Matrix type heating temperature control platform device for thermocuring mold

A platform device and matrix technology, applied in the field of matrix heating and temperature control platform devices, can solve the problems of affecting the yield and production line speed, uneven temperature field, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

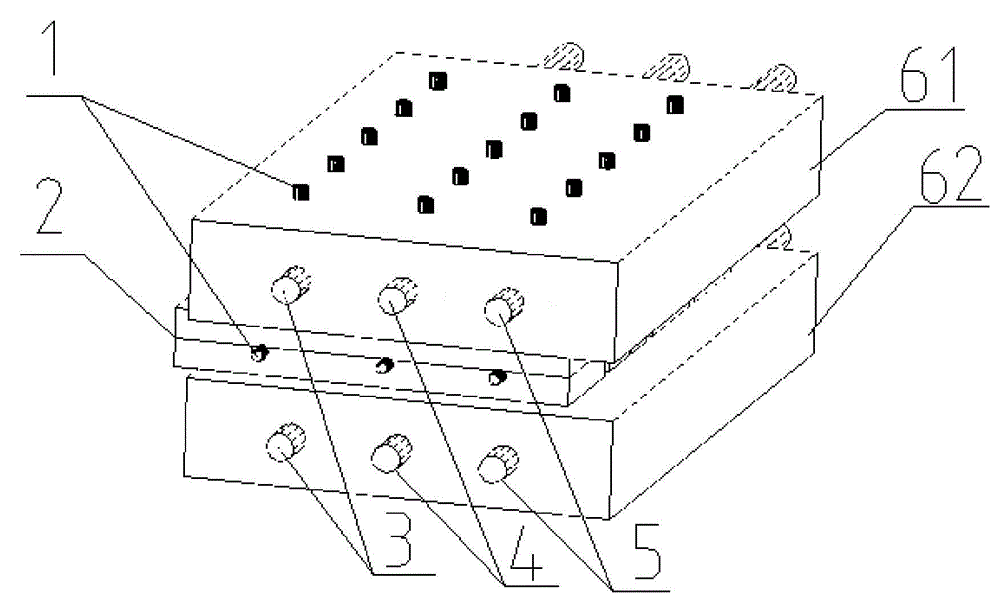

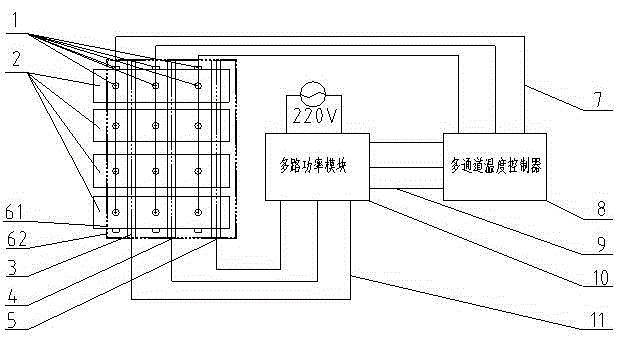

[0019] Such as figure 1 and 2 As shown, a matrix type heating temperature control platform device for thermosetting molds of the present invention includes upper and lower heating plates 61, 62, multiple sets of heating tubes, heated molds 2, matrix temperature measuring elements 1, multiple Channel temperature controller 8 and multi-channel power module 10; upper and lower heating plates 61, 62 are respectively placed on the upper plane and lower plane of the heated mold 2, and the matrix temperature measuring element 1 is used to measure the top and both sides directly above the mold The temperature on the side of the mold, the heat control pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com