Steel plate manufacturing facility and manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

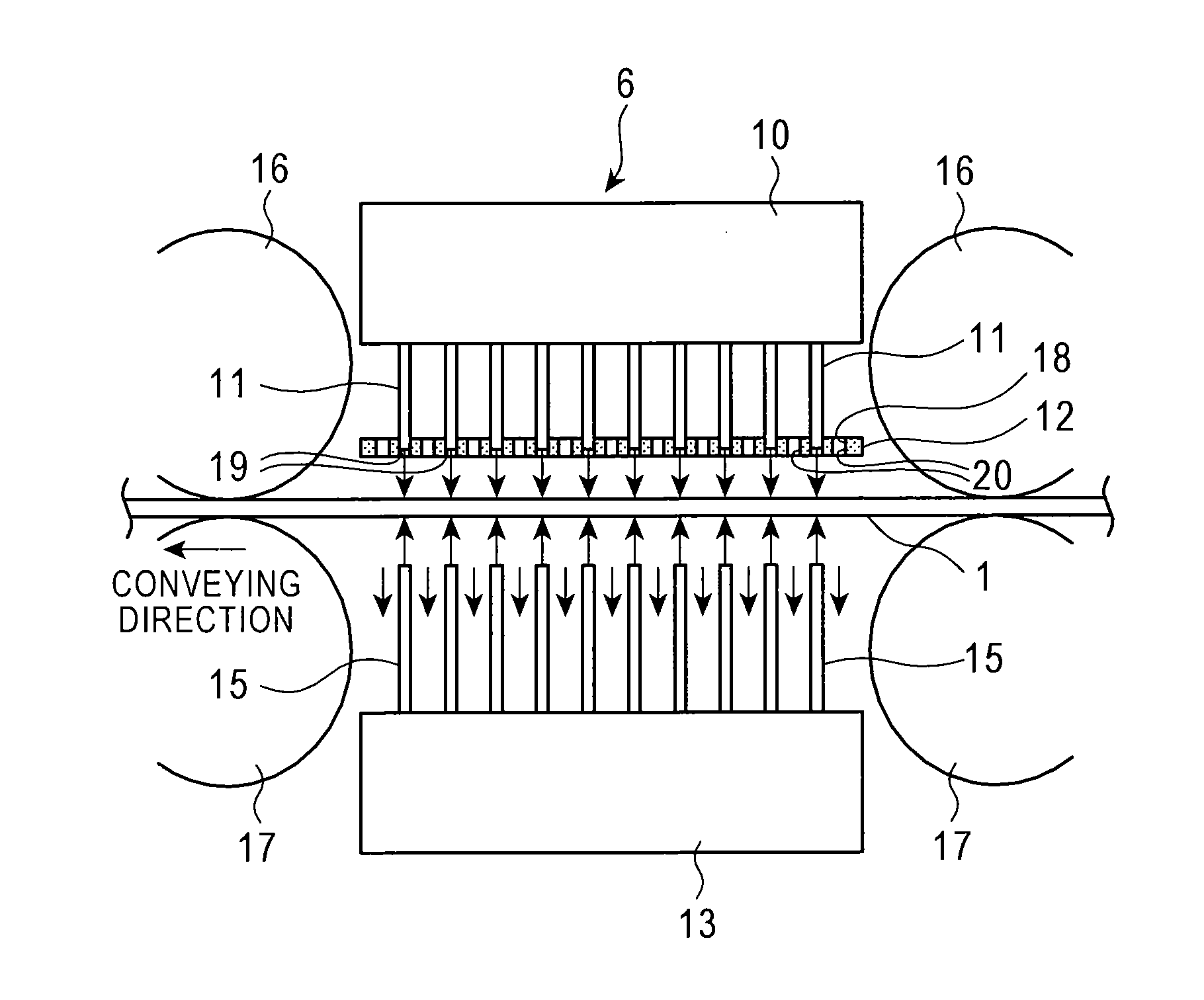

[0082]The steel plate 1, rolled by the hot rolling mill 3, having a thickness of 30 mm and a width of 3500 mm was passed through the first hot leveler 5 and the descaler 4 and was then controlled such that the steel plate was cooled from 820° C. to 420° C. As regards a condition for stable cooling calculated from the above-described expressions (6), (7), and (8), the period of time t between the completion of removal of scale on the steel plate 1 by the descaler 4 and the start of cooling of the steel plate 1 by the cooling equipment 6 is less than or equal to 42 s, preferably, less than or equal to 19 s, and more preferably, less than or equal to 5 s.

[0083]As regards the descaler 4, the spraying pressure of nozzles was 17.7 MPa, the spray flow rate per nozzle was 64 L / min / nozzle, the spraying distance (the distance between each spraying nozzle of the descaler 4 and each surface of the steel plate 1) was 130 mm, the spray angle of nozzle was 32°, the angle between the spray directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com