Blocking remover and blocking removal method for corrosion sulfate compound scale

A technology of sulfate and plugging agent, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of damage to the rock skeleton near the wellbore, fast reaction speed of acid rock, small treatment radius, etc. , to achieve the effects of inhibiting the formation of scale, prolonging the period of plugging removal, and inhibiting the expansion of clay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

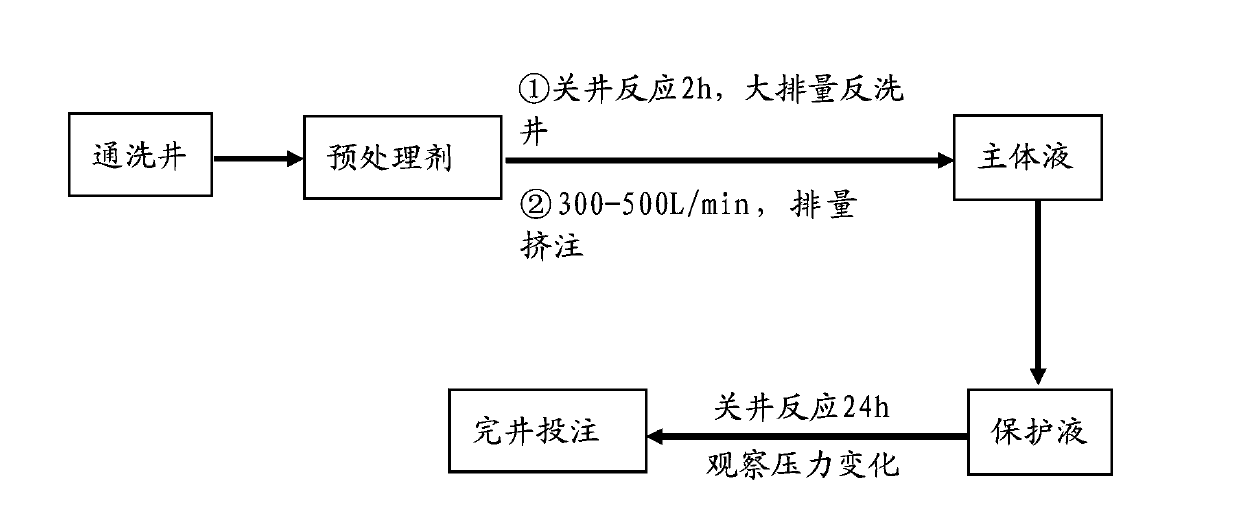

Method used

Image

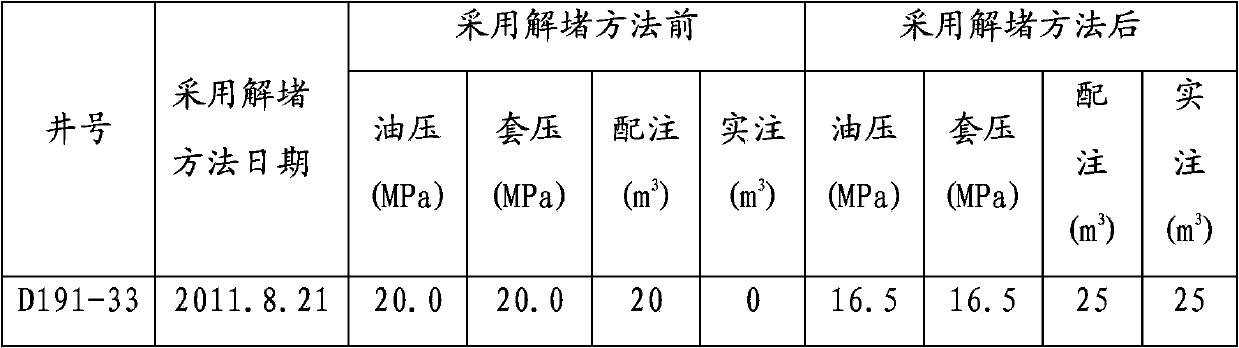

Examples

Embodiment 1

[0030] Weigh raw materials according to the following weights: (kg)

[0031] Pretreatment (consists of acid and surfactant):

[0032] 10 kilograms of methanesulfonic acid, 6 kilograms of toluenesulfonic acid, 4 kilograms of acetic acid, 10 kilograms of surfactants, 60 kilograms of water;

[0033] Among them, 30 kg of sodium heavy alkylbenzene sulfonate, 15 kg of isopropanol, 10 kg of isotridecyl alcohol polyoxyethylene ether, 2 kg of octylphenol polyoxyethylene ether, N,N'-bisoleoyl ethyl alcohol 1 kilogram of sodium diamine diethanesulfonate mixes and obtains surfactant, then chooses 10 kilograms of surfactant as the raw material of pretreatment agent.

[0034] Body fluid:

[0035] Sodium diethylenetriaminepentaacetic acid 15kg, sodium ethylenediaminetetramethylene phosphonate 8kg, disodium edetate 8kg, diethylenetriaminepentamethylenephosphonic acid 8kg, sodium acetate 2kg , 2 kg of sodium chloride, 57 kg of water;

[0036] Protective fluid:

[0037] Anti-scaling agent ...

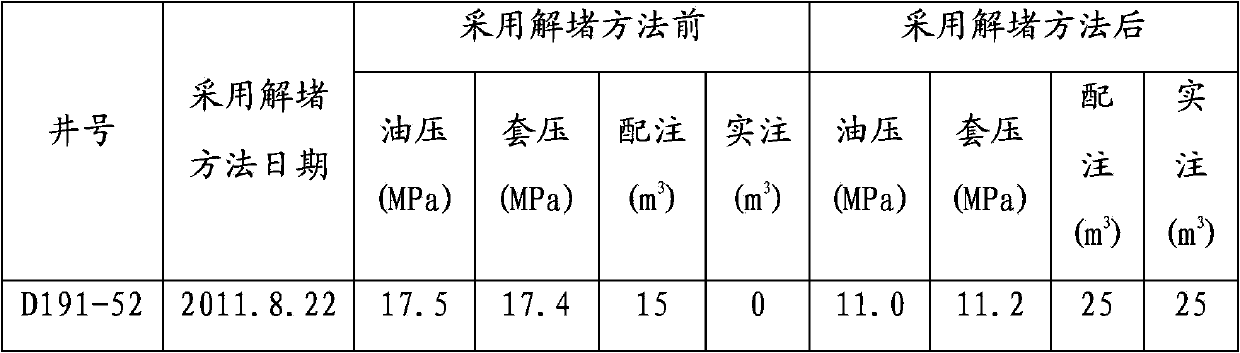

Embodiment 2

[0058]Weigh raw materials according to the following weights: (kg)

[0059] Pretreatment (consists of acid and surfactant):

[0060] 8 kilograms of methanesulfonic acid, 4 kilograms of toluenesulfonic acid, 6 kilograms of acetic acid, 8 kilograms of surfactants, 80 kilograms of water;

[0061] Among them, 20 kg of sodium heavy alkylbenzene sulfonate, 20 kg of isopropanol, 8 kg of isotridecyl alcohol polyoxyethylene ether, 3.5 kg of octylphenol polyoxyethylene ether, N,N'-bisoleoyl ethyl alcohol Sodium diamine diethanesulfonate 0.5 kilogram mixes and obtains tensio-active agent, then chooses 8 kilograms of tensio-active agent therefrom as the raw material of pretreatment agent.

[0062] Body fluid:

[0063] Diethylenetriaminepentaacetic acid sodium 17kg, ethylenediaminetetramethylene phosphonate sodium 9kg, edetate disodium 9kg, diethylenetriaminepentamethylenephosphonic acid 9kg, sodium acetate 2kg , 2 kg of sodium chloride, 52 kg of water;

[0064] Protective fluid:

[0...

Embodiment 3

[0084] Weigh raw materials according to the following weights: (kg)

[0085] Pretreatment (consists of acid and surfactant):

[0086] 12 kilograms of methanesulfonic acid, 8 kilograms of toluenesulfonic acid, 2 kilograms of acetic acid, 12 kilograms of surfactants, 40 kilograms of water;

[0087] Among them, 40 kg of sodium heavy alkylbenzene sulfonate, 10 kg of isopropanol, 13 kg of isotridecyl alcohol polyoxyethylene ether, 1.5 kg of octylphenol polyoxyethylene ether, N,N'-bisoleoyl ethyl alcohol 1.5 kilograms of sodium diamine diethanesulfonate mixes and obtains tensio-active agent, then chooses 12 kilograms of tensio-active agents therefrom as the raw material of pretreatment agent.

[0088] Body fluid:

[0089] Sodium diethylenetriaminepentaacetic acid 19kg, sodium ethylenediaminetetramethylene phosphonate 9kg, disodium edetate 8kg, diethylenetriaminepentamethylenephosphonic acid 9kg, sodium acetate 3kg , 2 kg of sodium chloride, 50 kg of water;

[0090] Protective fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com