NiCr-Al2O3 self-lubricating composite material and preparation method thereof

A composite material and self-lubricating technology, which is applied to the preparation of parts and components that serve under high-temperature conditions. In the field of preparation of high-temperature self-lubricating composite materials, it can solve the problems that no systematic research reports have been seen, and no solid lubricating materials have been retrieved. , to achieve the effect of good friction and wear performance and wide temperature range lubrication performance, improved friction and wear performance, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

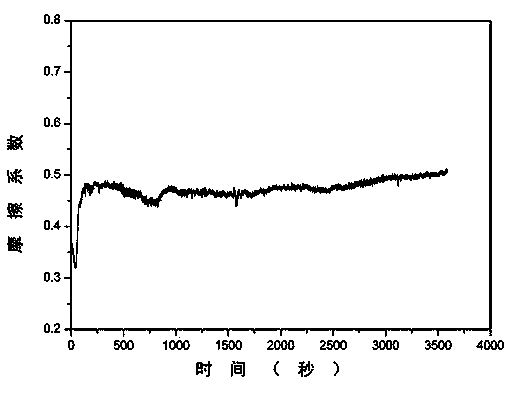

[0024] The present invention NiCr-Al 2 o 3 The components and mass percentages of the cermet-based wide-temperature range high-temperature self-lubricating composite material are: Ni: 38.4%, Cr: 9.6%, Al 2 o 3 : 32%, SrSO 4 : 10%, Ag: 10%. First, Ni and Cr powders with a purity greater than 99.0% were mixed according to the mass ratio of Ni: 38.4%, Cr: 9.6%, and the above mixture was mixed by wet ball milling on a four-pot planetary high-energy ball mill (FRITSCH, Germany). The ball milling time 20h, rotating speed 250r / min, ball material ratio 10:1. Then the powder purity greater than 99.0% Al 2 o 3 , SrSO 4 , Ag powder by nanometer Al 2 o 3 : 32%, SrSO 4 : 10%, Ag: 10% mass ratio mixed, and added to the above mixture, and then the above mixture using the above wet ball milling process, after drying, to obtain mixed powder. Weigh 50g of the above-mentioned mixed powder into a graphite mold for cold-press preforming, then put the above-mentioned graphite mold into a...

Embodiment 2

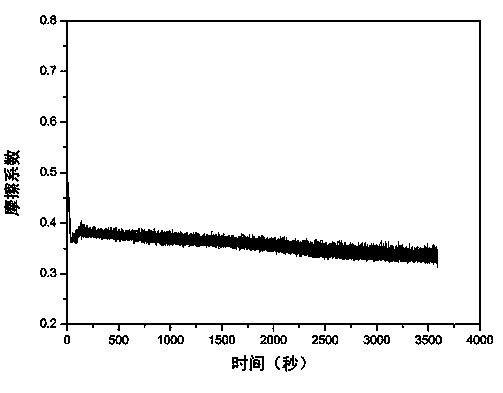

[0026] The present invention NiCr-Al 2 o 3 The components and mass percentages of the cermet-based wide-temperature range high-temperature self-lubricating composite material are: Ni: 36%, Cr: 9%, nano-Al 2 o 3 : 30%, SrSO 4 : 9%, Ag: 16%. First, Ni and Cr powders with a purity greater than 99.0% were mixed according to the mass ratio of Ni: 36%, Cr: 9%, and the above mixture was mixed by wet ball milling on a four-pot planetary high-energy ball mill (FRITSCH, Germany). The ball milling time 20h, rotating speed 200r / min, ball material ratio 10:1. Then the powder purity greater than 99.0% Al 2 o 3 , SrSO 4 , Ag powder by nanometer Al2 o 3 : 30%, SrSO 4 : 9%, Ag: 16% in mass ratio, mixed and added to the above mixture, and then the above mixture was subjected to the above-mentioned wet ball milling process, and after drying, a mixed powder was obtained. Weigh 50g of the above-mentioned mixed powder into a graphite mold for cold-press preforming, then put the above-ment...

Embodiment 3

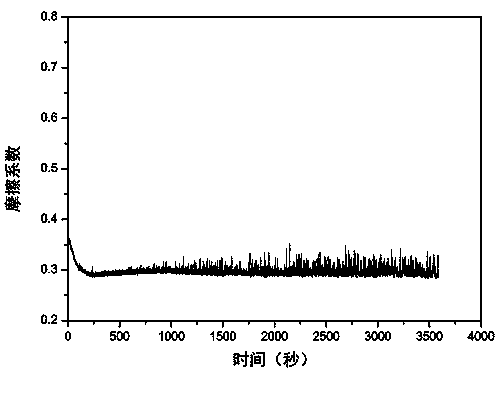

[0028] The present invention NiCr-Al 2 o 3 The components and mass percentages of the cermet-based wide temperature range high-temperature self-lubricating composite material are: Ni: 38.4%, Cr: 9.6%, Al 2 o 3 : 32%, SrSO 4 : 11%, Ag: 9%. First, Ni and Cr powders with a purity greater than 99.0% were mixed according to the mass ratio of Ni: 38.4%, Cr: 9.6%, and the above mixture was mixed by wet ball milling on a four-pot planetary high-energy ball mill (FRITSCH, Germany). The ball milling time 20h, rotating speed 250r / min, ball material ratio 10:1. Then the powder purity greater than 99.0% Al 2 o 3 , SrSO 4 , Ag powder by nanometer Al 2 o 3 : 32%, SrSO 4 : 11%, Ag: 9% in mass ratio, mixed and added to the above mixture, and then the above mixture was subjected to the above-mentioned wet ball milling process, and after drying, a mixed powder was obtained. Weigh 50g of the above-mentioned mixed powder into a graphite mold for cold-press preforming, then put the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com