Chelate blocking remover suitable for complicated scaling reservoir layers, and preparation method of chelate blocking remover

A plug-removing agent and chelating agent technology, applied in the field of chelating plug-removing agent and its preparation, can solve the problems of acid liquid secondary precipitation and plugging removal effect poor, long shut-in time, complicated treatment steps, etc., to achieve scale inhibition Effects of generating, prolonging action time, and reducing injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

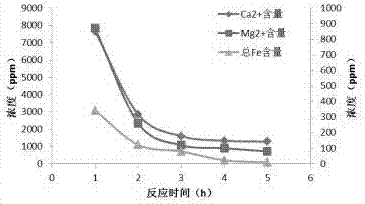

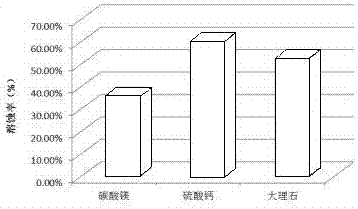

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned chelating plug-removing agent, the specific steps are as follows: add distilled water to the reaction kettle, and heat up to 50-55°C, then add the chelating agent, activator, penetrant, and scale inhibitor into the reaction kettle in sequence, Add one material and stir for 20-30 minutes, and stir for 30 minutes after adding all the materials to complete the preparation of the chelating plugging remover;

[0039] The addition amount of above-mentioned raw material all adds according to recipe amount.

[0040] The chelating agent is composed of the following components by mass percentage: 50% to 60% of aminocarboxylic acid chelating agents, 10% to 20% of hydroxycarboxylic acid chelating agents, 20% to 30% of organic phosphonate chelating agents, The chelating agent is prepared by mixing the above three components. The aminocarboxylic acid chelating agent is ethylenediaminetetraacetic acid, diethylenetriaminepentaacetic acid, m...

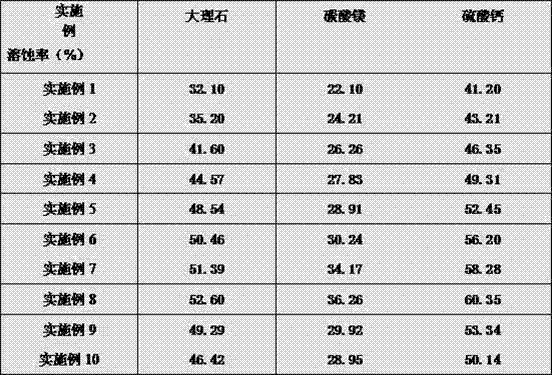

Embodiment 1

[0046] This embodiment provides a kind of chelation blockage removal agent suitable for complex scaling reservoirs, the chelation blockage removal agent is composed of the following components in mass percentage:

[0047] Chelating agent 5%, scale inhibitor 0.5%, activator 1%, penetrant 0.5%, and the rest is distilled water.

[0048] The preparation method of the above-mentioned chelating plug-removing agent, the specific steps are as follows: add distilled water to the reaction kettle, and heat up to 50-55°C, then add the chelating agent, activator, penetrant, and scale inhibitor into the reaction kettle in sequence, Add one material and stir for 20-30 minutes, and stir for 30 minutes after adding all the materials to complete the preparation of the chelating plugging remover.

[0049] In this embodiment, the chelating agent is composed of the following components by mass percentage: ethylenediaminetetraacetic acid (accounting for 30% by weight of the aminocarboxylic acid che...

Embodiment 2

[0051] This embodiment provides a kind of chelation blockage removal agent suitable for complex scaling reservoirs, the chelation blockage removal agent is composed of the following components in mass percentage:

[0052] Chelating agent 6%, scale inhibitor 0.6%, activator 1.5%, penetrant 0.7%, and the rest is distilled water.

[0053] The preparation method of the above-mentioned chelating plug-removing agent, the specific steps are as follows: add distilled water to the reaction kettle, and heat up to 50-55°C, then add the chelating agent, activator, penetrant, and scale inhibitor into the reaction kettle in sequence, Add one material and stir for 20-30 minutes, and stir for 30 minutes after adding all the materials to complete the preparation of the chelating plugging remover.

[0054] In this embodiment, the chelating agent is composed of the following components by mass percentage: diethylenetriaminepentaacetic acid (accounting for 30% by weight of the aminocarboxylic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com