Self-cleaning solar vacuum pipe

A solar energy and vacuum tube technology, applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problem of affecting the heat collection efficiency and service life of vacuum tubes, reducing the heat exchange efficiency between the endothermic coating and water, and reducing the heat exchange efficiency. and other problems, to achieve the effect of improving the descaling effect, reducing the degree of complexity and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

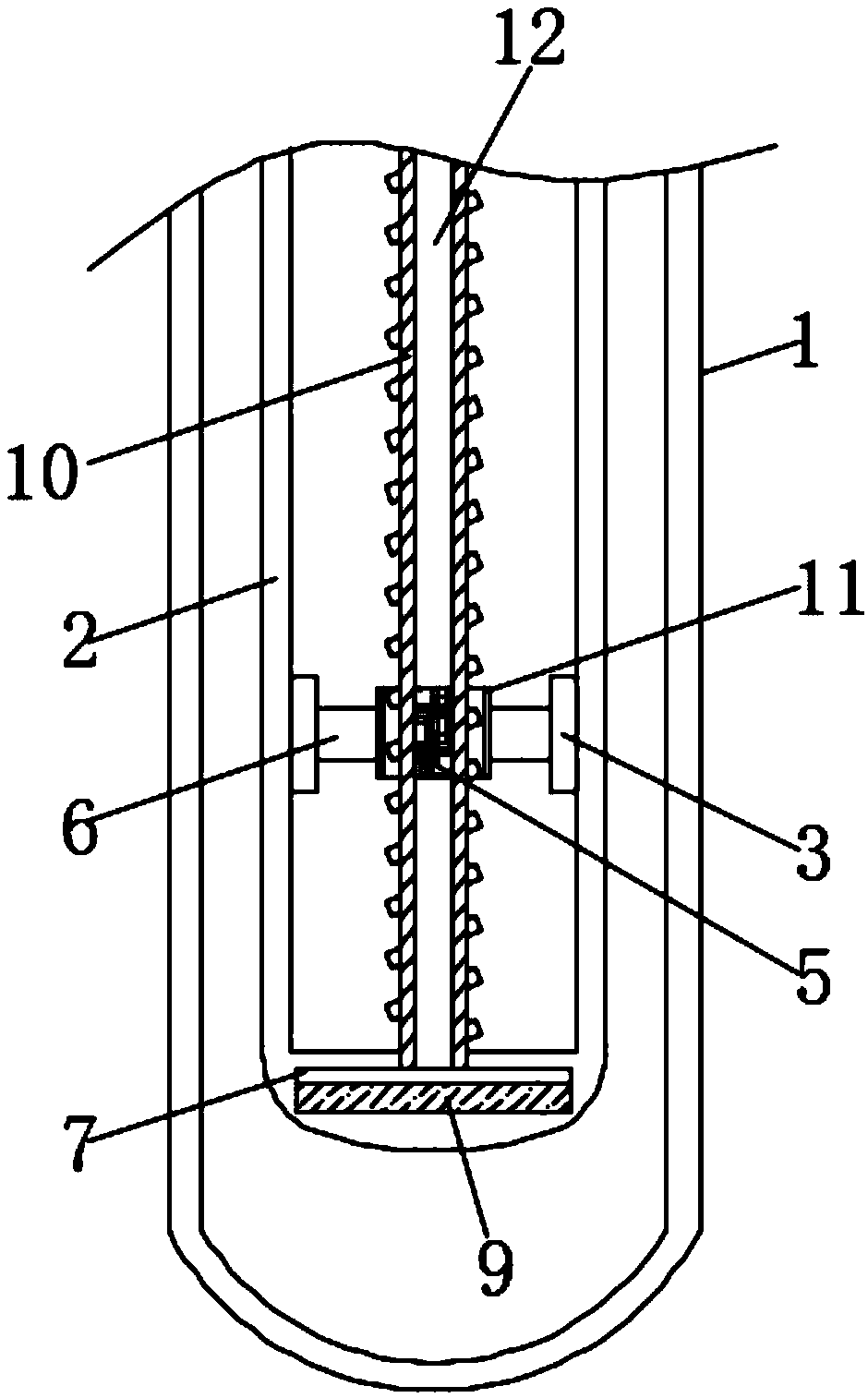

[0023] refer to figure 2 , the difference from Embodiment 1 is that the mobile device includes a ball screw 10 coaxially fixedly connected to the inner bottom of the inner tube 2, the side wall of the ball screw 10 is provided with a slide chamber 12 along its axial direction, and the slide chamber 12 The inner sliding seal is connected with a magnetic sliding plug 5, and the upper end of the ball screw 10 is provided with a vent hole communicating with the sliding chamber 12, and a waterproof and breathable membrane is installed in the vent hole, and a screw nut 11 is installed on the ball screw 10. And the lead screw nut 11 is attracted to the magnetic sliding plug 5 , and the end of the connector 6 away from the metal scraper ring 3 is fixedly connected to the side wall of the lead screw nut 11 .

[0024] In this embodiment, when the vaporized low-boiling evaporating liquid 9 pushes the magnetic slider 5 to move, it drives the screw nut 11 to move up through the attraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com