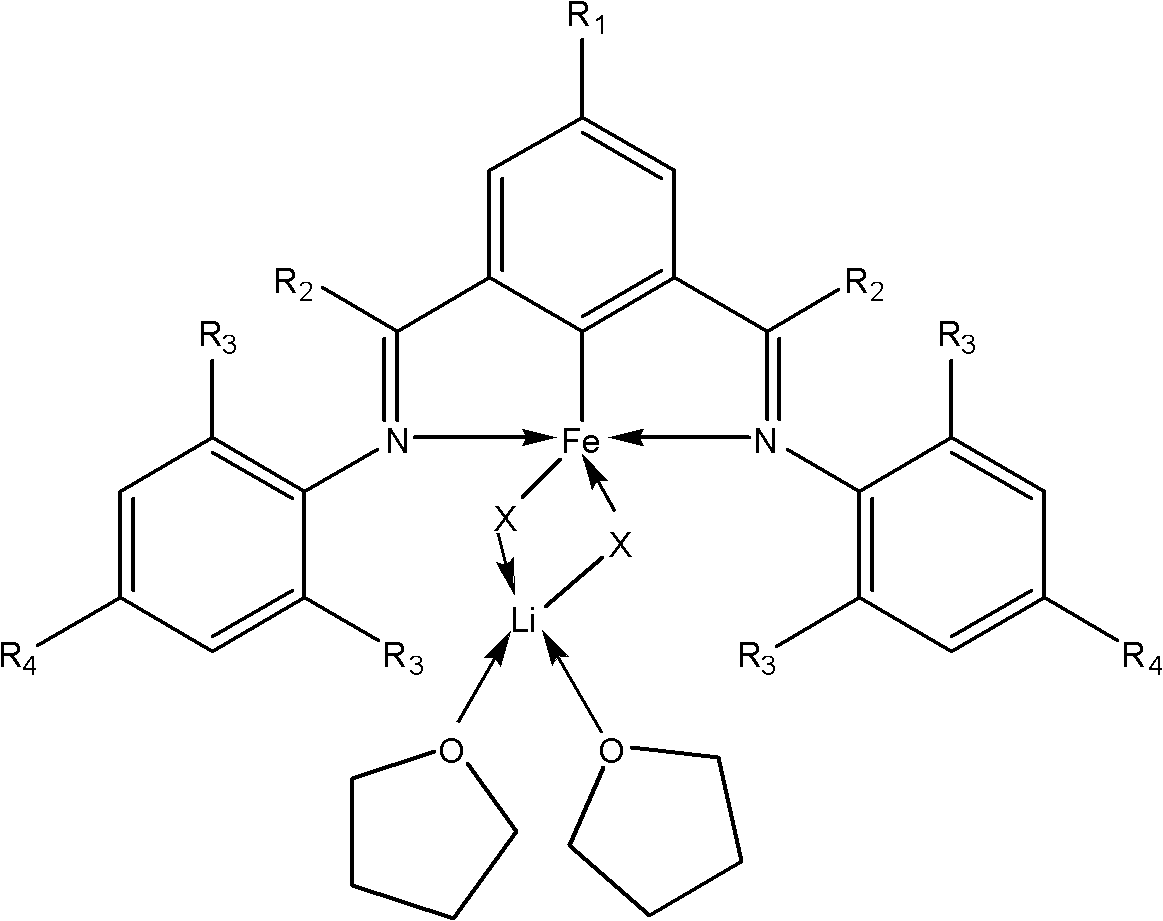

Clamp-type iron complex and preparation method and application thereof

An iron complex and clamp-type technology, which is applied in the field of catalysis, can solve the problems of difficult preparation, expensive boron additives, and high price, and achieve the effects of easy control of the reaction, stable catalytic performance, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

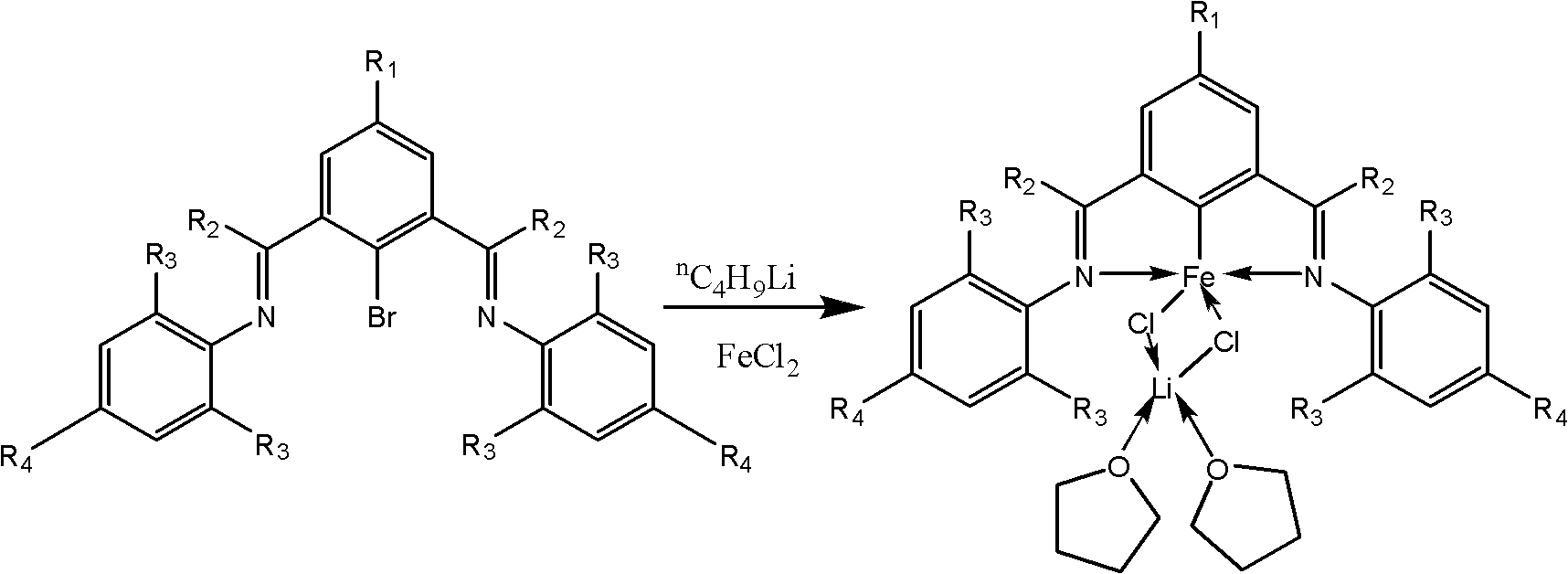

Method used

Image

Examples

Embodiment 1

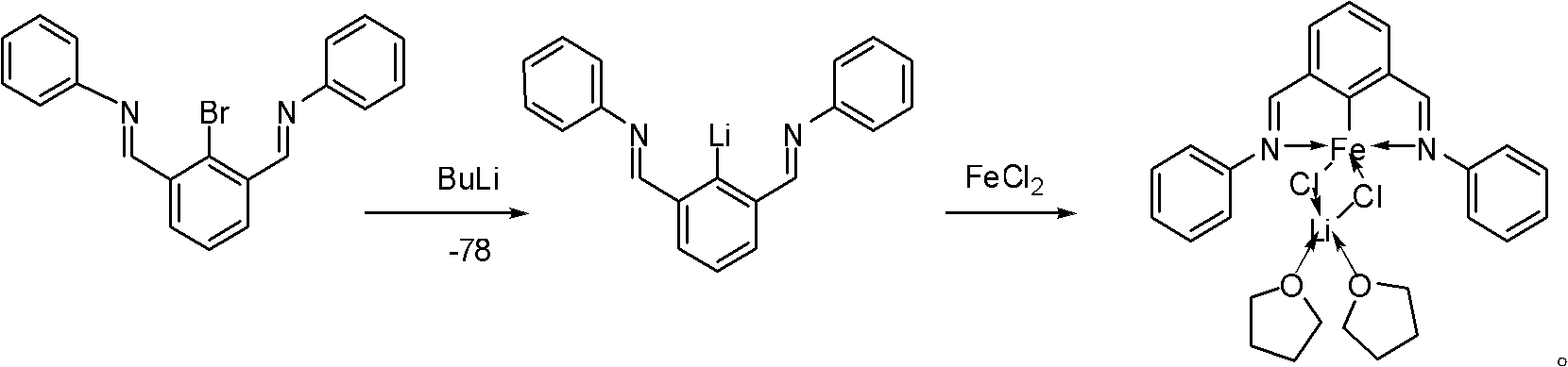

[0033] Example 1 Preparation of pincer iron complex (iron complex 1)

[0034]

[0035] At -78°C to -40°C, a hexane solution of butyllithium (1.2mL, 1.88mmol) was slowly added dropwise to 2,6-bis(N-phenyl)iminobromobenzene (0.6690g , 1.84mmol) in 30mL tetrahydrofuran solution, add FeCl to it after 30 minutes of low temperature reaction 2 (0.2332g, 1.88mmol), naturally rise to room temperature and continue to react for 12 hours, stop the reaction, concentrate the reaction solution to about 5ml, add about 15ml of hexane, filter out insoluble matter, and place the filtrate in a refrigerator at -30°C after concentration Freeze overnight to obtain 0.6200 g of purple crystalline compound with a yield of 60%. Elemental analysis, its molecular formula is C 28 h 31 Cl 2 FeLiN 2 O2 (%): C, 59.92; H, 5.57; Cl, 12.63; N, 5.86; Fe, 9.95;

Embodiment 2

[0036] Example 2 Preparation of pincer iron complex (iron complex 2)

[0037]

[0038] Under the condition of -78℃~-40℃, a hexane solution of butyllithium (1.2mL, 1.88mmol) was slowly added dropwise to 2,6-bis(N-2,6-dimethylphenyl) Aminobromobenzene (0.7716, 1.84mmol) in 30mL tetrahydrofuran solution, reacted at low temperature for 30 minutes, then added FeCl 2 (0.2332g, 1.84mmol), naturally rise to room temperature and continue to react for 12 hours, stop the reaction, concentrate the reaction solution to about 5ml, add about 15ml of hexane, filter out insoluble matter, and place the filtrate in a refrigerator at -30°C after concentration After freezing overnight, 0.7724 g of a purple crystalline compound was obtained, with a yield of 68%. Elemental analysis, its molecular formula is C 32 h 39 Cl 2 FeLiN 2 o 2 (%): C, 62.26; H, 6.37; Cl, 11.49; Fe, 9.05; Li, 1.12; N, 4.54;

Embodiment 3

[0039] Example 3 Preparation of pincer iron complex (iron complex 3)

[0040]

[0041] At -78°C to -40°C, a hexane solution of butyllithium (1.2mL, 1.88mmol) was slowly added dropwise to 2,6-bis(N-2,6-diethylphenyl) Aminobromobenzene (0.8748, 1.84mmol) in 30mL tetrahydrofuran solution, reacted at low temperature for 30 minutes, then added FeCl 2 (0.2332g, 1.84mmol), naturally rise to room temperature and continue to react for 12 hours, stop the reaction, concentrate the reaction solution to about 5ml, add about 15ml of hexane, filter out insoluble matter, and place the filtrate in a refrigerator at -30°C after concentration After freezing overnight, 0.8922 g of a purple crystalline compound was obtained with a yield of 72%. Elemental analysis, its molecular formula is C 36 h 47 Cl 2 FeLiN 2 o 2 (%): C, 64.20; H, 7.03; Cl, 10.53; Fe, 8.29; Li, 1.03; N, 4.16; O, 4.75.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com