Pipe shell heat exchanger having heat exchange tube embedded with spring

A technology with built-in springs and heat exchange tubes, used in indirect heat exchangers, heat exchanger types, fixed tubular conduit components, etc. The effect of scale effect, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below through the examples, but the examples will not constitute a limitation of the present invention.

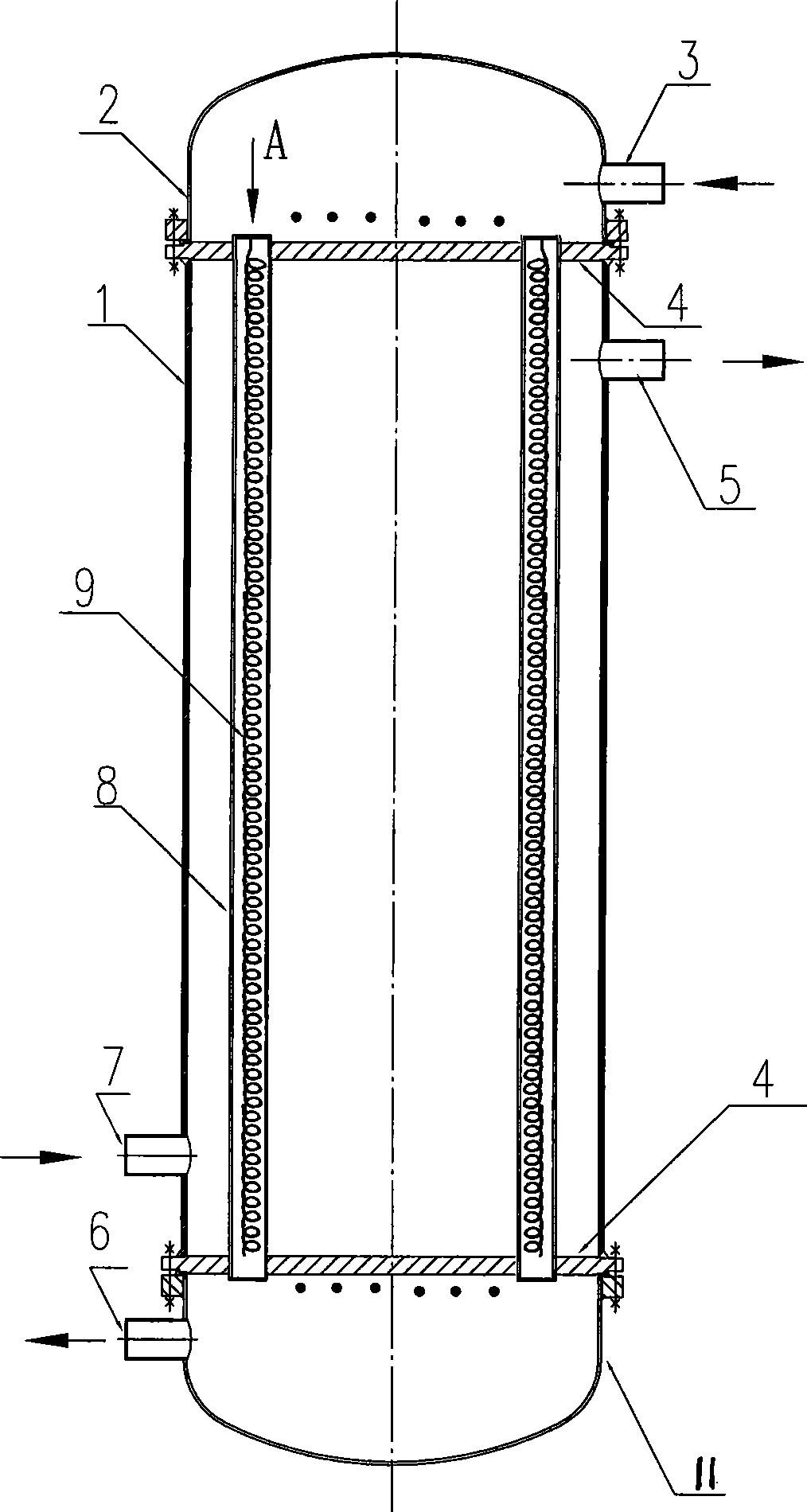

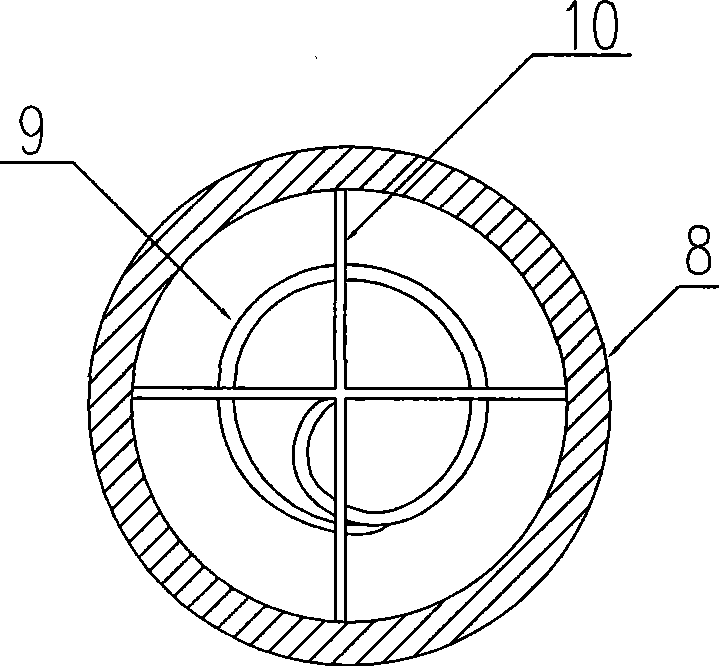

[0013] exist Figure 1-2 Among them, the heat exchange tube has a built-in spring type heat exchanger, which is mainly composed of shell 1, upper and lower heads (2, 11), tube plate 4, heat exchange tube 8, etc., wherein the upper and lower ends of the shell are respectively connected by the tube plate and The upper and lower heads are connected, the upper and lower ends of the heat exchange tubes are respectively fixed on the tube plate, the end surface of the water inlet of the heat exchange tube 8 is installed with a spring suspension 10, one end of the spring 9 is suspended on the spring suspension 10, and the other end of the spring 9 It belongs to the free end and is placed near the water outlet of the heat exchange tube 8. The diameter of the spring body is smaller than the inner diameter of the heat exchange tube an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com