Forming test mold for asphalt mixture rutting test piece

A technology for asphalt mixtures and test molds, which is applied in the direction of unloading devices, manufacturing tools, and preparation of test samples. It can solve problems such as poor thermal insulation effect, time-consuming and labor-intensive, loose mold connection parts, etc., and achieve small temperature fluctuations. The test process is simple and the effect of reducing test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

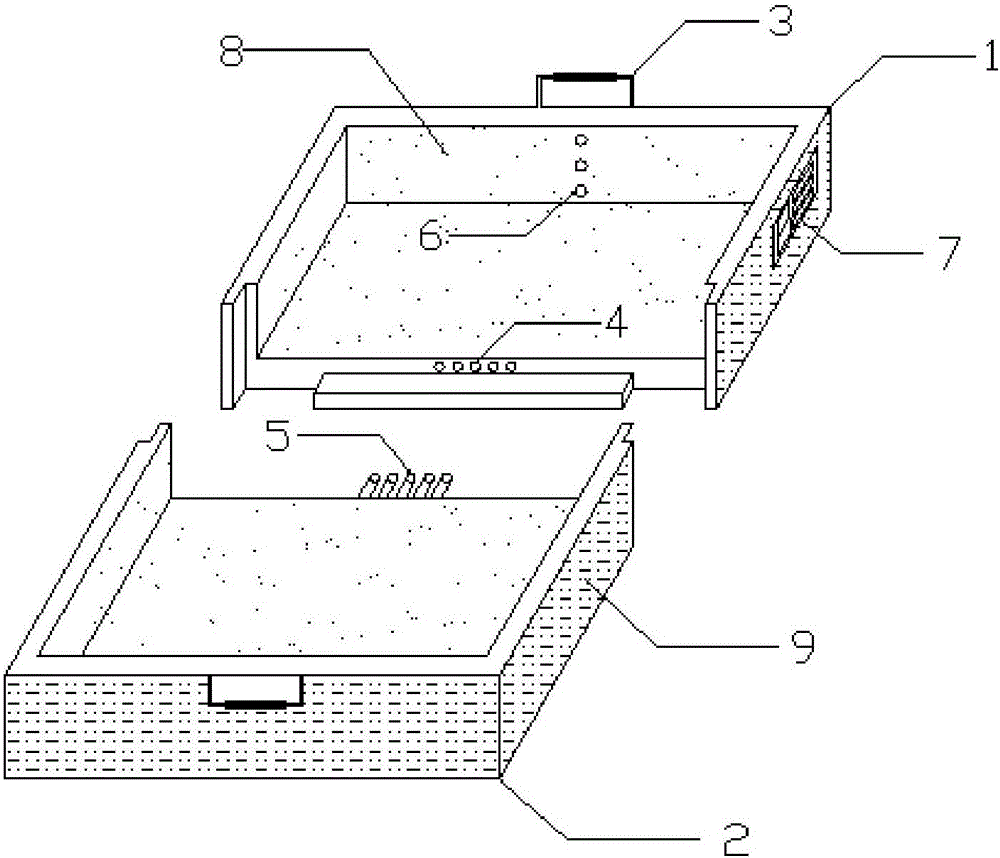

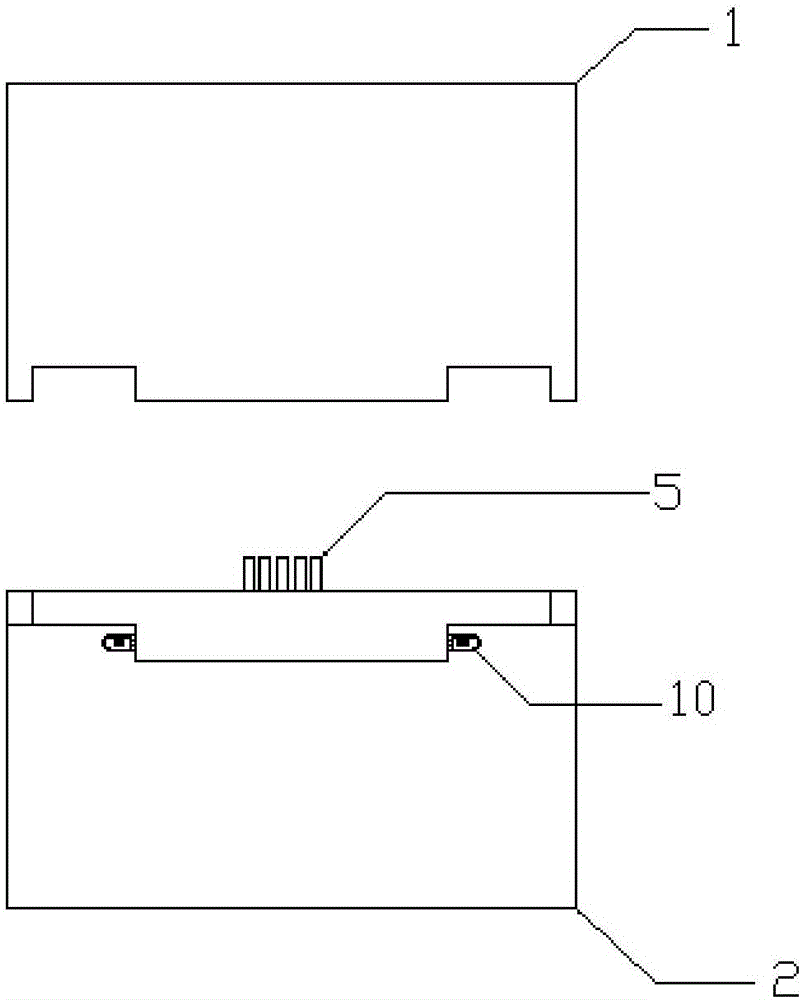

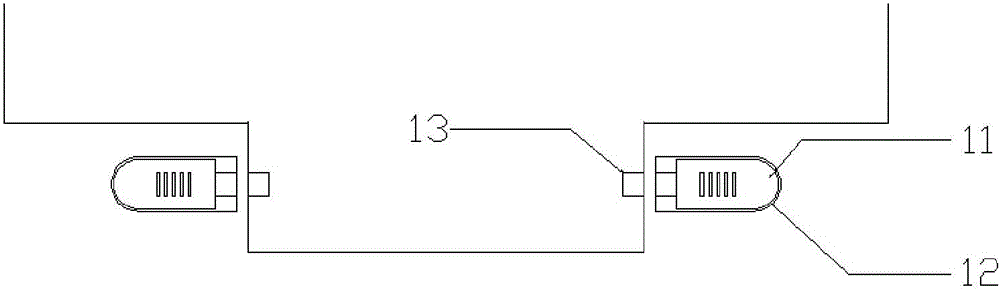

[0029] Such as figure 1 with figure 2 As shown, a separate asphalt mixture rutting specimen forming mold includes an upper separation tank 1, a lower separation tank 2, a heat insulation handle 3, a fixed shaft socket 4, a fixed shaft 5, a temperature sensor 6, and a dynamic temperature display 7 , anti-stick coating 8, high temperature heat insulation coating 9, sliding locking device 10. The sliding locking device 10 includes a locking slot 11 , a sliding locking plug 12 and a locking hole 13 . Among them, the upper separation tank and the lower separation tank are dustpan-shaped structures welded by three side plates and one bottom plate, which can form an asphalt mixture rutting specimen forming mold with an upper opening after connection. The upper separation tank 1 and the lower separation tank 2 are connected by a sliding locking devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com