Low-temperature resistant negative lead paste of lead storage battery and preparation method of negative lead paste

A lead-acid battery and negative lead paste technology, applied in lead-acid battery, lead-acid battery construction, battery electrodes, etc., can solve the problems of low utilization rate of active materials, weak conductivity, difficulty in meeting low-temperature performance batteries, etc., and achieve higher capacity. and service life, improving low-temperature discharge capacity, and improving the effect of charging acceptance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

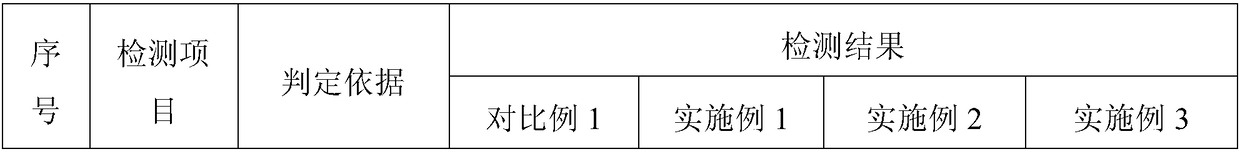

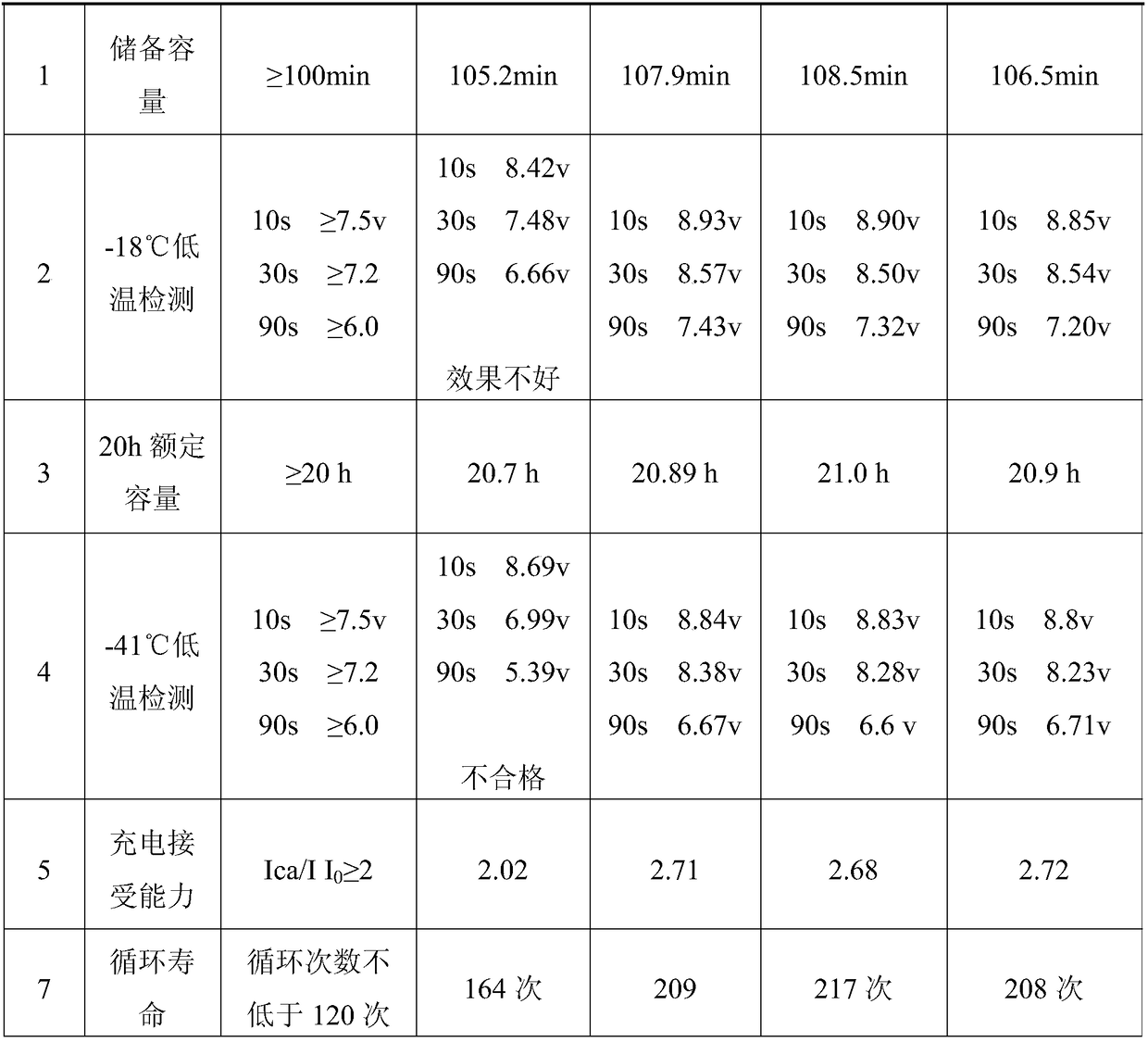

Examples

Embodiment 1

[0045] 1. Negative electrode paste formula: 100kg of lead powder, 0.7kg of superfine strontium sulfate or barium sulfate, 0.12kg of sodium lignosulfonate, 0.6kg of humic acid, 0.5kg of rubber bowl extract, 3# synthetic mixture (1.045g / cm 3 aqueous solution) 0.8kg, carbon nanotubes 0.15kg, nano Ketjen black 0.08kg, conductive carbon fiber (length 3mm) 0.12kg, hydroxymethylcellulose sodium CMC 0.3kg, dilute sulfuric acid (1.30~1.40g / cm 3 )7.8kg, production water 11.5kg.

[0046] 2. According to the mixing process of Comparative Example 1, negative electrode lead paste was prepared.

Embodiment 2

[0048] 1. Negative lead paste formula:

[0049] Lead powder 100kg;

[0050] Negative electrode additives: ultrafine strontium sulfate or barium sulfate 0.7kg, sodium lignosulfonate 0.12kg, humic acid 0.6kg, rubber bowl extract 0.5kg, 3# synthetic mixture (1.045g / cm 3 aqueous solution) 0.8kg, carbon nanotubes 0.15kg, nano Ketjen black 0.08kg, conductive carbon fiber (length 3mm) 0.12kg, sodium hydroxymethyl cellulose CMC 0.3kg;

[0051] Production water 11.5kg;

[0052] Synthetic acid (density 1.30~1.40g / cm 3 sulfuric acid solution) 7.8kg.

[0053] 2. Preparation method

[0054] (1) Put the synthetic tanning agent into a stainless steel container, pass in 0.3-0.5MPa water vapor, and blow the solid synthetic tanning agent directly through the steam nozzle until the synthetic tanning agent is blown into a liquid state, then add 2 times the volume of pure water, Cool the synthetic tanning agent aqueous solution to 20-30°C, then adjust the density to 1.045±0.005g / cm with pure ...

Embodiment 3

[0061] 1. Negative lead paste formula:

[0062] Lead powder 100kg;

[0063] Negative electrode additives: ultrafine strontium sulfate or barium sulfate 0.8kg, sodium lignosulfonate 0.11kg, humic acid 0.5kg, rubber bowl extract 0.4kg, 3# synthetic mixture (1.045g / cm 3 Aqueous solution) 1.0kg, carbon nanotube 0.17kg, nano Ketjen black 0.06kg, conductive carbon fiber (length 3mm) 0.13kg, sodium hydroxymethyl cellulose CMC 0.4kg;

[0064] Production water 11.5kg;

[0065] Synthetic acid (density 1.30~1.40g / cm 3 sulfuric acid solution) 7.3kg.

[0066] 2. Preparation method

[0067] (1) Put the synthetic tanning agent into a stainless steel container, pass in 0.3-0.5MPa water vapor, and blow the solid synthetic tanning agent directly through the steam nozzle until the synthetic tanning agent is blown into a liquid state, then add 2 times the volume of pure water, Cool the synthetic tanning agent aqueous solution to 20-30°C, then adjust the density to 1.045±0.005g / cm with pure w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com