Method for increasing scale removal effect of medium and heavy plate

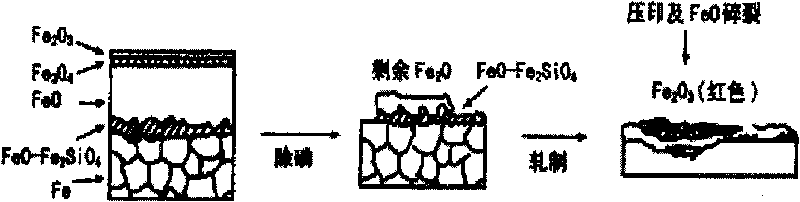

A high-pressure water descaling and thick steel plate technology, which is applied in the field of metallurgy, can solve the problems that cannot meet the high standard of steel plate surface quality level, so as to improve the descaling effect and eliminate the effect of "pitting"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] Specific embodiments of the present invention include:

[0015] 1. Chemical composition design.

[0016] The chemical composition of low-alloy high-strength medium-thick plates follows GB / T1591-2008, which requires the element Si≤0.50%. Fayalite (FeO-Fe) formed according to Si element 2 SiO 4 ), the principle of enhancing the adhesion of oxide scale and making it difficult to remove, through the comparison of industrial experiments with different Si contents, the optimum Si content design range of 0.15-0.35% is determined.

[0017] 2. Heating furnace temperature control

[0018] In the heating section of the heating furnace, a high-temperature rapid heating method is adopted, and the furnace temperature is controlled at 1200-1280 °C to reduce the thickness of the billet generated by primary oxidation in the furnace and reduce the thickness ratio of FeO in the iron sheet structure.

[0019] 3. Billet tapping temperature

[0020] The production of low-alloy high-stre...

Embodiment 1

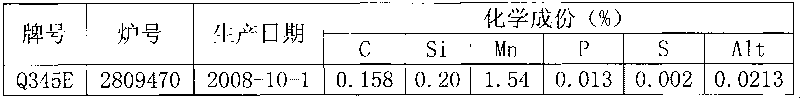

[0023] (1), chemical composition

[0024]

[0025] (2), slab size, steel plate specification

[0026] Slab size: 250*1600*3350mm (cold), steel plate size: 22*2480*8000mm

[0027] (3), rolling process parameters

[0028] Furnace temperature control in the heating section: 1200-1250°C. The billet tapping temperature is 1120°C, the second-stage finishing rolling temperature: 930°C, and the thickness of the intermediate billet to be heated: 60mm

[0029] (4) Slab primary oxidation, secondary oxidation descaling rate and surface condition of steel plate

[0030] After the inspection of 10 slabs and steel plates in one furnace, the descaling rate of the slab’s primary oxide scale after the descaling box reaches 100%, and the average descaling rate of the secondary oxide scale of the finish rolling reaches 95%. The finished steel plate is inspected after shot blasting , there is no "pitting" defect visible to the naked eye on the surface.

Embodiment 2

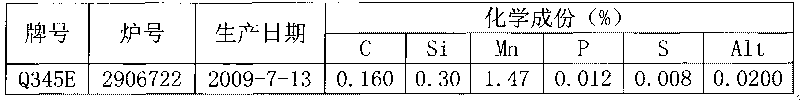

[0032] (1), chemical composition

[0033]

[0034] (2), slab size, steel plate specification

[0035] Slab size: 250*1600*3350mm (cold), steel plate size: 50*2480*8000mm

[0036] (3), rolling process parameters

[0037] Furnace temperature control in the heating section: 1200-1270°C. The billet tapping temperature is 1140°C, the second-stage finish rolling start-rolling temperature is 910°C, and the thickness of the intermediate billet to be warmed is 110mm.

[0038] (4) Slab primary oxidation, secondary oxidation descaling rate and surface condition of steel plate

[0039] After testing 9 pieces of slabs and steel plates in one furnace, the descaling rate of the slab’s primary oxide scale after the descaling box reaches 100%, and the average descaling rate of the secondary oxide scale of the finish rolling reaches 97%. The finished steel plate is inspected after shot blasting , there is no "pitting" defect visible to the naked eye on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com