Coil-winding type electronic induction water processing circuit and water processing method thereof

An electronic induction, coil winding technology, applied in the fields of magnetic field/electric field water/sewage treatment, water/sludge/sewage treatment, electronic switch, etc., can solve the problems of single output frequency, low decontamination efficiency, and inability to treat water bodies. , to achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

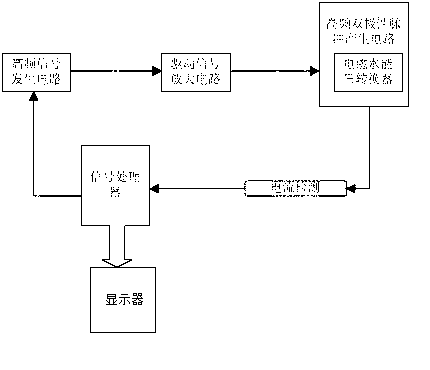

[0033] The high-frequency signal generating circuit is a signal source generating circuit, which generates a driving signal and transmits the driving signal to the driving signal amplifying circuit. The driving signal amplifying circuit uses TLP250 as the main device, which amplifies the driving signal from the high-frequency signal generating circuit and transmits it to the switch gate of the MOSFET in the high-frequency bipolar pulse generating circuit.

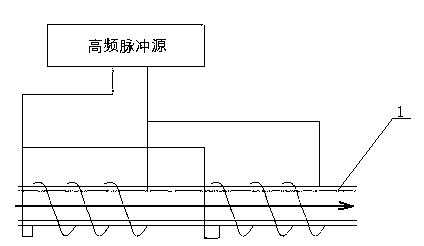

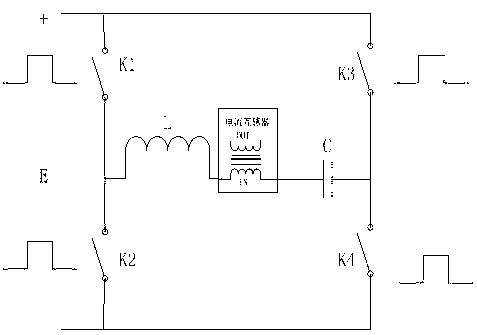

[0034] The high-frequency bipolar pulse generating circuit includes an electromagnetic water energy converter, combined with figure 1, the electromagnetic water energy converter is two sets of windings wound on the water supply pipe 1 in the same winding direction, and the two sets of windings are the resonant inductance L of the high-frequency bipolar pulse generating circuit. The high-frequency bipolar pulse generation circuit also includes 4 field effect transistor MOSFETs and a resonant capacitor C. These 4 field effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com