Ammonium chloride neutralization reaction kettle

A reaction kettle and ammonium chloride technology, applied in the field of ammonium chloride neutralization reaction kettle, can solve the problems of insufficient structural strength, short service life of the reaction kettle, high temperature of the reaction kettle, etc., and achieve excellent corrosion resistance and heat resistance, Reduced long-term investment costs and small temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

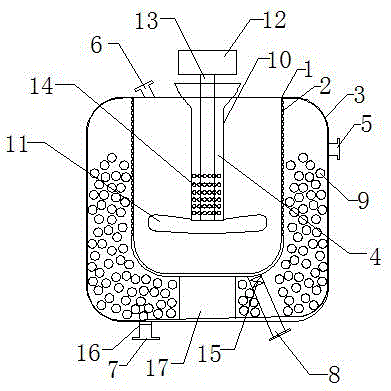

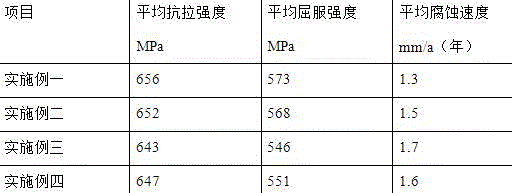

[0022] Such as figure 1As shown, a kind of ammonium chloride neutralization reactor comprises reactor body 1, and the outer wall of described reactor body 1 is evenly distributed with several U-shaped grooves 2, and reactor body 1 is provided with a layer of shell 3 outside, and inside A stirring device 4 is provided, one side of the upper part of the housing 3 is provided with a cooling liquid inlet 5, the other side is provided with a feeding port 6, one side of the lower part is provided with a cooling liquid outlet 7, and the other side is provided with a discharge Port 8, there is a gap between the reactor body 1 and the shell 3, the gap is filled with fiber ball filler 9, one end of the discharge port 8 communicates with the reactor body 1, and the other end passes through Pass through the housing 3 and protrude 3-10cm outside the housing 3 (7cm is the best, of course you can also choose 3cm or 10cm), the stirring device 4 includes a stirring shaft 10 and a stirring blad...

Embodiment 2

[0034] This embodiment is the same as Embodiment 1, except that the special titanium alloy is composed of the following mass percentages: aluminum is 5.2%, tin is 1.5%, nickel is 0.16%, iridium is 0.093%, and chromium is 0.18%, molybdenum is 0.17%, manganese is 0.86%, vanadium is 5.78%, niobium is 0.98%, and the balance is titanium and its inevitable impurities. The body of the special titanium alloy reactor is made through the following process steps;

[0035] Step 1. Using the existing preparation process for smelting titanium alloys, melting and casting the titanium alloys in a vacuum electric arc furnace according to the ratio of the above alloy elements to obtain titanium continuous casting slabs that meet the alloy composition requirements, and surface the obtained titanium continuous casting slabs Cleaned, then placed in a chamber furnace to heat and remove scale;

[0036] Step 2. Place the titanium continuous casting slab obtained in step 1 in a four-roll reversible ro...

Embodiment 3

[0044] This embodiment is the same as Embodiment 1 and Embodiment 2, except that the special titanium alloy is composed of the following mass percentages: aluminum is 5.5%, tin is 1.8%, nickel is 0.16%, iridium is 0.04% %, chromium is 0.16%, molybdenum is 0.27%, manganese is 0.5%, vanadium is 5.5%, niobium is 0.6%, and the balance is titanium and its inevitable impurities. The body of the special titanium alloy reactor is made through the following process steps have to;

[0045] Step 1. Using the existing preparation process for smelting titanium alloys, melting and casting the titanium alloys in a vacuum electric arc furnace according to the ratio of the above alloy elements to obtain titanium continuous casting slabs that meet the alloy composition requirements, and surface the obtained titanium continuous casting slabs Cleaned, then placed in a chamber furnace to heat and remove scale;

[0046] Step 2. Place the titanium continuous casting slab obtained in step 1 in a fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com