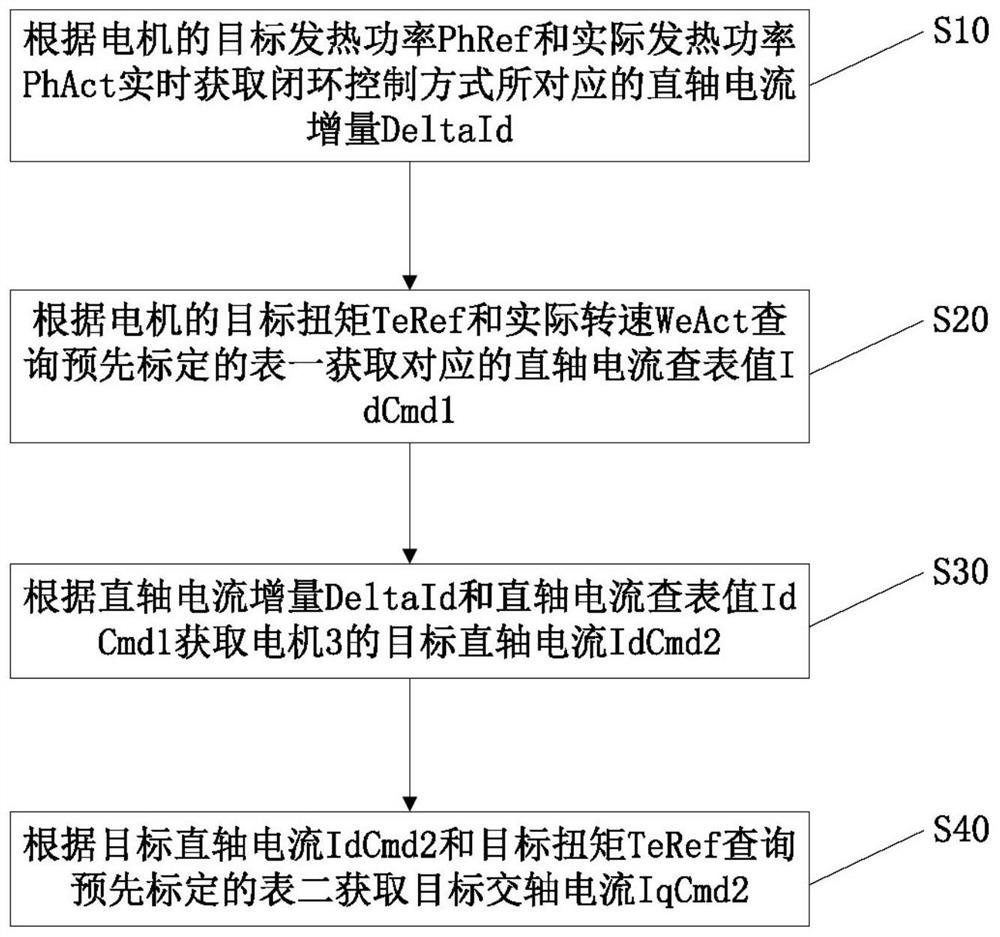

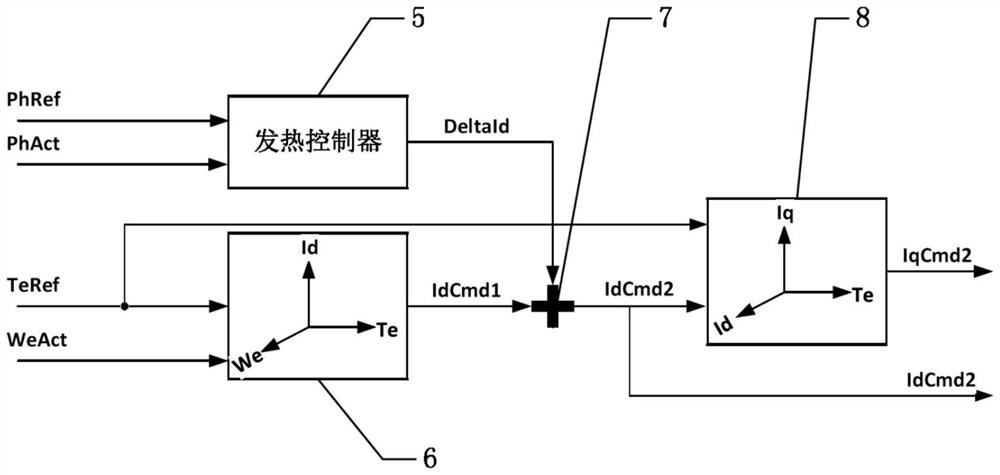

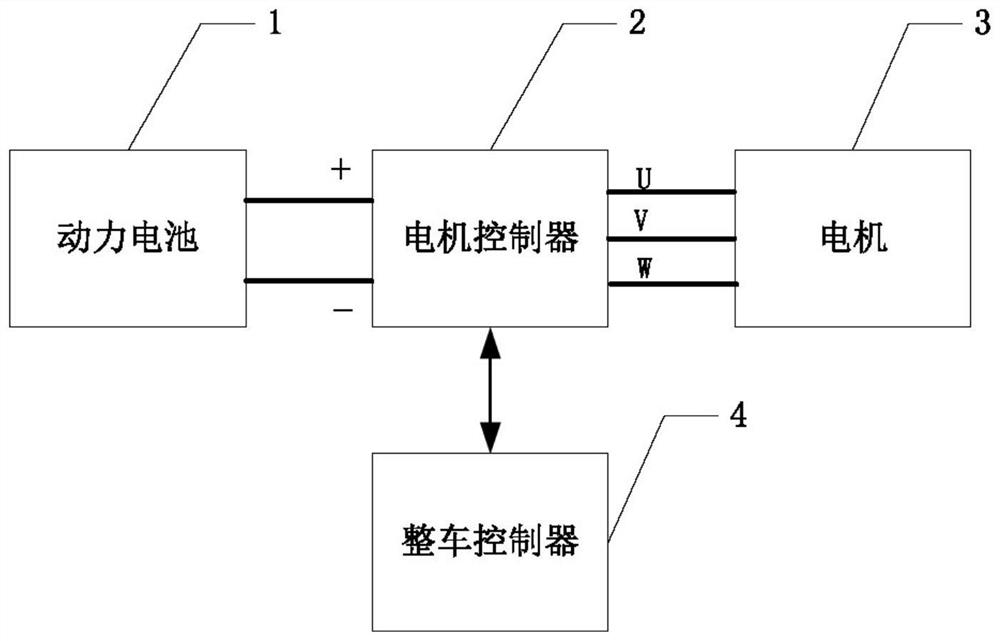

[0044] figure 1 is a flow chart of a motor heating control method according to an embodiment of the present invention. figure 2 is a schematic diagram of a motor heating control method according to an embodiment of the present invention. Such as figure 1 shown, see also figure 2 , the present invention provides a motor heating control method based on look-up table and closed-loop control, which may generally include the following steps:

[0045] S10: According to the target heating power PhRef and the actual heating power PhAct of the motor 3, the direct-axis current increment DeltaId corresponding to the closed-loop control mode is obtained in real time. The target heating power PhRef refers to the heating power value calculated and generated according to the heating demand of the whole vehicle, that is, the heating power value expected to be achieved by the motor 3 after passing through the control method.

[0046] S20: According to the target torque TeRef and the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com