Control method of speed and acceleration of continuous hot rolling roughing rolling unit

A technology of acceleration control and roughing unit, which is applied in acceleration control, variable acceleration control, variable speed of hot continuous rolling roughing unit controlled by computer system, and speed of hot continuous rolling roughing unit. Issues such as slippage of transitional specifications and impact on output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

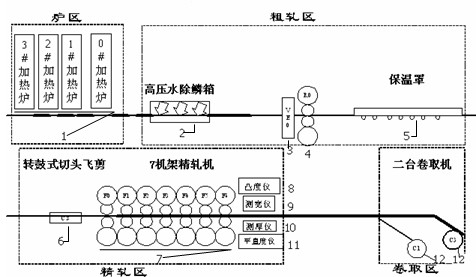

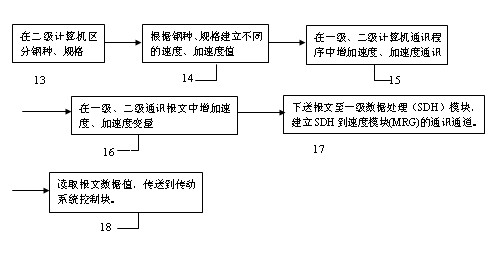

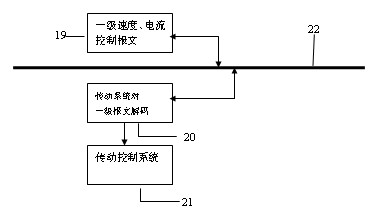

[0036] Embodiment 1. Speed and acceleration control method of hot continuous rolling roughing mill

[0037] The speed and acceleration control method of the hot continuous rolling rough rolling mill group of this example is the method that the computer system carries out automatic control to the hot continuous rolling rough rolling mill speed and acceleration, usually the concrete rolling process flow is determined by figure 1 indicate that in figure 1 Middle: 1 is the heating furnace (4 seats), 2 is the high-pressure water descaling box, 3 is the rough rolling vertical roll mill (VE0), 4 is the rough rolling flat roll mill (R0), 5 is the heat preservation cover, 6 is the drum Type cutting head flying shear, 7 is the finishing stand (7 additional frames), 8 is the crown gauge, 9 is the width gauge, 10 is the thickness gauge, 11 is the flatness gauge, and 12 is the coiler. The method for controlling the speed and acceleration of the hot continuous rough rolling unit is: the ...

Embodiment 2

[0068] Embodiment 2. Speed and acceleration control method of hot continuous rolling roughing mill

[0069] The difference between the hot continuous rolling rough rolling mill speed and the acceleration control method of this example and the hot continuous rolling rough rolling mill speed and acceleration control method of embodiment one are: the hot continuous rolling rough rolling mill speed of this example, the acceleration control method according to the rolling There are three small examples of different steel types as follows:

[0070]Example 1. The rolling steel grade in the speed and acceleration control method of the hot continuous roughing rolling mill in this example is carbon steel (including all soft steel and low alloy steel). V in the variable speed formula (1) of this example 0 (n) Creeping speed function, that is, the biting speed of each pass of the strip steel. When the rolled steel is carbon steel (including all soft steels and low alloy steels), the cr...

Embodiment 3

[0101] Embodiment 3. Speed and acceleration control method of hot continuous rolling roughing mill

[0102] The hot continuous rolling rough rolling mill speed of this example, acceleration control method and the hot continuous rolling rough rolling mill speed of embodiment one, embodiment two, the acceleration control method difference has: the hot continuous rolling rough rolling mill speed of this example, acceleration The control method has the following three small implementation examples according to the different types of rolled steel:

[0103] Example 1. The rolling steel grade in the speed and acceleration control method of the hot continuous roughing rolling mill in this example is carbon steel (including all soft steel and low alloy steel). V in the variable speed formula (1) of this example 0 (n) Creeping speed function, that is, the biting speed of each pass of the strip steel. When the rolled steel is carbon steel (including all soft steels and low alloy steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com